The intricate world of fuel delivery mechanisms plays a crucial role in the performance and efficiency of automotive engines. Analyzing the various elements involved in this process allows enthusiasts and technicians alike to appreciate the sophistication behind engine operation. Each component is designed to fulfill specific functions, ensuring the proper mixing of air and fuel for optimal combustion.

In this section, we will explore the essential components that contribute to effective fuel management. Understanding how these elements interact helps in diagnosing issues and enhancing performance. From the intricate adjustments to the essential flow regulators, each aspect is pivotal in maintaining the engine’s responsiveness and efficiency.

By examining these key elements, individuals can gain valuable insights into maintenance and upgrades. Whether for troubleshooting or enhancing vehicle performance, familiarity with these systems empowers users to make informed decisions. Delving into the specifics reveals not only how engines operate but also how to maximize their potential.

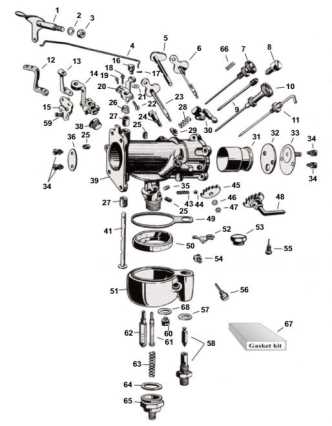

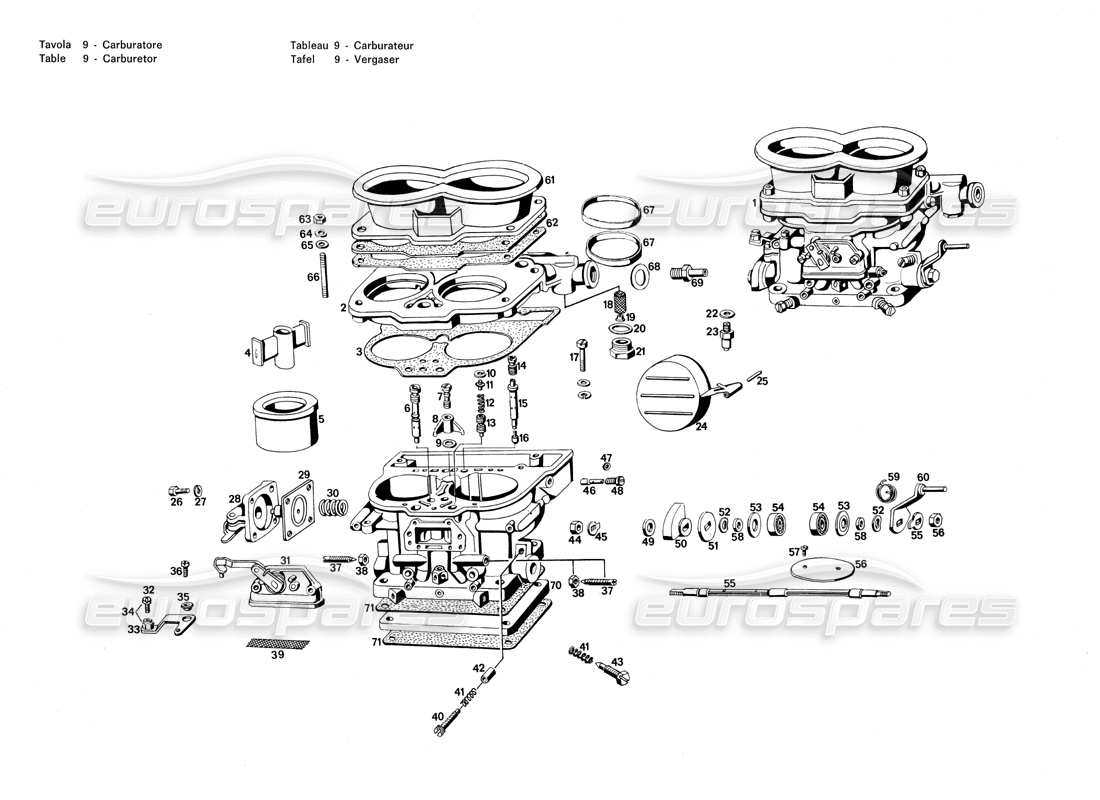

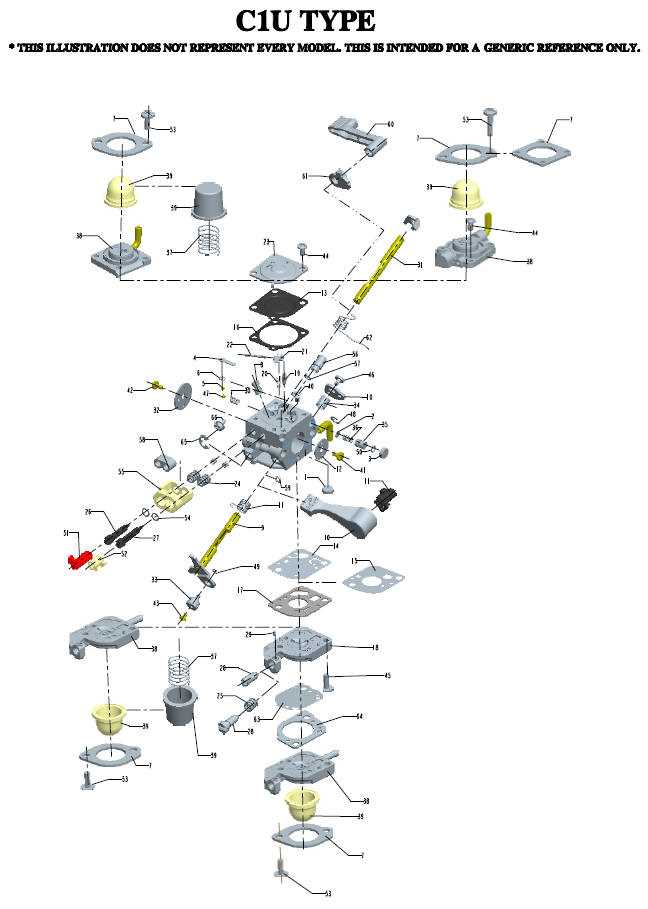

Understanding Carburetor Components

This section explores the essential elements of fuel delivery systems in engines, focusing on their functions and interactions. A thorough grasp of these components is crucial for effective maintenance and optimization of performance.

Key Elements and Their Functions

Each component plays a pivotal role in ensuring the proper mixing of air and fuel, impacting overall engine efficiency. Understanding their individual contributions helps in troubleshooting and enhancing performance.

