Modern tools designed for fastening tasks are known for their efficiency and reliability. Understanding the internal structure and various elements that contribute to the smooth operation of such devices is essential for maintenance and repairs. By breaking down the components, users can easily identify areas that may need attention or replacement, ensuring optimal performance.

For those working in construction or carpentry, having a clear understanding of how each element interacts with the rest of the device can be a game changer. Whether you’re dealing with a trigger mechanism, motor assembly, or fastener driver, knowing how these parts function together allows for quick troubleshooting and effective use of the tool.

In the following guide, we will explore the key elements of one such fastening tool, offering a detailed breakdown of each component. This knowledge will empower users to maintain and repair their devices with greater confidence and ease.

Understanding the Dewalt DCN623 Components

Every tool is built from various elements that contribute to its efficiency and performance. By familiarizing yourself with these key elements, you gain better insight into how the device operates and how each component interacts to provide a seamless experience. Understanding these individual elements helps in proper maintenance and troubleshooting when necessary.

Core structural elements make up the physical framework, ensuring durability and reliability. These sections house essential mechanisms that drive the tool’s functionality. The material and design of these parts are engineered for long-lasting use.

Next are the internal mechanisms responsible for delivering power and precision. These components work together to manage everything from energy distribution to precise control over the device’s output, allowing for consistent and accurate performance.

Another important aspect includes user controls, which allow

Key Parts of the Dewalt DCN623

Understanding the critical components of this versatile tool is essential for anyone looking to maintain or repair it. Each element plays a crucial role in ensuring smooth operation and efficient performance. By familiarizing yourself with the main sections of the device, you can better diagnose potential issues and ensure long-lasting functionality.

Nail Drive Mechanism is the powerhouse behind the tool’s function, responsible for propelling fasteners with precision and strength. Regular upkeep of this part is vital to prevent misfires or reduced efficiency.

The Magazine holds and feeds fasteners into the tool, making it a central feature for seamless operation. Ensuring it remains clean and free of obstructions is key to preventing jamming or delays during work.

One of the most important elements, the Trigger System, controls the release of fasteners. This part should be regularly checked for smoothness and responsiveness to ensure optimal control

