In the world of beverage preparation, an intricate network of elements works together to create the perfect blend. Each component plays a vital role, contributing to the overall functionality and efficiency of the apparatus. By exploring these essential segments, one can gain insight into how they synergize to enhance the brewing experience.

Delving into the specifics of these mechanisms reveals the ultimate interplay between design and performance. Understanding how each piece interacts allows enthusiasts and professionals alike to optimize their equipment for better results. This exploration not only deepens appreciation for the craft but also empowers users to troubleshoot and maintain their setups effectively.

Moreover, recognizing the nuances of each segment fosters a greater connection to the brewing process. Whether for hobbyists or industry experts, knowledge of these intricate details can transform the mundane into the extraordinary. Embracing this complexity can lead to more informed choices and improved outcomes in the final product.

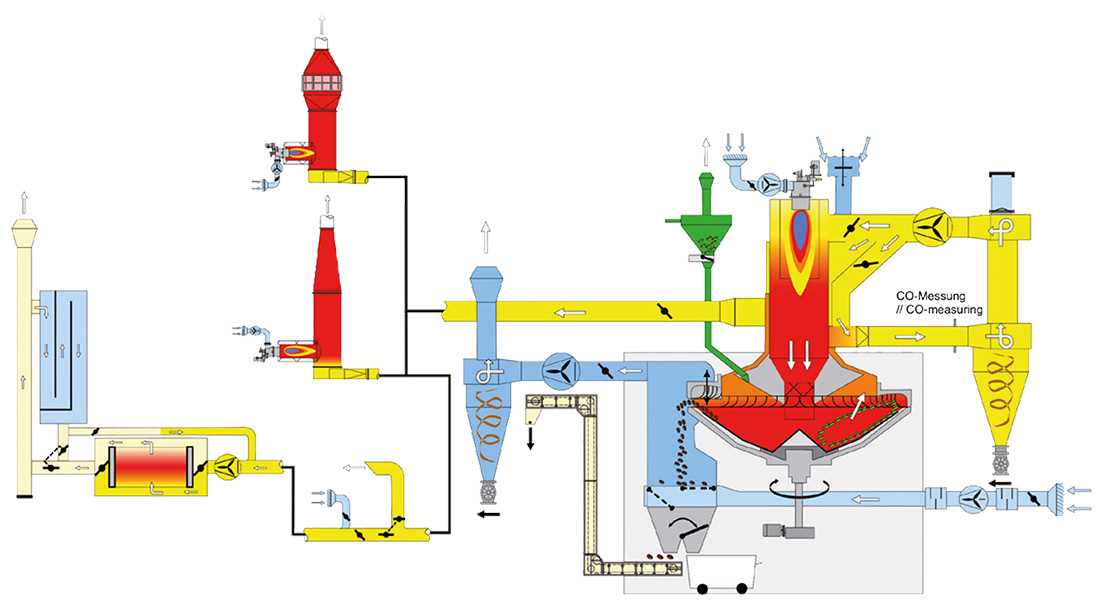

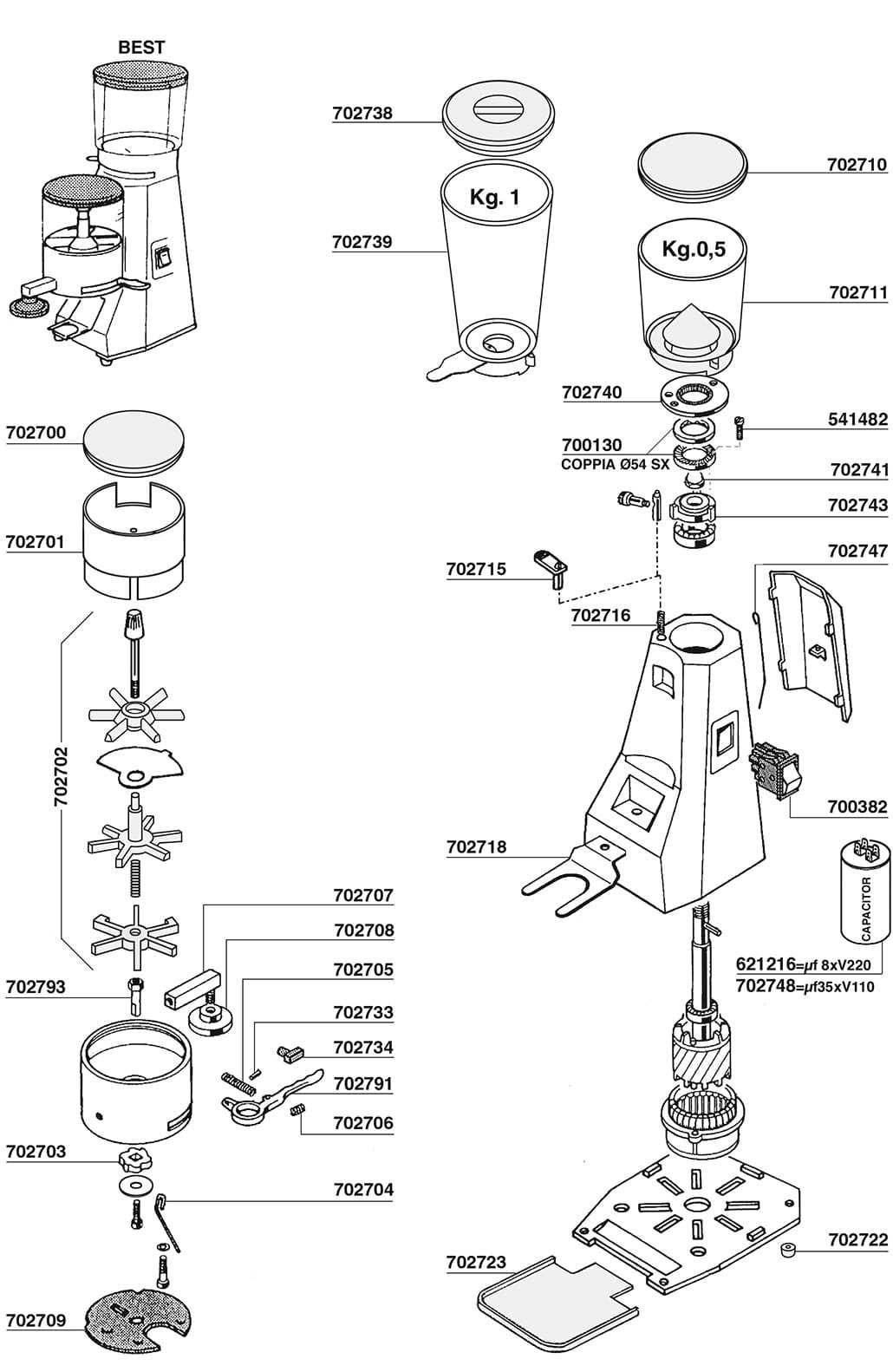

Coffee Roaster Parts Overview

This section provides a comprehensive look at the essential components involved in the process of transforming raw beans into the aromatic brew enjoyed worldwide. Understanding these elements is crucial for enthusiasts and professionals alike, as each plays a significant role in achieving the desired flavor profile and quality.

Heating Element: The source of thermal energy, crucial for initiating the transformation of the beans.

Drum: A rotating cylinder where the raw material is evenly exposed to heat, ensuring uniform roasting.