| Component | Function |

|---|---|

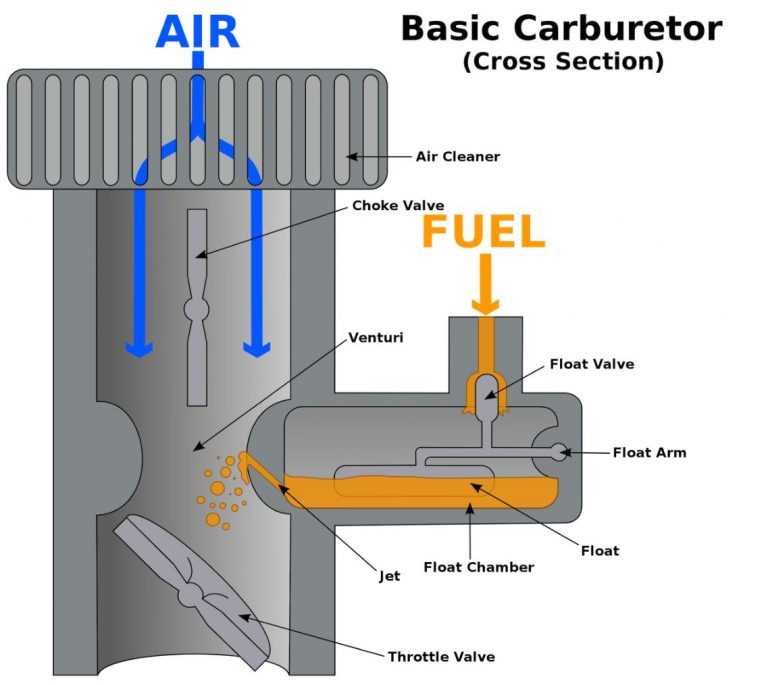

| Throttle Valve | Regulates airflow into the engine, controlling speed and power. |

| Float Chamber | Maintains a steady level of fuel for consistent delivery. |

| Jet | Controls the amount of fuel mixed with air, essential for combustion. |

Importance of Maintenance

Regular inspection of these components ensures optimal functionality and longevity of the system. Neglect can lead to performance issues, emphasizing the importance of understanding each part’s role.

Function of Each Carb Part

The components of a fuel delivery system play a crucial role in optimizing engine performance and efficiency. Each element contributes to the overall functionality, ensuring the right mixture of air and fuel reaches the combustion chamber.

Throttle Valve: This component regulates the amount of air entering the system, directly influencing engine power and responsiveness. Adjusting its position alters the engine’s speed and acceleration.

Float Chamber: This section maintains a steady supply of fuel, using a buoyant mechanism to balance the fuel level. It ensures that the engine receives a consistent flow, preventing starvation or flooding.

Main Jet: The orifice within this part controls the volume of fuel that mixes with air during operation. Its size determines the richness or leaness of the fuel mixture, impacting overall performance.

Choke: This mechanism enriches the fuel-air mix during cold starts, facilitating easier ignition. It restricts airflow to increase fuel flow until the engine warms up sufficiently.

Air Bleed: This feature allows a small amount of air to enter the fuel stream, promoting proper atomization of the fuel. It enhances combustion efficiency and engine smoothness.

Idle Mixture Screw: By adjusting this screw, the user can fine-tune the fuel mixture at low speeds, ensuring smooth idling and stability in various conditions.

Understanding the roles of these individual elements aids in troubleshooting and optimizing the overall system for better performance and reliability.

Common Carburetor Issues

Understanding the frequent problems encountered with fuel delivery mechanisms is essential for maintaining optimal engine performance. These complications can arise from various factors, impacting efficiency and overall functionality.

One prevalent issue is inadequate fuel supply, which may stem from clogs in the delivery system or faulty valves. This can lead to stalling or poor acceleration. Additionally, incorrect air-fuel mixtures can result in rough idling or excessive emissions, indicating a need for adjustment or cleaning.

Another concern involves leaks, which can be caused by worn gaskets or loose fittings. These leaks not only compromise performance but can also pose safety hazards. Regular inspection and maintenance are crucial to prevent such failures.

Furthermore, evaporation problems may occur, particularly in warmer climates, leading to starting difficulties. Addressing these concerns promptly can enhance reliability and extend the lifespan of the system.

Tuning Your Carburetor

Adjusting the fuel delivery system can significantly enhance your vehicle’s performance. This process involves fine-tuning various components to achieve optimal air-fuel mixture, improving efficiency and responsiveness. Understanding the basic adjustments is key to unlocking your engine’s potential.

Key Adjustments

Focus on modifying the idle speed, air-fuel mixture, and float height. Each element plays a crucial role in ensuring smooth operation and power delivery. Proper calibration can lead to better throttle response and overall driving experience.

