In the realm of farming machinery, the components of tillage tools play a crucial role in enhancing soil preparation and cultivation efficiency. Understanding the various elements that make up these implements can significantly aid in their maintenance and operation. This section aims to provide insight into the essential components involved in these agricultural tools.

By exploring the configuration and functionality of each segment, users can gain a comprehensive perspective on how to optimize their equipment’s performance. With an emphasis on the interconnections between various elements, this discussion will highlight the importance of knowing each piece’s role within the overall mechanism.

Ultimately, this knowledge empowers operators to troubleshoot effectively, ensuring their equipment runs smoothly and efficiently. The details provided will serve as a valuable resource for both novice and experienced users, facilitating a deeper understanding of the intricate workings behind successful farming operations.

This section explores the essential characteristics that set apart these agricultural implements, highlighting their functionality and design innovations. Understanding these features is crucial for farmers looking to optimize soil preparation and enhance crop yields.

| Feature | Description |

|---|---|

| Durability | Constructed from high-quality materials, ensuring long-lasting performance even under harsh conditions. |

| Adjustability | Offers customizable settings to adapt to various soil types and farming needs, enhancing versatility. |

| Weight Distribution | Engineered for optimal weight distribution, promoting stability during operation and reducing wear on equipment. |

| Cutting Edge Technology | Incorporates advanced cutting technology for efficient soil penetration and mixing, improving land preparation. |

| Ease of Maintenance | Designed with user-friendly features that simplify maintenance, ensuring minimal downtime and increased productivity. |

Importance of Proper Maintenance

Ensuring the longevity and efficiency of agricultural machinery requires diligent upkeep. Regular attention to equipment not only enhances performance but also minimizes the risk of unexpected breakdowns. A proactive approach to maintenance allows for the early identification of wear and tear, ultimately saving time and resources in the long run.

Enhancing Performance

Consistent care directly impacts the functionality of machinery. Keeping components clean and well-lubricated promotes smoother operation, which can lead to improved productivity during fieldwork. When all parts are in optimal condition, the equipment can perform its tasks more effectively, maximizing output.

Reducing Downtime

By prioritizing maintenance, operators can significantly reduce the likelihood of equipment failure. Scheduled inspections and timely repairs prevent small issues from escalating into major problems, thus minimizing downtime. This ensures that machinery is always ready for use, supporting ongoing agricultural activities without unnecessary interruptions.

Common Wear and Tear Issues

In agricultural equipment, certain components frequently experience degradation due to regular usage and environmental factors. Identifying these areas of concern can enhance maintenance strategies and extend the lifespan of the machinery.

- Blade Deterioration: Cutting edges may become dull or damaged, affecting performance.

- Frame Integrity: Structural elements may suffer from stress fractures or bends over time.

- Bearings Wear: Bearings may exhibit signs of excessive play or noise, indicating a need for replacement.

- Hydraulic Seal Failure: Seals can degrade, leading to leaks and reduced efficiency in hydraulic systems.

- Attachment Connections: Wear at connection points can result in misalignment and operational issues.

Regular inspections and timely replacements of these worn elements are crucial to maintaining optimal functionality and avoiding costly repairs in the long run.

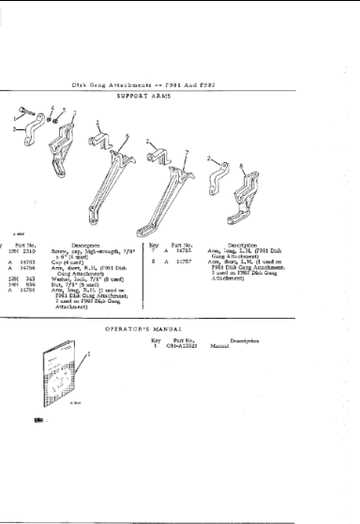

Identifying Replacement Parts Easily

When it comes to maintaining and repairing agricultural equipment, recognizing the correct components is essential. This ensures optimal performance and longevity of the machinery. Understanding how to identify the necessary elements can simplify the replacement process, making it more efficient for operators.

Key Features to Consider

Familiarizing yourself with specific characteristics of the components will aid in quick identification. Focus on aspects such as size, shape, and material. Additionally, consulting reference materials can provide valuable insights into the correct items required for your equipment.

