Maintaining a lush and vibrant landscape requires knowledge of the essential machinery involved in the process. This section provides a comprehensive overview of the key elements that contribute to efficient grass management. By grasping how these components function together, users can optimize their equipment’s performance and longevity.

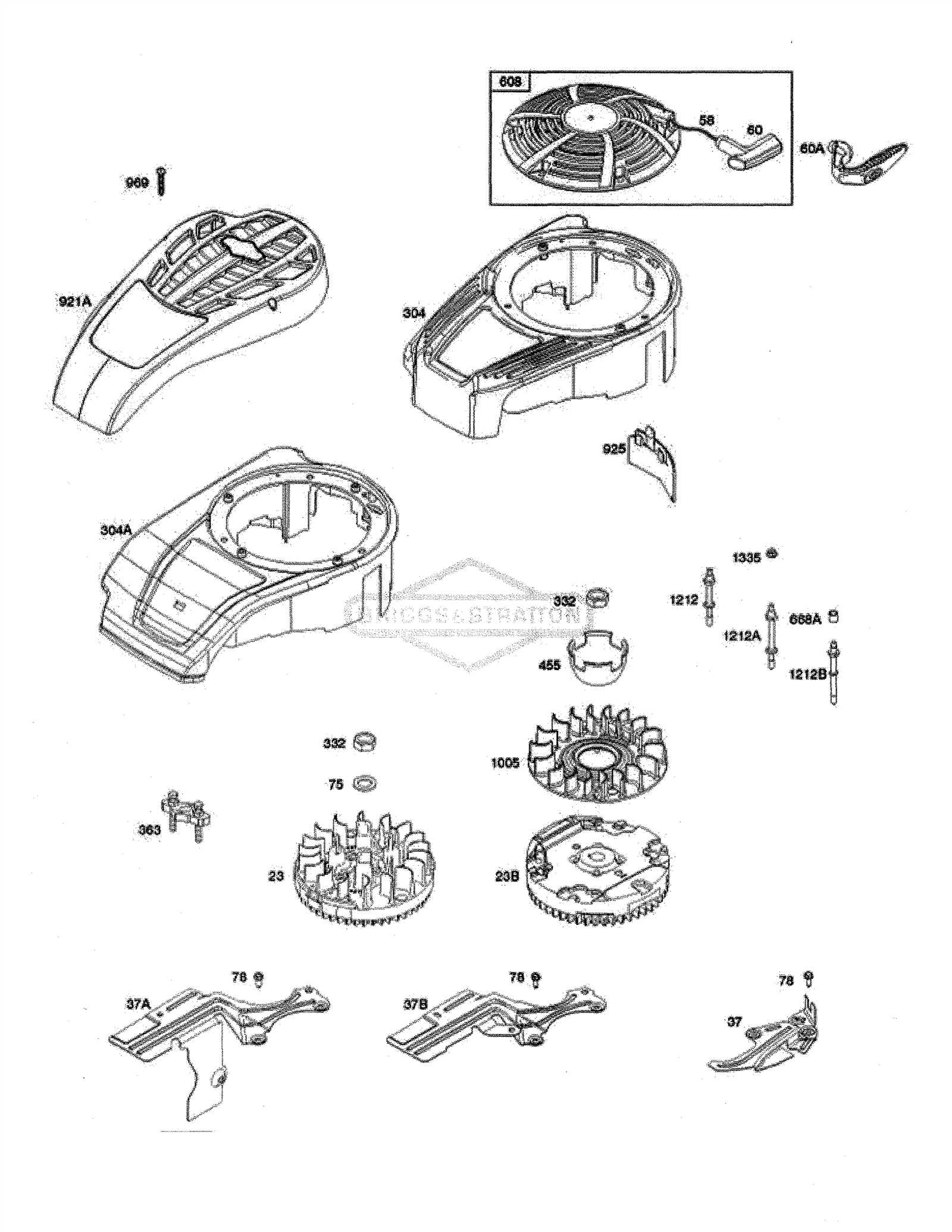

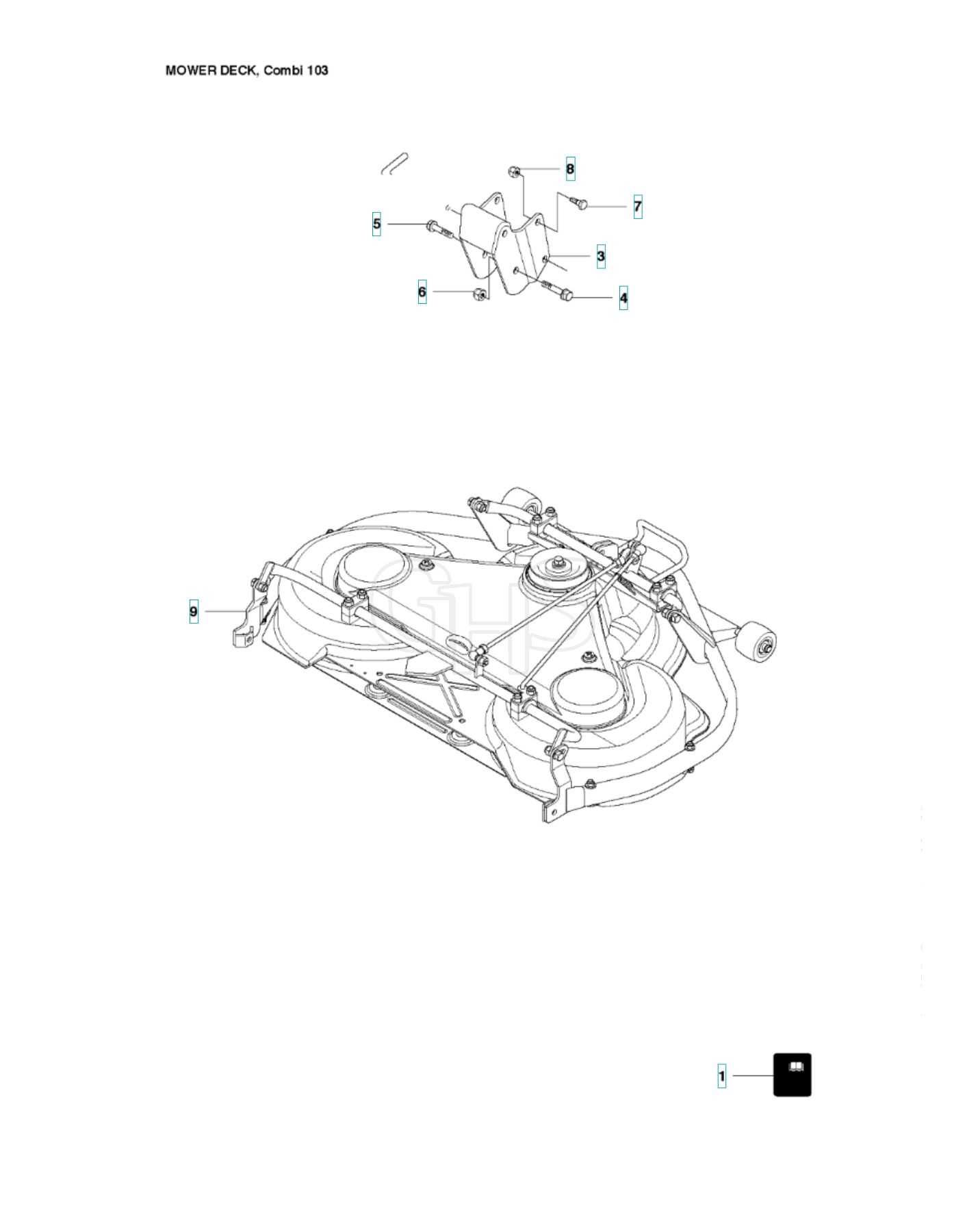

