The operation of an automated cleaning appliance relies on various essential elements that work in harmony to ensure efficient performance. Each component plays a significant role in enhancing the overall functionality and effectiveness of the device, allowing it to navigate spaces and maintain cleanliness with minimal human intervention.

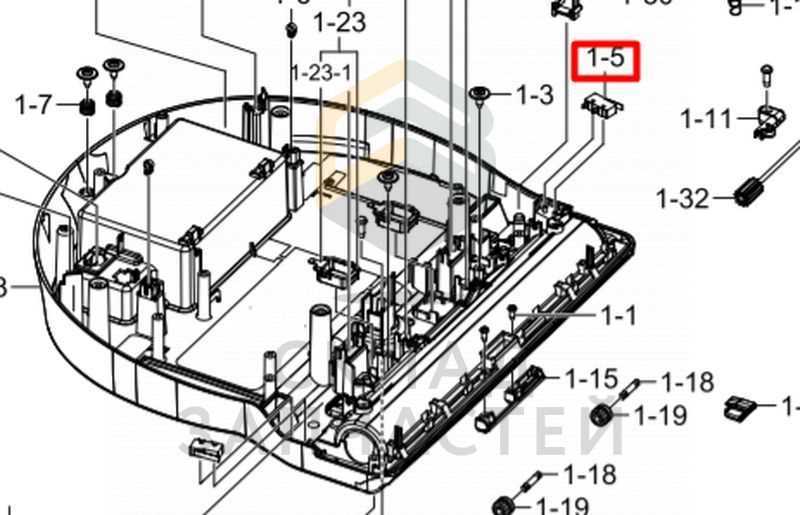

To fully grasp how this intelligent device operates, it is beneficial to explore its internal structure. By familiarizing oneself with the different sections and their respective functions, users can appreciate the engineering behind these machines and make informed decisions regarding maintenance and troubleshooting. Knowledge of each constituent enables better understanding of potential issues that may arise and aids in ensuring optimal performance.

Furthermore, comprehending the intricate layout of the cleaning device provides insight into how it adapts to various environments. This understanding not only enhances user experience but also empowers owners to utilize their appliances more effectively, ultimately leading to improved results in everyday cleaning tasks.

Understanding the fundamental elements of an automatic cleaning device is crucial for effective maintenance and operation. These components work in harmony to ensure optimal performance, making the cleaning process efficient and thorough.

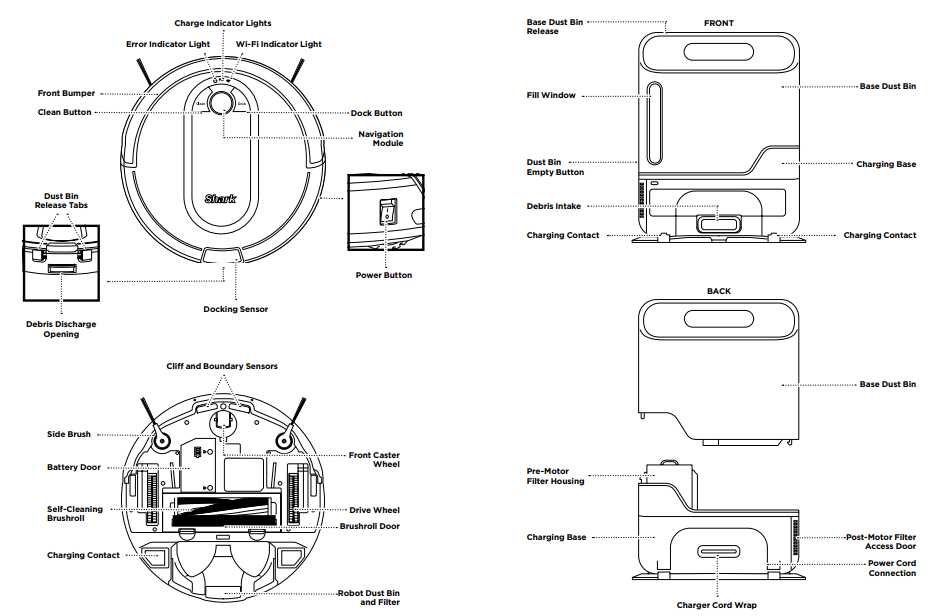

- Main Body: This is the core structure that houses all internal mechanisms and provides stability.

