In the realm of woodworking and construction, having a reliable fastening device is crucial for achieving optimal results. These tools are designed to enhance efficiency and precision in various projects. Familiarity with their internal mechanisms can significantly elevate a user’s skills and outcomes.

By examining the intricate elements that comprise these devices, one can gain insights into their functionality and maintenance. This understanding not only aids in troubleshooting but also enhances the overall user experience, allowing for smoother operation and improved longevity of the tool.

Exploring these components provides an ultimate opportunity to delve into the craftsmanship that goes into the creation of such devices. Whether for a novice or a seasoned professional, grasping the anatomy of these instruments is a key step towards mastery in the art of fastening.

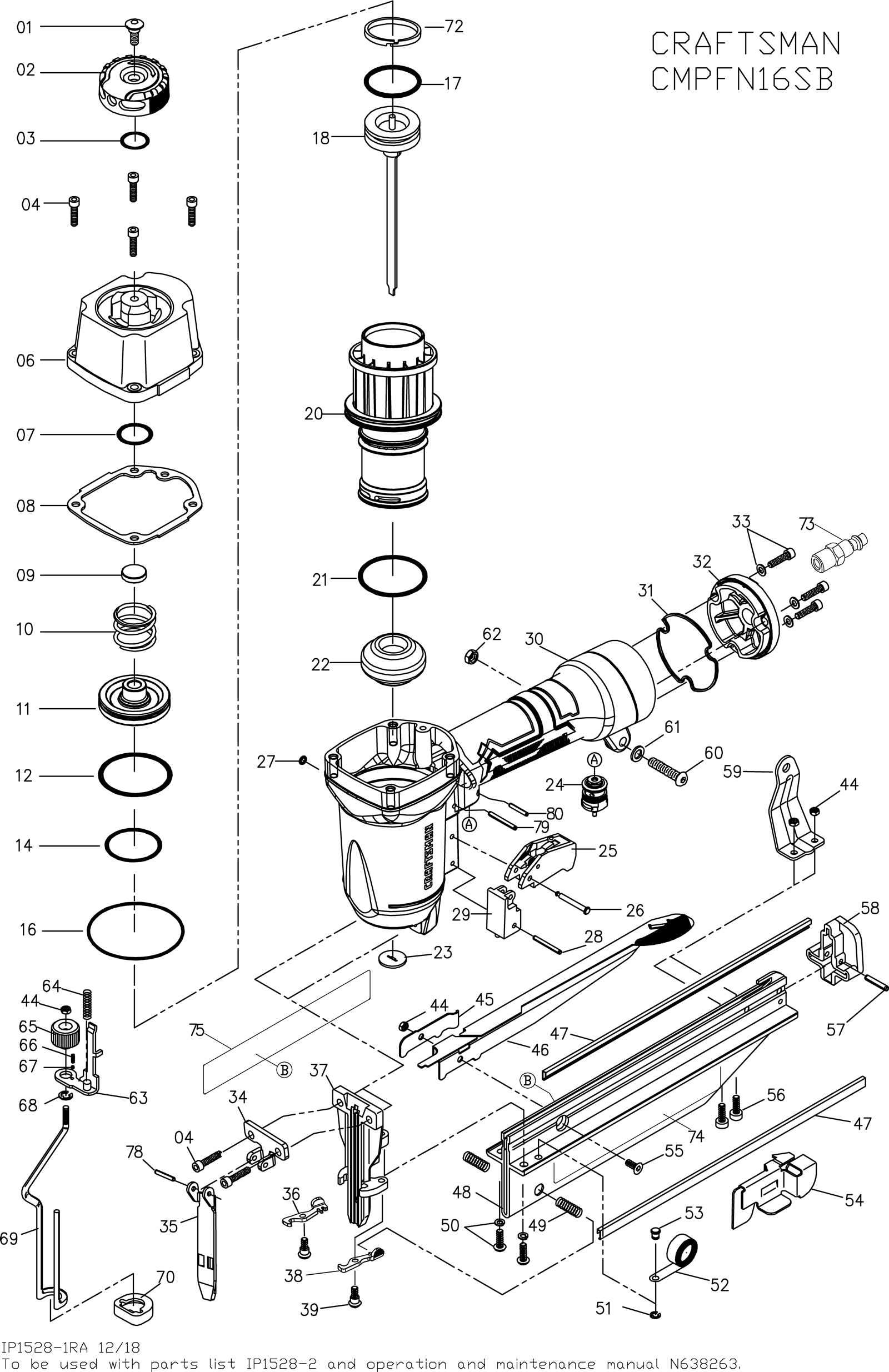

Understanding the Craftsman Brad Nailer

This section delves into the intricate components and functionality of a specific type of fastening tool commonly utilized in woodworking and construction projects. By examining its essential elements, users can enhance their understanding and improve their overall experience with the device.

Key Components

- Trigger: Initiates the fastening process with a simple pull.

- Magazine: Holds the fasteners securely for quick access.

- Drive Mechanism: Propels the fasteners into the material with precision.

- Exhaust Port: Directs air away from the user’s workspace.

- Depth Adjustment: Allows for control over how deeply the fastener is driven.

Operation Principles

- Load the fasteners into the magazine for efficient usage.

- Adjust the depth settings according to the material thickness.

- Engage the trigger to activate the drive mechanism.

- Monitor the exhaust to ensure safe operation.

- Maintain the tool regularly for optimal performance.