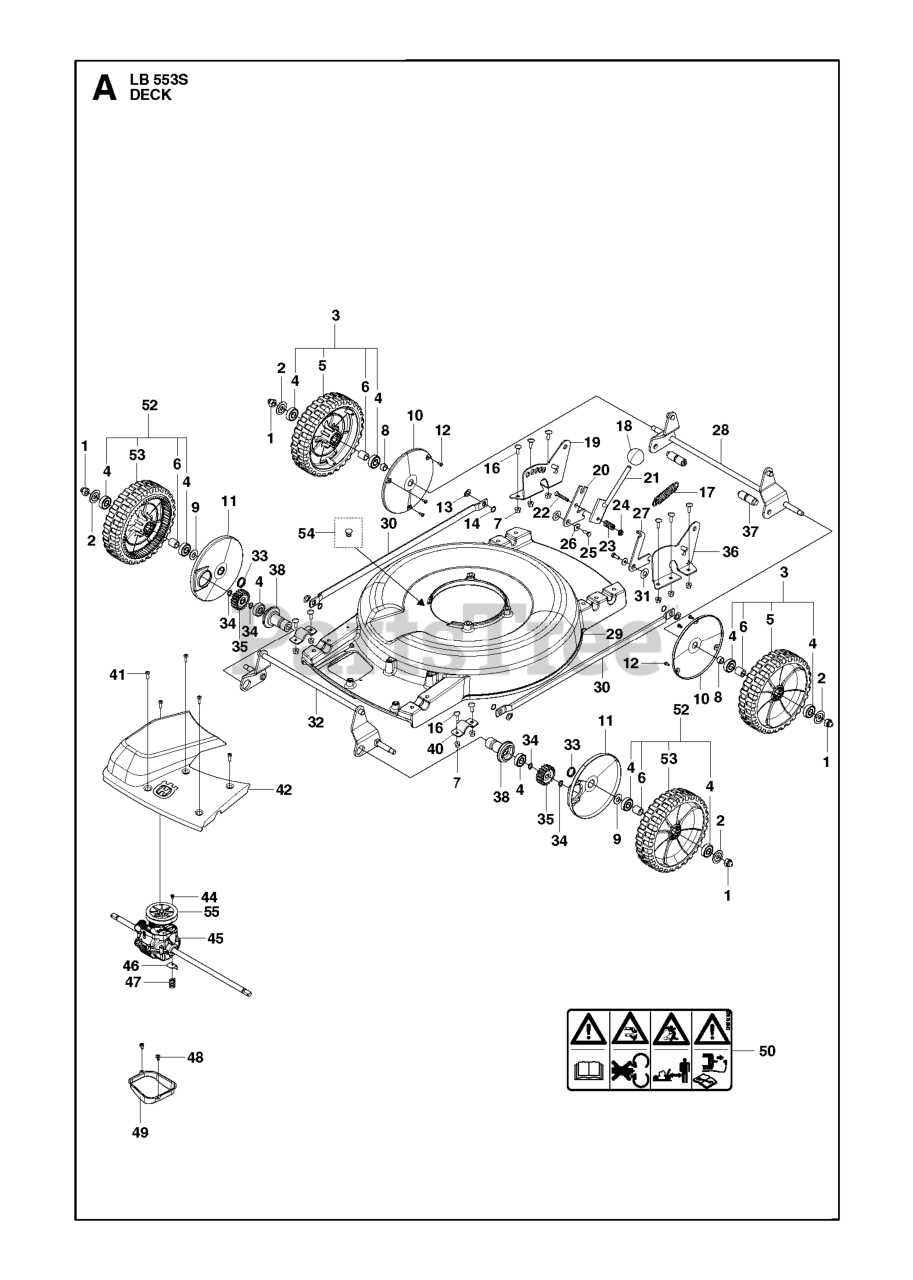

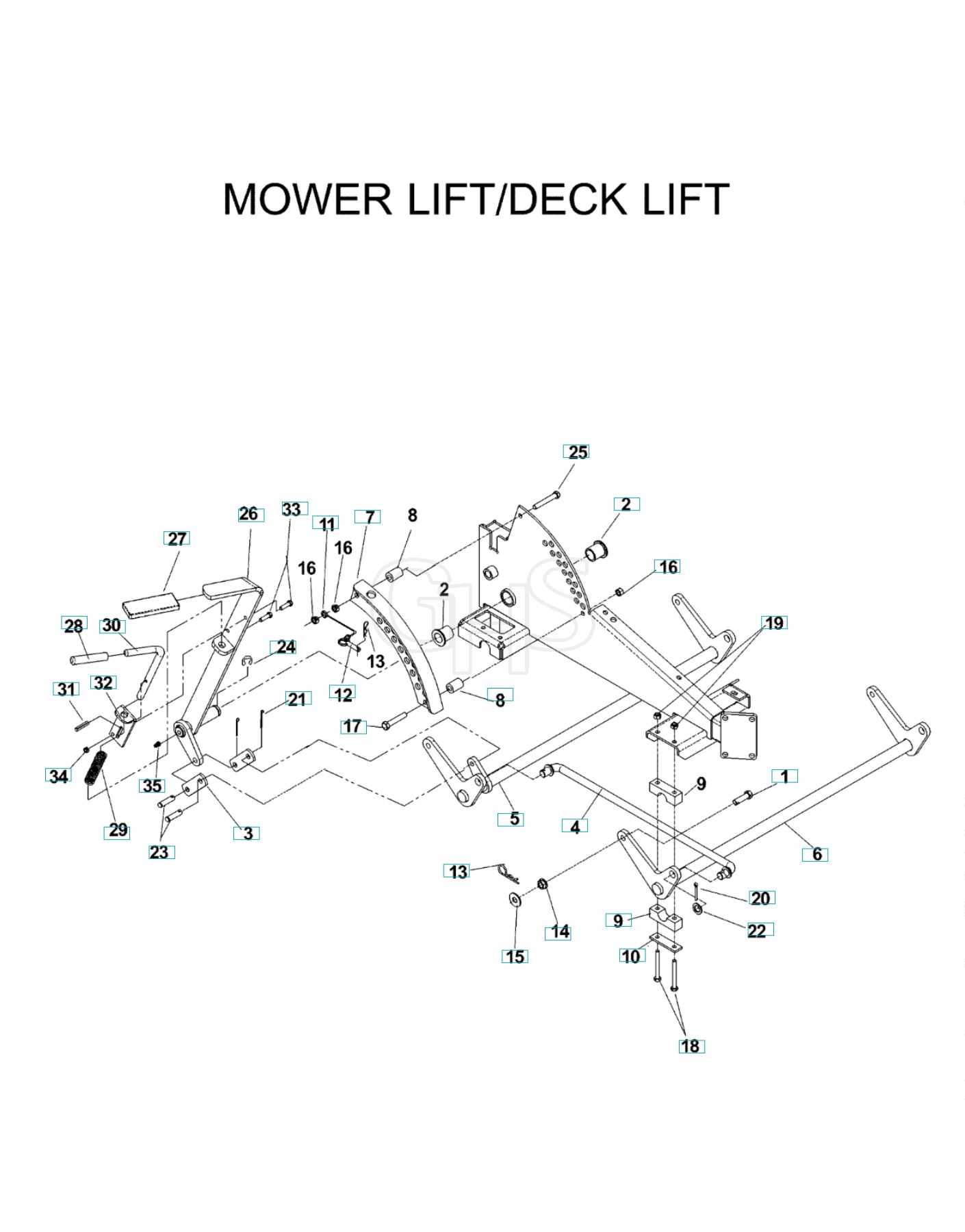

Visual aids play a crucial role in simplifying the complexities of these machines. A detailed representation of the various elements not only enhances understanding but also aids in identifying specific issues during maintenance. Exploring these illustrations can ultimately lead to more informed decisions regarding repairs and upgrades.

