The efficiency of any agricultural machinery relies heavily on its intricate components and how they work together. Grasping the layout and functionality of these elements is essential for optimal performance and maintenance. This section delves into the essential features of a particular type of equipment designed for handling hay and straw.

With a thorough comprehension of the mechanisms involved, users can enhance their operational strategies and ensure longevity in their equipment. Recognizing the individual roles of each segment allows for informed decision-making during repairs and upgrades. Moreover, it supports the seamless execution of tasks on the field, ultimately leading to improved productivity.

By familiarizing oneself with the structure and assembly of these vital mechanisms, operators can better troubleshoot issues that may arise. This knowledge not only facilitates quicker repairs but also contributes to a more efficient workflow, ensuring that the machinery performs at its best.

This section aims to provide a comprehensive understanding of the essential elements that make up a specific type of agricultural machinery. By examining the various components, users can better appreciate how each part contributes to the overall functionality and efficiency of the equipment.

Key Functional Elements

The machinery consists of numerous vital components that work in harmony to perform its tasks effectively. These include mechanisms for feeding materials, compressing them, and binding them securely. Understanding the role of each element helps in diagnosing issues and performing maintenance more efficiently.

Maintenance and Care

Key Functional Parts Explained

This section delves into the essential components that contribute to the efficiency and performance of hay-collecting machinery. Understanding these elements is crucial for optimizing functionality and ensuring seamless operation.

- Feeding System: This assembly is responsible for drawing in the material and ensuring a steady flow into the compression chamber.

- Compression Chamber: A vital area where the collected material is compacted to form uniform bundles, enhancing storage and transport efficiency.

- Cutting Mechanism: Equipped with sharp blades, this feature ensures that the input material is appropriately sized before entering the compression phase.

- Bailing Mechanism: This part actively shapes and ties the material into compact forms, readying it for easy handling and storage.

- Power Transmission: This system transfers energy from the tractor or engine to the working components, ensuring efficient operation.

Familiarity with these components not only aids in maintenance but also enhances overall productivity in agricultural operations.

Understanding the Baler Mechanism

The operation of a machine designed for compressing and packaging agricultural materials relies on several interconnected components that work in harmony. This system not only enhances efficiency but also ensures the optimal formation of the end product. By grasping the fundamental functions of each element, one can better appreciate how this technology contributes to modern farming practices.

Key Components of the System

At the heart of the mechanism are several crucial components that facilitate the effective handling of materials. Each part plays a specific role in ensuring the overall efficiency of the operation, from material intake to the final output.

| Component | Function |

|---|---|

| Feeding Mechanism | Grabs and guides materials into the processing area. |

| Compression Chamber | Compresses the gathered materials into a compact form. |

| Tying System | Secures the compressed materials to maintain shape. |

Operating Principles

Understanding the operating principles is essential for effective use. The machine employs a series of actions that convert loose materials into neatly packaged bundles. This transformation is achieved through the coordinated movements of various elements, which are powered by a robust engine, ensuring consistency and reliability.

Maintenance and Repair Considerations

Ensuring the longevity and optimal performance of agricultural machinery involves regular upkeep and timely interventions. Proper attention to maintenance can significantly reduce downtime and enhance efficiency in the field.

Key factors to consider include:

- Routine Inspections: Regularly check for wear and tear on components to identify potential issues early.

- Lubrication: Adequate lubrication of moving parts is crucial to minimize friction and prevent damage.

- Alignment: Maintaining correct alignment of elements is essential to ensure smooth operation and reduce stress on machinery.

- Replacement of Worn Components: Timely replacement of degraded parts can prevent further damage and costly repairs.

- Cleaning: Keeping machinery free from debris and buildup enhances performance and prolongs service life.

Implementing a comprehensive maintenance schedule can lead to improved functionality and reliability, ensuring that your equipment remains effective throughout its operational life.

