In the realm of mechanical systems, grasping the intricate arrangement of individual elements is crucial for effective maintenance and operation. A comprehensive overview of these components not only enhances one’s technical knowledge but also ensures optimal functionality of the equipment. The visual representation of these intricate assemblies plays a vital role in troubleshooting and repairs.

By delving into the specifics of each segment, users can better appreciate the synergy between different units. This understanding fosters a more profound engagement with the machinery, empowering individuals to address issues with confidence. Moreover, a clear illustration of these interconnected parts aids in identifying wear and potential failure points, promoting longevity and efficiency.

As we explore this topic further, the focus will be on the essential features that make up the operational essence of the system. This examination will highlight how each piece contributes to the overall performance, ensuring that operators are well-equipped to handle both routine maintenance and unexpected challenges.

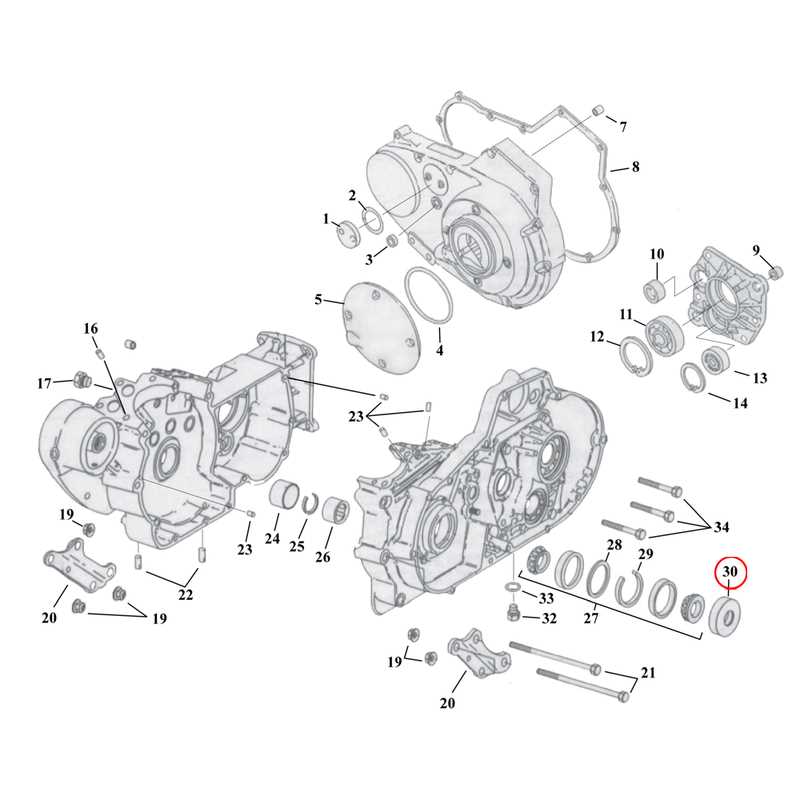

Understanding Jiffy 30 Parts

The intricate design of this equipment showcases a variety of essential components that work in harmony to ensure optimal performance. Grasping the function and arrangement of these elements is crucial for effective maintenance and operation.

Each segment plays a distinct role, contributing to the overall efficiency of the system. Recognizing how these individual elements interact allows users to troubleshoot issues more effectively and prolong the lifespan of the device.

Familiarity with the layout not only aids in identifying potential problems but also enhances the user experience by providing insights into upgrades or modifications that could improve functionality. A thorough understanding of this configuration empowers users to make informed decisions regarding care and enhancements.

Overview of Jiffy 30 Model

The Jiffy 30 model represents a notable achievement in the realm of compact, efficient machinery designed for outdoor use. It embodies a harmonious blend of innovation and functionality, making it an essential tool for enthusiasts and professionals alike.

Key Features

This model stands out due to its robust construction and user-friendly design, ensuring optimal performance in various conditions. The integration of advanced technology enhances its reliability and efficiency, allowing users to achieve their goals with ease.