Furthermore, recognizing the importance of each individual component empowers users to tackle challenges more effectively. Whether it’s routine maintenance or addressing specific malfunctions, having a clear reference can significantly improve the overall lawn care experience.

Understanding Husqvarna Mower Deck Components

The essential elements that contribute to the effective operation of lawn maintenance equipment are crucial for achieving optimal performance. Familiarity with these components not only enhances your understanding but also aids in maintenance and troubleshooting tasks.

Base Structure: The foundation of any cutting system is designed to support the entire assembly. This component ensures stability during operation and significantly affects the overall efficiency of the machine.

Cutting Blades: Sharp, well-maintained blades are vital for a clean and even cut. These instruments are engineered to slice through grass with precision, and their design can vary based on the intended purpose.

Drive System: The mechanism responsible for transferring power to the cutting instruments plays a pivotal role. It consists of belts and pulleys that must be kept in optimal condition to ensure smooth operation.

Height Adjustment Mechanism: This feature allows users to modify the elevation of the cutting instruments, catering to different grass lengths and conditions. Understanding its operation can lead to better lawn care practices.

Protection Features: Safety elements are integrated to minimize risks during use. These include shields and guards designed to protect users from debris and ensure safe handling.

By becoming acquainted with these vital components, you can enhance both your understanding and your ability to maintain the machinery effectively, leading to improved results in your lawn care endeavors.

Importance of Mower Deck Maintenance

Proper upkeep of cutting equipment is crucial for ensuring its longevity and efficiency. Regular attention to various components not only enhances performance but also prevents costly repairs down the line. By maintaining these crucial elements, users can achieve a well-groomed landscape with minimal effort.

| Benefit | Description |

|---|---|

| Enhanced Performance | Regular maintenance ensures that equipment operates at its peak capability, leading to cleaner and more efficient cuts. |

| Increased Longevity | Consistent care can significantly extend the lifespan of essential components, reducing the need for replacements. |

| Cost Efficiency | Preventative maintenance helps avoid major repairs, saving money in the long run. |

| Safety | Keeping equipment in top condition reduces the risk of accidents and injuries during operation. |

Common Issues with Mower Decks

Various complications can arise during the operation of lawn care equipment, impacting efficiency and performance. Recognizing these challenges early can prevent further damage and ensure a well-maintained cutting apparatus.

1. Uneven Cutting: One prevalent problem is inconsistent trimming height, often caused by misalignment or worn-out components. Regular checks can help maintain uniformity.

2. Clogging: Grass buildup can lead to blockages, affecting airflow and cutting efficiency. Keeping the underside clean is essential for optimal functionality.

3. Vibration: Excessive shaking can indicate loose or damaged elements, resulting in discomfort and potential harm to the machinery. Regular inspections can help identify and rectify these issues.

4. Rust and Corrosion: Exposure to moisture can cause deterioration, compromising durability. Applying protective coatings can mitigate this risk.

5. Blade Dullness: Blades that are not sharp enough can result in tearing rather than cutting grass cleanly. Regular sharpening is vital for achieving the best results.

Identifying Key Mower Deck Parts

Understanding the essential components of a cutting system is crucial for effective maintenance and operation. Each element plays a significant role in ensuring optimal performance, enhancing the overall functionality of the equipment. Familiarity with these critical sections not only aids in troubleshooting but also helps in making informed decisions regarding repairs and replacements.

Blade Assembly: The primary cutting element, responsible for achieving a clean and even finish. Regular inspection for wear and sharpness is necessary to maintain efficiency.

Spindle: This rotating mechanism supports the blade assembly and facilitates its movement. It is vital to ensure proper lubrication to avoid premature wear.

Chassis: The framework that houses various components, providing stability and support. A sturdy structure is essential for durability during operation.

Drive Belt: This crucial link transfers power from the engine to the blade assembly. Regular checks for tension and condition can prevent unexpected failures.

Deflector: This component directs grass clippings away from the cutting area, ensuring a neat appearance and preventing clumping. Keeping it clear of debris is essential for optimal performance.