Identifying Common Parts by Function

Understanding the various components of agricultural machinery is essential for efficient operation and maintenance. Each element plays a crucial role in the overall functionality of the equipment, contributing to its performance and reliability.

Key functions are often categorized based on their operational roles:

- Drive Mechanisms: These components are responsible for transmitting power and ensuring smooth operation.

- Cutting Elements: Essential for processing materials, these parts facilitate the initial harvesting phase.

- Collection Systems: Designed to gather and transport materials, these components ensure efficient workflow.

- Discharge Mechanisms: Critical for expelling the finished product, these parts contribute to effective output management.

Familiarizing oneself with these functional categories enhances troubleshooting skills and informs better maintenance practices, ultimately leading to improved machinery longevity.

Exploring the Hydraulic System

The hydraulic system plays a crucial role in the operation of agricultural machinery, facilitating various functions through the use of fluid pressure. This system consists of several interconnected components that work together to ensure efficient performance and responsiveness during operation.

In essence, the hydraulic mechanism converts mechanical energy into fluid power, allowing for the smooth execution of tasks such as lifting, lowering, and moving heavy loads. Understanding the intricacies of this system is essential for effective maintenance and troubleshooting, ensuring optimal functionality and longevity of the equipment.

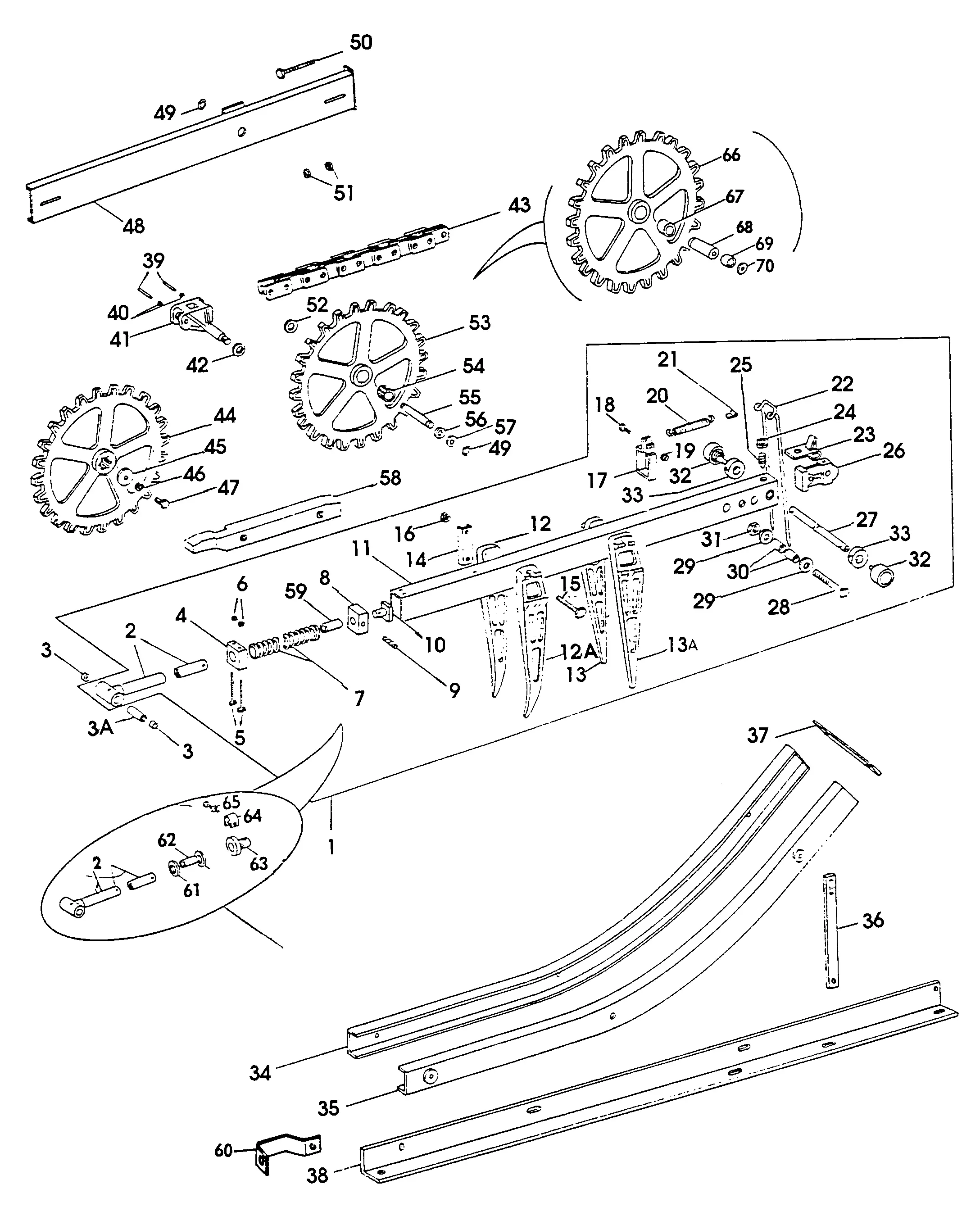

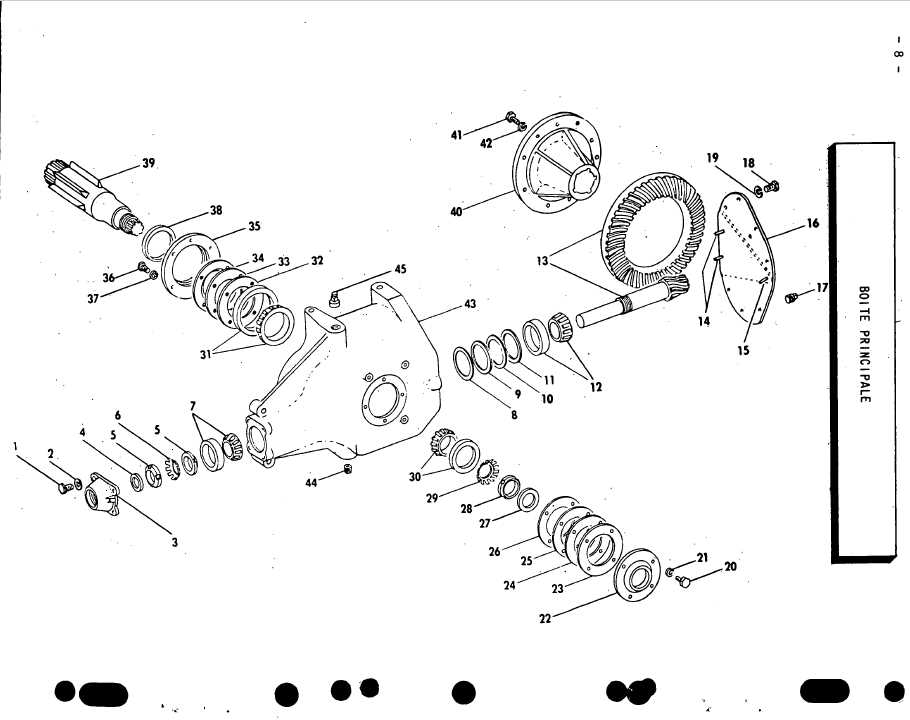

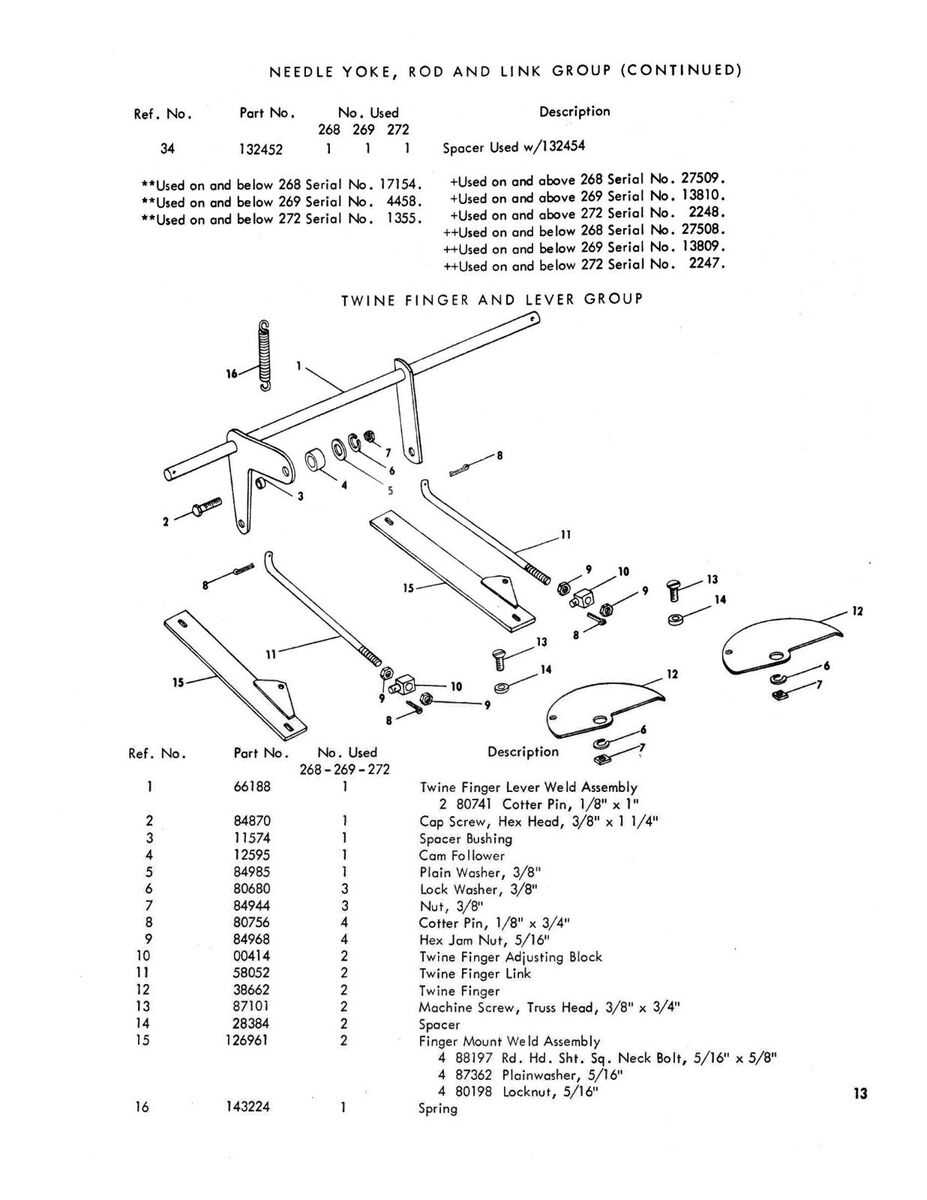

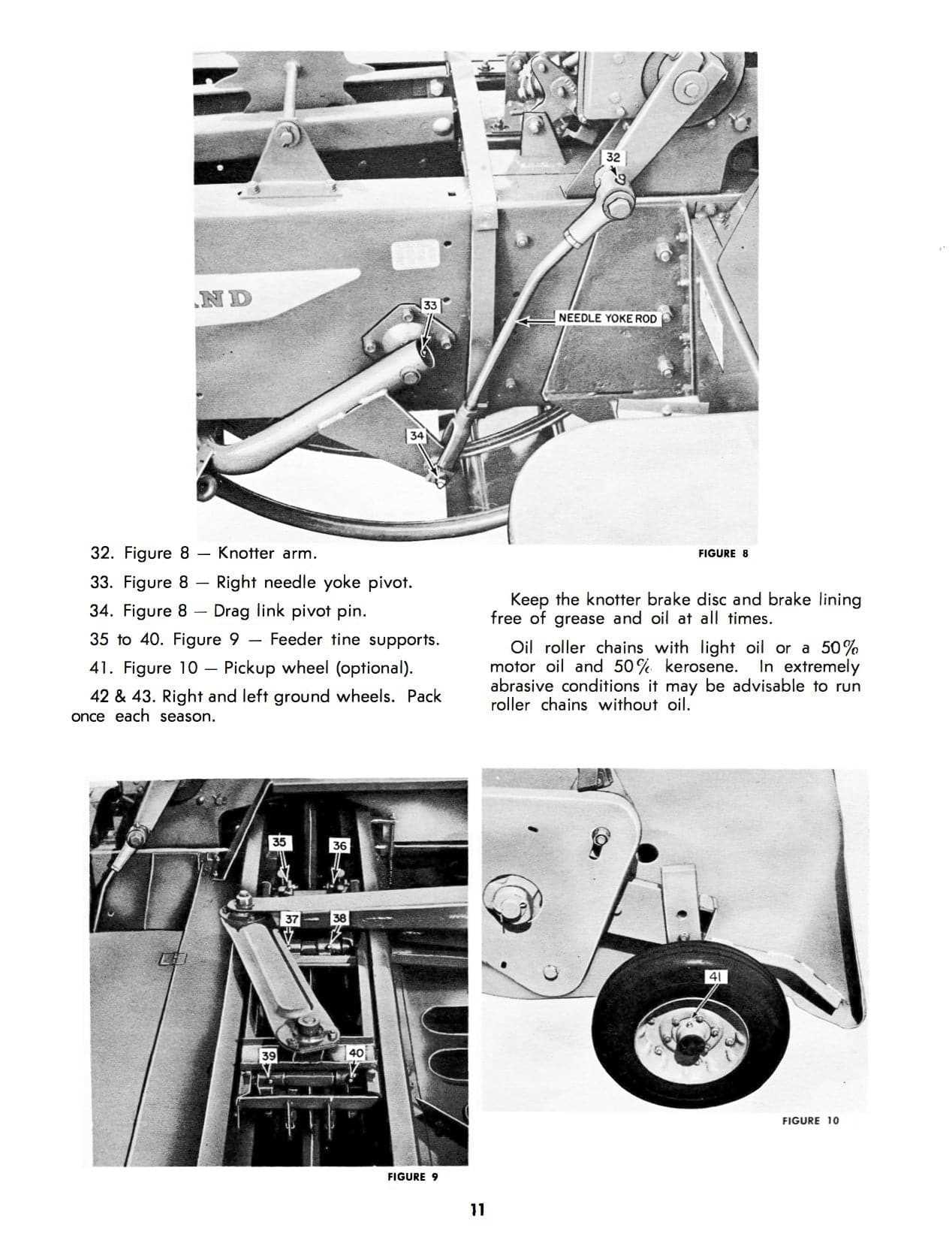

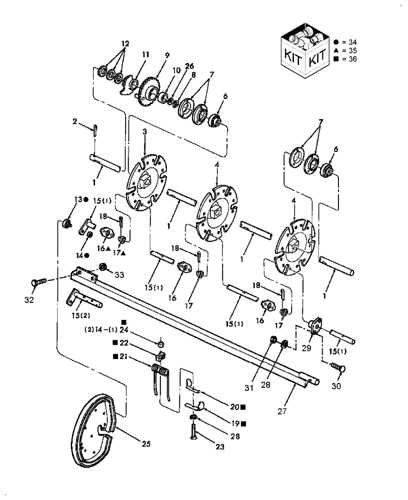

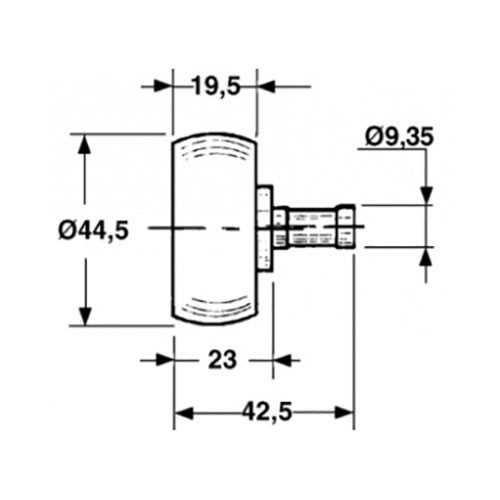

Diagram Analysis for Better Insights

Understanding the layout of machinery components can significantly enhance operational efficiency and maintenance procedures. By closely examining visual representations, one can identify interrelations among various elements, facilitating a more comprehensive grasp of functionality and performance.