Chaff Collector: A system designed to capture the outer layer that separates from the beans during roasting, maintaining cleanliness and efficiency.

Cooling Tray: An essential feature that rapidly cools the beans post-roasting, halting the process and preserving flavor.

Control Panel: The interface for monitoring and adjusting the various parameters, ensuring precision in every batch.

By delving into these components, one can appreciate the intricacies involved in creating the ultimate cup of brewed perfection.

Main Components of Coffee Roasters

Understanding the essential elements of a machine used for transforming raw beans into aromatic delights is crucial for enthusiasts and professionals alike. Each component plays a vital role in the overall functionality and efficiency of the roasting process, contributing to the development of unique flavors and aromas.

| Component | Description |

|---|---|

| Drum | The chamber where the beans are placed and subjected to heat, facilitating even roasting. |

| Heat Source | The element providing the necessary heat, whether it be electric, gas, or wood, influencing the roast profile. |

| Cooling Tray | A system designed to rapidly lower the temperature of the beans post-roasting, preserving their flavor and preventing overcooking. |

| Chaff Collector | A feature that collects the outer layer of the beans that sheds during roasting, helping maintain cleanliness and safety. |

| Control Panel | The interface that allows users to adjust settings such as temperature and time, ensuring precise roasting control. |

Each of these components collaborates seamlessly, ensuring that the transformation of green beans into flavorful delights is executed with precision and artistry.