Utilizing Resources for Assistance

Several resources can assist in finding the right components. Manuals, online databases, and manufacturer websites often have detailed information and illustrations. These tools can be invaluable when trying to locate specific items.

| Component Type | Identifying Features | Reference Resource |

|---|---|---|

| Blade | Length, width, and shape | User manual, manufacturer website |

| Frame | Material, dimensions, attachment points | Parts catalog, online resources |

| Wheel | Diameter, tread pattern, hub design | Online database, equipment manual |

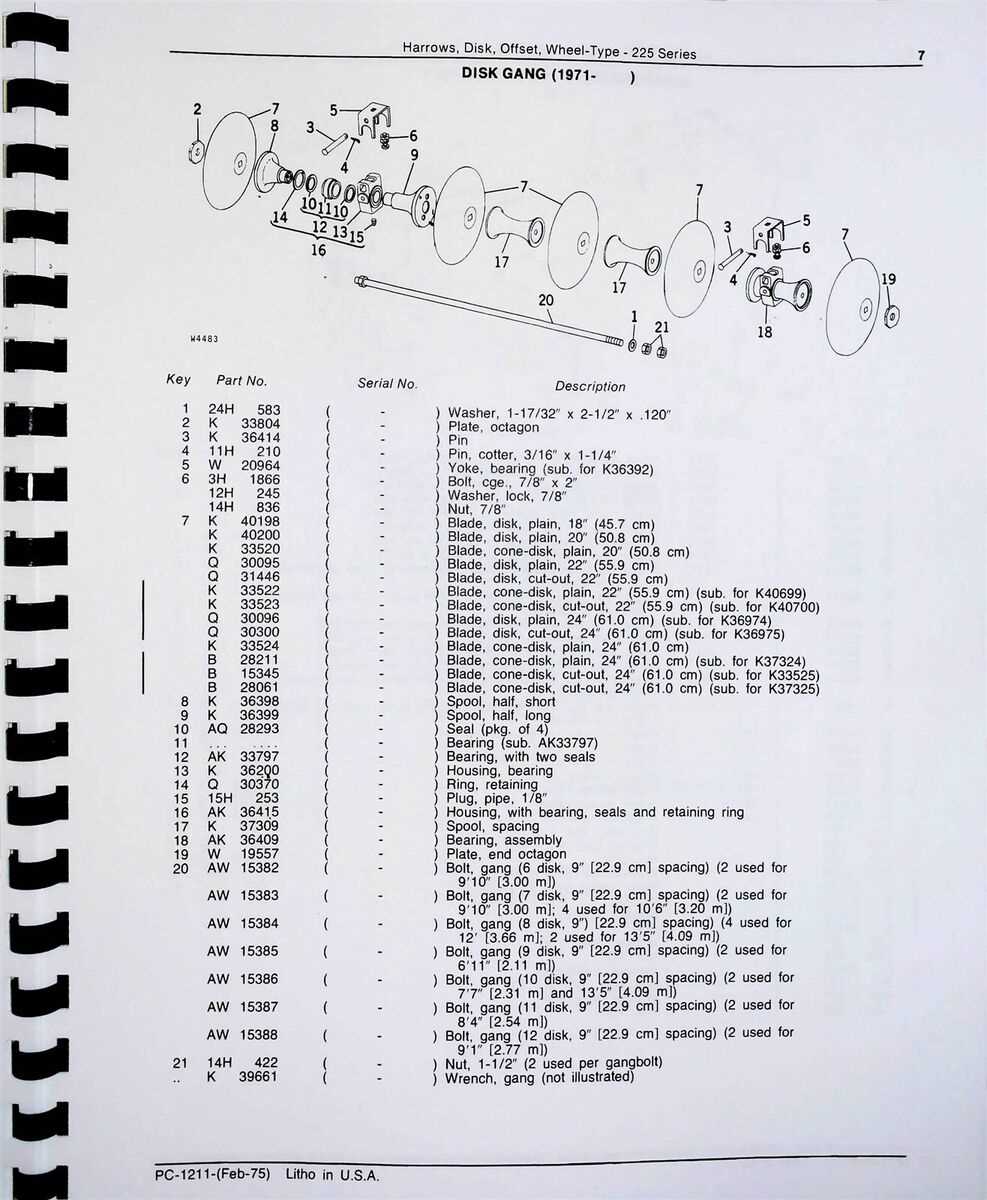