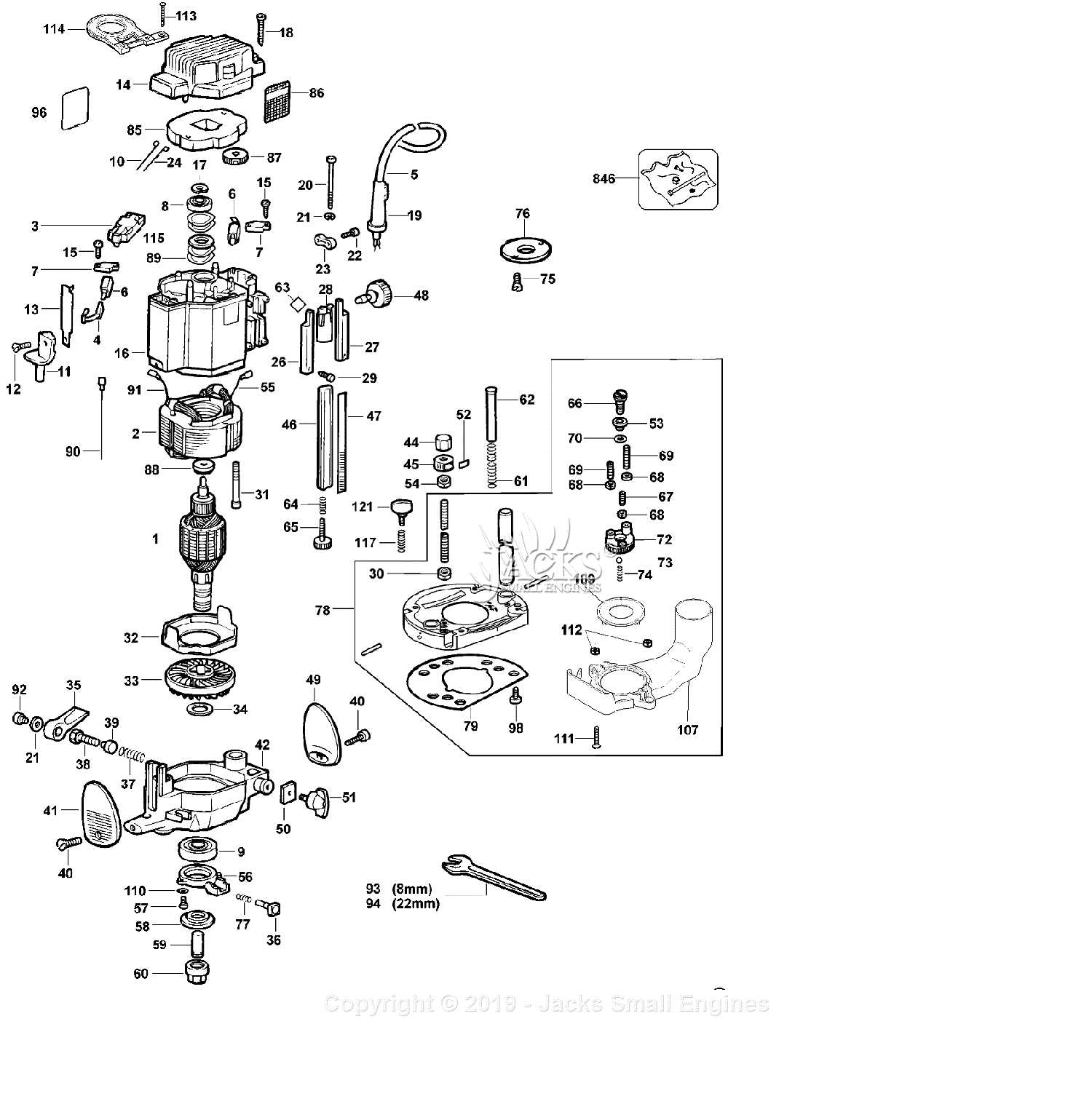

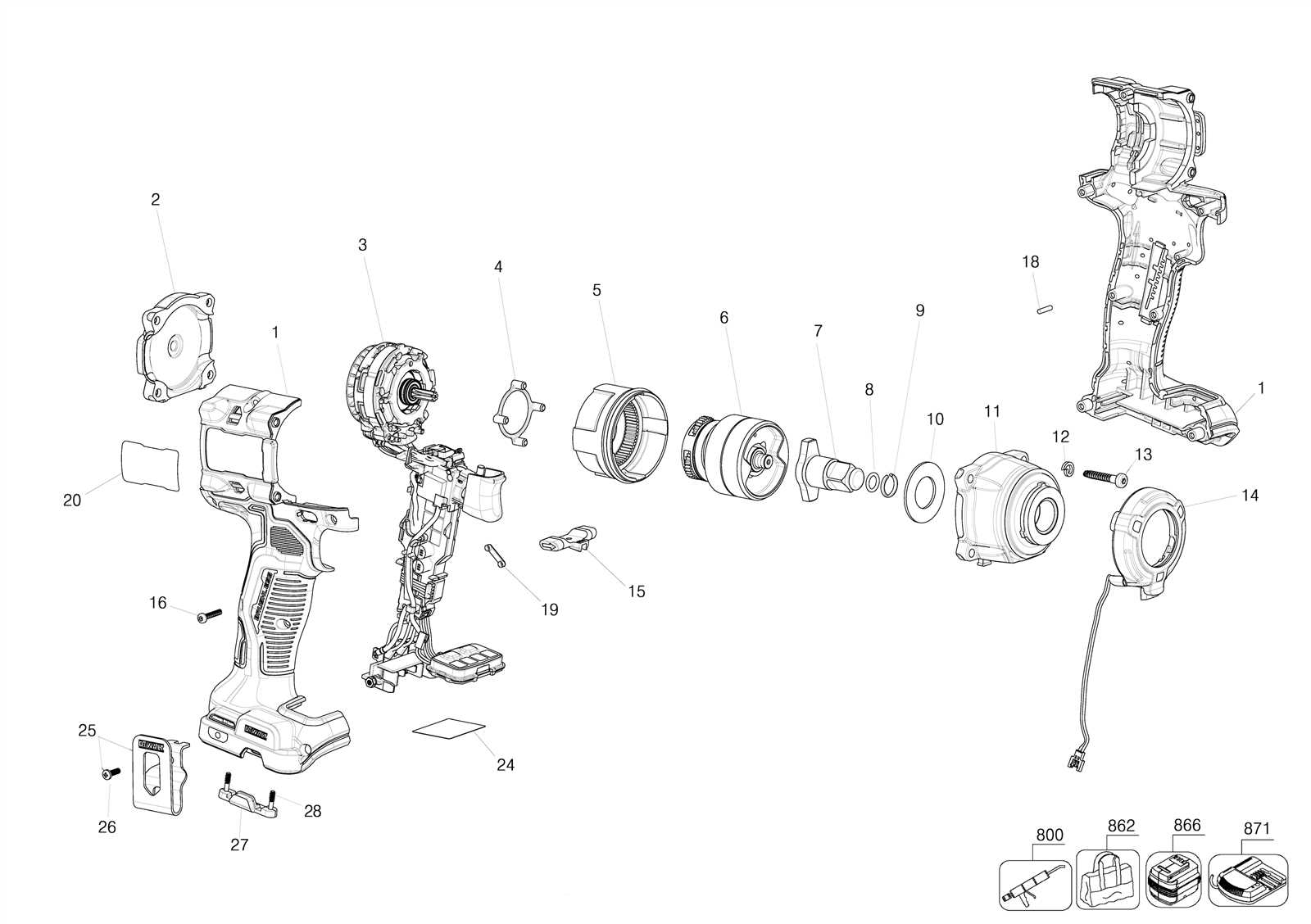

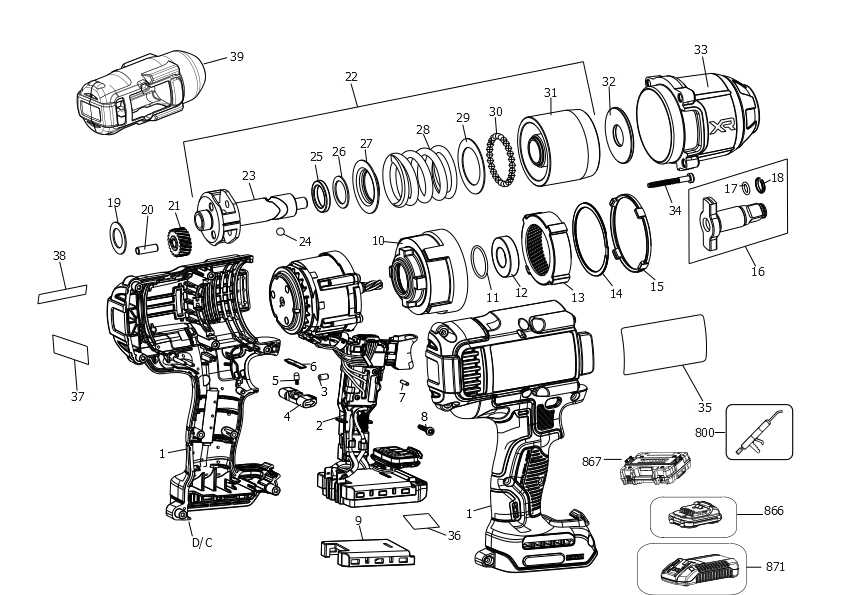

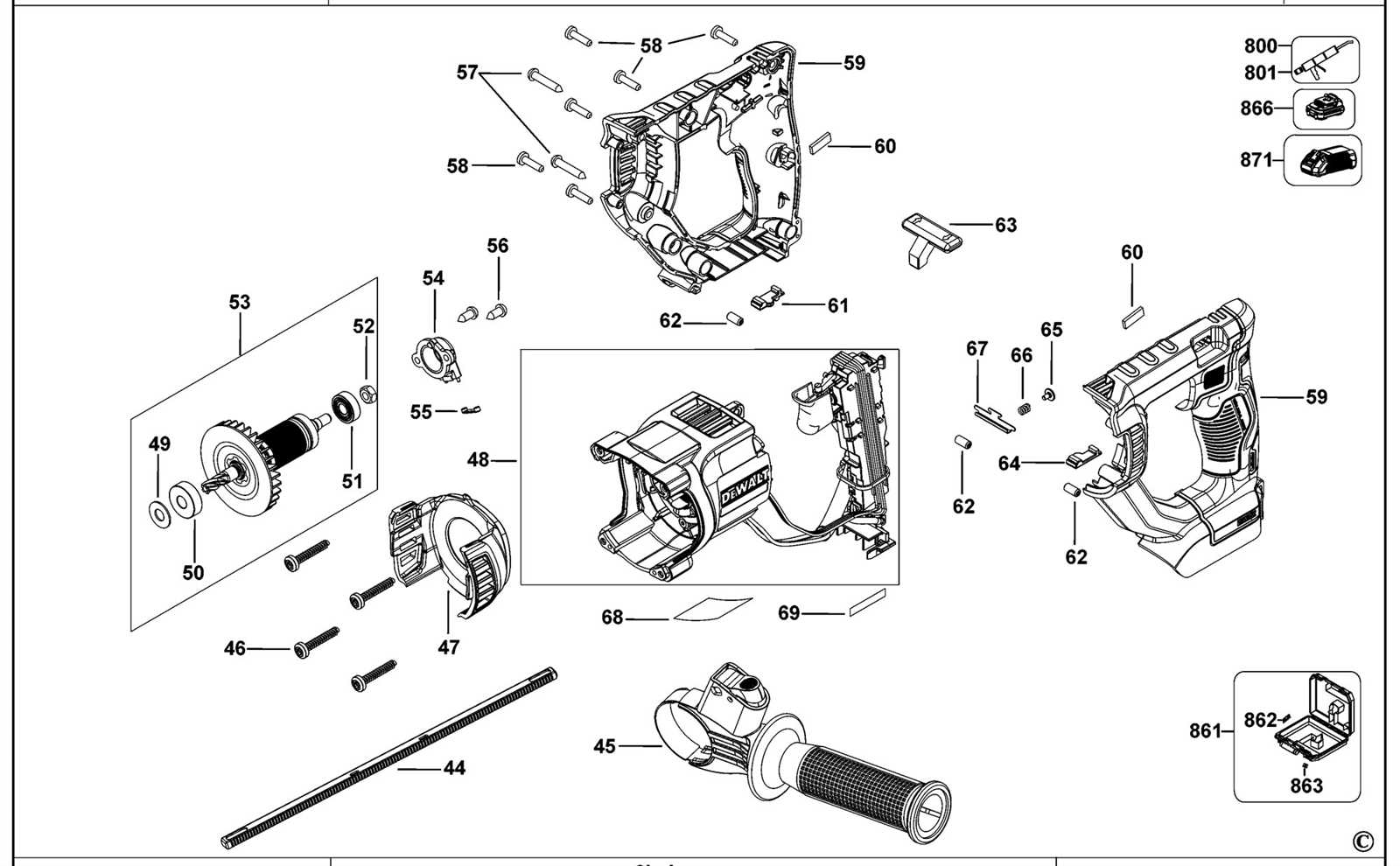

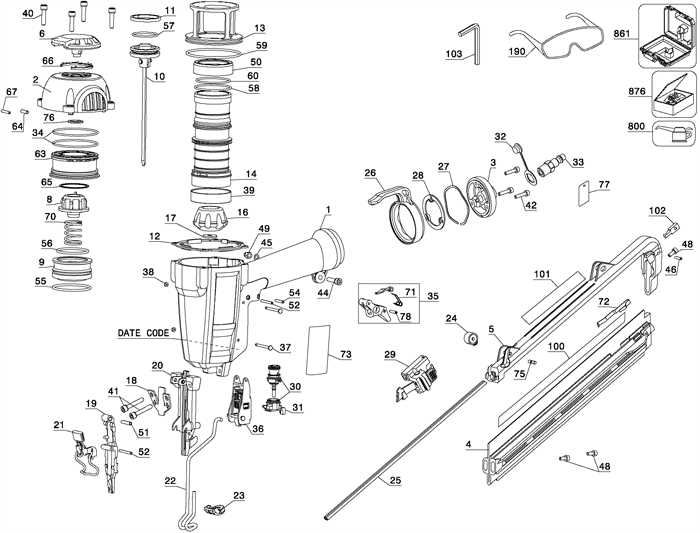

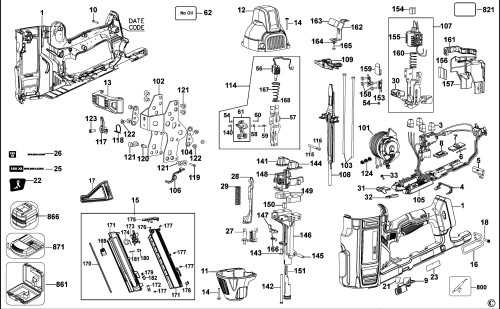

Exploded View of the Nail Gun

The breakdown of this tool offers a detailed visual representation of its internal components. It provides a clear view of how various sections are assembled, making it easier to understand how each element interacts within the mechanism. This helps in identifying key elements and their functions within the overall operation of the device.

Main Components Overview

The visual disassembly includes the core elements such as the body frame, trigger system, and fastener feeding mechanism. Each piece plays a vital role in the smooth functionality of the equipment. Observing these parts in a separated view allows for a better understanding of their individual roles.

Internal Mechanism Layout