Technical Specifications

| Feature | Specification |

|---|---|

| Engine Type | Two-stroke |

| Weight | 30 lbs |

| Fuel Capacity | 1.5 gallons |

| Operational Depth | Up to 36 inches |

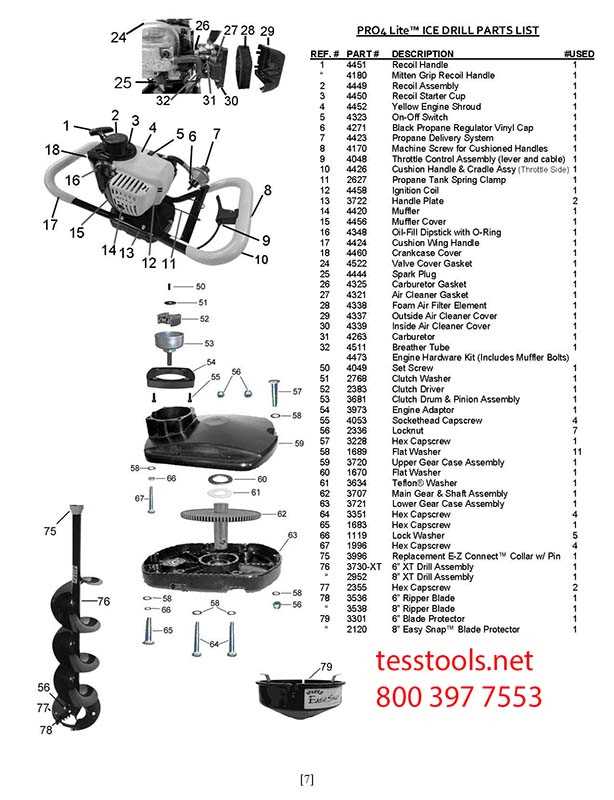

Importance of Parts Diagram

Understanding the components of a machine is essential for effective maintenance and repair. A visual representation serves as a crucial tool for technicians and users alike, enhancing clarity and facilitating efficient troubleshooting.

- Enhances communication among team members.

- Streamlines the repair process by identifying necessary elements.

- Reduces the risk of errors during assembly or disassembly.

- Helps in sourcing replacements accurately.

Ultimately, having a clear representation of all elements fosters better understanding and promotes efficient handling of equipment.

Key Components of Jiffy 30

This section explores the essential elements that contribute to the functionality and efficiency of the system. Understanding these components is crucial for anyone seeking to maximize performance and ensure reliability in operation.

Engine: The heart of the mechanism, it provides the necessary power for various tasks, ensuring smooth performance under diverse conditions.

Transmission: This vital element facilitates the transfer of energy, enabling seamless movement and control, which is essential for effective operation.

Fuel System: A critical aspect that manages the delivery of energy, ensuring that the engine operates efficiently and consistently during use.

Cooling Mechanism: This component prevents overheating, maintaining optimal temperatures for the engine to function effectively over extended periods.

Controls: User-friendly interfaces that allow operators to manage functions easily, enhancing overall usability and efficiency.

Each of these components plays a pivotal role in the overall performance, highlighting the intricate design and engineering behind this remarkable system.

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone involved in maintenance or assembly tasks. These visual representations simplify complex components and their relationships, enabling users to identify and locate each piece efficiently. Mastering the art of interpreting these visuals can significantly enhance your workflow and accuracy.

Familiarize Yourself with Symbols: Different illustrations utilize various symbols to denote specific elements. Taking time to learn what each symbol represents will help you quickly grasp the overall structure. This knowledge can prevent mistakes and save time during repairs or installations.

Follow the Flow: Many illustrations are organized in a logical sequence. Observing how components connect and interact with each other allows you to understand the assembly process. By following this flow, you can anticipate which parts need to be addressed first, improving your efficiency.

Pay Attention to Numbering: Most technical illustrations will include a numbering system for easy reference. This is crucial for identifying individual elements within the visual. By cross-referencing these numbers with a corresponding list, you can ensure that you have all necessary items on hand before starting your project.

Refer to Annotations: Look for notes or annotations that provide additional context or instructions. These details can offer valuable insights that may not be immediately apparent from the visual alone. Understanding these comments can prevent misunderstandings and guide you through the process more effectively.

By honing your skills in reading technical visuals, you can tackle projects with greater confidence and precision, leading to more successful outcomes.

Common Issues and Solutions

When dealing with mechanical systems, various challenges can arise that hinder performance and efficiency. Understanding these frequent problems and their corresponding remedies is essential for maintaining optimal functionality and prolonging lifespan.

Issue 1: Leakage can often occur due to worn seals or improper assembly. Regular inspections and timely replacements of seals can mitigate this problem.

Issue 2: Overheating is another common concern, often caused by inadequate lubrication or blocked airflow. Ensuring proper lubrication and clearing any obstructions can help maintain the right temperature.

Issue 3: Unusual noises may indicate loose components or misalignment. Tightening connections and realigning parts can resolve these disturbances effectively.

Addressing these typical issues promptly can lead to enhanced performance and longevity of the equipment in question.

Maintenance Tips for Jiffy 30

Proper upkeep is essential for ensuring optimal performance and longevity of your equipment. Regular attention to specific components not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Here are some key practices to keep in mind.

Regular Cleaning: Keeping the unit clean is vital. Remove any debris or residue after each use. This prevents buildup that can affect functionality.

Lubrication: Check the moving parts and apply appropriate lubricant as needed. This reduces friction and wear, extending the lifespan of mechanical elements.

Inspection: Periodically inspect for any signs of wear or damage. Addressing minor issues promptly can prevent them from escalating into major problems.

Storage: Proper storage is crucial during off-seasons. Ensure the unit is kept in a dry, temperature-controlled environment to avoid corrosion and degradation.