By recognizing and understanding these fundamental elements, users can enhance their equipment’s longevity and ensure effective operation throughout its lifespan.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. By familiarizing yourself with the layout and symbols, you can quickly identify and locate necessary elements for replacement or troubleshooting.

| Symbol | Description |

|---|---|

| Circle | Indicates a bolt or fastening point. |

| Square | Represents a component that can be replaced. |

| Arrow | Shows the direction of movement or assembly. |

| Line | Denotes connections between different elements. |

By studying these symbols and their placements, you can delve deeper into the assembly process, ultimately enhancing your repair skills and efficiency.

Tools Needed for Deck Repairs

Proper maintenance of your outdoor equipment requires a set of essential tools. These instruments not only facilitate effective repairs but also enhance the longevity of the equipment. Below is a list of tools that are crucial for performing maintenance tasks efficiently.

- Wrenches: Adjustable and socket wrenches are vital for loosening and tightening various components.

- Screwdrivers: A set of flathead and Phillips screwdrivers will help in removing and securing screws.

- Ratchet Set: This tool is useful for accessing hard-to-reach areas and can save time during assembly or disassembly.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Blades and Replacement Parts: Keeping spare blades and other crucial components on hand can streamline the repair process.

Additionally, safety equipment is essential:

- Gloves: Protect your hands from sharp edges and debris.

- Safety Glasses: Shield your eyes from flying particles during repairs.

- Steel-Toed Boots: Provide protection from heavy objects and enhance stability.

Having these tools readily available will make your maintenance tasks easier and more efficient, ensuring your equipment operates at peak performance.

Step-by-Step Deck Assembly Guide

This guide provides a comprehensive approach to assembling the essential components of your machine for optimal performance. By following these straightforward steps, you will ensure that everything fits together seamlessly, enhancing the efficiency of your equipment.

Step 1: Begin by gathering all necessary components and tools. Familiarize yourself with each item to streamline the process.

Step 2: Lay out the main base and secure it on a flat surface. This will serve as your foundation for assembly.

Step 3: Attach the side panels to the base using the provided fasteners. Ensure that each panel is aligned correctly for stability.

Step 4: Connect the front and rear sections, double-checking that all connections are tight and secure.

Step 5: Integrate any additional accessories or attachments, ensuring they are compatible and properly fitted.

Step 6: Finally, conduct a thorough inspection of the assembled structure. Test each component for functionality to confirm everything is in working order.

By following these detailed steps, you will achieve a well-assembled unit that meets your operational needs.

Replacing Worn Mower Deck Parts

Maintaining optimal performance of your grass-cutting equipment is essential for achieving a pristine lawn. Over time, certain components can become worn, affecting efficiency and the quality of the cut. Recognizing when to replace these elements can save you time and effort in the long run.

Identifying Worn Components

Before you proceed with replacements, it’s important to identify which components are showing signs of wear. Here are some common indicators:

- Unusual noises during operation

- Uneven cutting results

- Visible damage or rust on parts

- Difficulty in adjusting the height

Steps for Replacement

Once you’ve identified the components that need attention, follow these steps for effective replacement:

- Gather necessary tools and replacement components.

- Disconnect the power source for safety.

- Carefully remove the worn components according to your equipment’s manual.

- Install the new elements, ensuring they are properly secured.

- Reconnect the power and perform a test run to ensure everything is functioning correctly.

By staying proactive and addressing wear promptly, you can enhance the longevity and performance of your cutting equipment.

Upgrading Your Mower Deck Performance

Enhancing the efficiency and effectiveness of your cutting equipment is essential for achieving a pristine lawn. By focusing on key components, you can significantly boost performance, leading to a smoother and more uniform finish. This approach not only optimizes operation but also extends the lifespan of your machinery.

First, consider upgrading blades. High-quality, sharp blades can improve cutting precision and reduce strain on the engine. Investing in specialized blades designed for your specific needs can make a noticeable difference.

