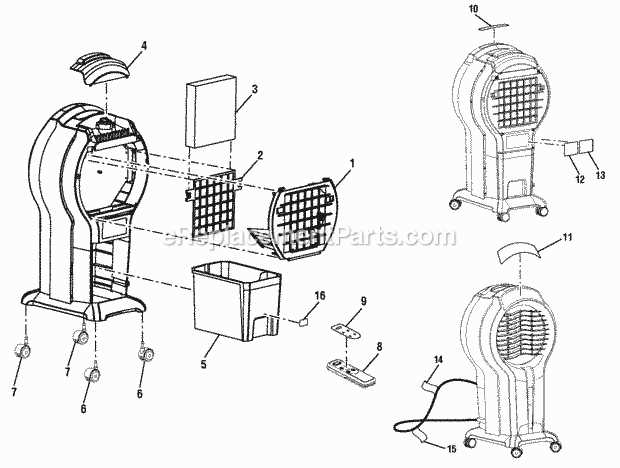

The efficiency of any evaporative system relies heavily on the intricate interplay of its essential elements. These systems are designed to enhance air quality and cooling by facilitating the movement of air through moisture-filled areas. While each component serves a specific purpose, their arrangement and interaction are crucial to overall performance.

Key mechanisms within the structure work together to ensure that air flows seamlessly, maintaining a balance between moisture and temperature. Understanding how these mechanisms are connected provides valuable insight into the operation and maintenance of the system. By knowing the layout of these elements, users can easily identify any potential issues and improve functionality.

Proper knowledge of how these elements fit together allows for effective maintenance and troubleshooting. Recognizing the role of each element, along with its positioning, ensures the system remains in optimal condition, offering reliable performance over time. Whether adjusting settings or replacing worn-out parts, having a clear picture of the system’s structure simplifies the process.