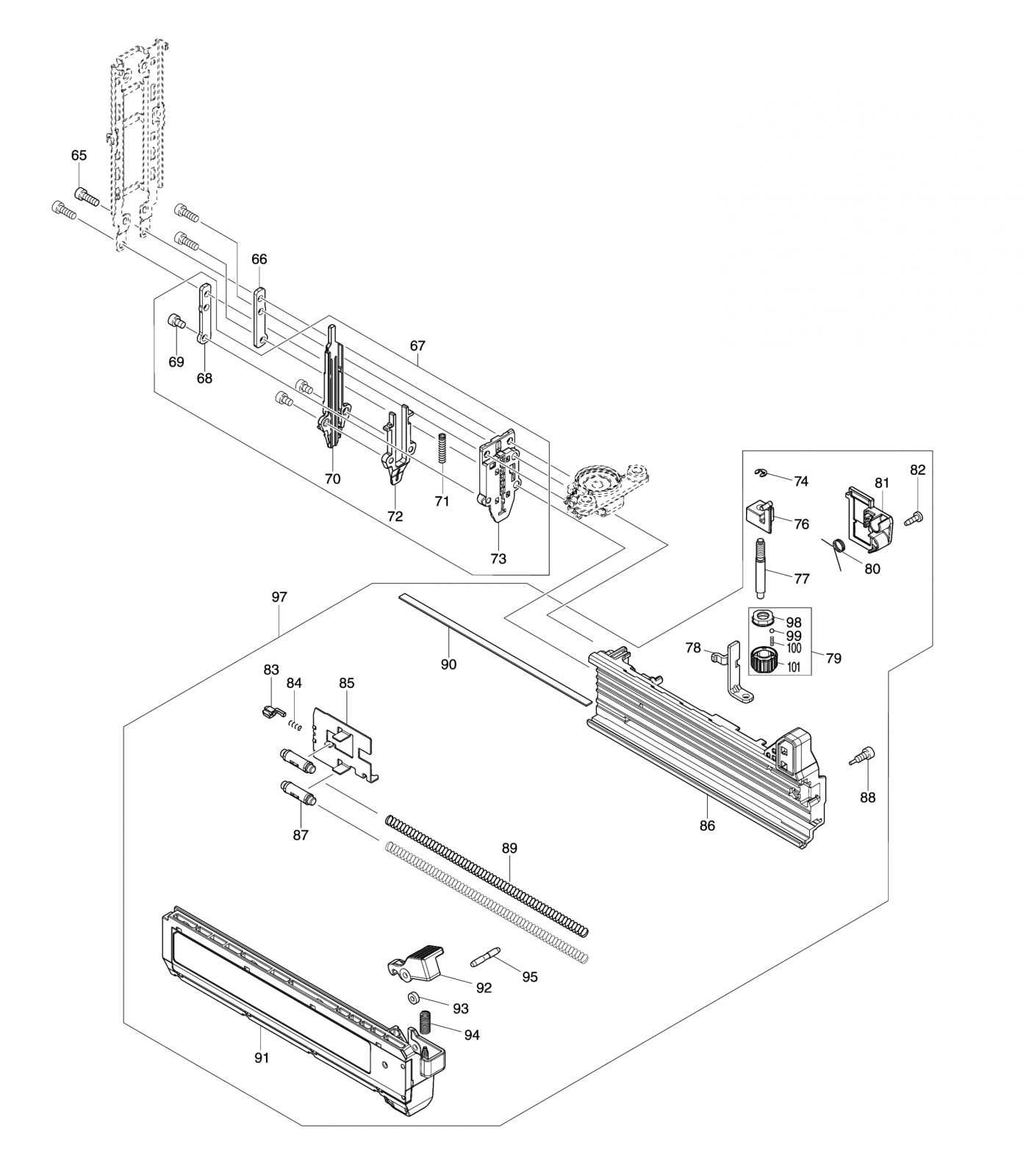

Key Components of a Brad Nailer

Understanding the essential elements of a fastening tool is crucial for effective usage and maintenance. Each component plays a significant role in ensuring precision and reliability during tasks.

- Trigger Mechanism: Initiates the fastening process and provides control over the operation.

- Magazine: Holds the fasteners securely, allowing for efficient loading and reloading.

- Driver Blade: Delivers the fastener into the material with force and accuracy.

- Air Compressor Connection: Supplies the necessary power for operation in pneumatic models.

- Exhaust Port: Directs expelled air away from the user, enhancing comfort during use.

- Depth Adjustment: Allows users to control how deep the fastener is driven into the surface.

Each of these elements contributes to the ultimate performance of the tool, making familiarity with them essential for any user.