Additionally, the internal workings, including the piston, air chamber, and locking system, are showcased in the exploded layout. This section highlights how the internal pressure and mechanical movements work together to ensure efficient nail delivery and reloading.

| Component |

|---|

| Component | Function |

|---|---|

| Power Source | Supplies energy for operation. |

| Trigger Mechanism | Controls the activation of the tool. |

| Driving Mechanism | Engages and disengages the fastener. |

| Housing | Protects internal components and provides a grip. |

Interaction of Components

The efficiency of the device relies on the seamless interaction among its elements. Each part must work in harmony to ensure reliable performance. Understanding this interaction helps in diagnosing issues and performing effective repairs.

Upgrading the Dewalt DCN623 with New Parts

Enhancing your tool’s performance with new components can significantly improve its functionality and lifespan. Whether you’re looking to boost efficiency or address wear and tear, upgrading essential elements is a smart investment for any professional or DIY enthusiast.

Here are some considerations when planning your upgrades:

- Assessing Needs: Determine which aspects of the tool require improvement, such as battery life, speed, or precision.

- Compatibility: Ensure that the new components are compatible with your existing equipment to avoid any issues during installation.

- Quality: Invest in high-quality replacements to ensure durability and reliability in demanding tasks.

- Installation: Familiarize yourself with the installation process to ensure a seamless upgrade experience.

By focusing on these areas, you can effectively enhance your tool’s capabilities and extend its operational lifespan.

Troubleshooting Common Issues with Parts

When using power tools, it is essential to address any malfunctions that may arise from their components. Identifying the source of these issues can lead to improved performance and longevity of the equipment. This section will provide guidance on recognizing and resolving common problems associated with the elements of your device.

Here are some typical issues and their possible solutions:

- Tool not operating:

- Check the power source to ensure it is connected properly.

- Inspect the trigger mechanism for any obstructions.

- Inconsistent performance:

- Examine the integrity of the components for wear or damage.

- Ensure all connections are secure and free from corrosion.

- Excessive noise:

- Identify any loose parts that may be vibrating during operation.

- Lubricate moving elements to minimize friction.

- Frequent jamming:

- Clear any debris or obstructions from the feeding mechanism.

- Verify that the materials being used are suitable for the device.

By systematically addressing these common concerns, users can enhance the functionality and efficiency of their equipment, ensuring a smoother operation for all tasks at hand.