These illustrations serve as valuable tools, enabling operators to pinpoint potential issues before they escalate. By familiarizing oneself with the arrangement and role of each segment, users can optimize workflows and streamline repairs. Furthermore, insights gained from such analyses can inform better decision-making regarding upgrades or replacements.

Incorporating this methodical approach not only improves technical knowledge but also promotes proactive measures that contribute to longevity and reliability. Ultimately, a thorough understanding of equipment layouts fosters a culture of preparedness and efficiency in operations.

Replacement Parts and Availability

This section focuses on the essential components and their procurement options for efficient machinery operation. Understanding the options available for sourcing these elements is crucial for maintaining optimal performance and minimizing downtime.

When seeking to replace specific components, consider the following sources:

- Authorized dealers: Ensure authenticity and compatibility with your equipment.

- Online marketplaces: A variety of options from multiple vendors can be explored.

- Local agricultural supply stores: Convenient access to essential elements and expert advice.

Additionally, assessing availability can be beneficial:

- Check inventory status regularly to avoid unexpected delays.

- Look for bulk purchase options to save on costs and ensure readiness.

- Inquire about warranty or return policies for peace of mind in case of discrepancies.

By exploring these avenues, operators can secure the necessary components to maintain efficient machinery function and longevity.

Safety Features of New Holland Balers

The importance of protective mechanisms in agricultural machinery cannot be overstated. These features are designed to enhance user safety and minimize risks during operation, ensuring a secure working environment. With advanced technology and thoughtful design, these devices play a critical role in safeguarding both the operator and the equipment.

Emergency Stops are essential components, allowing users to quickly halt operations in case of an unexpected event. This feature reduces potential hazards by providing immediate control over the machinery.

Safety Guards are strategically placed to prevent accidental contact with moving parts. These barriers not only shield the operator but also contribute to maintaining the integrity of the equipment, reducing wear and tear.

Operator Presence Systems ensure that the machinery only functions when the operator is safely positioned. This innovative technology prevents accidental activation, significantly lowering the risk of injury.

Warning Lights and Alarms are incorporated to alert users to potential issues, providing crucial information that enables prompt action. These visual and auditory signals enhance awareness, helping to avert dangerous situations.

Tips for Efficient Operation

Maximizing productivity during harvesting activities requires attention to detail and strategic approaches. Proper maintenance and operation techniques can lead to significant improvements in efficiency and output quality.

Regular Maintenance

Consistent upkeep of machinery is essential. Ensure that all components are functioning correctly and replace worn parts promptly. A well-maintained machine operates smoothly, reducing the likelihood of unexpected breakdowns.

Operator Training

Investing in comprehensive training for operators can enhance performance. Knowledgeable operators can identify potential issues early and make informed adjustments during operation, ultimately leading to better results.

Emphasizing efficiency through maintenance and training will not only improve productivity but also extend the lifespan of the equipment.