Adjustment Table

| Adjustment | Description | Impact |

|---|---|---|

| Idle Speed | Regulates engine speed at idle | Affects smoothness and stability |

| Air-Fuel Mixture | Controls the ratio of air to fuel | Influences power and efficiency |

| Float Height | Sets the fuel level in the bowl | Impacts fuel delivery consistency |

Choosing the Right Carburetor

Selecting the appropriate fuel delivery device is crucial for optimizing your vehicle’s performance. Various factors come into play when making this decision, ensuring that the chosen mechanism aligns with your engine’s requirements and driving style.

Factors to Consider

- Engine Size: Match the size of the delivery system to your engine’s displacement for optimal performance.

- Intended Use: Determine whether your vehicle will be used for daily driving, racing, or off-roading.

- Fuel Type: Ensure compatibility with the type of fuel your engine requires, whether gasoline or alternative options.

Types of Systems

- Single-Barrel: Ideal for smaller engines and economical performance.

- Two-Barrel: Offers a balance between efficiency and power, suitable for most applications.

- Four-Barrel: Best for high-performance setups requiring maximum airflow and power.

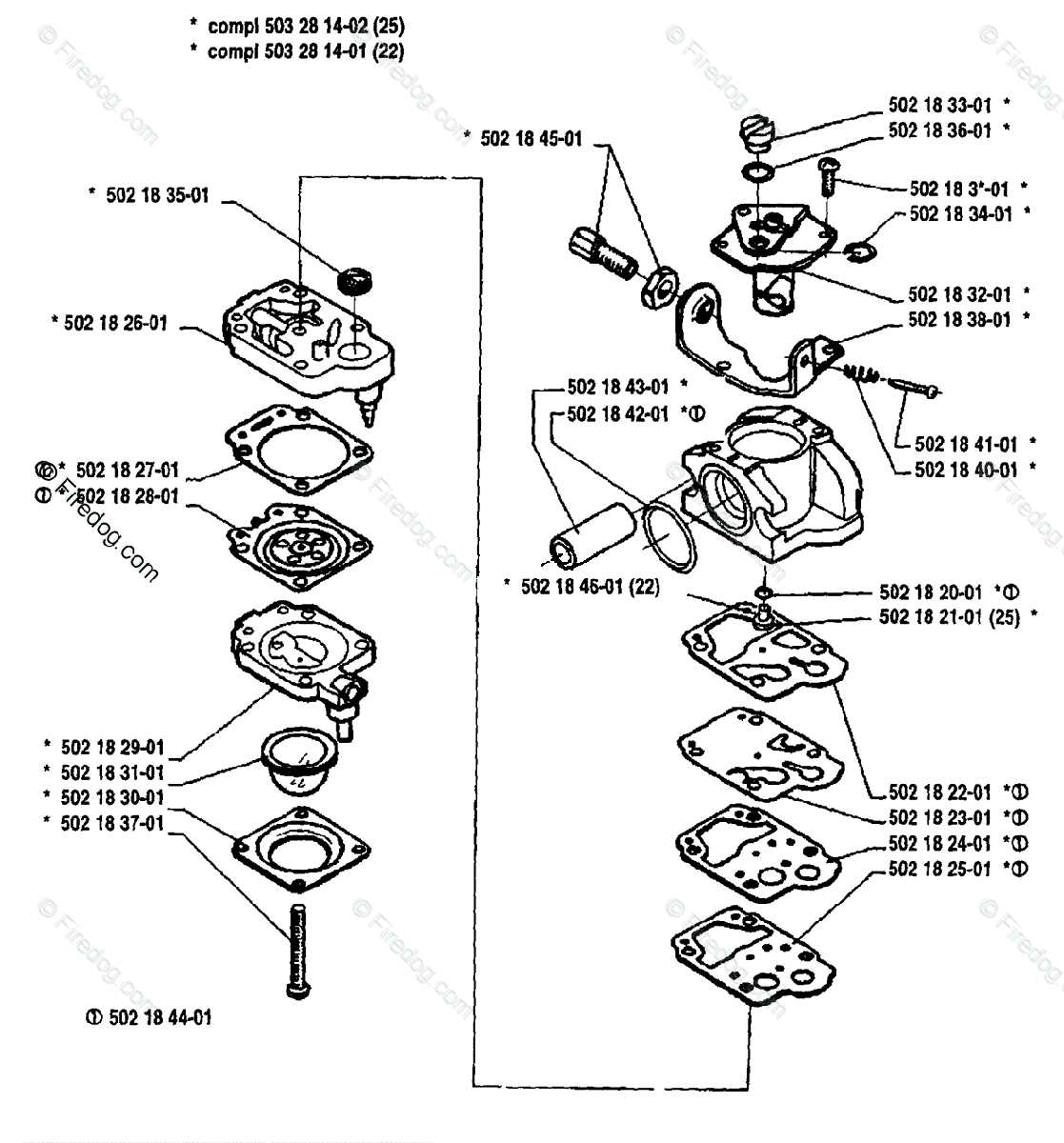

Maintenance Tips for Carburetors

Regular upkeep of fuel delivery systems is essential for optimal engine performance. Proper maintenance helps prevent issues that can lead to decreased efficiency and increased emissions. Here are some practical strategies to keep your system running smoothly.

Routine Inspection

- Check for leaks around connections and seals.

- Inspect for signs of wear on gaskets and components.

- Ensure all screws and fittings are tight to prevent air leaks.

Cleaning and Adjustments

- Periodically clean the fuel passages and jets to avoid blockages.