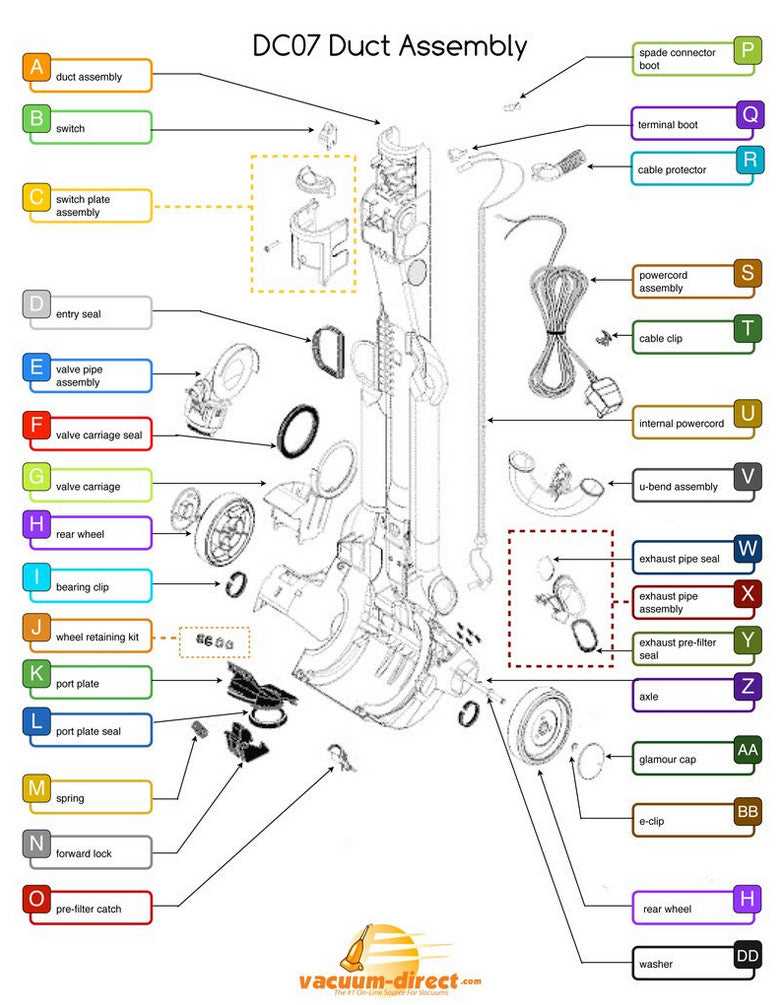

- Motor: The powerhouse that drives the device, enabling suction and movement across various surfaces.

- Brush Roll: A rotating element that dislodges dirt and debris from floors and carpets, ensuring a deep clean.

- Dust Bin: A collection container that gathers the debris, which needs to be emptied regularly for effective functioning.

- Filter: Essential for trapping fine particles, preventing them from being released back into the environment.

- Wheels: Designed for mobility, allowing the unit to navigate around obstacles and different floor types.

- Battery: Provides the necessary power for operation, enabling cordless functionality.

- Charging Dock: A station where the device recharges when not in use, ensuring it’s always ready for the next cleaning session.

Each component plays a significant role in ensuring the effective operation of the machine. Regular inspection and maintenance of these elements can greatly enhance performance and prolong the lifespan of the device.

Understanding the Navigation System

The navigation system plays a crucial role in the efficiency and effectiveness of automated cleaning devices. It is designed to facilitate movement within various environments, ensuring that the unit can maneuver around obstacles, reach different areas, and optimize its cleaning path. A well-engineered navigation mechanism enhances the overall performance, allowing the device to operate with minimal supervision.

Types of Navigation Technologies

Various technologies contribute to the navigation capabilities of these devices. Sensor-based navigation employs a combination of infrared sensors, ultrasonic sensors, and cameras to detect obstacles and map the surroundings. Some units may utilize laser navigation, which creates a detailed layout of the area, allowing for precise movements. Each technology has its advantages, impacting how effectively the device cleans different spaces.

