The intricate world of ammunition assembly involves various components that work harmoniously to ensure efficiency and precision. A thorough comprehension of these elements is essential for enthusiasts and professionals alike. Each segment plays a pivotal role in the overall functionality, making it crucial to familiarize oneself with their arrangement and interconnections.

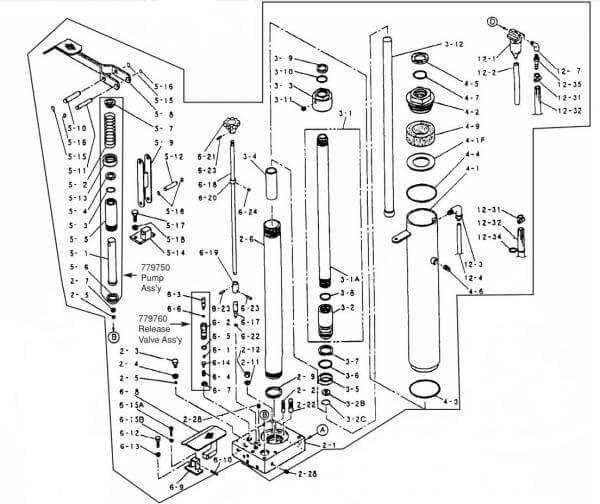

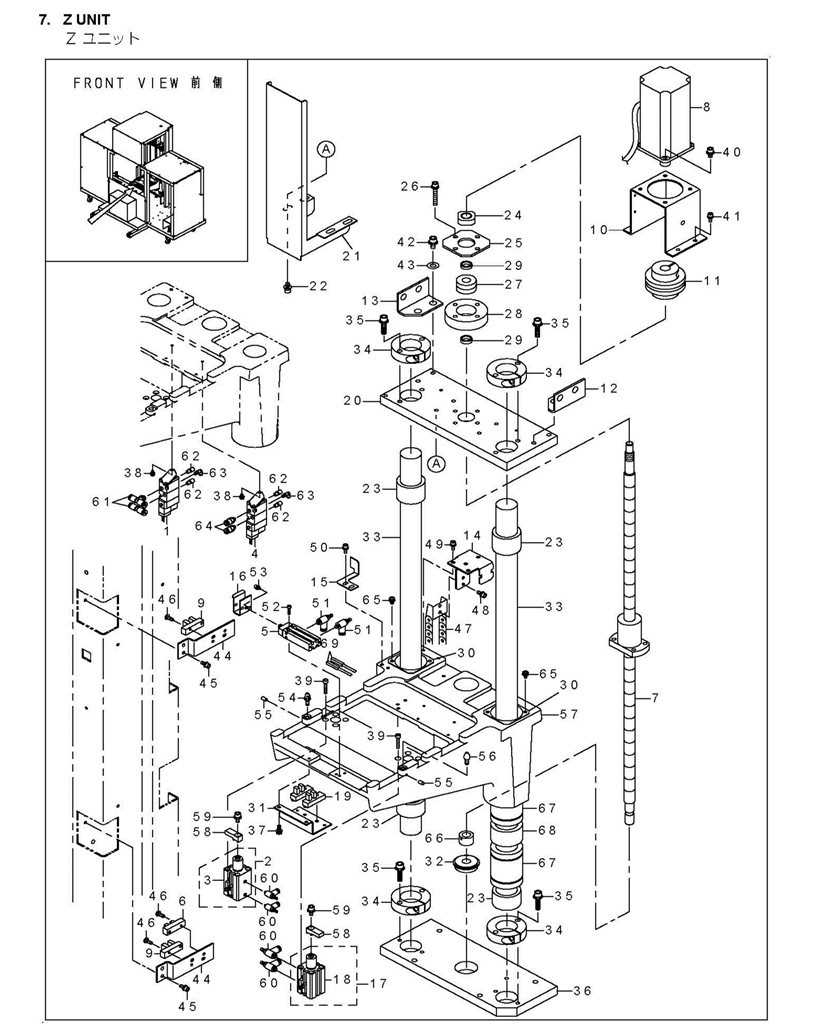

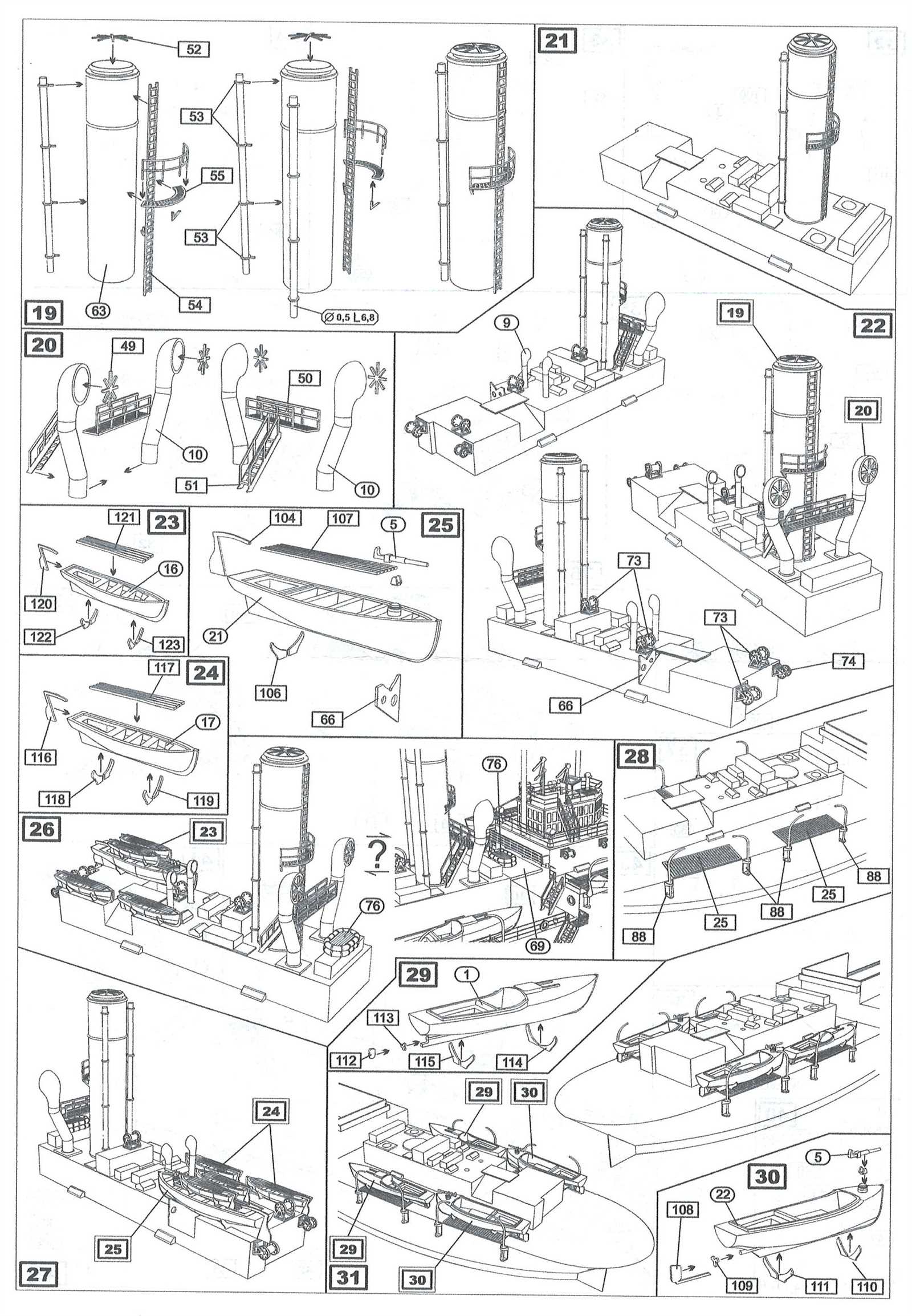

Visual representations of these components offer invaluable insights into their structure and operation. By exploring detailed layouts, users can identify each section’s specific function and contribution to the process. This knowledge not only enhances the reloading experience but also aids in troubleshooting and maintenance.