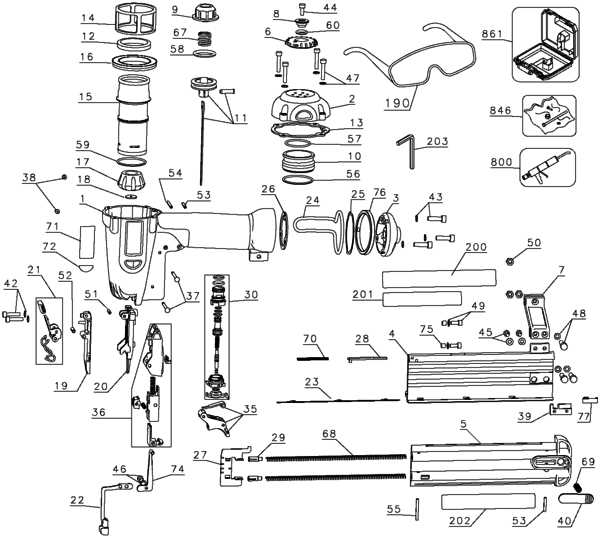

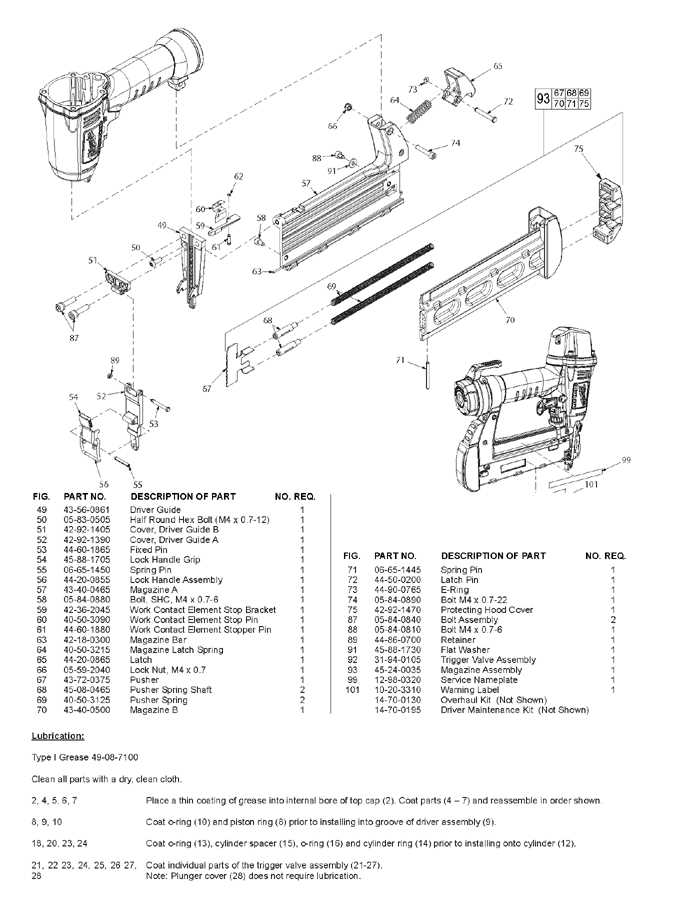

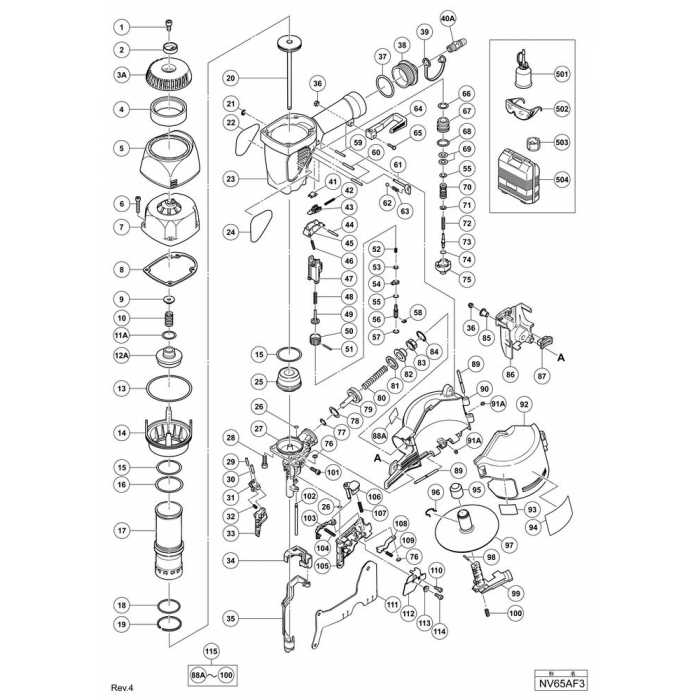

