In the realm of heating solutions, various systems are employed to ensure optimal temperature control and comfort in residential and commercial settings. This section delves into the intricate elements that make up these systems, highlighting their functions and significance in the overall operation. A comprehensive overview of these components can enhance one’s understanding of their role in maintaining efficient and reliable heating.

Exploring the Assembly and Functionality is essential for anyone interested in the mechanics of climate control technology. By examining the layout and interconnections of these components, one gains insight into how each part contributes to the unit’s effectiveness. This knowledge empowers users to troubleshoot issues and perform necessary maintenance, ensuring longevity and performance.

Moreover, understanding these intricate mechanisms not only facilitates better performance management but also aids in making informed decisions regarding upgrades or replacements. Awareness of the various elements can lead to more efficient energy usage and a greater appreciation for the technological advancements in heating solutions.

This section aims to provide a comprehensive overview of a specific heating unit, focusing on its essential components and their functionalities. By dissecting the system, readers will gain insight into the operational aspects and maintenance needs, thereby enhancing their understanding of how each element contributes to the overall performance of the device.

Key Components and Their Functions

Understanding the critical elements of the heating unit is vital for effective troubleshooting and repair. Each component plays a unique role in ensuring efficient operation, and familiarity with these can aid in identifying potential issues.

| Component | Function |

|---|---|

| Blower Motor | Circulates air throughout the system. |

| Heat Exchanger | Transfers heat from combustion to the air. |

| Ignitor | Initiates the combustion process. |

| Limit Switch | Shuts down the system if overheating occurs. |

Maintenance Tips for Optimal Performance

Regular maintenance is crucial for the longevity and efficiency of the heating unit. Implementing a routine check of the components will help in early detection of problems and ensure smooth operation.

Key Components of Lennox Furnaces

Understanding the essential elements of heating systems is crucial for efficient operation and maintenance. Each component plays a significant role in ensuring optimal performance and reliability. Below are some of the primary elements that contribute to the functionality of these systems.

1. Heat Exchanger

The heat exchanger is a vital component that transfers heat generated by combustion to the air that circulates throughout the space. Its design is crucial for efficiency and safety, allowing for effective heat transfer while minimizing the risk of gas leaks.

2. Ignition System

The ignition system is responsible for initiating the combustion process. Various types of ignition systems are used, including pilot lights and electronic igniters. Their reliability is essential for ensuring that the heating cycle starts without issues.

- Pilot Light: A small flame that ignites the gas when needed.

- Electronic Igniter: A device that creates a spark to ignite the gas directly.

3. Blower Motor

The blower motor circulates air throughout the living space, distributing warm air from the heat exchanger. A properly functioning blower is essential for maintaining comfort and ensuring even temperature distribution.

4. Control Board

The control board acts as the system’s brain, managing the various components and ensuring they work together efficiently. It monitors temperature settings and operational status, allowing for precise control over the heating process.

- Monitors temperature.

- Coordinates operation of components.

- Ensures safety protocols are followed.

Familiarizing oneself with these components enhances the ability to troubleshoot issues and maintain optimal functionality. Regular inspections and maintenance of these elements can lead to increased efficiency and a longer lifespan for the heating system.

Common Issues with Furnace Parts

Heating systems are essential for maintaining comfort in homes, yet they can experience various challenges that may affect their performance. Understanding these common issues is crucial for effective troubleshooting and maintenance.

Wear and Tear of Components

Over time, individual components can undergo significant wear, leading to reduced efficiency. Regular inspections can help identify worn-out elements before they cause more extensive damage, ensuring the system operates optimally.

Electrical Failures

Electrical malfunctions are a frequent concern that can disrupt the operation of heating systems. Faulty wiring or damaged connections may result in overheating or system shutdown. It is advisable to conduct routine checks to prevent potential hazards.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan of your heating system. By implementing proactive measures, you can enhance performance, reduce operational costs, and prevent unexpected failures. Understanding key practices and routines is crucial for achieving optimal functionality and reliability.