In this exploration, we will delve into the key features and functionalities of these mechanisms. Understanding the layout can empower users to optimize their setup, ensuring a seamless workflow while enhancing overall performance. A well-organized system is fundamental for achieving consistent results in ammunition preparation.

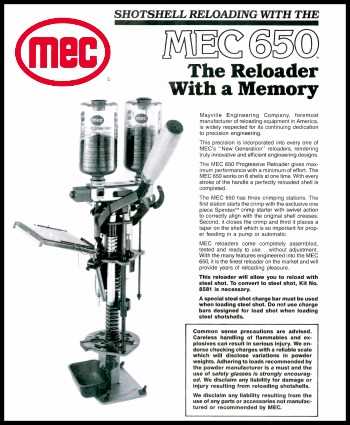

Mec Reloader Overview

This section provides a comprehensive look at a specific type of equipment designed for ammunition assembly. Understanding its components and functionalities is essential for enthusiasts and professionals alike. The following details outline the essential features and benefits of this machine, enhancing the overall loading process.

| Feature | Description |

|---|---|

| Efficiency | Optimizes the loading cycle, allowing for quicker assembly of cartridges. |

| Durability | Constructed with robust materials, ensuring longevity and consistent performance. |

| Customizability | Offers various configurations to suit individual needs and preferences. |

| Precision | Engineered for accuracy, contributing to the reliability of the finished product. |

Importance of Reloading Equipment

Having the right tools for ammunition preparation is essential for enthusiasts and professionals alike. Quality equipment not only enhances the reloading process but also ensures safety and precision. Understanding the significance of reliable tools can lead to better outcomes and increased enjoyment in the activity.

Here are some key reasons why quality tools matter:

- Consistency: Well-designed instruments contribute to uniformity in ammunition, which is crucial for accuracy.

- Safety: Properly manufactured equipment minimizes the risk of accidents during the preparation process.

- Cost-effectiveness: Investing in durable tools can reduce overall expenses in the long run by allowing for repeated use.

- Customization: Reliable machinery enables users to tailor their loads to specific needs, enhancing performance for various applications.

- Efficiency: Quality equipment streamlines the process, allowing for quicker turnaround times without sacrificing quality.

Ultimately, the right tools can transform the experience of preparing ammunition, making it safer, more enjoyable, and efficient.

Understanding Reloader Parts Functionality

Grasping the essential components of ammunition assembly is crucial for both novice and experienced enthusiasts. Each element plays a significant role in ensuring the process is efficient and effective. By familiarizing oneself with the intricacies of these components, users can optimize their operations and enhance their overall experience.

The key functions of each segment contribute to the seamless workflow, allowing for precise and consistent outcomes. From the initial stages of material handling to the final stages of product readiness, understanding these roles is vital. A comprehensive knowledge empowers users to troubleshoot issues and make informed adjustments.

Moreover, recognizing how each piece interacts with others reveals the system’s complexity. This interconnectedness highlights the importance of maintenance and care, ensuring longevity and reliability in usage. Ultimately, a deeper comprehension leads to more successful and enjoyable assembly practices.