Mapping and Path Planning

Advanced navigation systems incorporate mapping and path planning algorithms that enable the unit to create a virtual map of its environment. This process involves analyzing the layout, identifying high-traffic areas, and determining the most efficient routes for cleaning. By continuously updating the map as it operates, the device can adapt to changes in the environment, ensuring thorough coverage and minimizing the chance of missing spots.

Brush Mechanism and Its Function

The brush assembly is a crucial element in enhancing cleaning efficiency. This mechanism works by rotating bristles to agitate and lift debris from various surfaces, ensuring thorough removal of dirt and dust. The design and function of the brush contribute significantly to the overall performance of the cleaning device.

Design and Components

Typically, the brush mechanism consists of several components, including the main roller, side brushes, and motor. The main roller is designed to capture larger particles, while side brushes help in reaching edges and corners. Together, these components create a comprehensive cleaning action.

Operational Mechanism

The operational functionality relies on the rotation of the brush, which is powered by an internal motor. As the brush spins, it creates a disturbance in the dust and debris, making it easier for the device to collect and remove contaminants from the floor. This dynamic action is essential for achieving effective cleaning results.

Battery Specifications and Types

The energy source is a crucial component in any cleaning device, impacting its performance and longevity. Understanding the various specifications and types of energy units available can help users make informed decisions when selecting a suitable option for their needs.

Common Battery Types

Typically, there are a few prevalent varieties of energy units used in these devices. Lithium-ion batteries are favored for their efficiency and extended life cycle, providing reliable power. Nickel-metal hydride batteries, on the other hand, are more affordable but may have a shorter operational lifespan. Understanding the differences between these types can significantly affect the overall functionality of the appliance.

Specifications to Consider

When evaluating energy units, key specifications should be taken into account. Voltage ratings indicate the power output, while capacity, measured in milliamp hours (mAh), reflects how long the device can run before needing a recharge. Additionally, charging time and cycle life are important factors that contribute to the usability and convenience of the cleaning tool.

Dustbin Design and Features

The container for collected debris plays a crucial role in the overall functionality of cleaning devices. Its construction and characteristics significantly impact performance, ease of use, and maintenance.

Materials and Structure

The materials used in the design of the waste receptacle are essential for durability and efficiency. Commonly employed materials include:

- Plastic: Lightweight and resistant to corrosion, facilitating easy handling.

- Metal: Provides robustness, often found in more advanced models for enhanced longevity.

- Composite Materials: Combining various substances to achieve a balance between weight and strength.

Functional Features

Several design elements contribute to the effectiveness of the waste collection unit:

- Capacity: Larger volumes allow for extended cleaning sessions without frequent emptying.

- Sealing Mechanisms: Prevents dust and allergens from escaping during operation and disposal.

- Ease of Emptying: Many units include features that simplify the removal of debris, such as one-touch release systems.