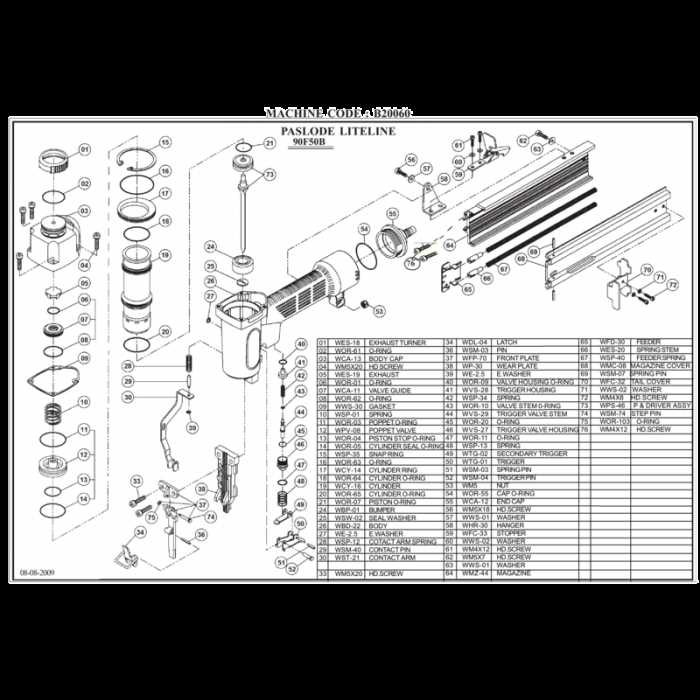

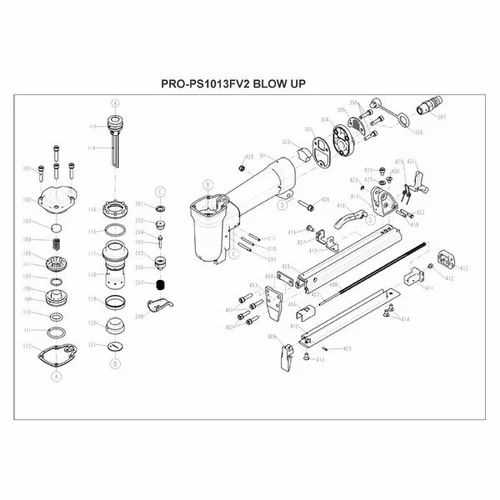

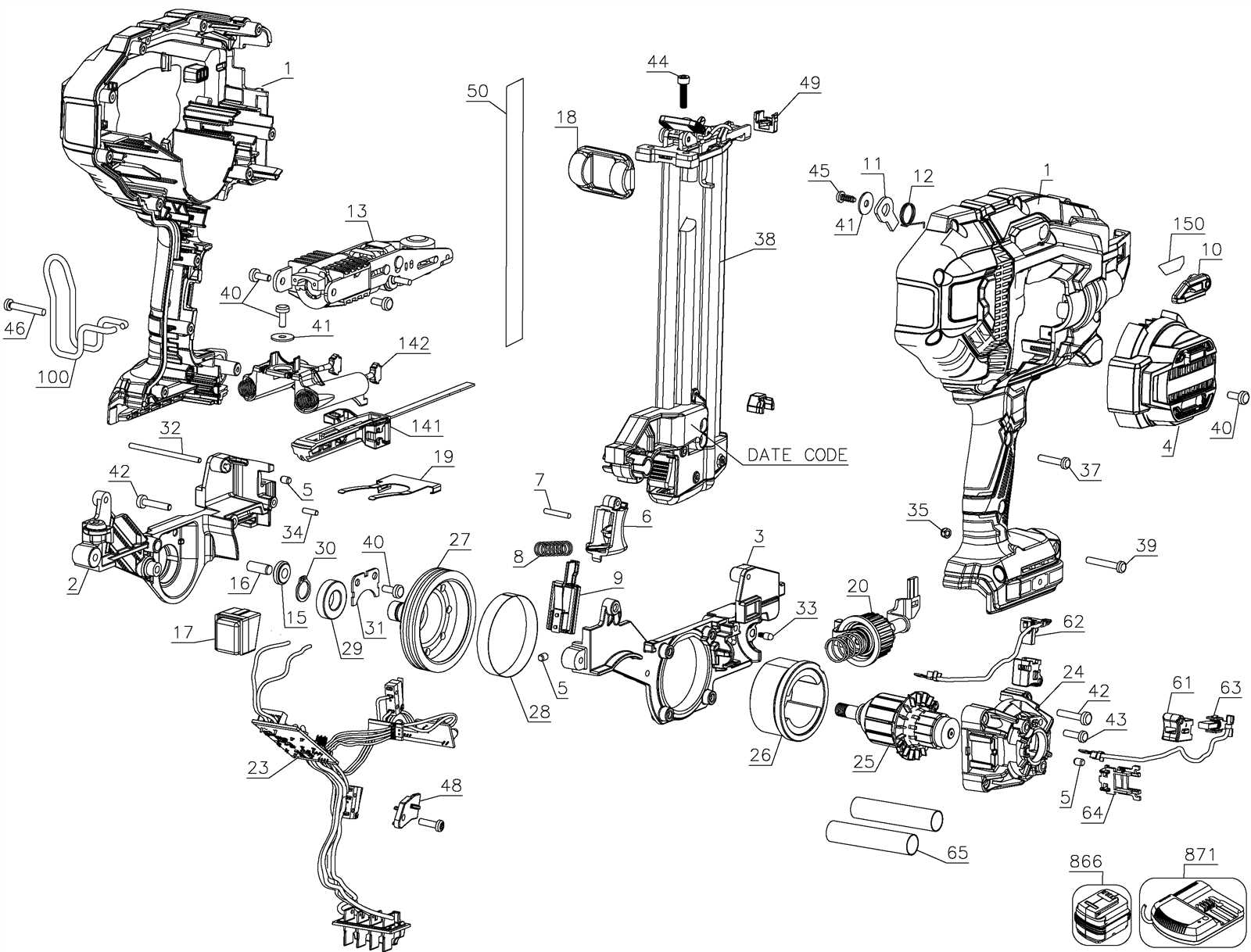

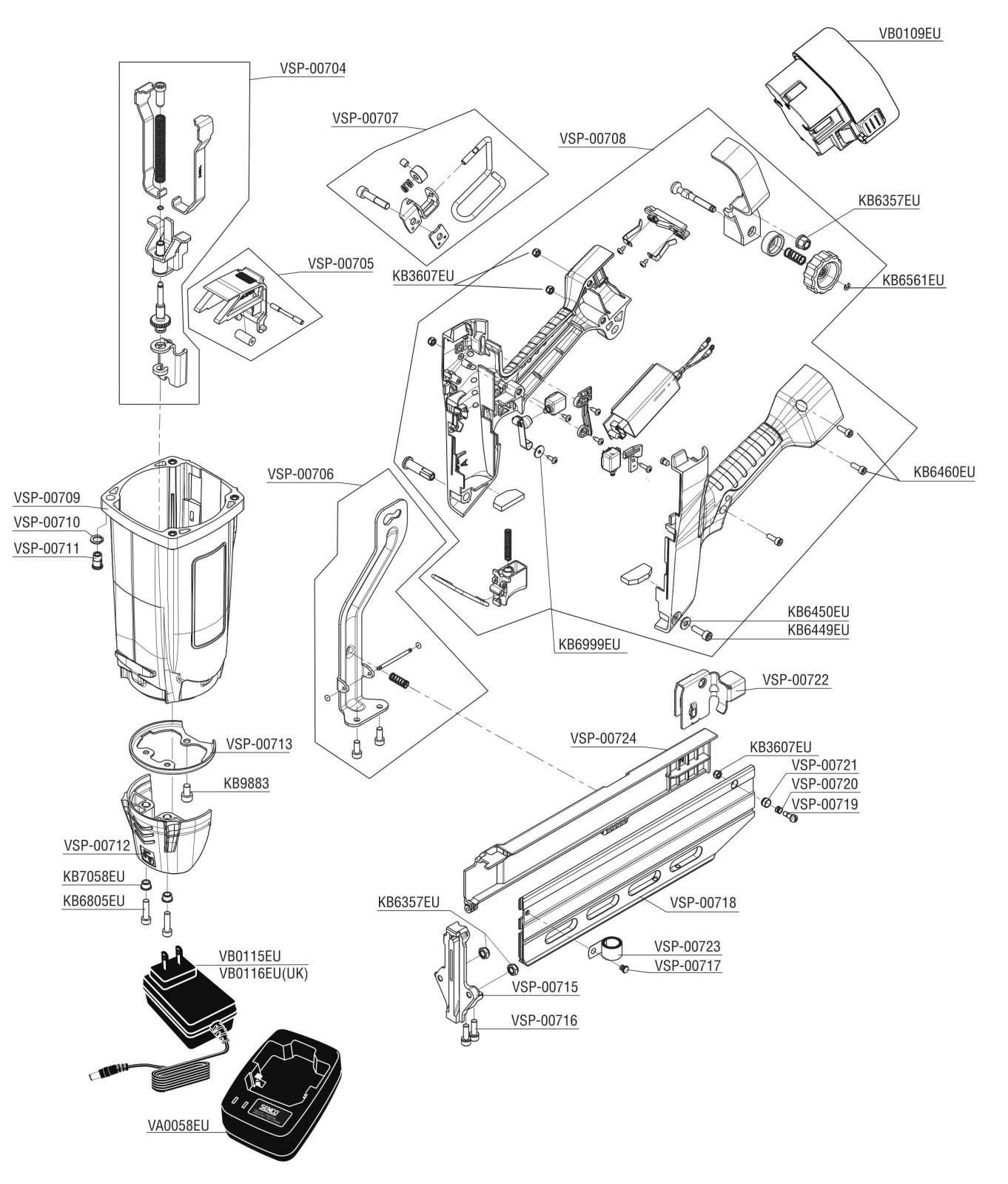

How to Read a Parts Diagram

Understanding a visual representation of components can greatly enhance your ability to identify and locate specific elements within a device. This knowledge is essential for troubleshooting, maintenance, or replacement tasks.