Understanding Heat Transfer in Roasters

The process of transforming raw materials through heat involves complex interactions that significantly affect the final product. Grasping the principles of thermal dynamics is essential for optimizing flavor and consistency. This section explores the key mechanisms that govern how heat is distributed and absorbed during this transformative phase.

Conduction, Convection, and Radiation

Heat transfer occurs primarily through three mechanisms: conduction, convection, and radiation. Conduction is the direct transfer of heat between solid surfaces, essential for achieving uniform temperatures in the material. Convection involves the movement of air, which plays a crucial role in ensuring that heat reaches all surfaces effectively. Radiation refers to the emission of energy in the form of electromagnetic waves, which can also contribute to heating, particularly from external sources.

Optimizing Temperature Control

Effective temperature management is vital for achieving the desired flavor profile. By understanding how each mechanism contributes to heat distribution, operators can make informed adjustments to enhance efficiency and quality. This knowledge enables a deeper appreciation of how nuances in temperature can lead to the ultimate product characteristics.

Importance of Roasting Chamber Design

The configuration of the chamber where the transformation occurs plays a crucial role in the overall quality of the final product. This component influences various factors, such as heat distribution, airflow, and even the duration of the process. A well-designed space ensures that the raw material is subjected to optimal conditions, leading to a uniform and desirable outcome.

Key Factors in Chamber Design

Several elements must be considered when designing the roasting environment. These include material selection, thermal efficiency, and ventilation mechanisms. Each factor contributes significantly to how the ingredients react during the heating process.

| Factor | Description |

|---|---|

| Material | High-quality materials ensure durability and optimal heat retention. |

| Heat Distribution | Uniform heat prevents scorching and ensures consistent results. |

| Airflow | Effective ventilation allows for even cooking and removes unwanted smoke. |

| Size | Proper sizing accommodates varying batch sizes while maintaining efficiency. |

Impact on Final Product

The design of the heating chamber directly influences flavor profile, aroma, and overall consistency. When these elements are optimized, the resulting characteristics of the end product can significantly enhance consumer satisfaction and marketability.