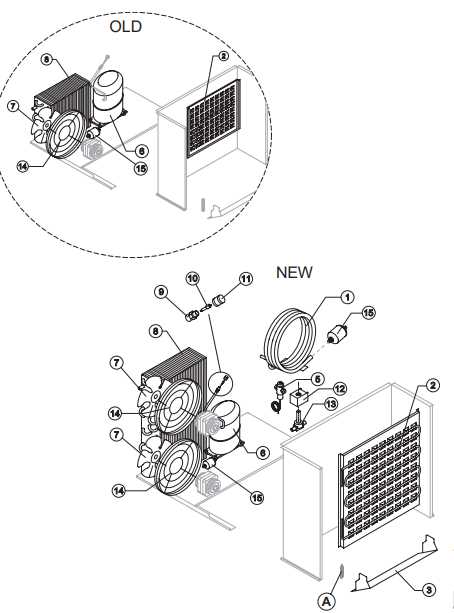

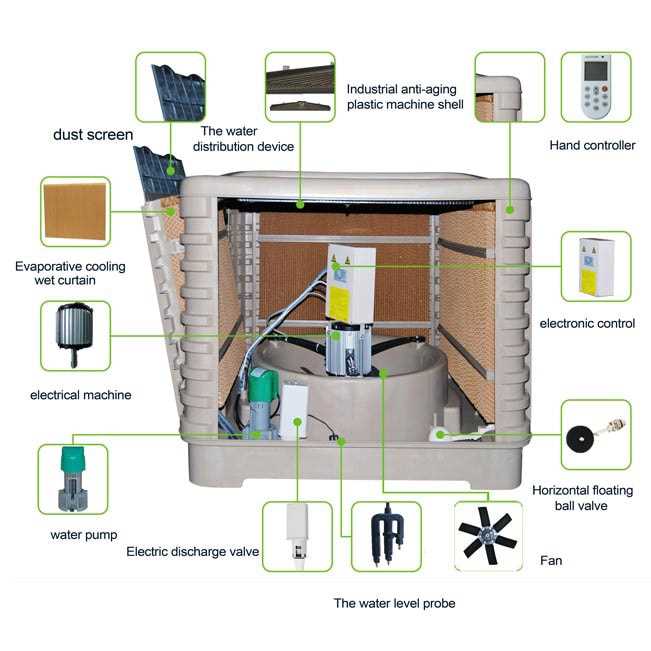

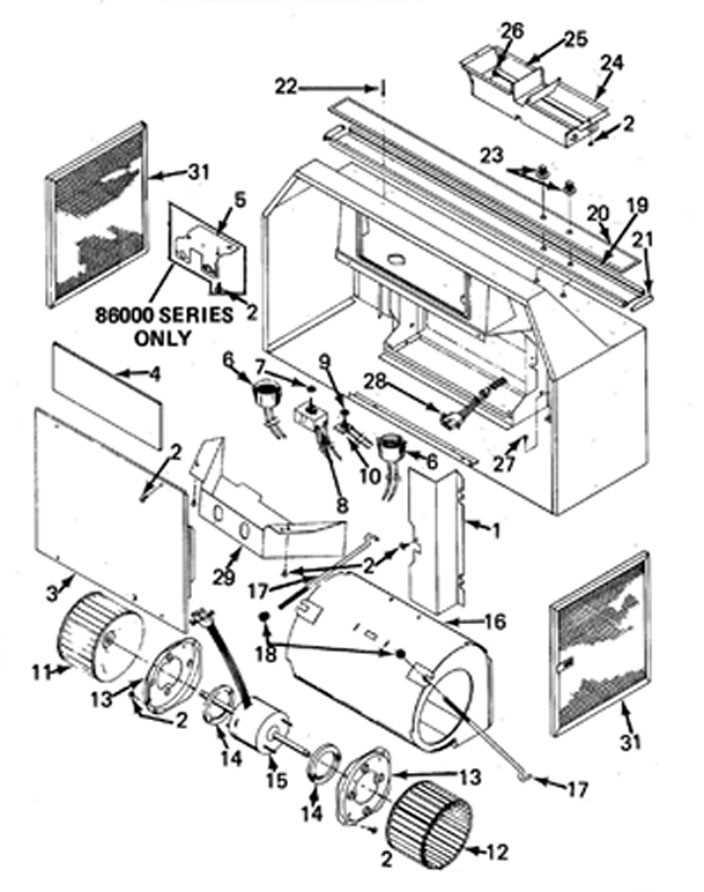

Swamp Cooler Parts Diagram

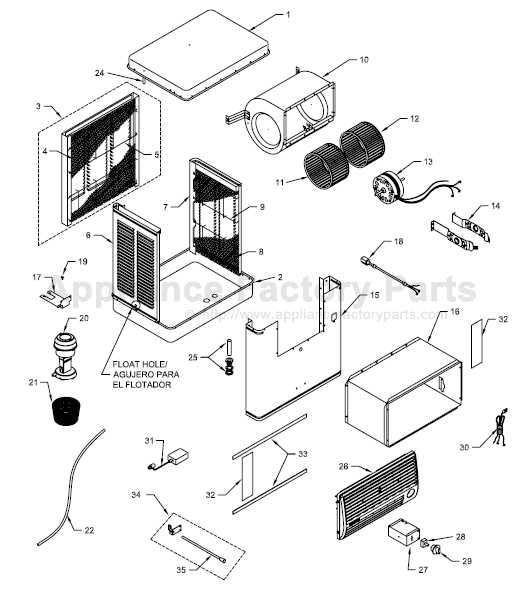

This device relies on a series of interconnected components that work together to ensure efficient operation. Each element plays a specific role, contributing to the overall functionality and performance of the system. Understanding the layout of these components can aid in maintenance, repairs, and optimization of performance.

| Component | Function |

|---|---|

| Main Housing | Encloses the internal mechanisms and supports air flow management. |

| Water Reservoir | Holds the liquid necessary for evaporation, ensuring consistent moisture supply. |

| Fan Blades | Circulate the air, directing it through the system for cooling. |

| Pump | Transfers liquid from the storage area to the cooling pads. |

| Cooling Pads | Absorb moisture and facilitate the evaporation process, lowering the temperature. |

