In this detailed exploration, we delve into the intricate mechanisms that comprise the core of a firearm, unveiling its inner complexity through a meticulous dissection.

Unveiling the intricate systems, we uncover the interplay of various components that operate in harmony to ensure precise functionality.

Understanding the nuanced connections between each part reveals the orchestration required for seamless operation, highlighting the synergy that defines its mechanical prowess.

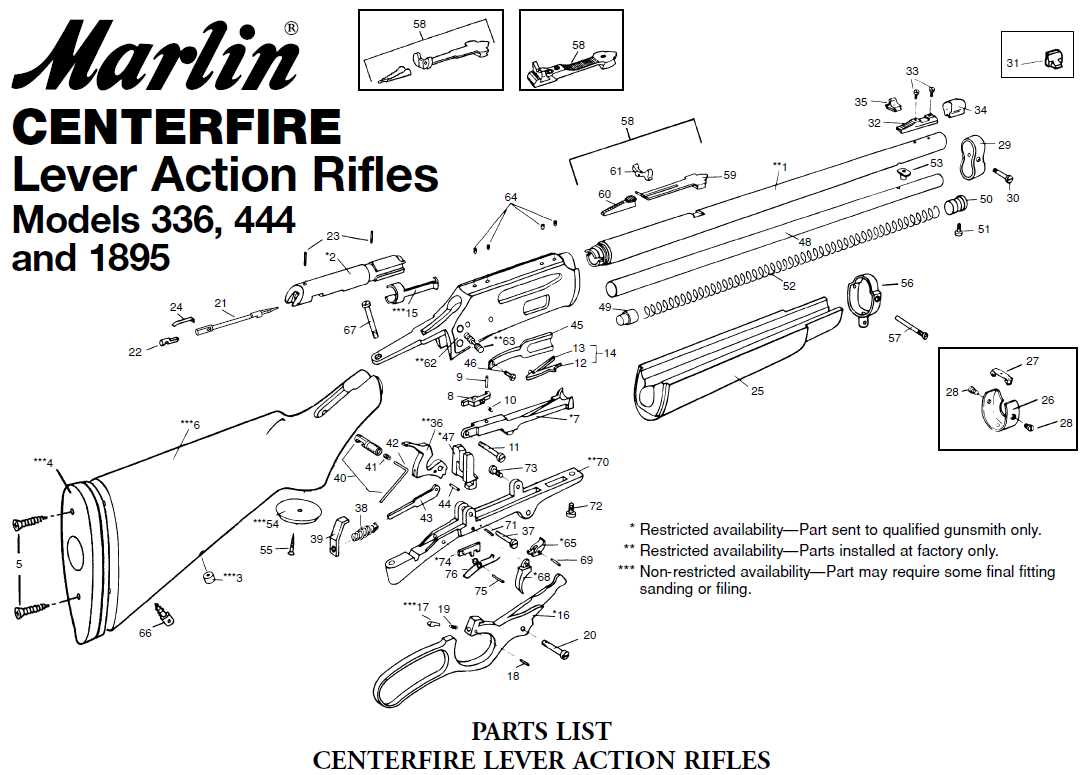

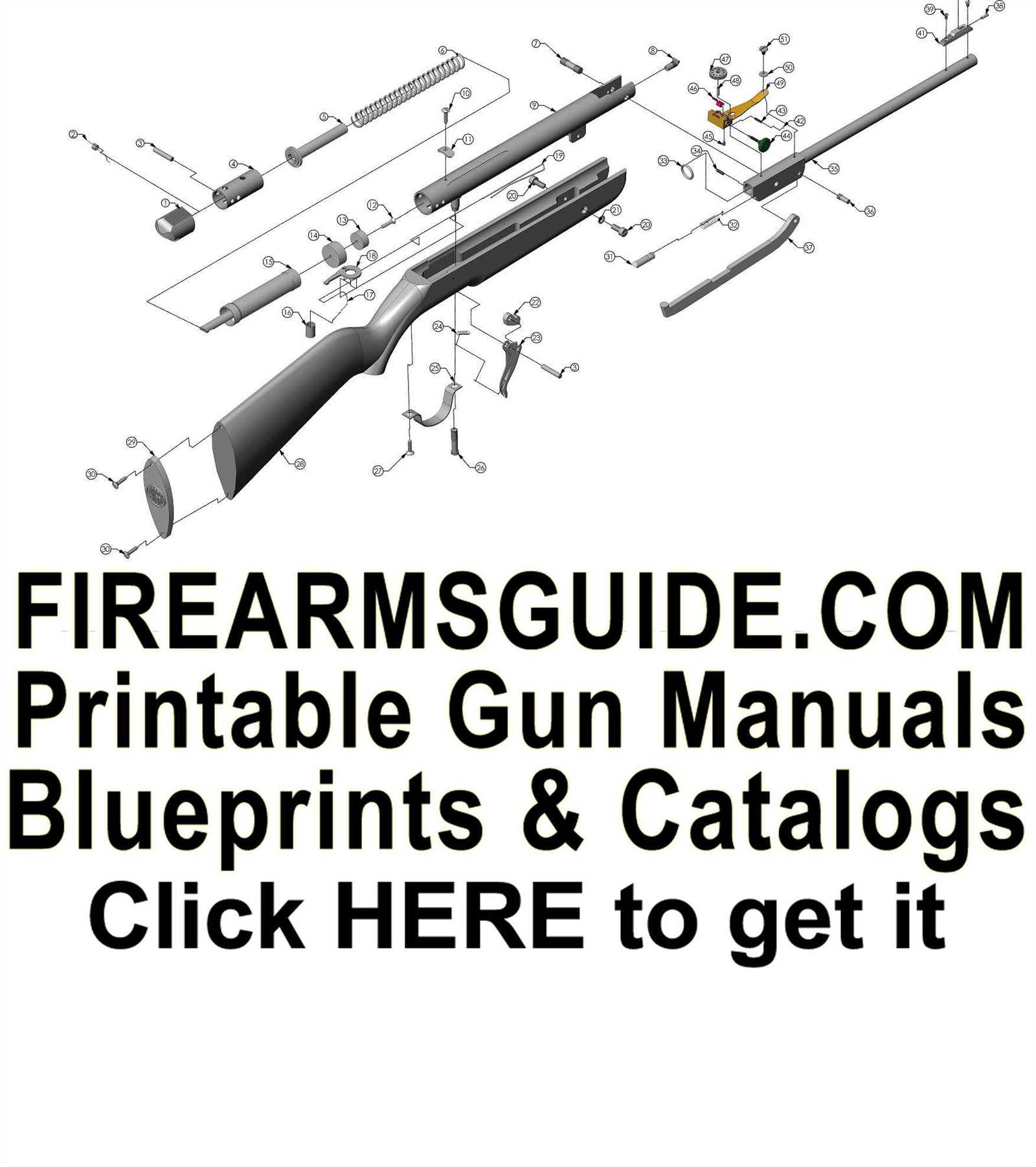

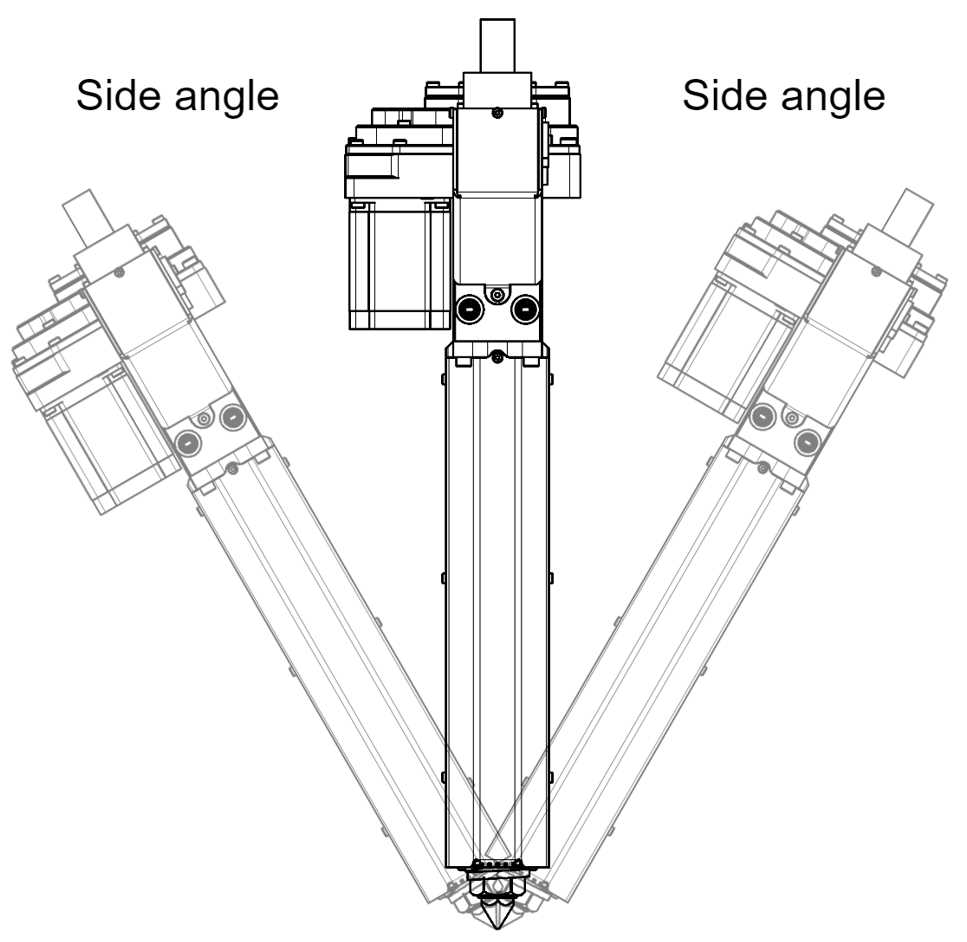

Overview of Marlin 795 Components

In this section, we will explore the essential elements that make up the structure of the Marlin 795 rifle. Understanding the key components is crucial for maintaining and operating this firearm effectively. Let’s delve into the fundamental parts that contribute to the functionality and performance of the Marlin 795.

Main Assembly: The core unit of the rifle includes the receiver, barrel, and stock, which form the primary framework. Each of these components plays a critical role in the overall stability and handling of the firearm.

Action Mechanism: This intricate system comprises the bolt, trigger assembly, and safety mechanism, ensuring precise firing and reliable operation. The action mechanism is designed to handle various conditions while maintaining consistent performance.

Magazine System: Responsible for ammunition storage and feeding, the magazine system is a pivotal part of the Marlin 795. It enables quick and efficient reloading, enhancing the usability of the rifle in different shooting scenarios.

Sights and Optics: These components provide aiming and targeting capabilities, essential for achieving accuracy over short and long distances. Whether using iron sights or optics, these elements contribute significantly to the rifle’s versatility.

Stock and Grip: Designed for ergonomic comfort and stability, the stock and grip of the Marlin 795 ensure proper handling and control during shooting. These components are crucial for minimizing recoil and enhancing shooting precision.

Accessories and Attachments: Optional additions such as slings, bipods, and scope mounts can further customize the rifle to suit individual preferences and specific shooting conditions, expanding its utility and effectiveness.

By understanding the function and importance of each component, users can appreciate the engineering behind the Marlin 795 and maximize its performance in various shooting applications.

