Every machine, no matter its complexity, is built from a collection of interconnected elements that work in harmony to ensure smooth operation. When it comes to maintaining your outdoor equipment, having a clear view of how these elements are organized can be a game changer. By exploring the specific arrangement and the role of each element, you can better understand how to keep your equipment in top shape.

In this guide, we will delve into the essential components that make up your lawn equipment. Understanding these elements will not only help you with repairs but also with routine maintenance, ensuring longevity and optimal performance. Whether you are a seasoned technician or just getting started, this overview will provide a solid foundation for managing your equipment.

Let’s break down the core elements, explore their functions, and understand how they fit together to form a well-tuned, efficient machine. With the right knowledge, maintaining and repairing your machinery will become a much simpler and more efficient task.

Overview of the Craftsman YT4000 Riding Mower

The machine under discussion is a powerful lawn tractor designed for individuals seeking efficient and reliable lawn care. It combines a solid frame with advanced features to handle both small and large yards, offering precision and durability in its performance.

This riding mower is equipped with a robust engine that ensures smooth operation over various terrains. Its ergonomic design makes it comfortable for extended use, while its cutting capabilities allow for a clean, even trim across different grass types.

With user-friendly controls and multiple adjustment options, this model is tailored for those who need versatility and ease of maintenance. Its intuitive design simplifies the mowing process, making it suitable for both beginners and seasoned users alike.

Key Components of the YT4000 Engine System

The engine system of this powerful machine is a collection of several key elements that work together to ensure smooth and efficient operation. Understanding the roles of these elements can help maintain the performance and longevity of the equipment. Below, we explore the main components responsible for fuel intake, power generation, and cooling mechanisms.

Fuel and Ignition Elements

- Carburetor: Manages the mixing of air and fuel to ensure optimal combustion inside the engine.

- Spark Plug: Ignites the fuel mixture, initiating the combustion process that powers the machine.

- Fuel Pump: Transfers fuel from the tank to the carburetor for efficient engine performance.

Cooling and Power Systems

- Cooling Fan: Helps maintain an appropriate temperature by circulating air through the system.

- Alternator: Charges the battery while the engine is running, ensuring a continuous power supply.

- Air Filter: Prevents dirt and debris from entering the engine, contributing to better performance and durability.

These components are crucial for the overall function of the engine, working in unison to keep the system running efficiently under various conditions.