Main Components of a Swamp Cooler

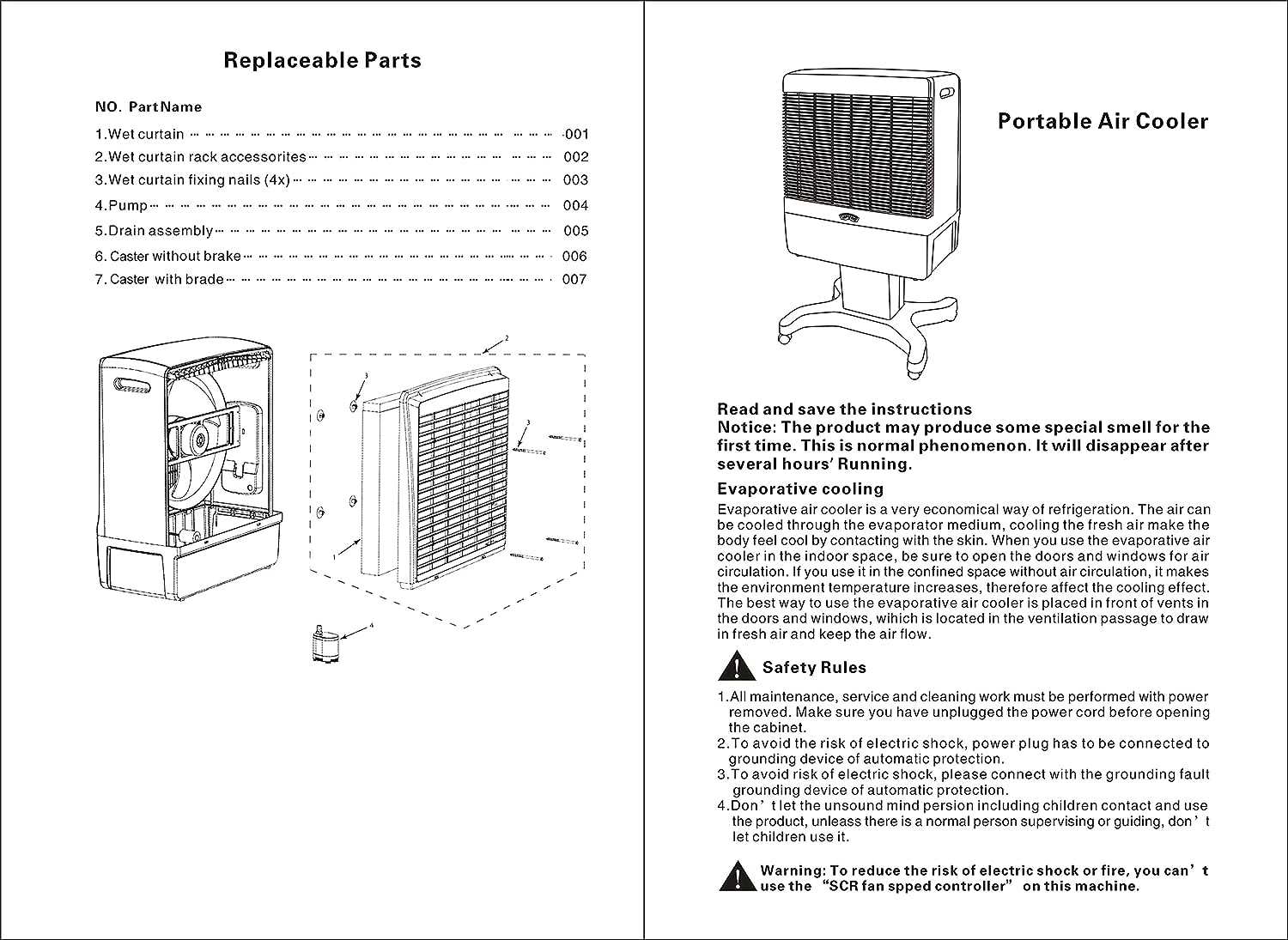

Effective air conditioning systems rely on several key elements working together to maintain a comfortable environment. These systems utilize a combination of airflow, water circulation, and temperature control to efficiently cool the air in a space. Below is an overview of the essential components that contribute to this process.

- Water distribution system: This feature is responsible for evenly distributing water throughout the cooling pads, ensuring consistent moisture levels.

- Cooling pads: These porous materials absorb water, which allows air passing through to cool as it evaporates.

- Fan or blower: This part draws in warm air and pushes it through the wet cooling pads, creating a cooling effect as the air exits.

- Pump: The pump circulates water from the reservoir to the distribution system, keeping the pads moist for optimal evaporation.

- Motor: This powers the fan or blower, driving the air circulation required for the system to function efficiently.

- Water reservoir: A tank that stores the water used in the system, ensuring a steady supply for the cooling process.