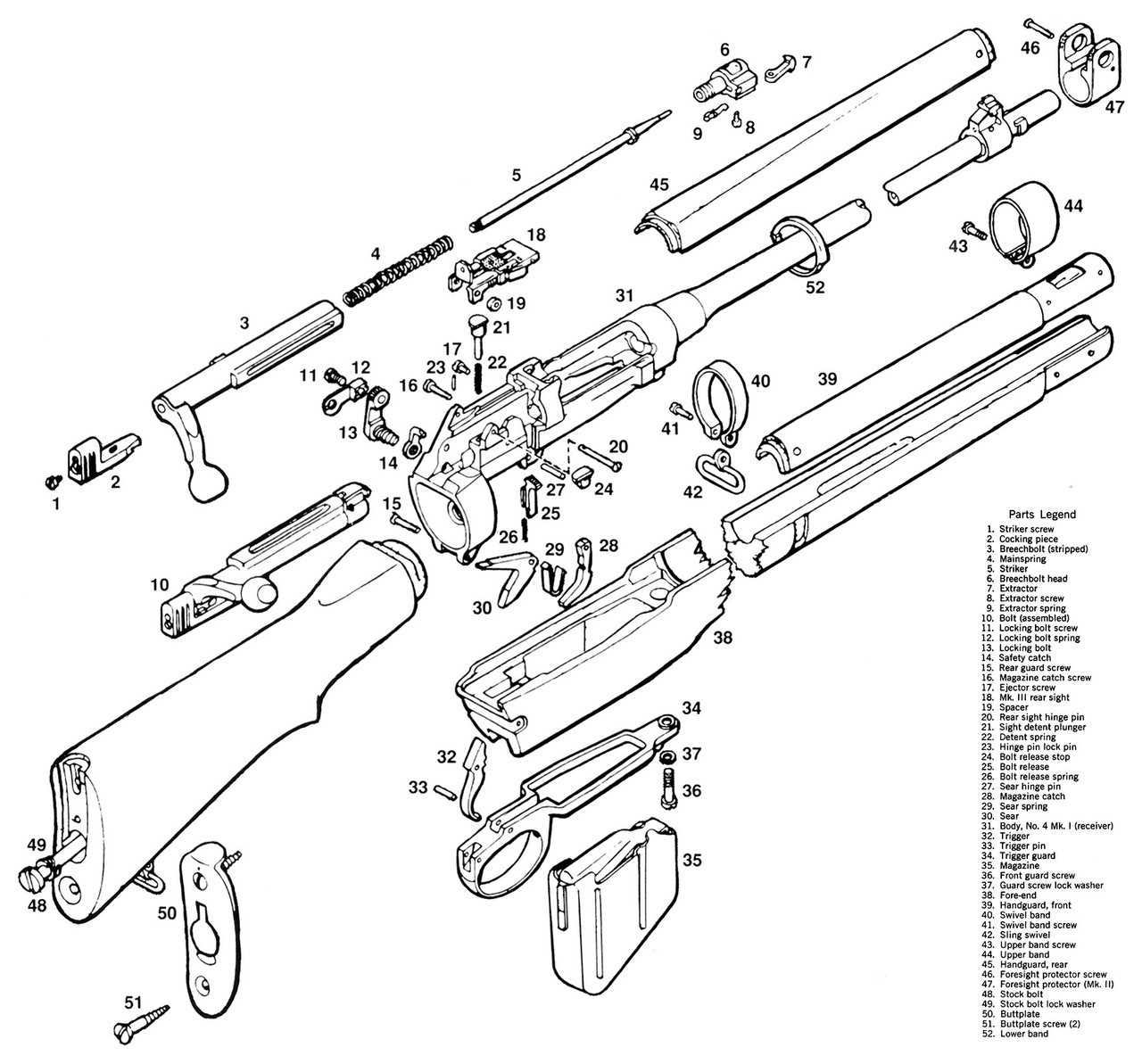

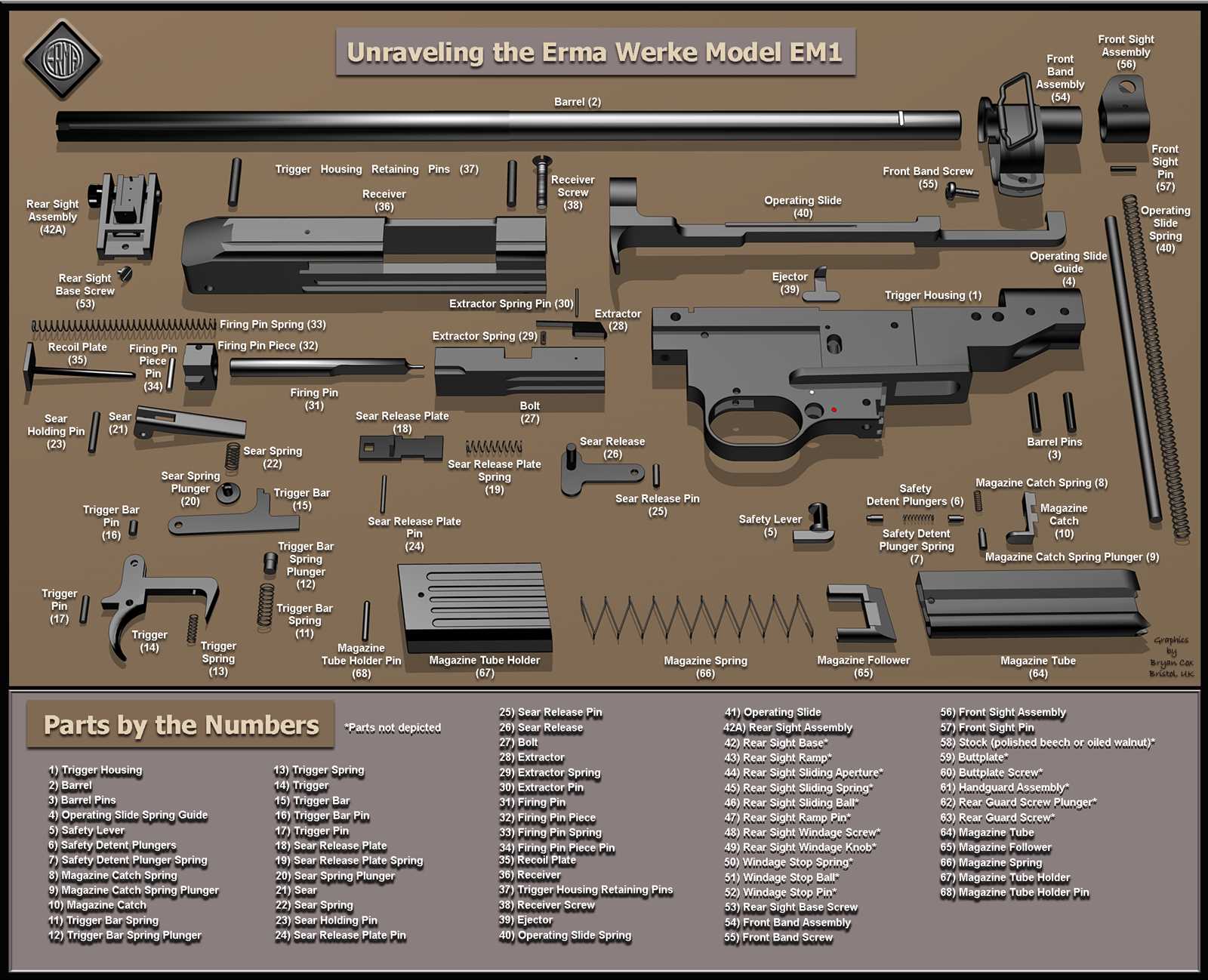

Exploring the Receiver and Bolt Assembly

In this section, we delve into the intricate workings of the main housing unit and the mechanism responsible for chambering and locking the cartridge. Understanding the inner workings of this crucial component provides insights into how the firearm functions during operation.

Receiver: Often referred to as the core frame, this component houses vital parts such as the trigger group and the magazine well. Its design and material composition directly influence the firearm’s durability and precision.

Bolt Assembly: Comprising the bolt, firing pin, and extractor, this assembly plays a pivotal role in the firing cycle. It secures the cartridge in place, strikes the primer, and extracts the spent casing after firing, ensuring seamless operation.

Exploring these elements enhances our understanding of the firearm’s mechanics, highlighting the precision engineering required for reliable performance.

Key Features of the Magazine Mechanism

The magazine mechanism in this model is designed to ensure smooth and reliable feeding of ammunition during operation. Its construction focuses on efficiency, providing a seamless experience in loading and unloading. A well-optimized structure allows for improved performance, enhancing the overall functionality of the system.

Durable Build: The mechanism is crafted from high-quality materials that ensure long-term durability, even under frequent use. This contributes to a robust design capable of withstanding harsh conditions.

Easy Maintenance: The structure is simple to disassemble, making it easy for users to clean and maintain without requiring specialized tools. This ensures that the mechanism stays in good working condition over time.

Efficient Ammunition Handling: Designed for consistent and smooth cycling, the mechanism ensures that rounds are properly aligned and fed into the chamber without interruptions. This feature enhances overall reliability during use.

Stock Design and Customization Options

The standard stock design offers a balanced combination of functionality and simplicity, providing users with a reliable base. Its structure is designed to fit comfortably, allowing for ease of use during extended periods of activity. While the basic design meets the needs of most, there are several customization choices available for those looking to enhance their experience.

Materials for stock upgrades vary, including synthetic and wood, each offering distinct advantages. Synthetic stocks tend to be lightweight and more durable under extreme conditions, whereas wooden stocks provide a classic appearance and a comfortable feel.