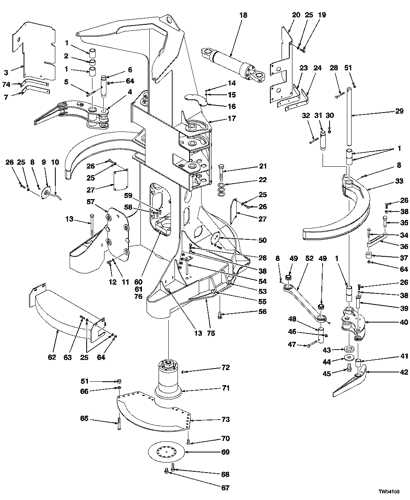

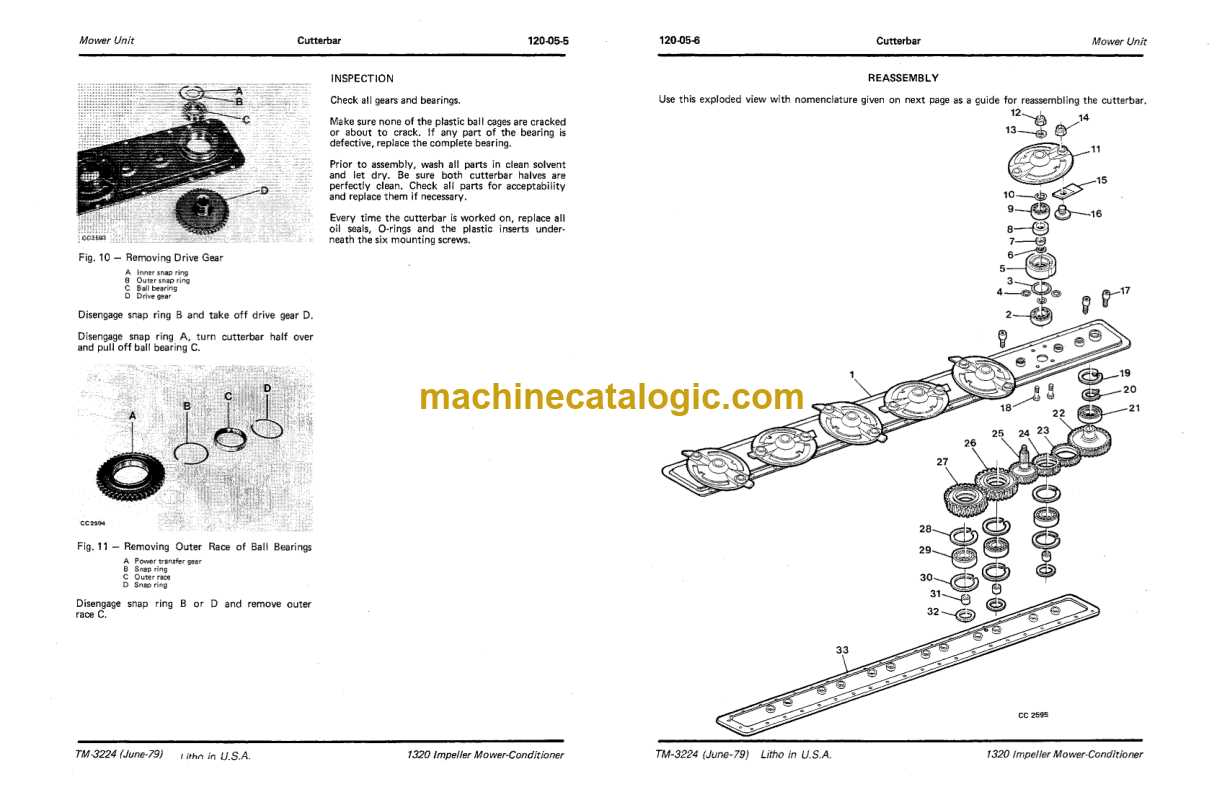

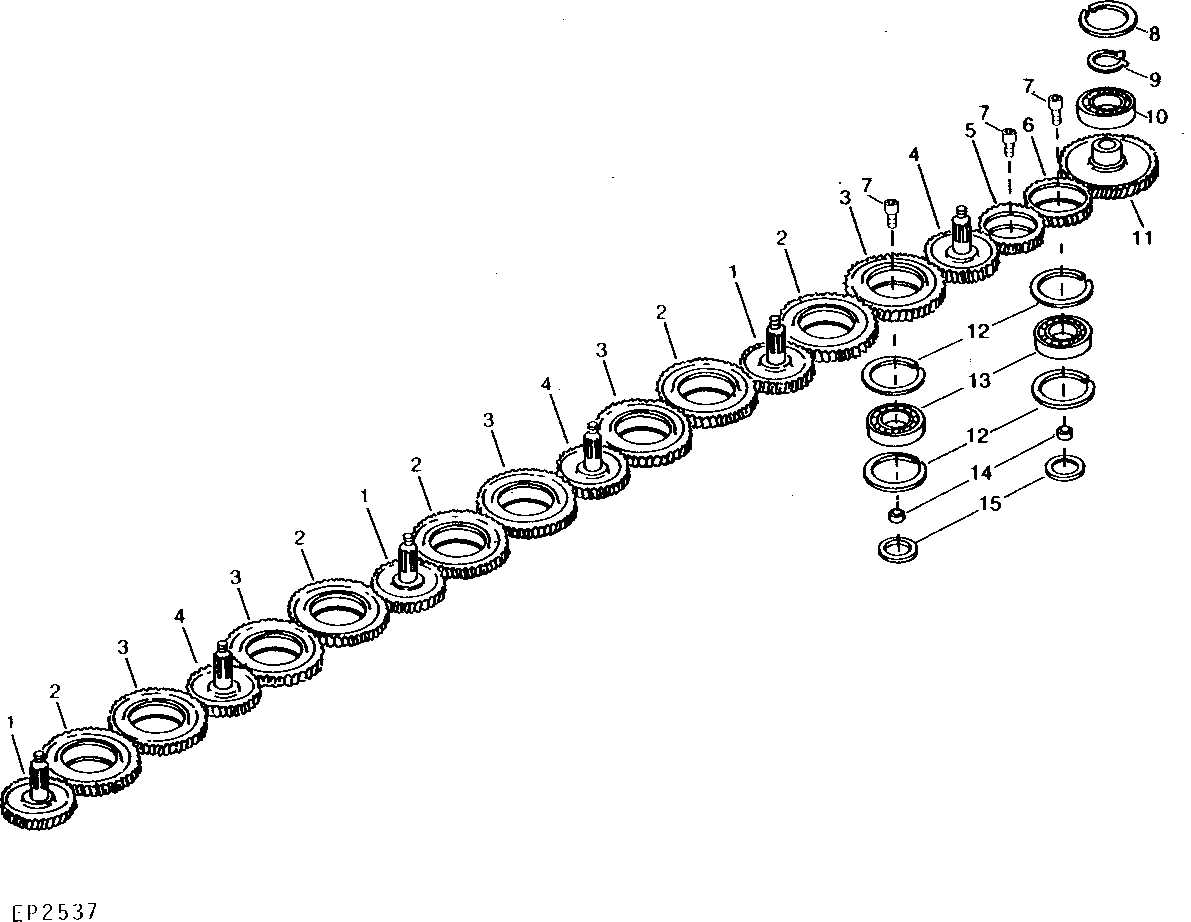

How to Read Parts Diagrams

Understanding technical illustrations is essential for efficient maintenance and repair tasks. These visuals provide a clear representation of components, their arrangement, and how they interact within a system. By familiarizing yourself with these drawings, you can easily identify necessary elements and their respective roles.

Typically, these illustrations are accompanied by a legend or key, which explains the symbols and notations used. Here are some key aspects to consider when interpreting such visuals:

| Aspect | Description |

|---|---|

| Symbols | Familiarize yourself with common symbols representing various components. |

| Labels | Pay attention to labels that indicate part numbers or names for easy reference. |

| Orientation | Understand the orientation and arrangement of elements to visualize their placement. |

| Connections | Look for lines or arrows that indicate how components are connected or interact. |

By focusing on these elements, you can effectively interpret technical illustrations and enhance your understanding of the system as a whole.