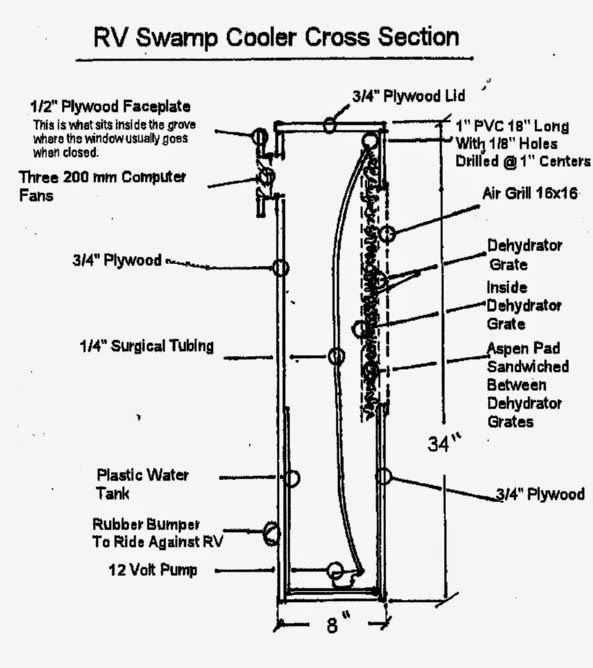

Understanding the Water Distribution System

The water distribution system is crucial for ensuring efficient moisture flow across the surfaces it interacts with. This process relies on a network that moves water evenly to create a consistent, balanced distribution. By regulating how moisture spreads, the system helps maintain optimal humidity levels and contributes to the overall performance of the device.

Key elements of the distribution system include channels that direct the water, and specialized components that ensure it reaches every necessary area. Properly functioning elements are essential for smooth operation and consistent results.

Regular checks and maintenance can improve the longevity of the system, preventing potential issues like blockages or inefficiencies. A well-maintained distribution setup is vital for keeping performance at its best.

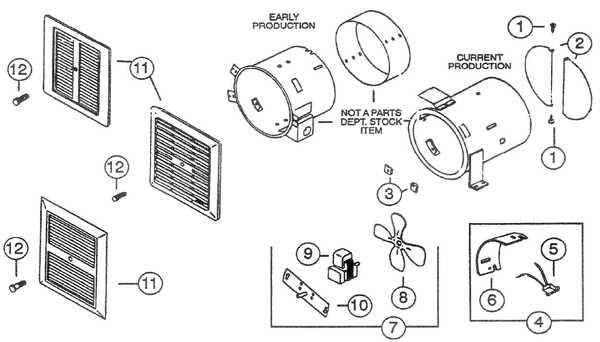

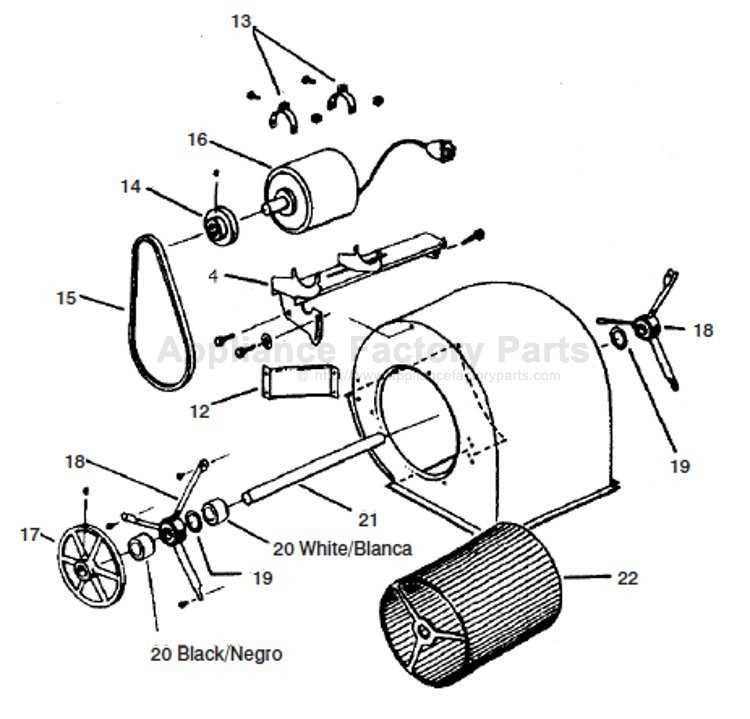

How the Fan and Motor Work Together

The fan and motor function in harmony to ensure efficient air movement. Their coordinated operation creates a flow that enhances the cooling process by moving air through the system. The fan’s ability to circulate air depends on the motor’s performance, which provides the necessary force to keep the blades rotating at the optimal speed.