To effectively interpret such illustrations, follow these guidelines:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the layout and orientation of the drawing. |

| 2 | Identify labels or numbers corresponding to each component. |

| 3 | Refer to the accompanying legend or key for detailed information. |

| 4 | Cross-reference with your device to locate parts accurately. |

By mastering these steps, you’ll be better equipped to manage repairs and enhancements with confidence.

Common Issues with Brad Nailers

Power tools designed for fastening can encounter various challenges that affect their performance and efficiency. Understanding these common problems can help users troubleshoot and maintain their equipment effectively.

- Jams: Frequent blockages can occur when fasteners become lodged in the mechanism. This often requires disassembly to clear.

- Misfires: An inconsistent firing can lead to missed fasteners. This issue may stem from low pressure or a faulty trigger mechanism.

- Leakage: Air leaks can compromise the tool’s power. Check connections and seals to ensure they are intact.

- Inconsistent Depth: Problems with depth adjustment can result in fasteners being driven too deep or not deep enough, affecting the finish.

- Overheating: Prolonged use can cause overheating, which may damage internal components. Allowing the tool to cool down periodically can help.

Regular maintenance and understanding these issues can significantly enhance the longevity and reliability of your fastening tool.

Maintenance Tips for Longevity

Ensuring the durability of your fastening tool requires consistent upkeep and attention to detail. By following a few essential practices, you can extend its lifespan and maintain optimal performance. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency during projects.

1. Keep it Clean: Regularly remove dust and debris from the exterior and internal components. Use a soft brush or compressed air to clear out any accumulated particles, which can impede functionality.

2. Lubricate Moving Parts: Apply a light oil to the moving mechanisms as per the manufacturer’s recommendations. Proper lubrication reduces friction, minimizing wear and tear on essential components.

3. Check for Wear: Periodically inspect all elements for signs of damage or excessive wear. Replace worn or damaged parts immediately to avoid further issues during operation.

4. Store Properly: When not in use, keep your tool in a dry, climate-controlled environment. Utilizing a protective case can shield it from moisture and accidental damage.

5. Follow Operating Guidelines: Always adhere to the manufacturer’s operating instructions. Using the tool outside of its specified parameters can lead to premature wear and potential safety hazards.

6. Monitor Air Supply: Ensure that the air supply is clean and at the recommended pressure. Contaminated or incorrect pressure can cause malfunctions and reduce efficiency.

Implementing these straightforward maintenance tips will help ensure your fastening tool remains reliable and effective for years to come.

Repairing Your Brad Nailer Effectively

Ensuring your tool operates smoothly requires understanding its components and the common issues that may arise. Regular maintenance and timely repairs can enhance performance and prolong its lifespan.

Common Issues and Solutions

Identifying typical problems can help you tackle repairs efficiently. Here are some frequent challenges along with their remedies:

| Issue | Solution |

|---|---|

| Misfiring | Check the air pressure and clean the firing mechanism. |

| Jamming | Inspect for debris and ensure correct loading of fasteners. |

| Loss of power | Examine the air supply and inspect for leaks in the hose. |

Maintenance Tips

Regular upkeep is essential for optimal function. Clean the tool after each use and lubricate moving parts periodically. Additionally, storing it in a dry place can prevent rust and deterioration.

Choosing the Right Fasteners

Selecting the appropriate fastening components is crucial for ensuring strong and lasting connections in various projects. The right choice not only enhances the structural integrity but also contributes to the overall efficiency of your work. Understanding the different types available can significantly impact the final outcome of your endeavors.

Types of Fasteners

Fasteners come in various forms, including nails, screws, and staples, each designed for specific applications. Nails are typically used for framing and construction, while screws offer greater holding power, making them suitable for heavy-duty tasks. Staples are ideal for securing lighter materials, providing a quick and effective solution.

