The intricate design of mechanical assemblies plays a crucial role in their functionality and efficiency. A comprehensive overview of these structures can significantly enhance one’s understanding of how individual elements interact within a system. Recognizing the various components and their placements is essential for anyone involved in maintenance or engineering.

In this section, we will explore the arrangement of different elements, highlighting their specific roles and connections. By breaking down the assembly into its fundamental parts, users can gain insights into the overall operation and troubleshooting processes. This knowledge not only aids in effective repairs but also fosters a deeper appreciation of mechanical ingenuity.

As we delve into the layout, we will focus on the unique characteristics of each segment. Understanding these distinctions is vital for optimizing performance and ensuring the longevity of the system. Mastery of this information will empower users to make informed decisions and enhance their technical proficiency.

This section aims to provide a comprehensive understanding of the various components and their functions within the specified assembly. By breaking down the intricate relationships between each element, readers will gain insight into how these pieces work together to create a cohesive unit. This overview sets the stage for a deeper exploration of each component’s significance in the overall system.

Key Components

The following table outlines the main elements of the assembly, highlighting their respective roles and importance:

| Component Name | Description | Function |

|---|---|---|

| Receiver | The main housing that holds all other elements. | Provides structural support and houses the firing mechanism. |

| Barrel | A long tube through which projectiles are fired. | Directs the projectile’s path and ensures accuracy. |

| Trigger Assembly | Includes the trigger and related mechanisms. | Controls the firing process by releasing the firing pin. |

| Magazine | Holds ammunition and feeds it into the firing chamber. | Ensures a steady supply of projectiles for firing. |

| Sight | A device used for aiming at targets. | Enhances accuracy and helps in targeting. |

| Safety Mechanism | Prevents accidental discharges. | Ensures user safety by controlling the firing function. |

Understanding Functionality

Each component plays a critical role in the assembly’s operation. Recognizing how these elements interact will enhance the user’s ability to effectively manage and maintain the system. The synergy of these parts is essential for optimal performance and reliability.

Importance of Accurate Diagrams

Precise representations of mechanical assemblies play a crucial role in the effective management and operation of machinery. These visual aids enable users to understand complex structures, ensuring that each component is correctly identified and utilized. Clarity in these illustrations can significantly reduce the likelihood of errors during maintenance and assembly processes, leading to enhanced efficiency and safety.

Enhancing Communication

Clear visuals facilitate better communication among technicians, engineers, and operators. When everyone involved can refer to a standardized illustration, misunderstandings can be minimized. This shared understanding promotes teamwork and expedites problem-solving when issues arise.

Facilitating Maintenance and Repairs

Detailed visual guides are invaluable during maintenance and repair tasks. They provide step-by-step instructions that help technicians identify where components are located and how they can be accessed or replaced. This level of detail not only speeds up the repair process but also ensures that tasks are performed correctly, ultimately prolonging the lifespan of the machinery.

| Benefits | Description |

|---|---|

| Improved Understanding | Facilitates comprehension of complex systems. |

| Reduced Errors | Minimizes mistakes in assembly and repairs. |

| Streamlined Processes | Enhances efficiency in maintenance activities. |

| Effective Training | Aids in training new employees on system layouts. |

Key Components Explained

This section provides an overview of essential elements that contribute to the functionality and performance of a specific mechanism. Understanding these components is crucial for effective maintenance and optimization.

Main Functional Elements

- Frame: The foundational structure that supports all other components and ensures stability.

- Trigger Mechanism: Responsible for initiating the operation, allowing for controlled engagement.

- Barrel: Guides the projectile during its launch, significantly influencing accuracy and velocity.

Supporting Features

- Stock: Provides a comfortable hold and aids in stability during operation.

- Sights: Enhances targeting precision by aligning the user’s line of sight with the intended trajectory.

- Magazine: Serves as the storage for ammunition, enabling quick reloads and efficient firing sequences.

Common Issues and Solutions

In the realm of mechanical devices, users often encounter various challenges that can affect performance and functionality. Addressing these concerns promptly can lead to improved efficiency and longevity of the equipment. Below are some frequently observed problems along with their effective remedies.