The motor drives the fan, delivering the energy required for rotation, while the fan converts this energy into airflow. This collaboration ensures that air is constantly moved, helping to maintain a consistent environment.

As the motor activates, the fan spins at a determined rate, ensuring that airflow is sustained. The balance between the motor’s power and the fan’s design is crucial for achieving effective ventilation. Together, they work seamlessly to create a smooth and continuous air circulation process.

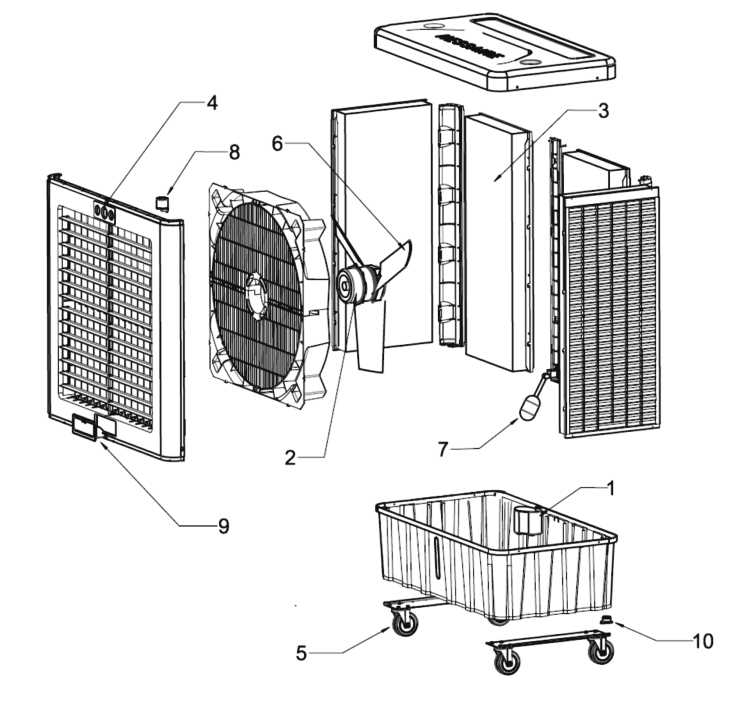

Cooling Pads and Their Role

Cooling pads are essential in systems designed to lower temperatures through evaporation. Their structure allows for water absorption, providing a surface area where warm air can interact with moisture. As air flows through these pads, heat is extracted from the environment, enhancing the overall cooling process.

Material and Efficiency of cooling pads can significantly influence how effectively they contribute to temperature reduction. High-quality pads are typically made from materials that retain water longer, ensuring a steady and consistent cooling effect. The better the water retention, the more efficient the evaporation process becomes.

Maintenance of these components is also critical. Regular cleaning and replacement of worn-out pads can ensure optimal performance, as debris and mineral buildup can reduce their effectiveness over time. Proper care extends their lifespan and enhances the cooling system’s efficiency.

Key Functions of the Pump

The pump plays a vital role in the efficient operation of an evaporative cooling system, ensuring that the process of cooling air is both effective and reliable. Its primary responsibility involves circulating water, which is essential for the evaporation process that cools the incoming air. Understanding its main functions can help users appreciate its importance in maintaining optimal performance.

Water Circulation

One of the pump’s critical functions is to provide a steady flow of water to the evaporative media. By consistently supplying moisture, the pump enables the media to absorb heat from the air, facilitating the cooling effect. This circulation is crucial for maintaining the desired humidity levels and ensuring effective temperature reduction.

Pressure Regulation

Another important function of the pump is to regulate pressure within the system. By maintaining appropriate pressure levels, it ensures that water reaches all necessary components without causing overflow or insufficient supply. This regulation is essential for the longevity of the system and helps prevent potential malfunctions.

Airflow Control Mechanism in Coolers

The airflow management system plays a crucial role in enhancing indoor comfort by regulating the movement of air within a space. This system is designed to optimize airflow, ensuring that the environment remains cool and pleasant, particularly during warmer months. Effective airflow control can significantly influence the overall efficiency of the device and the comfort level it provides.

Key Components

Several essential components contribute to the functionality of the airflow regulation system. These include fans, ducts, and adjustable vents. The fans generate a steady stream of air, while ducts direct this airflow throughout the area. Adjustable vents allow users to customize the airflow according to their preferences, ensuring optimal circulation.