Material Considerations

Fasteners are made from different materials, including steel, stainless steel, and aluminum. Steel is strong and cost-effective, while stainless steel resists corrosion, making it perfect for outdoor projects. Aluminum is lightweight and ideal for applications where weight is a concern. Choosing the right material enhances durability and performance in your specific application.

Safety Precautions for Operation

Ensuring safety during the use of pneumatic fastening tools is essential to prevent accidents and injuries. Proper knowledge of operational protocols and adherence to safety guidelines can significantly reduce the risk associated with these powerful devices.

Always wear appropriate personal protective equipment, including safety goggles and hearing protection. This gear safeguards against potential debris and excessive noise generated during operation. Additionally, maintain a safe distance from others in the work area to prevent unintended harm.

Before commencing work, inspect the tool for any signs of damage or wear. Check the air supply connections and ensure that all components are securely fastened. Avoid using the equipment if any issues are identified, as malfunctioning tools can lead to serious accidents.

When operating the device, maintain a firm grip and steady stance. Always point the tool away from yourself and others, and never place your fingers near the firing mechanism. Utilize the safety features provided to minimize the chance of accidental discharge.

Be mindful of your surroundings. Ensure the work area is free from clutter and that you have a clear path to move safely. Keep any bystanders at a safe distance to minimize the risk of injury.

Lastly, always follow the manufacturer’s instructions for operation and maintenance. Familiarity with the guidelines will help you use the equipment safely and efficiently, prolonging its lifespan while safeguarding your well-being.

Upgrading Your Nailing Tools

Improving your fastening equipment can significantly enhance both the quality of your work and your overall efficiency. By investing in modern alternatives, you can ensure precise application and better results, whether you’re engaged in professional tasks or DIY projects. This upgrade is not just about getting new tools; it’s about choosing the right ones that suit your specific needs.

Consider Your Projects: Before making any purchases, evaluate the types of projects you frequently undertake. Different jobs require different tools, so understanding your requirements can guide you in selecting the most appropriate options. Whether it’s light assembly or heavy-duty construction, the right equipment can make all the difference.

Features Matter: When exploring new tools, pay attention to key features that can improve performance. Look for models with adjustable settings, ergonomic designs, and compatibility with various fasteners. These attributes not only enhance usability but also contribute to your overall comfort during extended use.

Maintenance and Durability: Opting for durable and easy-to-maintain tools can save you time and money in the long run. High-quality materials and user-friendly designs can reduce wear and tear, ensuring that your equipment remains reliable for years to come. Always read reviews and consider warranty options when selecting new gear.

Stay Updated: The world of fastening technology is continually evolving. Stay informed about the latest innovations and advancements. By keeping abreast of industry trends, you can make informed decisions and choose tools that enhance your capabilities and efficiency.

Comparing Brad Nailers on the Market

When evaluating the tools available today for fastening materials, it’s essential to understand the various features and specifications that differentiate them. This comparison will highlight key aspects such as performance, durability, and ease of use, helping users make informed decisions tailored to their specific needs.

Performance and Power

Different models offer varying levels of power and efficiency. Some tools excel in speed and precision, making them suitable for extensive projects, while others prioritize compactness and portability. Evaluating these factors ensures that you choose a device capable of handling your intended tasks effectively.

Durability and Build Quality

Longevity is another critical consideration. Tools made from high-quality materials are often more resilient to wear and tear, providing better value over time. Investing in a reliable option can save costs on repairs and replacements, making it a wise choice for both professionals and DIY enthusiasts.

Frequently Asked Questions on Usage

This section addresses common inquiries regarding the operation and maintenance of fastening tools, offering insights to enhance user experience and ensure optimal functionality.

How do I properly load fasteners?

To correctly load fasteners, first ensure the device is disconnected from the power source. Open the magazine according to the manufacturer’s instructions and insert the fasteners, aligning them as indicated. Secure the magazine back in place before reconnecting the power.

What should I do if the tool jams?

If a jam occurs, immediately disconnect the tool to ensure safety. Refer to the user manual for specific instructions on clearing jams, which often involve opening the magazine and removing any stuck items carefully to prevent damage.