Adjustability is another key feature in customized designs. Adjustable stocks can offer enhanced ergonomics, allowing the user to modify the length of pull or cheek rest height for better alignment and comfort. Some designs may even include tactical elements like rail systems or sling mounts for added versatility.

For users seeking a more personalized touch, custom color schemes and finishes are available, allowing for aesthetic modifications without sacrificing function. From subtle tones to vibrant designs, the options allow owners to create a unique look tailored

Understanding the Trigger Group and Functionality

The trigger group is an essential component of any firearm, responsible for initiating the firing sequence. Its design and functionality play a crucial role in the accuracy, safety, and reliability of the overall mechanism. Understanding how the trigger mechanism works is key to both maintaining and enhancing performance, especially when considering modifications or repairs.

Main Components of the Trigger Group

The trigger assembly is composed of various interconnected parts that work together to release the hammer or firing pin. Each element plays a distinct role in ensuring the proper functioning of the mechanism.

- Trigger – The physical component pressed by the user to initiate the shot.

- Sear – A vital link that holds the hammer or firing pin in place until the trigger is pulled.

- Hammer – This part strikes the firing pin, which in turn ignites the cartridge.

How the Trigger Group Operates

When the trigger is pulled, it moves the sear, releasing the hammer. The hammer then springs forward, striking the firing pin, which hits the primer of the cartridge, leading to the ignition of the propellant. This process results in the firing of the round.

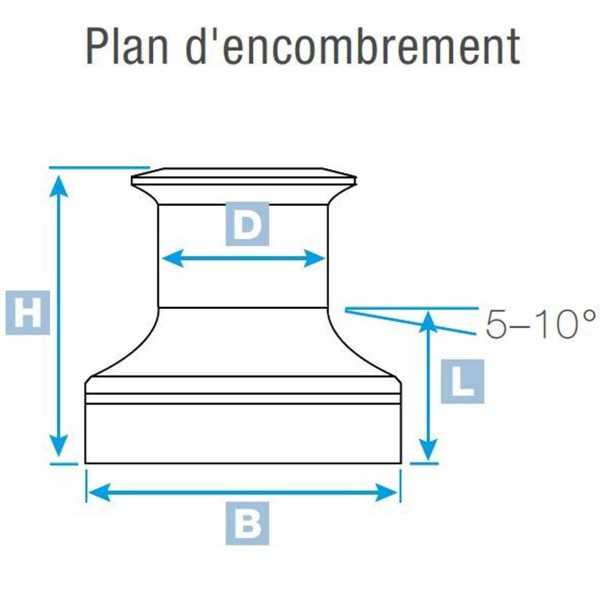

Barrel Specifications and Performance Factors

The barrel is a critical component that significantly impacts both accuracy and overall handling. Its dimensions, materials, and finish contribute to how effectively a firearm performs under various conditions. Understanding the key elements of barrel construction can help optimize shooting performance and longevity.

Material Composition and Durability

Barrels are typically constructed from high-grade steel to withstand the extreme pressure and heat generated during firing. The choice of material directly affects the longevity and resilience of the barrel, with modern coatings often added to reduce wear and corrosion. The balance between strength and weight is crucial for maintaining maneuverability without sacrificing durability.

Length and Twist Rate

Barrel length and rifling twist rate play vital roles in stabilizing the projectile. Longer barrels often improve accuracy by providing a more extended distance for the bullet to stabilize, while the twist rate must match the ammunition to ensure consistent spin. These factors work together to enhance precision, particularly at greater distances.

Details of the Rear and Front Sights

The aiming devices located on the front and rear of the firearm play a crucial role in accuracy and precision. These components work together, allowing the user to align their shot with the target effectively. By adjusting these elements, it becomes possible to fine-tune the weapon for different distances and conditions, ensuring consistent performance in a variety of situations.

Rear Sight

The rear aiming piece is typically adjustable and allows for both elevation and windage modifications. It provides the shooter with flexibility to adapt to changing shooting conditions. This element is essential for achieving the correct alignment with the front sight, ensuring accuracy over longer ranges.

Front Sight

The forward aiming component, usually fixed, provides the initial reference point for targeting. Its design helps the user quickly acquire their aim. Combined with the rear sight, this part ensures proper alignment and accuracy, making it a vital part of the aiming process.