Operation Principles

The mechanism operates by drawing warm air from the surroundings and passing it through a cooling medium. As the air flows over this medium, it absorbs moisture, which lowers its temperature before being circulated back into the space. This continuous cycle not only cools the environment but also maintains humidity levels at a comfortable rate.

Benefits of Efficient Airflow Control

Implementing a well-designed airflow control mechanism offers numerous advantages. It enhances energy efficiency, reduces operational costs, and improves air quality. Additionally, it ensures that cool air is evenly distributed, preventing hot spots and creating a consistently comfortable atmosphere.

Drain and Overflow Systems Explained

The drainage and overflow mechanisms are essential components of various cooling systems, ensuring proper water management and preventing potential damage. These systems are designed to effectively remove excess water and minimize the risk of overflow, contributing to the overall efficiency and functionality of the equipment.

Drain Systems typically consist of a network of pipes and channels that direct excess water away from the unit. This ensures that moisture does not accumulate, which could lead to corrosion or mold growth. The drain is often strategically placed to facilitate efficient water flow, making maintenance easier and reducing the likelihood of blockages.

Overflow Mechanisms play a crucial role in safeguarding the system against unexpected water levels. These features are equipped with sensors that detect rising water and trigger automatic drainage, thus preventing overfilling. This proactive approach not only protects the equipment but also promotes a safe environment by mitigating water-related hazards.

Understanding these systems is vital for effective maintenance and operation. Regular inspections and timely adjustments can ensure that both the drainage and overflow components function optimally, contributing to the longevity and reliability of the cooling apparatus.

Electrical Wiring and Connections Overview

The efficiency and performance of a ventilation system largely depend on its electrical setup. Understanding the wiring and connections is crucial for proper installation and maintenance. This section will provide insights into the electrical components and their arrangement, ensuring a seamless operation of the system.

Wiring Types play a significant role in ensuring the correct functioning of the equipment. Different systems may require specific wire gauges and insulation types to handle varying electrical loads. It is essential to choose the appropriate wiring to prevent overheating and ensure safety.

Connections are equally important in maintaining an effective electrical network. Properly securing connections can prevent short circuits and ensure a reliable flow of electricity. Regular checks on terminals and junctions can help identify potential issues before they escalate.

Safety Precautions must be observed when working with electrical systems. Always disconnect power sources before making any changes. Utilizing appropriate tools and protective gear is essential to avoid accidents and ensure compliance with electrical standards.

Proper Maintenance of Swamp Cooler Parts

Regular upkeep of evaporative cooling systems is essential for optimal performance and longevity. Ensuring that each component functions correctly not only enhances efficiency but also reduces energy consumption. Proper care can prevent unnecessary repairs and extend the lifespan of the equipment.

Begin with cleaning the filtration elements to eliminate dust and debris that can obstruct airflow. It’s advisable to inspect and replace these filters as needed, typically at the start of each season. In addition, check the water distribution system for clogs or blockages, ensuring it operates smoothly to provide consistent moisture to the air.

Furthermore, inspect the motor and belt for any signs of wear or damage. Lubricating moving parts can help maintain their functionality and prevent overheating. Pay attention to any unusual noises that may indicate a malfunction, and address these issues promptly to avoid more significant problems down the line.

Finally, clean the outer casing and ensure that the unit is free from debris and obstructions. Seasonal maintenance not only enhances performance but also contributes to a more comfortable indoor environment.

Common Swamp Cooler Component Failures

Understanding the typical issues that can arise in evaporative cooling systems is essential for effective maintenance. Various components may experience wear and tear, leading to diminished performance or complete failure. Recognizing these common failures can help users take preventive measures and ensure optimal functionality.

Frequent Component Issues

- Water Distribution Problems: Inefficient water flow can cause inadequate moistening, leading to overheating.

- Fan Malfunctions: A malfunctioning fan may result in poor air circulation, impacting overall efficiency.

- Motor Failures: Motors can become faulty over time, leading to reduced performance or stopping entirely.

- Filter Clogs: Dirty filters can obstruct airflow, diminishing cooling effectiveness.

Signs of Impending Failures

- Unusual noises during operation.

- Inconsistent cooling output.

- Visible leaks or water pooling around the unit.

- Increased energy consumption without corresponding cooling benefits.

Identifying these warning signs early can lead to timely repairs and extend the lifespan of the equipment.