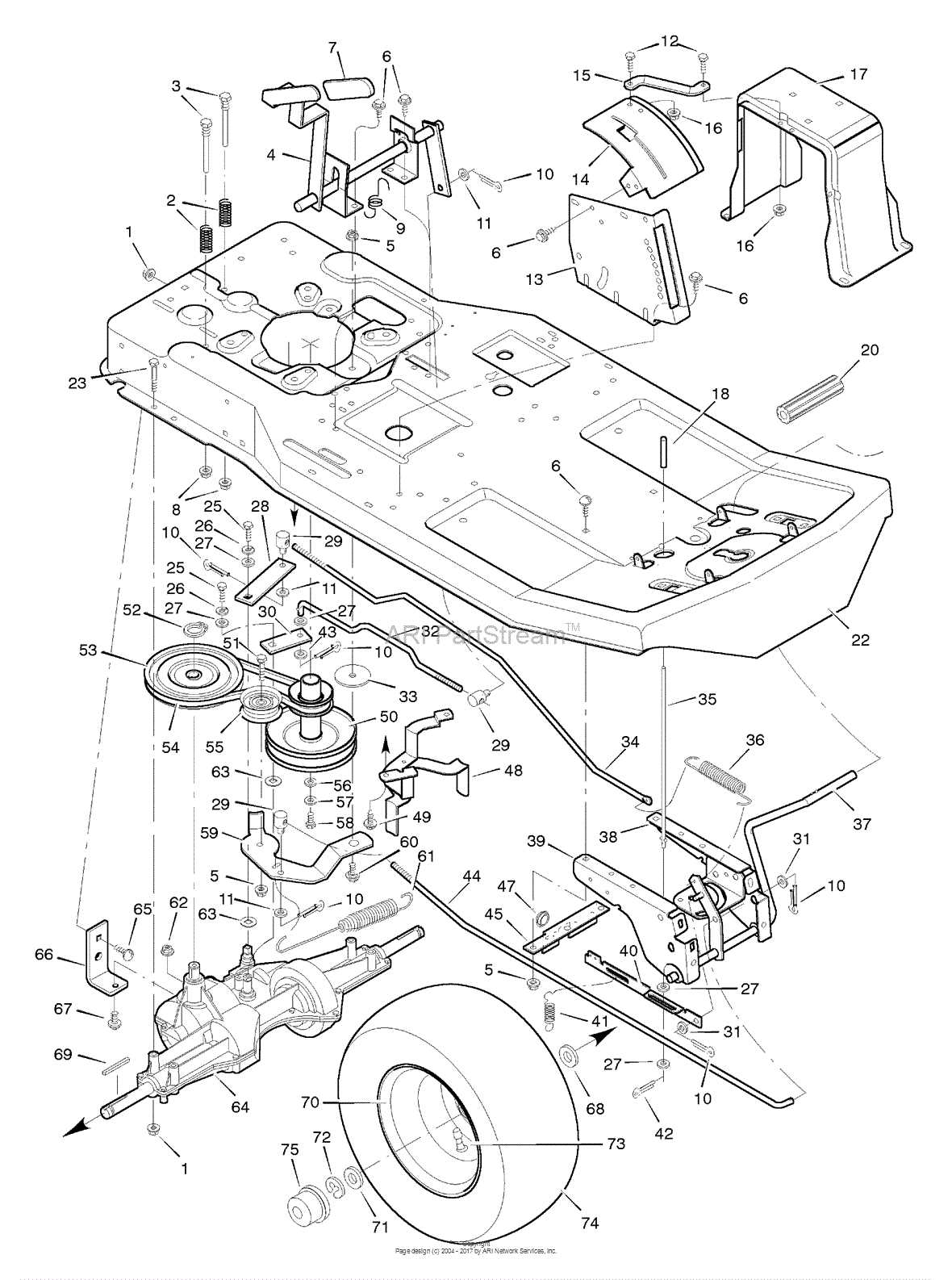

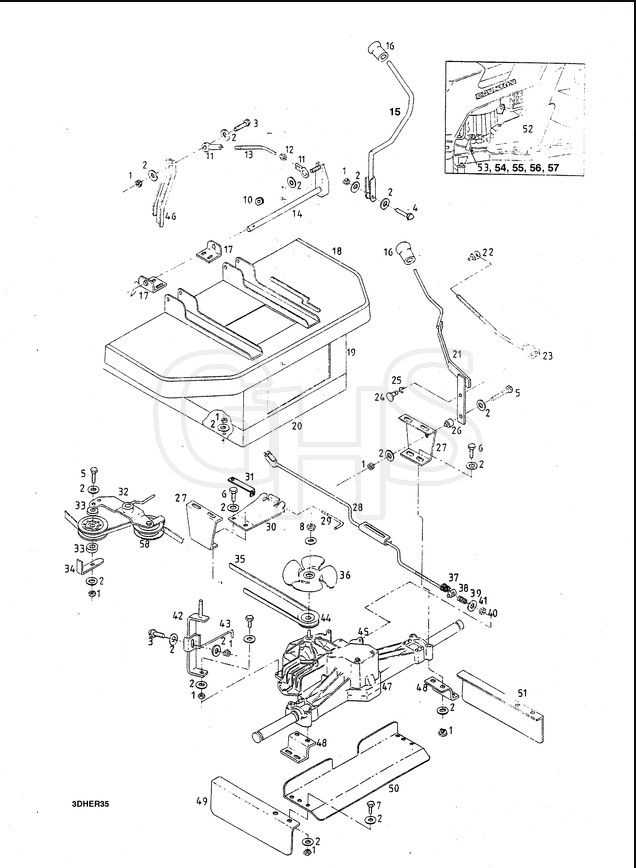

Understanding the Transmission System Layout

The transmission mechanism in a riding vehicle plays a crucial role in controlling the speed and power delivered to the wheels. Its arrangement ensures smooth transitions between various operational modes, whether the machine is moving at low speed or operating at its maximum capacity. This section explores the key components that interact within this system, focusing on their coordination and how they influence overall performance.