Routine Inspections

Conducting frequent assessments of your heating system can help identify potential issues before they escalate. Look for signs of wear and tear, leaks, or any unusual sounds that may indicate underlying problems. It is advisable to schedule a professional evaluation at least once a year.

Filter Maintenance

Changing or cleaning filters regularly is vital for maintaining efficient airflow and preventing strain on the unit. Clogged filters can reduce efficiency and lead to overheating. Ensure that you check and replace filters every one to three months, depending on usage.

| Maintenance Task | Frequency |

|---|---|

| Routine Inspection | Annually |

| Filter Replacement | Every 1-3 months |

| Clean Burners | Annually |

| Check Thermostat | Seasonally |

How to Identify Faulty Parts

Determining malfunctioning components within a heating system is essential for maintaining efficiency and safety. By recognizing signs of wear or failure, homeowners can take timely action to rectify issues and prevent further damage. This section provides insights into the common indicators that suggest a component may need attention.

Common Symptoms of Malfunction

Several warning signs may indicate that a component is not functioning properly. For instance, unusual noises such as banging or rattling could signal loose or damaged elements. Additionally, inconsistent heating performance, such as uneven temperatures across rooms, may suggest an underlying issue that requires investigation.

Visual Inspection Techniques

Conducting a thorough visual assessment can help identify problematic components. Look for signs of corrosion, wear, or any physical damage. Discoloration on surfaces might point to overheating, while accumulated debris can indicate airflow restrictions. Regular inspections will aid in early detection and facilitate maintenance efforts.

Repair vs. Replacement Considerations

When facing issues with heating systems, the decision between fixing existing components or opting for new installations is critical. Evaluating factors such as cost, efficiency, and longevity can significantly influence the choice made by homeowners. Each option presents its own set of advantages and disadvantages, and understanding these can lead to more informed decisions.

Before deciding, it is essential to analyze the current condition of the equipment and its historical performance. If repairs are frequent or costly, replacing the unit might be a more economical and sustainable solution in the long run.

| Criteria | Repair | Replacement |

|---|---|---|

| Cost | Often lower initial expense | Higher upfront investment |

| Longevity | May extend life for a short period | New units often have longer warranties |

| Efficiency | Older systems may be less efficient | New models often have better energy efficiency ratings |

| Reliability | Potential for recurring issues | Generally more reliable with modern technology |

Ultimately, homeowners should consider their specific circumstances, including budget constraints and future heating needs, to determine the best course of action.

Wiring Connections in Pulse Models

Understanding the electrical layout in these systems is essential for both installation and maintenance. The connections between various components must be configured precisely to ensure optimal functionality. Each wire has a designated role, linking key elements that drive the overall operation.

Key Connection Points include areas where power is distributed, signaling is directed, and safety controls are integrated. Identifying these crucial links allows for a smoother setup process and enhances troubleshooting efficiency.

Proper Configuration ensures that each segment of the system operates within its specified parameters, minimizing the risk of errors. Adjustments should be made carefully, following best practices to align with the specific requirements of each model.

Importance of Proper Ventilation

Effective airflow management is a critical aspect of maintaining a safe and efficient heating system. Ensuring that the air circulates correctly helps prevent potential hazards and optimizes the unit’s performance. Without proper ventilation, the system may encounter issues that can impact both functionality and safety.

Benefits of Adequate Airflow

- Enhanced Efficiency: Proper airflow reduces the strain on the system, allowing it to operate more effectively and consume less energy.

- Extended Lifespan: When ventilation is well-regulated, it prevents unnecessary wear and tear on the components, contributing to a longer operational life.

- Improved Safety: Adequate air movement reduces the risk of harmful gas buildup, promoting a safer indoor environment.

Key Considerations for Ventilation Setup

- Check for Blockages: Regularly inspect vents and ducts to ensure they are free of obstructions that could limit air circulation.