Breakdown of the Ejector and Extractor Parts

The functioning of the ejector and extractor mechanisms is essential for the proper operation of many firearms. These components work together to ensure smooth cycling, extracting spent casings and ejecting them from the chamber effectively. Understanding how these mechanisms operate helps identify potential issues during maintenance or troubleshooting.

Ejector Components

The ejector is responsible for removing the casing from the chamber once the round has been fired. It usually consists of several interconnected pieces that work in harmony to push the spent casing out.

- Ejector spring: This small yet crucial element provides the necessary force to push the casing out of the chamber.

- Ejector pin: The pin holds the ejector in place and ensures it moves correctly during cycling.

Extractor Components

The extractor grabs the rim of the casing, pulling it out of the chamber after firing. This mechanism is equally crucial for smooth operation,

Safety Mechanism: Structure and Importance

The safety mechanism in firearms is a critical feature designed to prevent accidental discharge, ensuring the user’s security during operation. Understanding how this component functions is essential for responsible handling. The structure of the safety system involves a series of parts that work together to control when and how the weapon can be fired, enhancing both control and reliability.

From a structural standpoint, the safety mechanism is typically positioned to block or release key internal elements. Its role is crucial, as it determines the readiness of the firearm while protecting against unintentional triggers. Ensuring the proper functionality of this feature contributes greatly to the overall reliability and secure usage of the weapon, making it an indispensable aspect of firearm design.

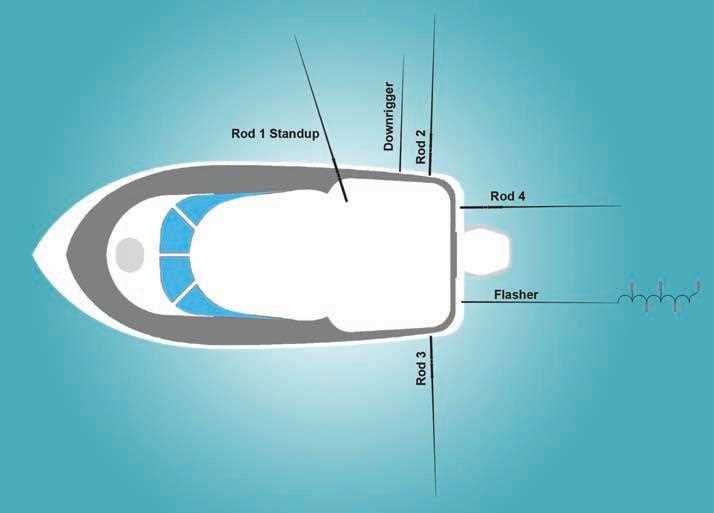

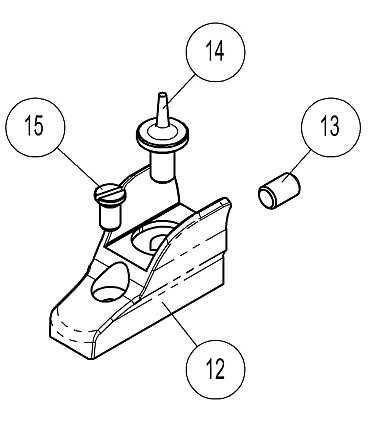

Mounting Options for Scopes and Optics

Choosing the right mounting system for scopes and other optics is essential for maximizing accuracy and stability. With various methods available, it’s important to understand how different options can affect the performance of your setup. The correct selection will ensure a secure fit, helping to maintain precision during use.

Rings and Bases

One of the most common methods involves using rings and bases. Rings hold the scope securely, while the base attaches directly to the receiver. These components come in different heights and diameters, allowing for customization depending on the optic’s specifications and the user’s preferences. A well-aligned setup ensures durability and consistent targeting.

Picatinny and Weaver Rails

Picatinny and Weaver rails provide a versatile solution for mounting optics. These rail systems offer a stable platform and make it easy to swap or adjust optics when necessary. Both systems feature a series of slots along the rail, enabling flexible placement of the mounting hardware, ensuring the right eye relief and comfort during use.