Key Components of the System

The transmission layout consists of several integral elements that work together to distribute power efficiently. Gears, belts, and pulleys are commonly employed to regulate the transfer of energy from the engine to the drive wheels. Each component has a specific function, ensuring that the user can control the movement precisely under different conditions.

How the Layout Affects Efficiency

An optimized transmission arrangement enhances the efficiency of power utilization. By reducing friction and ensuring effective gear shifts, the system minimizes energy loss and contributes to the smooth operation of the vehicle. Proper alignment and maintenance of these elements are critical to achieving maximum operational efficiency.

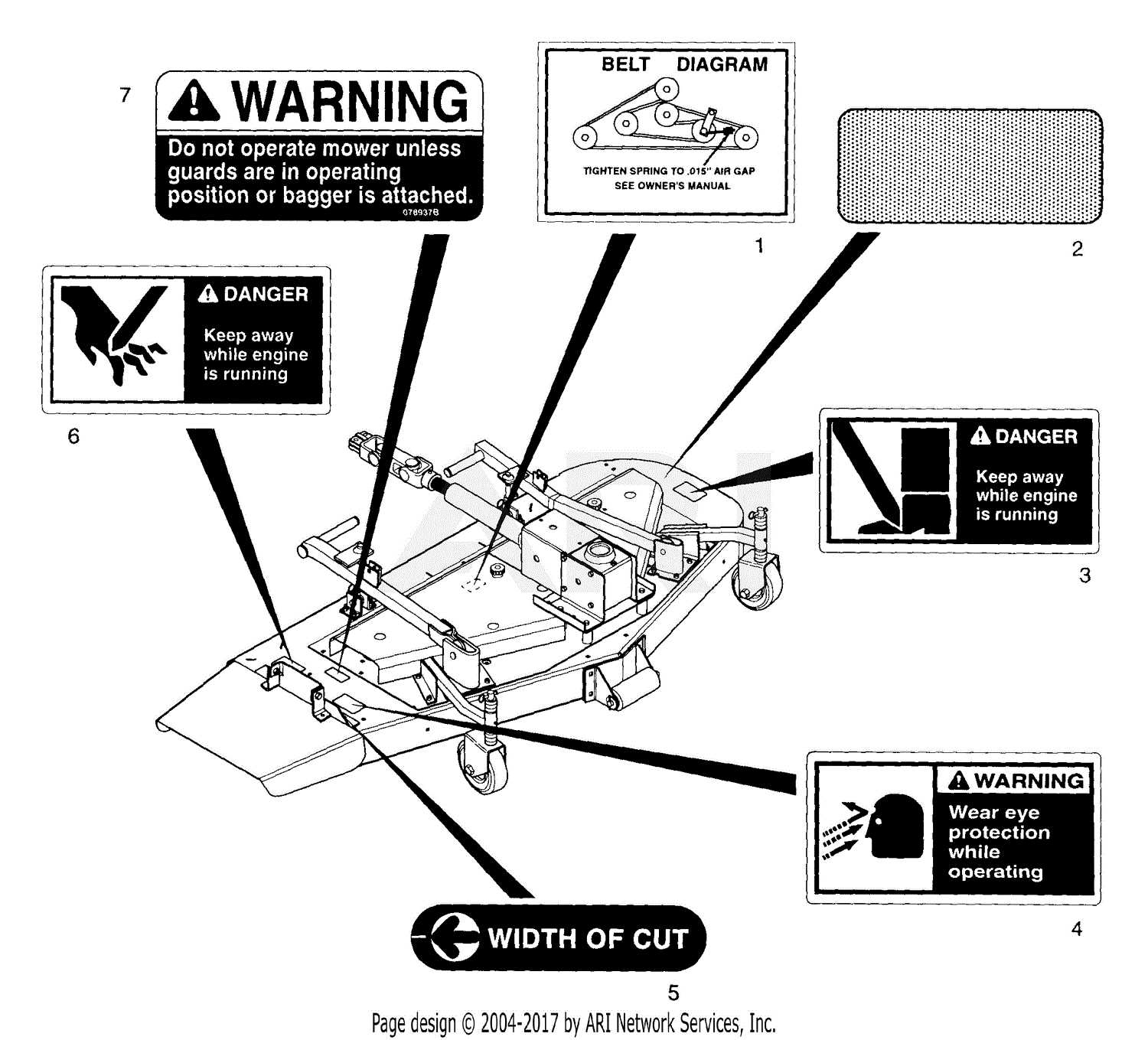

Detailed Look at the Cutting Deck Assembly

The cutting deck is a critical component in ensuring efficient grass trimming. By understanding how its various mechanisms work together, you can maintain optimal performance and extend the lifespan of your equipment. This section explores each element of the deck, providing insights into its structure and function.