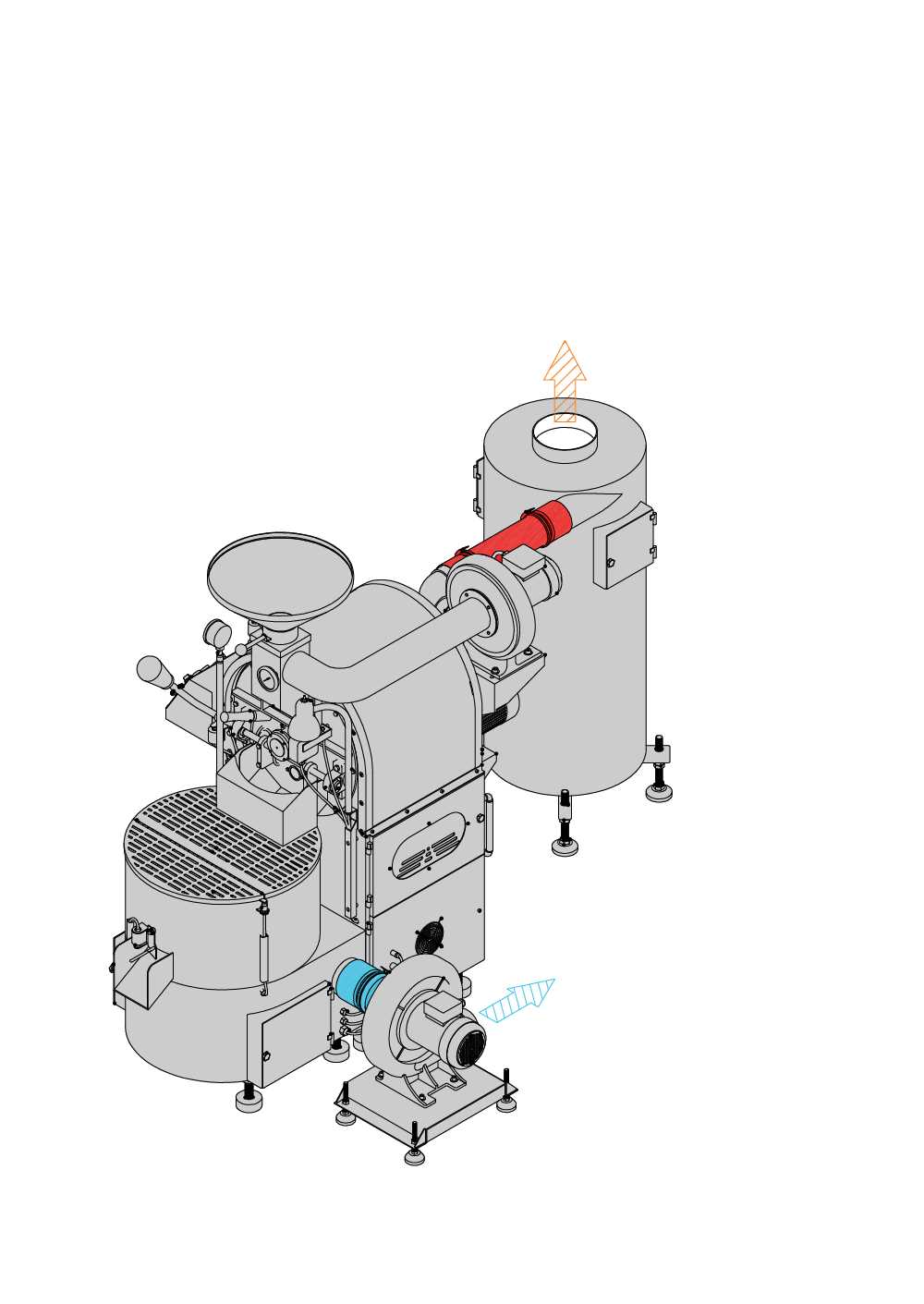

Role of the Exhaust System

The exhaust mechanism plays a critical role in maintaining optimal conditions during the roasting process. Its primary function is to effectively remove smoke, gases, and other byproducts, ensuring a clean and safe environment. This not only enhances the quality of the end product but also protects equipment and personnel from harmful emissions.

Moreover, a well-designed exhaust system contributes to precise temperature control, allowing for consistent results. Proper ventilation aids in regulating airflow, which is essential for achieving the desired roast profile. Ultimately, a robust exhaust setup is vital for efficiency and performance, reflecting on the overall quality of the operation.

Cooling Mechanism in Coffee Roasters

The process of rapidly reducing temperature after the roasting phase is crucial for achieving optimal flavor and aroma. This mechanism not only halts the roasting process but also ensures a more consistent product by preventing overdevelopment. Effective cooling techniques are essential for maintaining quality and enhancing the overall experience of the brewed beverage.

Electric vs. Gas Roasting Parts

This section explores the contrasting components utilized in various heating methods, focusing on their functionality and efficiency. Understanding these elements is crucial for optimizing the roasting experience, whether one opts for an electric or gas-driven system.

Efficiency and Control

Electric systems often provide precise temperature control, enabling consistent results. In contrast, gas setups offer rapid heating and potentially lower operating costs, appealing to those seeking speed and flexibility.

Maintenance and Durability

Maintenance requirements vary significantly between the two. Electric units generally demand less upkeep, while gas models may require more attention to ensure safety and performance longevity.

| Feature | Electric | Gas |

|---|---|---|

| Temperature Control | High precision | Rapid adjustment |

| Operating Cost | Higher | Lower |

| Maintenance | Minimal | More involved |

| Heat Up Time | Longer | Quicker |

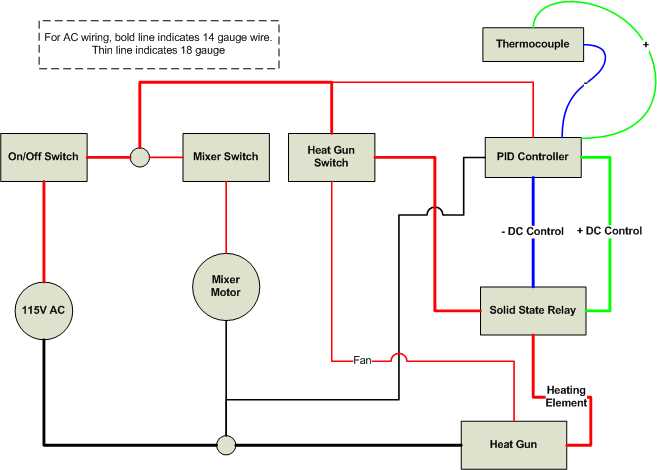

Key Features of Control Panels

Control panels serve as the central interface for managing various operations in equipment. Their design and functionality are crucial for ensuring optimal performance, user accessibility, and precise control over processes. Understanding their key features can enhance usability and efficiency.