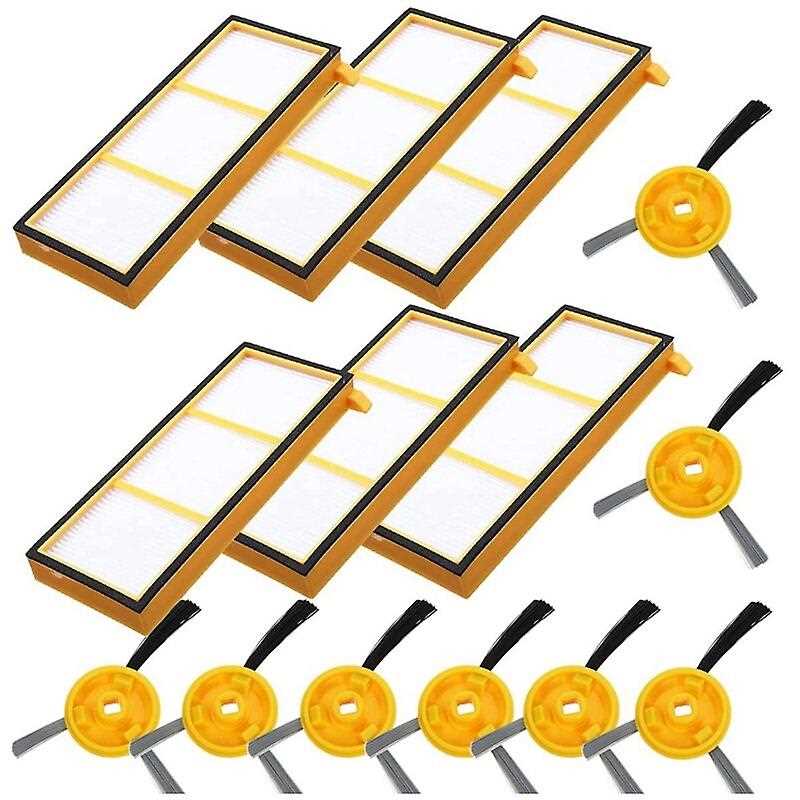

Filters and Maintenance Guidelines

Maintaining optimal performance in automated cleaning devices requires regular attention to various components, particularly the filtration systems. These elements play a crucial role in ensuring effective dust and allergen capture, which enhances overall indoor air quality.

It is essential to check and replace filters periodically according to the manufacturer’s recommendations. Clogged or damaged filters can reduce suction power and lead to inefficient operation. In addition, cleaning the filters regularly can extend their lifespan and improve performance.

For optimal functionality, follow a maintenance schedule that includes inspecting brushes and wheels for debris buildup. Keeping these parts clean not only promotes efficient cleaning but also prevents potential damage to the device. Regular upkeep ensures that your automated cleaning solution operates at its best.

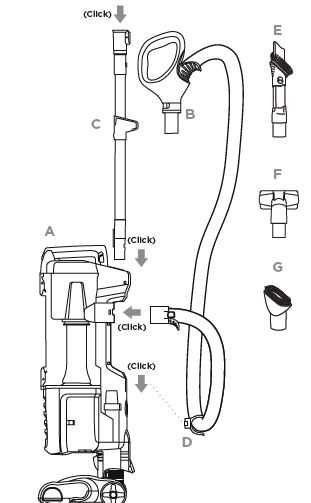

Charging Dock and Setup Instructions

Establishing a suitable charging station is essential for maintaining the functionality of your cleaning device. This section outlines the necessary steps to properly position and prepare the charging base for optimal use.

Placement of the Charging Station: Select a location that is easily accessible and close to a power outlet. Ensure the surface is flat and free from obstacles that could obstruct the unit’s path when it returns for recharging.

Connecting the Power Supply: Plug the provided power adapter into the electrical outlet and connect the other end to the charging dock. Confirm that the connection is secure to avoid interruptions during charging.

Initial Setup: Once the charging base is powered, position the device onto the dock, aligning it with the charging contacts. You should hear a sound or see an indicator light confirming that the connection is successful.

Testing the Setup: After completing the initial setup, it’s advisable to run a short cleaning cycle. Monitor the unit’s return to the charging station to ensure it docks correctly. If any issues arise, double-check the placement and connections.

Sensor Types and Their Roles

In modern cleaning devices, various sensing technologies play crucial roles in enhancing performance and efficiency. These mechanisms enable the machine to navigate its environment, avoid obstacles, and adapt to different surfaces, ensuring a thorough cleaning process. Understanding the different sensor types is essential for appreciating how they contribute to the overall functionality.

Infrared Sensors are commonly used for detecting obstacles. They emit infrared light and measure the reflection off nearby objects, allowing the unit to change its path to avoid collisions. This technology ensures that the device can navigate around furniture and other barriers without getting stuck.

Cliff Sensors are designed to prevent falls from stairs or ledges. By using a combination of light and infrared detection, these sensors can identify edges and drop-offs, prompting the machine to reverse or alter its route, thus avoiding potential damage.

Optical Sensors are utilized for surface recognition. They help the cleaning apparatus determine the type of floor it is on, allowing for adjustments in cleaning techniques and settings. This adaptability is vital for maintaining optimal performance across various floor types, from carpets to hard surfaces.