- Deck Frame: The foundation that supports all the other components, designed to withstand tough conditions and provide stability during operation.

- Blades: Responsible for cutting grass evenly, the blades rotate at high speed and must be sharp to deliver precise results.

- Belt System: A series of belts that transfer power from the engine to the blades, ensuring smooth rotation and efficiency during mowing.

- Spindles: These hold the blades in place and allow them to rotate smoothly. They must be regularly lubricated to prevent wear and tear.

- Discharge Chute: The pathway that directs cut grass away from the deck, ensuring a clean and even mowing surface.

- Anti-Scalp Wheels: Small wheels located beneath the deck to prevent the blades from scalping the lawn on

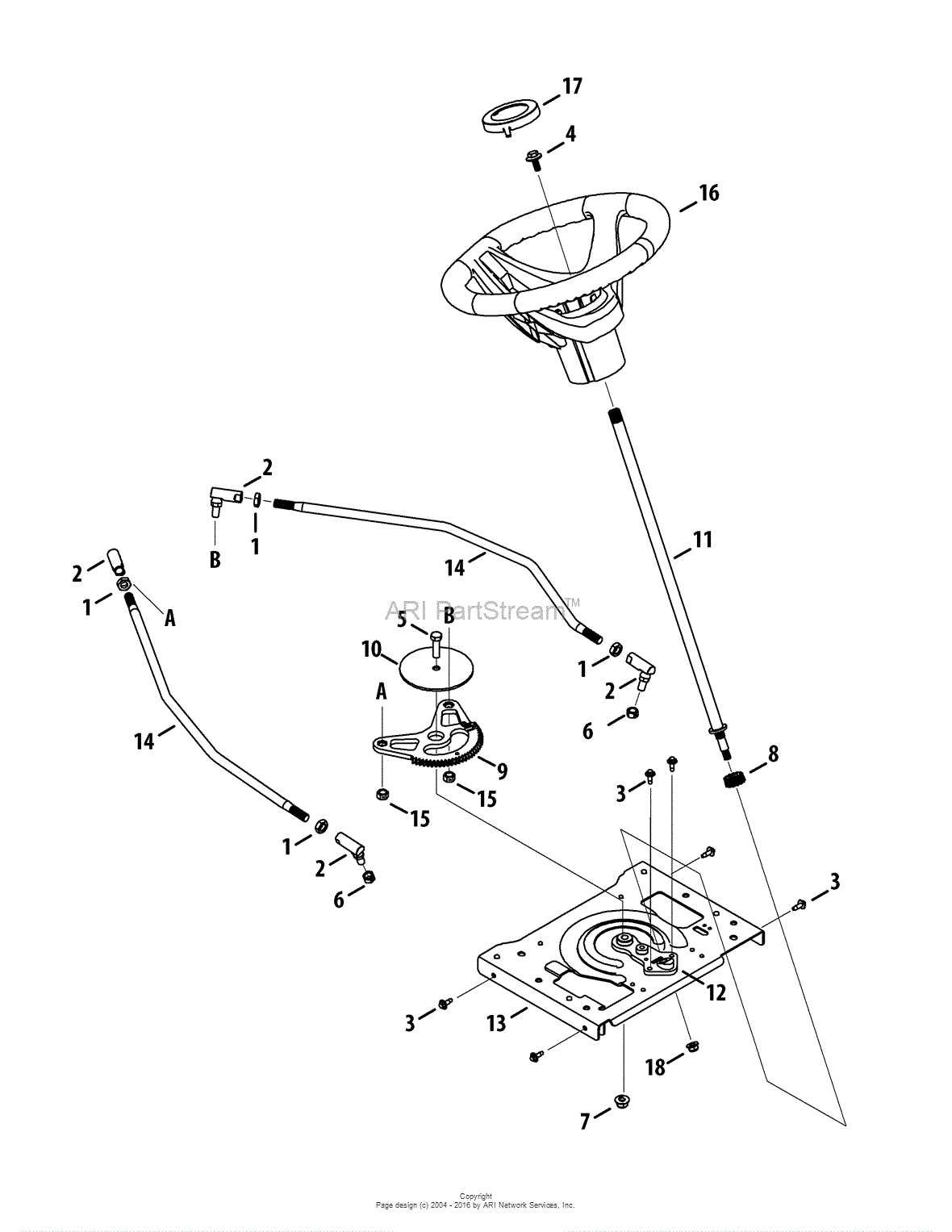

Steering and Control Mechanism Breakdown

The steering and control system is vital for managing the direction and movement of the machine. This section delves into the interconnected components that ensure precise maneuvering and operational efficiency. Understanding how each element works together will help in maintaining the system’s integrity and ensure long-lasting performance.

Key Components Overview

The mechanism consists of various elements that work in harmony to provide smooth directional control. These include rotating parts, connecting elements, and pivoting units. Proper alignment and lubrication of these elements are crucial for reducing wear and maintaining smooth operation.

Component Interaction and Functions

The interaction between the steering controls and the movement response is achieved through a combination of gear systems, rods, and bearings. Adjustments to these components can impact the accuracy and sensitivity of steering.

Component Function Maintenance Tip Steering Shaft Transmits motion from the wheel to the control mechanism. Inspect for any bends or damage. Gear Assembly Converts the rotational input into mechanical action. Lubricate regularly to prevent friction Examining the Electrical System and Battery