User Interface

A well-designed user interface is vital for effective interaction. Intuitive layouts, clear labels, and responsive controls enable operators to monitor and adjust settings seamlessly. Visual feedback, such as LED indicators or touchscreens, enhances real-time data visibility.

Programmability and Automation

Advanced control panels often include programmable settings that allow for automation of repetitive tasks. This feature not only reduces human error but also optimizes workflow. Customization options empower users to tailor functions to specific requirements, making the operation more efficient.

Materials Used in Roaster Construction

The selection of materials is crucial for the efficiency and longevity of any roasting equipment. The right components not only influence performance but also play a significant role in flavor development and consistency. Various substances are employed in the construction to enhance durability, heat retention, and ease of maintenance.

Stainless steel is commonly chosen for its resistance to corrosion and ability to withstand high temperatures. This material ensures a hygienic environment, which is vital for preserving the quality of the beans. Additionally, aluminum is frequently used for its lightweight nature and excellent thermal conductivity, allowing for precise temperature control during the roasting process.

Moreover, certain parts may be made from cast iron, known for its superior heat retention, which facilitates an even roasting experience. Insulation materials are also essential; they help to minimize heat loss and improve energy efficiency. These selections reflect the balance between functionality and performance in the design of roasting equipment.

In summary, the choice of materials greatly impacts the efficiency, durability, and overall quality of the roasting apparatus. Understanding these components is essential for anyone looking to optimize their roasting experience.

Common Issues with Roaster Parts

In the world of bean processing, various components may encounter challenges that affect performance and quality. Understanding these common issues can aid in troubleshooting and maintaining optimal functionality.

| Component | Common Issue | Possible Solution |

|---|---|---|

| Drum | Uneven heating | Check for blockages and ensure proper calibration. |

| Chaff Collector | Clogging | Regularly clean and empty to prevent buildup. |

| Thermometer | Inaccurate readings | Calibrate or replace to ensure precise temperature monitoring. |

| Fan | Reduced airflow | Inspect for obstructions and clean the blades regularly. |

Maintenance Tips for Roasting Equipment

Regular upkeep of your equipment is essential for ensuring optimal performance and longevity. Proper maintenance not only enhances the efficiency of the machine but also improves the overall quality of the end product. Establishing a routine can help prevent breakdowns and costly repairs, allowing for a smoother operational flow.

Start by routinely inspecting all components for wear and tear. Check for any signs of damage, rust, or buildup that could interfere with functionality. Pay special attention to the heating elements, as they play a crucial role in achieving consistent temperatures.

Cleaning is another vital aspect of maintenance. Ensure that all surfaces are free from residue and oils that can accumulate over time. Use appropriate cleaning agents to avoid damaging any sensitive parts. Regularly empty and clean any collection trays or hoppers to maintain optimal performance.

Additionally, lubricate moving parts as needed to prevent friction and overheating. Refer to the manufacturer’s guidelines for the recommended types of lubricants and intervals for application. This will help in extending the lifespan of your machinery.

Finally, keep an eye on the calibration of your equipment. Periodic checks will ensure that all settings are accurate and functioning as intended. This step is crucial for achieving the desired outcomes consistently.

Future Trends in Roaster Technology

As the industry evolves, innovations are reshaping the way we approach the art of transforming raw materials into delightful experiences. Advancements in machinery, automation, and sustainability practices are at the forefront of this evolution, promising enhanced efficiency and flavor consistency.

One significant trend is the integration of smart technology, allowing for real-time monitoring and adjustments during the roasting process. This not only improves precision but also enables users to experiment with different profiles, enhancing the overall quality of the final product.

Another emerging focus is on eco-friendly practices, with many manufacturers developing energy-efficient equipment and utilizing renewable resources. This shift not only minimizes environmental impact but also appeals to a growing consumer base that prioritizes sustainability.

Additionally, advancements in materials science are leading to the creation of more durable and effective components, which can withstand higher temperatures and reduce maintenance needs. These innovations ensure that producers can operate more effectively while maintaining the integrity of their craft.

Ultimately, the future landscape promises a harmonious blend of tradition and technology, paving the way for new methodologies and enhancing the overall experience for both producers and consumers.