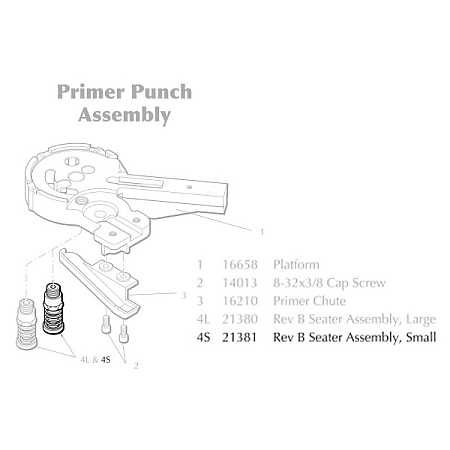

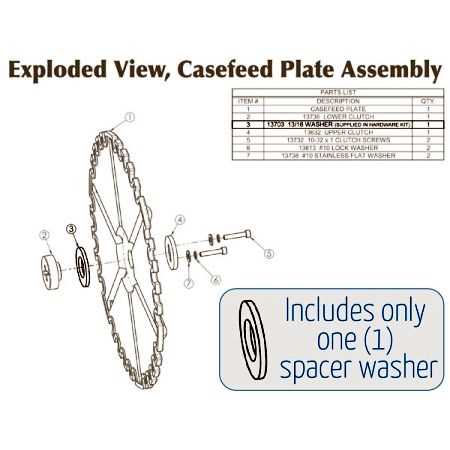

Common Components of Mec Reloaders

Understanding the fundamental elements involved in the reloading process can significantly enhance the efficiency and precision of ammunition crafting. These essential parts work together to streamline operations, ensuring consistent results for enthusiasts and professionals alike.

Key Elements

Among the primary components are the shell holders, which secure cases during the loading phase, and the charge bars that accurately dispense powder. Additionally, the resizing die plays a crucial role in ensuring that cases are returned to their original dimensions, facilitating a flawless reloading cycle.

Supporting Features

Other vital features include the primer seating mechanism, designed for precise placement, and various funnels that aid in the smooth transfer of materials. Collectively, these elements form a cohesive system that optimizes the reloading experience.

How to Read Parts Diagrams

Understanding visual representations of mechanical components is essential for effective assembly and maintenance. These illustrations provide a clear overview of individual elements and their relationships, aiding in troubleshooting and repairs.

To effectively interpret these visuals, consider the following steps:

- Familiarize Yourself with Symbols: Each representation uses specific symbols to denote various elements. Recognizing these is crucial for comprehension.

- Identify the Key: Most visuals include a legend or key that explains the symbols used. Review it before diving into the details.

- Study the Layout: Observe how components are arranged. This often reflects their function and interconnectivity.

- Trace Connections: Follow lines or arrows that indicate how elements link to one another. This can clarify assembly processes.

- Cross-Reference with Manuals: Consult accompanying documentation for additional context and explanations about specific parts.

By mastering these techniques, you can delve deeper into the intricacies of mechanical systems and ensure a smoother assembly experience.

Maintenance Tips for Reloader Parts

Proper upkeep of your ammunition assembly components is crucial for ensuring optimal performance and longevity. Regular attention not only enhances functionality but also prevents potential issues that could arise from neglect.

1. Clean Regularly: Dust and residue can accumulate, affecting the efficiency of your equipment. Utilize a soft brush or cloth to keep surfaces clear.

2. Lubricate Moving Parts: Application of appropriate lubricants helps minimize friction, reducing wear and tear. Make sure to choose products that are safe for your materials.

3. Inspect for Wear: Regularly examine components for signs of damage or fatigue. Early detection allows for timely replacements, ensuring consistent operation.

4. Store Properly: Maintain a dry and clean environment for your equipment. Proper storage prevents rust and deterioration, prolonging the life of your tools.

5. Follow Manufacturer Guidelines: Always refer to the specific instructions provided by the manufacturer. Adhering to their recommendations ensures that maintenance practices align with the design of your equipment.

Troubleshooting Common Issues

When engaging with equipment for ammunition preparation, encountering problems can be a common experience. Understanding typical challenges and their solutions is essential for maintaining efficiency and ensuring safety during operation.

Inconsistent Ammunition Quality: One frequent issue is the inconsistency in the final product. This can result from improper calibration or wear of specific components. Regularly inspect and adjust settings to ensure uniformity in every batch.

Feeding Failures: Malfunctions during the feeding process may arise due to debris or misalignment. Make it a habit to clean and inspect mechanisms frequently, ensuring all parts are correctly positioned and functioning smoothly.

Unusual Noises: Hearing unexpected sounds during operation can signal a problem. Identify the source of the noise, as it may indicate friction or loose components. Addressing these issues promptly can prevent more significant breakdowns.