Gyroscopic Sensors assist in navigation by providing information on the device’s orientation and movement. They help the machine maintain a consistent cleaning path and improve its overall efficiency by ensuring it covers the intended area without missing spots.

Each type of sensor contributes to the cohesive operation of these cleaning machines, enabling them to function autonomously while adapting to their surroundings. This integration of technology ensures a more effective and convenient cleaning experience for users.

Wheel Functionality and Adjustments

The movement system of an automated cleaning device plays a crucial role in its overall performance. Understanding the mechanisms and settings associated with the wheels can enhance the efficiency and maneuverability of the appliance.

These components are designed to navigate various surfaces, ensuring optimal coverage and effective cleaning. The ability to adjust the wheels can significantly impact how well the device handles different terrains.

Key Features of Wheel Mechanisms

- Terrain Adaptability: The wheels are engineered to transition seamlessly between hard floors and carpets, maximizing cleaning efficiency.

- Rotation and Steering: The wheels allow for smooth turns and agile movement, facilitating navigation around furniture and obstacles.

- Height Adjustment: Some models feature adjustable wheel heights to optimize contact with different floor types, ensuring thorough cleaning.

Adjustments and Maintenance

Regular adjustments and maintenance of the wheels can lead to improved performance. Consider the following tips:

- Check for debris or obstructions that may hinder wheel movement.

- Ensure that wheels are securely attached and free from wear and tear.

- Periodically adjust the wheel height according to the floor type to achieve the best results.

By focusing on the functionality and proper adjustments of the wheels, users can significantly enhance the cleaning effectiveness and longevity of their automated cleaning device.

Control Panel and User Interface

The control panel and user interface serve as the primary means for interacting with the cleaning device. This essential feature allows users to easily manage various functions and settings, ensuring a seamless experience. With intuitive layouts and responsive controls, the interface is designed to enhance usability while providing access to a range of functionalities.

Functional Elements

The main components of the interface include buttons, displays, and indicators that facilitate operation. Each button typically corresponds to specific tasks, such as starting or stopping the device, scheduling cleanings, or adjusting modes. Visual indicators offer real-time feedback, allowing users to monitor the status and performance of the equipment at a glance.

User Experience

An effective user interface prioritizes simplicity and clarity. Well-organized menus and clearly labeled controls enable effortless navigation through options. Moreover, the inclusion of audible alerts and visual cues enhances user engagement, ensuring that individuals can easily understand the device’s current state and respond accordingly.

Accessory Parts and Their Uses

Various supplementary components play a crucial role in enhancing the functionality and efficiency of cleaning devices. Each element is designed to fulfill specific tasks, contributing to overall performance and convenience. Understanding the purpose of these accessories allows users to maximize the effectiveness of their equipment.

For instance, brush attachments are essential for agitating dirt and debris from surfaces, making them particularly effective on carpets. Filter systems ensure optimal air quality by trapping allergens and fine particles, promoting a healthier living environment. Additionally, specialized tools for edge cleaning help reach corners and tight spaces that standard mechanisms might miss.

Battery units are vital for powering the device, ensuring uninterrupted operation during cleaning sessions. Moreover, docking stations provide a convenient means for recharging and storing equipment when not in use. By selecting and maintaining the appropriate accessories, users can significantly enhance their cleaning experience.

Common Replacement Parts Availability

When it comes to maintaining household cleaning devices, understanding the availability of various components is crucial. Many individuals seek reliable sources for essential elements that can enhance the functionality and longevity of their devices. This ensures that users can quickly address any issues that arise during operation.

Several common components are typically accessible through a variety of outlets:

- Filters: Essential for trapping dust and allergens, ensuring clean air circulation.

- Brushes: These play a vital role in capturing debris and maintaining cleaning efficiency.

- Batteries: Crucial for powering devices, ensuring they operate at optimal levels.

- Wheels: Allow for smooth navigation across different surfaces, aiding mobility.

- Charging docks: Essential for recharging batteries, enabling devices to function without interruption.

In addition to physical stores, online platforms offer a convenient way to find these items, often providing user reviews and ratings to assist in making informed choices. Maintaining access to these necessary elements allows users to ensure their cleaning devices remain in excellent working condition.