Parts Replacement: Familiarize yourself with essential components that may require replacement over time. Staying ahead of potential wear can ensure continuous operation.

Consulting Manuals: Always refer to the manufacturer’s guidelines for specific maintenance recommendations. These documents provide valuable insights into the best practices tailored for your model.

By implementing these practices, you can ensure that your equipment remains reliable and efficient for years to come.

Where to Find Replacement Parts

Finding suitable components for your equipment can be a straightforward process if you know where to look. Numerous sources are available that cater to various needs, ensuring that you can obtain the necessary items without hassle.

Online retailers often provide a vast selection, allowing you to compare prices and availability from the comfort of your home. Websites dedicated to tools and machinery frequently feature user reviews, helping you make informed decisions.

Local suppliers are also valuable resources, as they can offer immediate access to items and personalized assistance. Visiting a physical store allows you to examine products firsthand and consult with knowledgeable staff.

Specialty shops may carry unique or hard-to-find components, making them an excellent option for those with specific requirements. Networking within community forums can also lead to recommendations for reliable sources.

Regardless of the approach, ensuring that you choose reputable vendors will ultimately lead to a successful acquisition of the components you need.

DIY Repairs for Jiffy 30

Taking on repairs can seem daunting, but with the right guidance, it’s a rewarding experience. This section will explore practical steps to tackle common issues that may arise, allowing you to maintain your equipment efficiently.

- Assess the Issue: Identify the problem accurately to determine the necessary steps.

- Gather Tools: Ensure you have the essential tools for the task at hand.

- Disassemble: Carefully take apart the device, following the sequence in the instruction manual.

- Inspect Components: Look for wear, damage, or any malfunctioning elements that need replacement.

- Clean and Lubricate: Remove debris and apply lubricant where necessary to ensure smooth operation.

- Reassemble: Put everything back together methodically, ensuring all parts fit snugly.

- Test Functionality: Once reassembled, test the device to confirm the repairs were successful.

By following these guidelines, you can enhance the longevity and performance of your equipment, making DIY repairs an ultimate solution for maintenance.

Tools Needed for Repairs

When tackling maintenance tasks, having the right equipment is essential for achieving optimal results. Proper tools not only streamline the repair process but also enhance safety and efficiency.

- Wrenches

- Screwdrivers

- Socket set

- Pliers

- Utility knife

Additionally, consider these helpful items:

- Measuring tape

- Torque wrench

- Safety goggles

- Gloves

Equipping yourself with these essentials will enable a thorough and effective approach to your repair endeavors.

Safety Precautions During Repairs

Ensuring a safe environment while conducting maintenance is crucial for preventing accidents and injuries. Proper preparation and awareness can significantly mitigate risks associated with repair tasks.

First and foremost, always wear appropriate protective gear, such as gloves and safety goggles. This equipment serves as a barrier against potential hazards, safeguarding your body from harmful substances and sharp objects.

Moreover, maintain a clean and organized workspace. Clutter can lead to slips or trips, so keep tools and materials neatly stored and within reach. It’s also essential to have adequate lighting to enhance visibility during intricate tasks.

Additionally, ensure that all equipment is in proper working condition before use. Regularly inspect tools for damage and replace any faulty items to avoid malfunctions that could lead to injury.

Finally, never hesitate to seek assistance when needed. Collaborating with others not only provides support but can also enhance safety through shared vigilance during complex procedures.

Frequently Asked Questions

This section aims to address common inquiries related to assembly and components, providing clarity and enhancing understanding for users. Here, we explore typical concerns and offer insightful answers to ensure a seamless experience.

What should I do if I can’t find a specific element?

If a particular component is missing, double-check your setup instructions and ensure all parts are accounted for. Often, elements can be overlooked during initial assembly.

How can I maintain the longevity of my equipment?

Regular maintenance, including cleaning and timely replacements, is essential. Always refer to the user manual for specific care instructions.

Is there a way to identify components easily?

Yes, many guides and reference materials offer visual aids or descriptions to help identify various elements quickly. Utilizing these resources can save time and effort.

Where can I find replacement components?

Replacement elements are typically available through authorized dealers or online retailers specializing in equipment supplies. Always ensure you are purchasing from a reputable source.

Customer Reviews and Experiences

This section aims to provide insights into the feedback and personal accounts from users regarding their interactions with the product. Understanding how others have perceived and utilized the item can offer valuable perspectives for potential buyers and enthusiasts alike.

Positive Feedback

Many users have expressed satisfaction with the reliability and efficiency of the item. Customers frequently highlight the ease of use and the seamless integration into their routines. Numerous reviews mention that it exceeded their expectations in terms of performance, making tasks more manageable and enjoyable.

Areas for Improvement

While most experiences are positive, some users have pointed out aspects that could benefit from enhancement. Common suggestions include improving durability and providing clearer instructions for maintenance. These insights reflect the diverse experiences of customers and contribute to ongoing product development.