Additionally, regularly maintaining and replacing worn-out components will ensure consistent performance. This includes checking belts and pulleys for wear, as these can affect overall functionality. Staying proactive with maintenance is key to avoiding costly repairs.

Lastly, exploring different attachments can provide versatility, allowing you to tackle various terrains and grass types more effectively. Adapting your setup to your specific environment can elevate your overall cutting experience.

Safety Tips for Mower Maintenance

Proper upkeep of outdoor equipment is essential not only for performance but also for personal safety. Ensuring that all maintenance tasks are conducted with care can prevent accidents and prolong the lifespan of the machinery. Here are some crucial safety guidelines to follow during maintenance activities.

Preparation Before Maintenance

- Always wear appropriate personal protective equipment, such as gloves and safety glasses.

- Ensure the machine is turned off and cooled down before starting any work.

- Disconnect the spark plug or power source to avoid accidental starts.

- Keep the workspace clean and free of clutter to prevent tripping hazards.

During Maintenance

- Follow the manufacturer’s guidelines for specific maintenance tasks.

- Use the correct tools to prevent injury and damage to the equipment.

- Inspect all components for wear and replace them as needed to avoid failures.

- Never attempt to make repairs without proper training or understanding of the machinery.

By adhering to these safety tips, you can ensure a safer and more effective maintenance experience, ultimately leading to better performance and longevity of your outdoor equipment.

Where to Find Replacement Parts

When maintaining outdoor equipment, sourcing high-quality components is crucial for ensuring optimal performance. Various avenues exist for locating reliable replacements, each offering unique advantages depending on your needs.

Online retailers provide a vast selection, often featuring detailed descriptions and customer reviews to guide your choices. Local hardware stores and specialized shops may offer personalized service and the opportunity to see items in person. Additionally, manufacturer websites frequently have dedicated sections for ordering direct replacements, ensuring compatibility and quality. Lastly, online marketplaces can yield competitive prices, but it’s essential to verify the credibility of sellers before making a purchase.

Understanding Mower Deck Adjustment Techniques

Achieving optimal performance from your cutting equipment involves mastering various adjustment methods. Proper calibration ensures even trimming and enhances the longevity of the machine. This section explores essential techniques for fine-tuning the components that influence the quality of your lawn maintenance.

1. Height Adjustment: One of the primary factors affecting the quality of the cut is the height at which the blades operate. Adjusting this setting allows for a uniform trim that caters to different grass types and seasonal growth patterns. It is crucial to find the right balance, as cutting too low can harm the grass, while too high may lead to uneven growth.

2. Leveling the Blades: Ensuring that the blades are perfectly level is vital for achieving a consistent cut. Misalignment can lead to uneven edges and an unkempt appearance. Regular checks and adjustments can prevent this issue, making it easier to maintain a neat lawn.

3. Tension Settings: The tension of the drive belt plays a significant role in the effectiveness of the cutting action. Proper tension prevents slippage and ensures that the blades operate at the correct speed. Periodically checking and adjusting these settings can lead to improved performance and efficiency.

4. Angle of Attack: The angle at which the blades approach the grass can significantly impact the cutting results. Fine-tuning this angle can help achieve a cleaner cut and reduce the risk of scalping. Experimenting with different angles may yield the best results for specific terrain and grass conditions.

By understanding and implementing these adjustment techniques, users can enhance the efficiency and effectiveness of their cutting equipment, leading to a healthier and more aesthetically pleasing lawn.

Comparing Different Husqvarna Models

When exploring various models from a leading manufacturer, it’s essential to understand the unique features and specifications that set them apart. Each design offers distinct advantages tailored to different needs and preferences. By examining key aspects such as performance, efficiency, and user-friendly controls, one can identify which option aligns best with specific requirements.

Some models prioritize power and cutting capacity, making them ideal for larger areas, while others focus on maneuverability and ease of use, suitable for smaller spaces. Additionally, variations in build quality and available attachments can enhance versatility, allowing users to tackle diverse tasks efficiently. Comparing these elements aids in making an informed choice, ensuring optimal satisfaction and performance.