- Adjust the mixture settings as needed for optimal performance.

- Replace any worn or damaged components promptly to maintain efficiency.

Signs of Carburetor Failure

Recognizing the indicators of malfunction in the fuel delivery system is essential for maintaining optimal engine performance. Various symptoms can signal underlying issues, which may lead to significant operational problems if not addressed promptly.

Common Symptoms

- Unusual engine noises, such as sputtering or backfiring.

- Poor acceleration or sluggish response when pressing the throttle.

- Frequent stalling, especially during idling or low-speed operation.

- Inconsistent fuel consumption, resulting in decreased efficiency.

- Excessive smoke emissions from the exhaust, indicating a rich mixture.

Potential Causes

- Clogged passages, which restrict proper fuel flow.

- Worn components leading to inadequate sealing and pressure loss.

- Improper adjustments affecting the air-fuel ratio.

- Age-related wear, diminishing the effectiveness of the unit.

Monitoring these signs can help prevent further damage and ensure the longevity of your vehicle’s engine.

Upgrading Your Carburetor System

Enhancing your fuel delivery mechanism can significantly improve performance and efficiency. Whether you’re aiming for better throttle response or increased power, several options exist to optimize your setup.

Key Considerations for Improvement

- Assess your current configuration for compatibility with upgrades.

- Research aftermarket options tailored for your specific model.

- Evaluate your vehicle’s performance goals to guide your choices.

Steps to Enhance Your System

- Upgrade to a high-performance fuel delivery unit for better flow.

- Consider adjusting the tuning to match new components.

- Replace any worn or outdated elements for optimal functionality.