1. Inconsistent Operation: Many users report irregular functioning of their equipment, which may stem from wear and tear or improper maintenance. Regular inspections and timely replacements of worn components can help mitigate this issue, ensuring smooth operation.

2. Difficulty in Assembly: Complications during the assembly process can arise, often due to misalignment or lack of proper guidance. Referencing clear instructional materials can aid in correctly aligning parts, thus facilitating a more straightforward assembly experience.

3. Reduced Efficiency: Over time, the effectiveness of the machinery may diminish, often due to accumulation of debris or lack of lubrication. Regular cleaning and lubrication of moving parts can significantly enhance performance and extend the lifespan of the device.

Assembly Process Simplified

The assembly procedure can often seem daunting, yet breaking it down into manageable steps can facilitate a smoother experience. By understanding the sequence and requirements, anyone can confidently engage in the assembly task.

Here are the key phases to consider:

- Preparation:

- Gather all necessary components and tools.

- Ensure a clean workspace to avoid losing any items.

- Review the assembly instructions for clarity.

- Initial Assembly:

- Begin with larger components for a solid foundation.

- Follow the sequence outlined in the instructions closely.

- Utilize proper fastening techniques for stability.

- Final Adjustments:

- Inspect all connections to confirm security.

- Make any necessary adjustments to ensure proper alignment.

- Test the assembled structure to verify functionality.

By adhering to these simplified steps, the process can be transformed from a complex task into a straightforward endeavor, resulting in successful completion and satisfaction.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right instruments at hand is crucial for achieving optimal results. These essential implements not only streamline the repair process but also enhance efficiency, ensuring that every task is executed with precision and care.

Basic Hand Tools: A comprehensive set of hand tools is fundamental for any repair job. This includes wrenches, screwdrivers, and pliers, which are vital for loosening and tightening components effectively. Additionally, a reliable hammer is necessary for tasks that require more force.

Power Tools: For more complex repairs, power tools such as drills and grinders can significantly reduce the time and effort involved. These tools offer greater torque and speed, allowing for quick adjustments and modifications.

Safety Equipment: Personal safety should always be a priority. Utilizing protective gear, including gloves, goggles, and ear protection, is essential to prevent injuries while working.

In conclusion, equipping yourself with the right tools and safety gear will not only facilitate smoother repairs but also ensure a safer working environment.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the extended functionality of any equipment. By implementing a few simple practices, users can significantly enhance the lifespan and reliability of their devices. These practices not only help in avoiding costly repairs but also contribute to optimal performance.

Regular Inspection

Conducting routine checks can identify potential issues before they escalate. Look for signs of wear, damage, or loose connections. Addressing these concerns promptly can prevent further complications.

Cleaning and Lubrication

Maintaining cleanliness is crucial for optimal operation. Remove dirt, dust, and debris from all accessible areas. Additionally, regular lubrication of moving components minimizes friction and wear, thereby promoting smoother operation.

| Maintenance Activity | Frequency | Benefits |

|---|---|---|

| Visual Inspection | Monthly | Early detection of issues |

| Cleaning | Bi-weekly | Improved performance |

| Lubrication | Every 3 months | Reduced friction and wear |

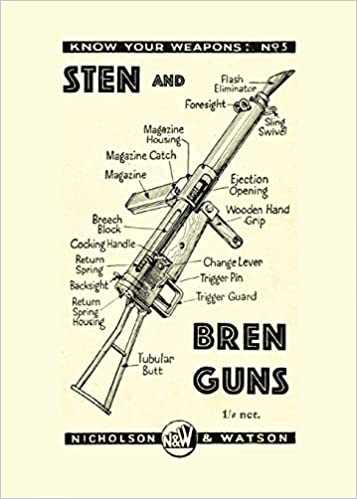

Differences Between Sten Models

The variations among different firearm designs can significantly impact their functionality and usability. Each iteration may introduce unique features, altering the overall performance and user experience. Understanding these distinctions is crucial for enthusiasts and collectors alike.