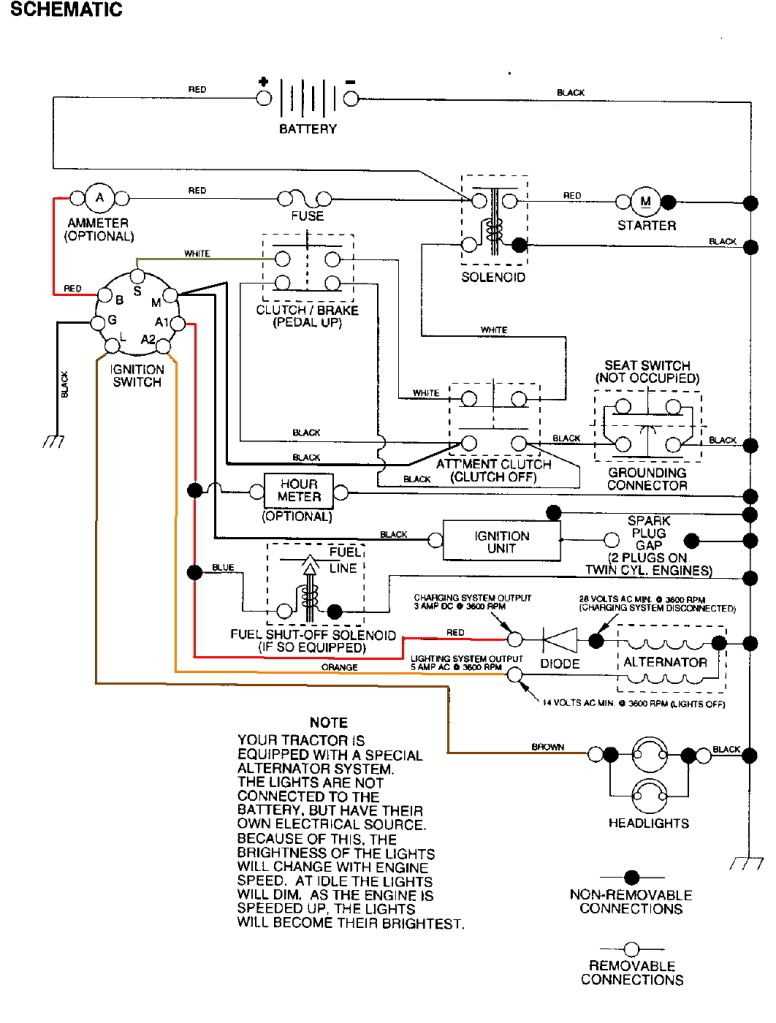

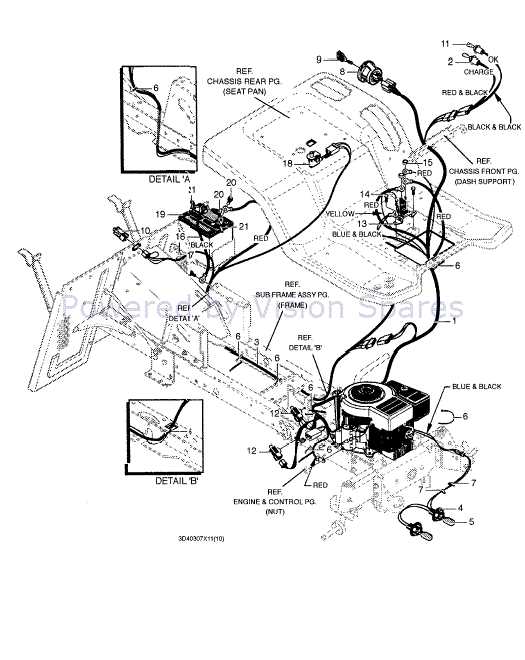

Understanding the overall structure of the electrical system is crucial for ensuring smooth operation and long-term reliability. This section focuses on the key components that make up the energy distribution network, highlighting their functions and potential issues that can arise during regular use.

Battery Health and Maintenance

The energy storage unit plays a vital role in powering the vehicle’s systems, particularly during ignition and heavy load periods. Regular checks of the battery’s charge levels, as well as cleaning the terminals, can prevent common electrical failures. It’s also essential to monitor for signs of wear, such as corrosion or reduced capacity, which could affect performance.