Installation Guide for Carburetors

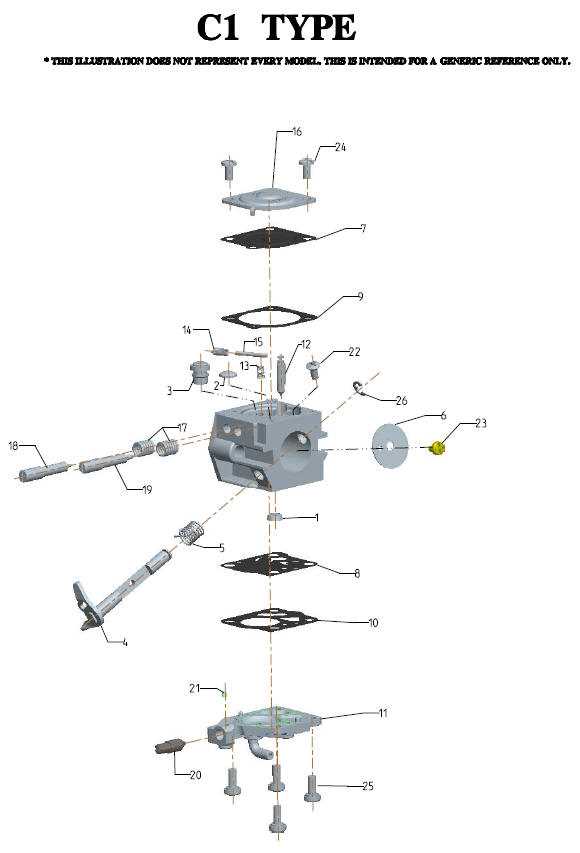

This section provides essential steps for the proper installation of fuel management systems, ensuring optimal performance and efficiency. Following these guidelines will help facilitate a seamless setup, minimizing potential issues and enhancing the overall driving experience.

Preparation Steps

Before starting the installation, gather all necessary tools and components. Ensure that the area is clean and well-lit to avoid any mishaps. It’s advisable to review the manufacturer’s instructions thoroughly to familiarize yourself with the specific requirements of the system you are working with.

Installation Process

Begin by removing any existing components carefully, taking note of their placement for reinstallation if necessary. Align the new system with the existing mounts, ensuring a secure fit. Connect all necessary fuel lines and verify that they are free from obstructions. Once everything is in place, double-check all connections and start the engine to test for proper functionality.

Essential Tools for Carb Repair

Having the right equipment is crucial for effective restoration and maintenance of fuel delivery systems. A well-equipped workspace ensures efficiency and precision, allowing for thorough cleaning and reconditioning of components.

Basic Tools

- Screwdrivers: Various sizes for different fasteners.

- Wrenches: Essential for loosening and tightening bolts.

- Pliers: Useful for gripping and bending small parts.

Specialized Equipment

- Cleaning Solvent: For removing dirt and deposits from components.

- Gasket Scraper: To ensure a smooth surface for sealing.

- Calibration Tools: For adjusting airflow and fuel mixture accurately.

Equipping yourself with these essential tools will make the process of restoration smoother and more effective, leading to optimal performance of the system.

Fuel Types and Carb Compatibility

Understanding the relationship between different fuel varieties and their suitability for specific engine configurations is crucial for optimal performance. Each fuel type possesses unique characteristics that can influence the overall efficiency and functionality of the system.

Petrol and Its Characteristics

Petrol is the most commonly used fuel, known for its ability to ignite easily and provide reliable power. Its volatility allows for quick vaporization, essential for smooth operation in various engine setups.

Alternative Fuels and Their Implications

Alternative fuels, such as ethanol blends or biodiesel, offer distinct advantages and challenges. These fuels can enhance efficiency and reduce emissions, but they may also require specific adjustments to ensure compatibility with the system components.

Environmental Impact of Carburetors

The use of certain fuel delivery systems in vehicles has significant implications for the environment. These mechanisms, while effective in managing engine performance, contribute to various forms of pollution and resource depletion. Understanding their ecological footprint is crucial for assessing their role in modern transportation.

Emissions and Air Quality

These fuel systems can emit pollutants that adversely affect air quality. When engines operate, they release harmful substances such as hydrocarbons and nitrogen oxides, which can lead to smog formation and respiratory issues in humans. Reducing these emissions is essential for promoting cleaner air and safeguarding public health.

Resource Consumption

The manufacturing and operation of these systems also involve substantial resource use. The production processes require energy and raw materials, contributing to the depletion of natural resources. By focusing on more sustainable alternatives, the automotive industry can mitigate the environmental impact and move towards greener technologies.