- Install Proper Ductwork: Using the right type and size of ducts helps maximize airflow and minimizes pressure loss.

- Maintain Clean Filters: Replacing or cleaning filters regularly is essential to keep the air moving smoothly through the system.

Safety Features in Heating Systems

Modern heating units come equipped with a variety of protective mechanisms designed to ensure both user safety and efficient operation. These features work collectively to prevent malfunctions, control temperature, and address potential hazards in a timely manner.

| Feature | Description |

|---|---|

| Automatic Shut-Off | This function triggers when unusual temperature levels are detected, immediately cutting off the unit to prevent overheating and damage. |

| Pressure Relief Valves | These components release excess pressure from the system, protecting internal parts from the risk of rupture or leaks. |

| Flame Sensor | A sensor that continuously monitors the flame to ensure that it remains stable, shutting down the system if irregularities occur. |

| Carbon Monoxide Detection | Integrated systems that detect harmful gas levels, automatically stopping the unit’s operation if any hazardous conditions are identified. |

Efficiency Ratings and Their Impact

Understanding the role of efficiency ratings in heating systems is crucial for both performance and energy consumption. These ratings provide insight into how effectively a system converts fuel into heat, influencing both operational costs and environmental impact.

The Importance of High Efficiency

Opting for a high-efficiency system can significantly reduce energy expenses over time. Such systems are designed to maximize fuel use, ensuring that minimal energy is wasted during operation. This focus on efficiency not only benefits the user but also contributes to a reduction in overall energy consumption.

Factors Influencing Efficiency Ratings

- Design Innovations: Modern heating systems incorporate advanced features that enhance thermal output, leading to higher ratings.

- Fuel Type: The type of fuel used plays a significant role in determining how efficiently the system operates.

- Maintenance: Regular upkeep and proper adjustments are key factors in maintaining high performance levels.

Efficiency ratings should be a primary consideration when evaluating different models, as they directly impact both long-term savings and sustainability efforts.

Where to Find Replacement Parts

Locating suitable substitutes for your heating equipment can be crucial for maintaining its efficiency. The availability of components often determines how quickly you can resolve any issues that arise. Let’s explore some of the most reliable sources to acquire these items for your setup.

- Manufacturer’s Website: One of the primary places to seek replacement items is directly from the producer’s official online platform. This source often provides the most up-to-date and compatible products tailored for your specific unit.

- Specialty Retailers: Numerous retailers focus on providing a wide range of components for different systems. These stores can be found both online and locally, offering a variety of options to suit different requirements and budgets.

- Online Marketplaces: Websites dedicated to buying and selling can be an excellent resource. They often list new and gently used items that might be more affordable while still meeting quality standards.

- Authorized Service Centers: Engaging with certified service providers ensures that you receive genuine components and professional guidance. These centers typically have direct access to the most reliable parts for your equipment.

Choosing the right source for replacement components not only extends the lifespan of your system but also enhances its overall performance. Prioritize quality and compatibility when making your selection.