Wiring and Connections

Inspecting the wiring layout ensures that current flows correctly to all essential components. Secure connections are critical for avoiding short circuits and power disruptions. Pay special attention to connectors and fuses, which may become loose or worn out over time. Properly routed and insulated wires can prevent energy loss and reduce the risk of electrical malfunctions.

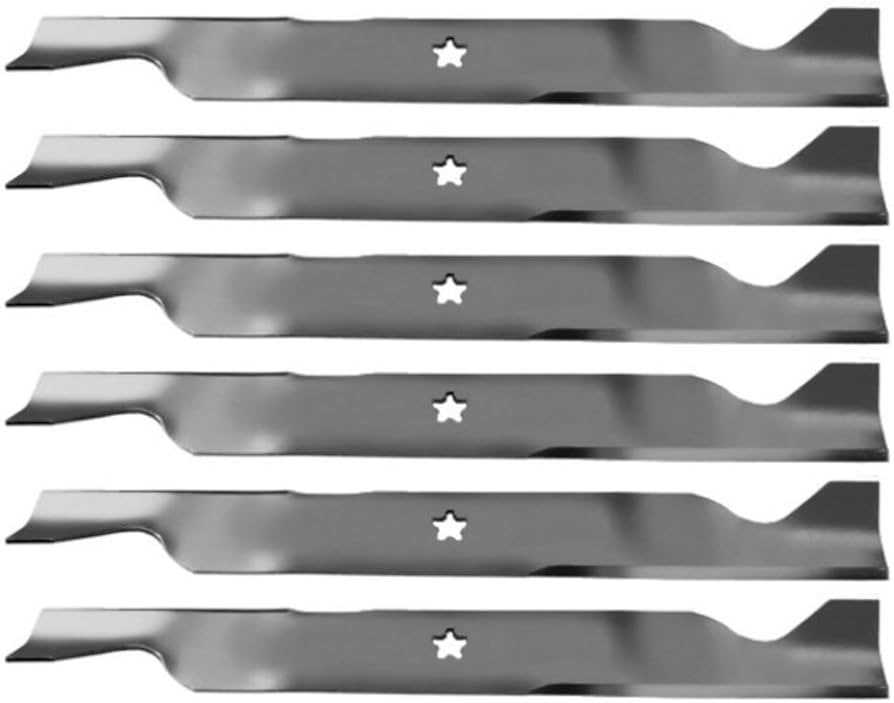

Maintenance Guide for Blades and Belts

Proper upkeep of cutting elements and drive components is essential for the longevity and efficiency of outdoor machinery. Regular attention to these parts not only enhances performance but also ensures safety during operation. This guide outlines best practices for maintaining these critical components.