Difficulty in Operation: If you find it challenging to operate the machinery, verify that all parts are well-lubricated and functioning as intended. Consult the user manual for troubleshooting steps and consider reaching out to professionals if issues persist.

By being proactive and attentive to these common issues, users can enhance the longevity of their equipment and achieve reliable results with each use.

Benefits of Upgrading Components

Enhancing various elements of a reloading system can lead to significant improvements in efficiency, precision, and overall performance. Upgrades can make the entire process smoother and more enjoyable for users, allowing for a more tailored experience.

Enhanced Performance

- Improved accuracy in ammunition production.

- Faster cycle times, leading to increased output.

- Greater reliability and reduced maintenance needs.

Customization Options

- Ability to choose components that suit specific needs.

- Opportunities for personalization in the setup.

- Access to advanced technologies for better results.

Where to Find Replacement Parts

When seeking components for your equipment, it’s essential to explore various avenues to ensure you find the right pieces for optimal functionality. Whether you are maintaining, upgrading, or repairing, knowing where to look can save time and money.

Online Retailers: Numerous online platforms specialize in offering a wide selection of components. Websites dedicated to outdoor activities or specialized equipment often have detailed catalogs and competitive prices. Check reviews and ratings to ensure reliability.

Manufacturer’s Website: The official website of the original manufacturer is usually the best place to start. They typically offer genuine components and may provide detailed specifications to assist you in making the right choice.

Local Shops: Don’t overlook local retailers and specialized stores. They can provide personalized service and may have the specific items you need on hand, saving you shipping time.

Online Marketplaces: Websites like eBay or Amazon can be great resources for finding both new and used components. Look for sellers with good ratings and consider the condition of the items before purchasing.

Forums and Community Groups: Engaging with online forums or local clubs can connect you with fellow enthusiasts who may have spare components or valuable advice on where to find what you need. Networking within the community can lead to unexpected finds.

By exploring these options, you can effectively locate the necessary components to keep your equipment performing at its best.

Comparing Mec Reloaders with Others

This section explores the distinctions between various ammunition loading systems, focusing on functionality, efficiency, and user experience. Understanding these differences can aid enthusiasts in making informed choices based on their specific needs and preferences.

Key Features to Consider

- Loading speed

- Durability of materials

- Ease of setup and operation

- Customization options

Pros and Cons

- Efficiency: Some systems offer faster cycle times but may compromise on consistency.

- Quality: Higher-end models often provide better build quality, enhancing longevity.

- Price: Budget-friendly options are available, but they might lack advanced features.

Safety Precautions During Reloading

Ensuring a secure environment while preparing ammunition is crucial to prevent accidents and promote a safe experience. Adopting specific measures can significantly reduce risks and enhance overall safety.

- Always wear appropriate protective gear, including safety glasses and gloves.

- Maintain a clean and organized workspace to avoid distractions and hazards.

- Store components in clearly labeled containers to prevent confusion.

- Keep flammable materials away from the reloading area.

In addition, it is vital to:

- Carefully read and follow manufacturer instructions for each component.

- Double-check measurements and avoid overloading any cartridge.

- Never rush the process; take your time to ensure accuracy.

- Have a fire extinguisher nearby and know how to use it.

By implementing these guidelines, you can foster a safer environment during the ammunition preparation process.

Resources for Further Learning

Exploring the intricate world of equipment assembly can significantly enhance your understanding and skills. This section provides valuable resources for anyone eager to deepen their knowledge, offering insights into various components and their functionalities.

Online Forums and Communities

Participating in dedicated online platforms can be a great way to connect with enthusiasts and experts alike. Websites like Reddit and specialized forums allow users to share experiences, ask questions, and delve into discussions that can lead to ultimate mastery of the subject.

Books and Manuals

Comprehensive guides and manuals are essential for anyone looking to refine their skills. Look for publications that cover assembly techniques, troubleshooting methods, and detailed overviews of various mechanisms. These resources provide both theoretical knowledge and practical insights, making them invaluable for learners.