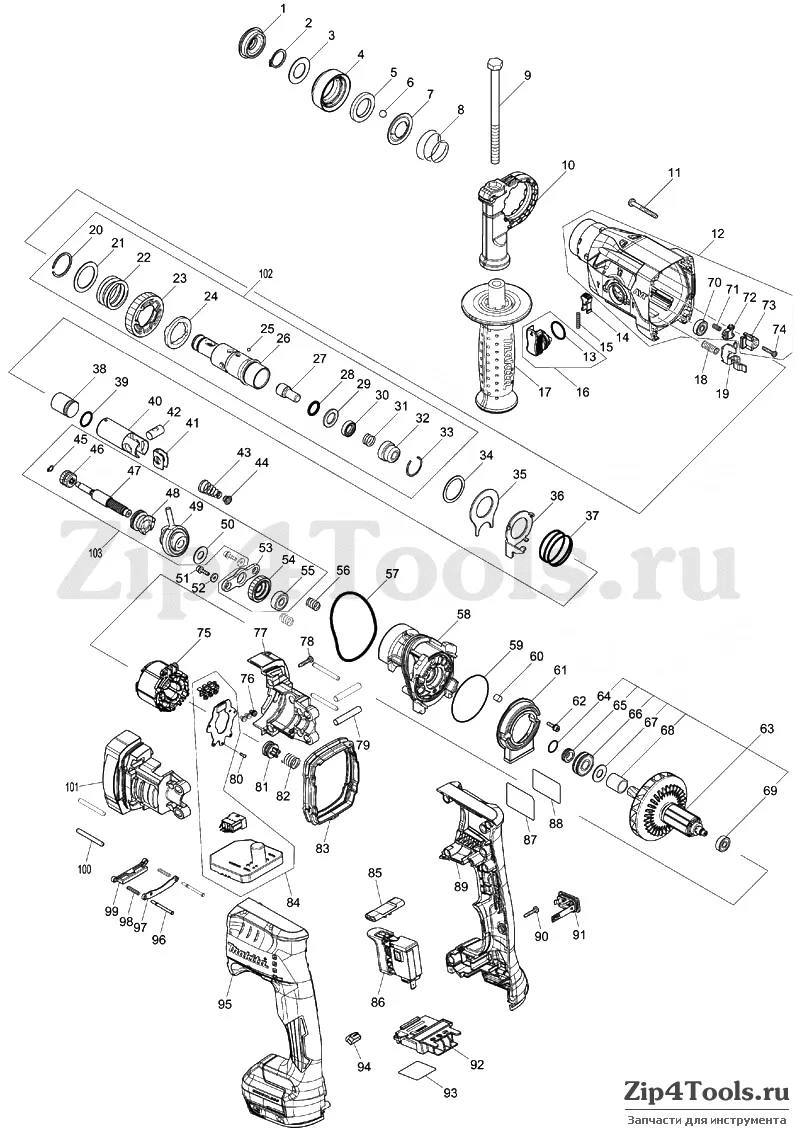

Maintenance Tips for Internal Components

Proper care of the internal mechanisms ensures smooth operation and longevity of the equipment. Regular upkeep prevents malfunctions and helps in maintaining optimal performance. Follow these simple steps to keep the inner elements in top condition.

- Regular cleaning: Dust and debris can accumulate inside, causing wear or reducing efficiency. Periodic cleaning with a soft brush or compressed air helps prevent buildup.

- Lubrication: Oiling moving components is crucial to avoid friction and wear. Use appropriate oils and ensure to apply them sparingly to prevent excessive buildup.

- Inspect for wear: Regularly check the surfaces of internal parts for any signs of damage, such as scratches or deformations, and replace them if necessary.

- Ensure proper assembly: After cleaning or replacing any elements, carefully reassemble everything, ensuring each part fits securely to prevent operational issues.

By following these guidelines, you can extend the life of your device and maintain its effectiveness over time.

Troubleshooting Common Assembly Issues

When assembling any mechanical device, it’s common to encounter minor challenges that can hinder the process. Understanding how to quickly identify and resolve these issues will ensure smooth assembly and optimal performance. Whether you’re dealing with misaligned components or difficulty in fitting parts together, a systematic approach can make all the difference.

Alignment Problems

One frequent issue during assembly is the misalignment of key components. This can occur due to incorrect positioning or improper handling of individual pieces. To fix this, ensure all parts are properly aligned before securing them in place, using reference points where possible.

Difficulty in Securing Fasteners

Another challenge is difficulty in securing screws, bolts, or other fasteners. This could result from incorrect threading or using the wrong