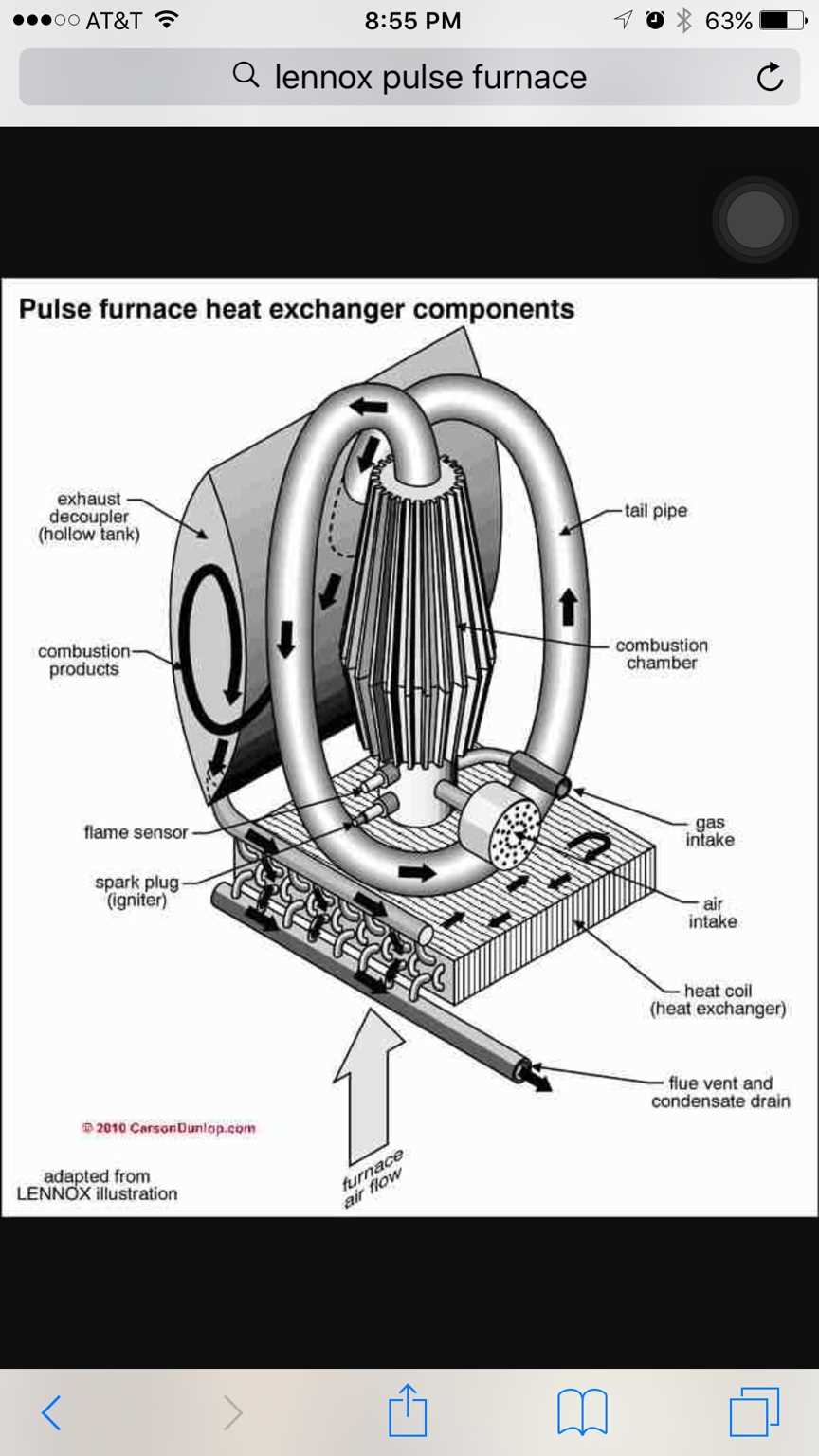

Using Diagrams for Troubleshooting

Visual schematics can be invaluable tools when identifying issues within complex systems. They allow for a structured approach to pinpointing areas that require attention, streamlining the process of diagnosis. By carefully interpreting each component’s connections and sequences, it’s possible to efficiently narrow down the potential sources of malfunctions.

Below is a table that outlines the key steps to effectively utilize these visuals in problem-solving scenarios:

| Step | Description |

|---|---|

| Identify the Components | Start by recognizing each element in the illustration, noting their symbols and positions to understand their functions within the system. |

| Trace the Connections | Follow the paths between elements, checking for interruptions or inconsistencies that may lead to operational issues. |

| Analyze Signal Flow | Examine the flow of signals or energy through the setup, looking for any discrepancies or unexpected behaviors that could indicate faults. |

| Compare with Specifications | Cross-reference the current state of each part against the expected performance standards to detect any deviations. |

| Isolate the Issue | Once potential problem areas are identified, focus on those specific sections to perform further tests or adjustments as needed. |