Tools Needed for Repairs

When it comes to maintaining agricultural equipment, having the right tools at your disposal is essential for efficient and effective repairs. Proper equipment not only ensures a smooth workflow but also enhances the longevity and performance of your machinery. Below is a list of essential tools that can help facilitate the repair process.

Essential Hand Tools

Hand tools are the backbone of any repair job. They are used for a variety of tasks, from simple adjustments to more complex disassemblies.

| Tool | Purpose |

|---|---|

| Wrenches | For loosening and tightening nuts and bolts. |

| Screwdrivers | For driving screws in various sizes. |

| Pliers | For gripping and manipulating small parts. |

Power Tools for Efficiency

In addition to hand tools, power tools can significantly speed up the repair process, making it easier to tackle tougher jobs.

| Tool | Purpose |

|---|---|

| Drill | For creating holes and driving fasteners quickly. |

| Impact Wrench | For high-torque applications, such as removing stubborn bolts. |

| Angle Grinder | For cutting and grinding materials. |

Tips for Efficient Assembly

When working on the assembly of agricultural machinery components, following a systematic approach can greatly enhance efficiency and accuracy. This section outlines several strategies to streamline the process, ensuring a smooth experience from start to finish.

- Prepare Your Workspace: Ensure your assembly area is clean and organized. Having all tools and materials within reach reduces distractions and saves time.

- Review the Manual: Familiarize yourself with the assembly instructions before starting. Understanding the steps involved will help you anticipate challenges and avoid mistakes.

- Gather Necessary Tools: Make sure you have all the required tools on hand. Using the right equipment for each task can prevent delays and improve overall performance.

Additionally, consider the following tips for optimal results:

- Work Methodically: Follow the assembly sequence closely. Completing tasks in the correct order minimizes the risk of redoing steps.

- Take Breaks: If you find yourself frustrated or fatigued, take a short break. Returning with a fresh perspective can help you overcome obstacles more effectively.

- Collaborate: If possible, work with a partner. Two sets of hands can make certain tasks easier and faster, enhancing overall efficiency.

By implementing these strategies, you can significantly improve the assembly process, leading to a successful outcome and a well-functioning machine.

Safety Precautions During Repairs

When performing maintenance on machinery, ensuring personal safety and proper handling of equipment is crucial. Adhering to safety measures can prevent accidents and injuries, allowing for a smoother repair process.

First and foremost, always wear appropriate protective gear, such as gloves, goggles, and sturdy footwear. This equipment shields against potential hazards, including sharp edges and heavy components.

Additionally, ensure the work area is well-lit and free from clutter. A clean workspace minimizes distractions and allows for better focus on the task at hand.

Lastly, familiarize yourself with the machinery’s operational guidelines. Understanding how the equipment functions can significantly reduce risks during repairs.

Recommended Maintenance Schedules

Regular upkeep is essential for ensuring optimal performance and longevity of agricultural equipment. Following a systematic approach to maintenance can prevent costly repairs and improve overall efficiency.

General Guidelines

Adhering to specific time frames for routine checks and services is crucial. Operators should consult their equipment manuals for tailored schedules while considering factors such as usage frequency and environmental conditions.

Maintenance Tasks

| Task | Frequency |

|---|---|

| Lubrication of moving components | Every 50 hours of operation |

| Inspection of wear parts | Every 100 hours of operation |

| Grease fittings check | Every 150 hours of operation |

| Hydraulic system evaluation | Every 200 hours of operation |

| Fluid changes | Every 500 hours of operation |

Where to Source Authentic Parts

Finding genuine components for agricultural machinery is essential for maintaining optimal performance and longevity. Quality materials ensure that your equipment operates efficiently, reducing the risk of breakdowns and costly repairs. Here are some reliable avenues to explore for authentic replacements.

Authorized Dealers

One of the best options for acquiring original components is through authorized dealers. These distributors are directly connected to the manufacturers and can provide a wide selection of genuine products.

Online Marketplaces

Reputable online platforms also offer a range of authentic components. Look for sellers with high ratings and positive reviews to ensure the quality of the items.

| Source | Benefits |

|---|---|

| Authorized Dealers | Direct access to manufacturer support and guarantees of authenticity. |

| Online Marketplaces | Convenient shopping with a variety of options and competitive pricing. |