For instance, one model may incorporate enhancements in materials, contributing to a lighter build without sacrificing durability. Others might feature modifications in the firing mechanism, leading to differences in accuracy and rate of fire. Additionally, variations in magazine capacity can influence operational efficiency during use.

Moreover, aesthetic elements such as finishes and ergonomic designs can vary across models, affecting the handling and appeal. These factors not only define the individuality of each version but also reflect the evolution of design philosophies over time.

In conclusion, recognizing the unique characteristics of each firearm version is essential for informed choices, whether for historical appreciation or practical application in modern contexts.

Upgrading Sten Components

Enhancing the functionality and performance of a specific firearm involves a strategic approach to its various elements. This process not only improves efficiency but also aligns the weapon’s capabilities with the user’s requirements. A careful selection of enhancements can lead to a more reliable and effective tool for shooting enthusiasts and professionals alike.

One critical aspect of this improvement process is identifying components that can be optimized. Upgrading the trigger mechanism can significantly influence accuracy and responsiveness, while selecting higher-quality barrels may enhance precision and range. Additionally, investing in improved optics can provide better targeting capabilities, thus augmenting the overall shooting experience.

Moreover, attention to materials used in the construction of these elements can lead to increased durability and reduced weight. Choosing advanced composites or alloys may not only extend the life of the weapon but also contribute to a more balanced handling. Regular maintenance and timely upgrades ensure that the firearm remains in optimal condition, ready to perform at its best.

Safety Precautions During Assembly

Ensuring safety during the assembly process is crucial for preventing accidents and ensuring the longevity of the equipment. Following specific guidelines can significantly reduce the risk of injuries and enhance the overall effectiveness of the assembly task.

Personal Protective Equipment

Using appropriate protective gear is essential for safeguarding against potential hazards. Consider the following items:

- Safety goggles: Protect your eyes from debris.

- Gloves: Wear sturdy gloves to prevent cuts and abrasions.

- Hearing protection: Use earplugs or earmuffs in noisy environments.

- Steel-toed boots: Ensure foot protection from heavy objects.

Work Area Safety

Maintaining a clean and organized workspace is vital for safety. Follow these recommendations:

- Keep the area free from clutter and obstacles.

- Ensure proper lighting to enhance visibility.

- Store tools and materials securely to avoid tripping hazards.

- Regularly inspect equipment for any defects or wear.

Resources for Further Learning

For those seeking to enhance their understanding of related mechanisms and components, a variety of educational materials is available. Engaging with diverse resources can significantly improve knowledge and skills in this domain.

Books and manuals provide in-depth insights and are excellent starting points. Many of these texts cover essential theories and practical applications, making them suitable for both beginners and advanced learners.

Online platforms and courses offer interactive learning experiences. These resources often include video tutorials, quizzes, and forums for discussion, fostering a collaborative environment for knowledge exchange.

Additionally, joining community groups and forums can be invaluable. Networking with peers and experts in the field allows for sharing experiences, asking questions, and receiving guidance on complex topics.

Lastly, hands-on workshops and training sessions can deepen practical expertise. These events typically feature expert instructors and provide opportunities for real-world applications, reinforcing theoretical concepts.

Frequently Asked Questions

This section aims to address common inquiries related to the assembly and components of specific machinery. By providing clear and concise answers, we hope to enhance understanding and assist users in navigating potential challenges.

Many users wonder about the compatibility of various components with their equipment. It is essential to ensure that each element aligns with the specifications outlined by the manufacturer to guarantee optimal performance.

Another frequent question concerns maintenance practices. Regular upkeep is crucial for extending the lifespan of the machinery and preventing operational issues. Users are encouraged to follow recommended guidelines for cleaning and servicing.

Inquiries about troubleshooting common problems also arise. Identifying the source of a malfunction can often be simplified by consulting detailed resources or seeking advice from experienced technicians. Knowledge of typical issues can help in finding effective solutions.

Lastly, customers often seek information regarding the availability of replacement items. Understanding where to source quality alternatives can save time and ensure the continuous functionality of the equipment.