To keep blades in optimal condition, follow these steps:

- Regular Inspection: Check for signs of wear, rust, or damage. Look for chips or cracks on the cutting edges.

- Sharpening: Maintain sharp blades to ensure clean cuts. Use a sharpening tool or seek professional services as needed.

- Cleaning: Remove debris, grass clippings, and mud after each use to prevent corrosion and buildup.

- Replacement: If blades are excessively worn or damaged, replace them promptly to maintain performance.

Maintaining belts is equally important for smooth operation:

- Visual Inspection: Check for fraying, cracks, or signs of stretching. Look for any misalignment that may cause uneven wear.

- Tension Adjustment: Ensure belts are properly tensioned to prevent slippage or breakage. Adjust according to manufacturer specifications.

- Lubrication: Apply appropriate lubricants to pulleys and bearings to reduce friction and wear.

- Replacement Schedule: Follow a routine replacement schedule based on usage to avoid unexpected failures.

By adhering to these maintenance practices, you can ensure that your cutting elements and drive components operate effectively, prolonging the life of your equipment.

Seat and Comfort Features of the YT4000

The seating arrangement and comfort attributes of this model significantly enhance the user experience during operation. Designed with the operator in mind, it prioritizes both support and ease of use, allowing for prolonged periods of use without discomfort.

Ergonomic Design

The chair boasts an ergonomic structure, which provides optimal lumbar support, ensuring that users maintain a healthy posture. This thoughtful engineering reduces fatigue and strain on the back, enabling extended periods of work without discomfort.

Adjustable Features

Equipped with adjustable settings, the seating can be modified to fit the unique preferences of each operator. Features such as height adjustments and reclining capabilities allow for a personalized experience, making it easier to find the ideal position for various tasks. Additionally, cushioned surfaces contribute to overall comfort, making this model suitable for both leisure and demanding tasks.

Troubleshooting the Hydraulic Lift Mechanism

The hydraulic lift system is essential for the effective operation of various equipment. When this mechanism experiences issues, it can lead to performance problems and hinder functionality. Understanding common faults and their solutions is crucial for efficient maintenance and repair.

Here are some common problems you may encounter with the hydraulic lift system:

- Fluid Leaks: Check for any visible fluid leaks around the hydraulic cylinder and connections. Leaks can result in reduced pressure and lifting capability.

- Inadequate Lifting Force: If the lift mechanism struggles to raise the load, inspect the hydraulic fluid level and quality. Low or contaminated fluid can impair performance.

- Unresponsive Controls: If the controls do not respond as expected, examine the electrical connections and switch operation. Faulty wiring or switches can prevent the system from functioning correctly.

- Jerky Movement: Irregular or jerky lifting motion may indicate air trapped in the hydraulic lines. Bleeding the system can help eliminate air and restore smooth operation.

To address these issues effectively, follow these troubleshooting steps:

- Inspect the hydraulic fluid level and top it up if necessary.

- Look for leaks and tighten connections or replace damaged seals.

- Check the operation of the control switches and replace any faulty components.

- Bleed the hydraulic system to remove any trapped air.

Regular maintenance and prompt troubleshooting can help ensure the hydraulic lift system operates efficiently, enhancing the overall performance of the equipment.

Replacement Parts and Their Functions

Maintaining the efficiency of outdoor equipment often requires the timely exchange of various components. Understanding the role of each element is crucial for optimal performance and longevity. This section outlines essential replacements and their specific functions to ensure smooth operation.

Key Components and Their Functions

- Engine: The powerhouse of the machinery, converting fuel into mechanical energy.

- Transmission: Facilitates the transfer of power from the engine to the wheels, allowing for movement.

- Blades: Responsible for cutting grass or other materials, ensuring a clean finish.

- Belt: Connects various moving parts, enabling coordinated movement.

- Battery: Provides the necessary electrical energy to start the machine and power accessories.

Importance of Quality Replacements

Using high-quality replacements is vital for maintaining the integrity of the equipment. Inferior components can lead to malfunction, inefficiency, or even complete breakdowns. Investing in reliable substitutes ensures the longevity and effectiveness of outdoor machinery.