Understanding how each element fits into a cleaning system is essential for efficient maintenance and troubleshooting. By familiarizing yourself with the internal structure and external connections, you can ensure optimal performance and easily address any mechanical or operational challenges that may arise.

Whether you’re replacing a worn-out component or exploring how the system is designed to function, it’s helpful to break down the various elements. Each section plays a distinct role, working together to deliver effective and consistent results. A clear view of the system’s design aids in both repair and routine upkeep.

This guide offers a detailed examination of how the essential components interact, giving you the insight necessary for maintaining peak efficiency and resolving any issues swiftly. Understanding the flow and purpose of these interconnected parts is key to keeping your machine running smoothly.

Bissell Spotbot Pet: Key Components Overview

Understanding the essential mechanisms of this portable cleaning device can significantly improve its maintenance and performance. Each element plays a specific role in ensuring the effective removal of stains from various surfaces. By identifying the core features, users can maximize the device’s functionality and ensure long-lasting operation.

Water and Solution Tanks are designed to hold cleaning solutions and rinse water separately, allowing for efficient application during the cleaning process. Proper care of these tanks ensures continuous and effective use.

The Cleaning Brushes are responsible for agitating and loosening dirt from surfaces, delivering deeper and more thorough cleaning. Their regular inspection and cleaning are crucial for maintaining performance.

The control panel offers easy access to preset cleaning modes, making it user-friendly while adapting to different cleaning tasks with minimal effort.

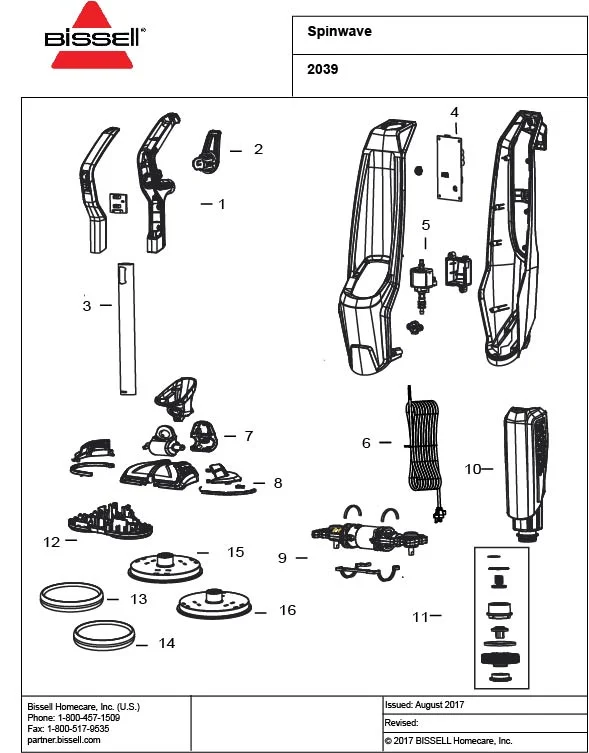

Understanding Internal Mechanisms and Parts

Grasping the inner workings of cleaning devices enhances the ability to maintain and repair them effectively. This section delves into the essential components that contribute to the functionality of these machines. By understanding how these elements interact, users can ensure optimal performance and longevity of their cleaning equipment.

Key Components and Their Functions

The main elements within these cleaning units serve specific purposes that collectively contribute to efficient operation. The following list outlines critical components and their roles:

- Motor: Powers the suction mechanism and other moving parts.

- Tank: Stores cleaning solution and collects debris.

- Brush System: Agitates dirt and stains for effective removal.

- Hoses: Facilitate the flow of cleaning solution and suction.

- Control Panel: Allows users to operate the machine and select settings.

Maintenance Tips for Optimal Performance

Proper care of these devices is essential for maintaining their efficiency. Here are some practical maintenance suggestions:

- Regularly empty and clean the tank to prevent clogs.

- Inspect hoses for blockages or damage.

- Check and replace brushes as needed to ensure effective cleaning.

- Keep the motor and electrical components free from dust and debris.

- Follow the manufacturer’s guidelines for periodic maintenance.

Exploring the Cleaning Solution Tank Layout

This section delves into the configuration of the liquid reservoir used in portable cleaning devices. Understanding the layout of this essential component is crucial for effective maintenance and optimal cleaning performance.

Key Features of the Liquid Reservoir

The cleaning solution tank is designed with several important features that enhance its usability:

- Capacity: The size of the reservoir determines how much cleaning solution can be used before needing a refill.

- Easy Access: Many models offer a straightforward opening mechanism for hassle-free filling and emptying.

- Indicator Markings: Level markers help users monitor the amount of solution left in the tank.

Maintenance Tips for the Reservoir

Proper care of the liquid tank ensures longevity and efficiency:

- Regularly clean the tank to prevent residue buildup.

- Inspect the seals and gaskets for wear to avoid leaks.

- Follow manufacturer guidelines for storage and usage to maintain optimal performance.

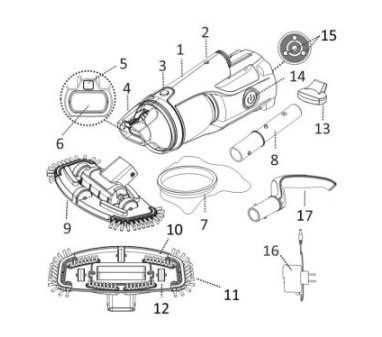

How the Brush Assembly Works

The brush mechanism plays a crucial role in maintaining cleanliness by effectively agitating dirt and debris from various surfaces. Its design allows for optimal performance, ensuring that the cleaning process is thorough and efficient. Understanding how this assembly functions can enhance the user’s experience and prolong the life of the cleaning device.

Components and Functionality

The brush assembly consists of rotating bristles that work in unison to dislodge embedded particles from carpets and upholstery. As the unit operates, the brushes spin rapidly, creating a scrubbing action that penetrates fibers, lifting away stubborn grime. This movement is powered by a motor that provides the necessary torque for effective cleaning.

Maintenance Tips

To ensure optimal performance, regular maintenance of the brush assembly is essential. This includes checking for tangles or blockages that may hinder movement and cleaning the bristles to prevent buildup of hair and debris. By keeping the assembly in good condition, users can maximize cleaning efficiency and extend the lifespan of the appliance.

Understanding the Suction System Design

The effectiveness of any cleaning device largely depends on its ability to create and maintain a powerful airflow. This section delves into the fundamental aspects of the suction mechanism, focusing on how it is engineered to remove dirt and debris from surfaces efficiently. By comprehending the design intricacies, users can better appreciate the technology behind the cleaning process.

The suction system typically consists of several key components that work in harmony to generate the necessary pressure differential. At its core, a motor drives a fan that pulls air through an intake, creating a vacuum effect. This design not only facilitates the removal of unwanted particles but also ensures optimal performance across various surfaces.

Additionally, the configuration of the suction pathway plays a critical role in enhancing efficiency. A well-designed system minimizes air leaks and optimizes the flow of air, which maximizes the cleaning power. Understanding these elements can significantly impact the overall effectiveness of the cleaning appliance.

Water and Solution Dispensing Parts

The effective distribution of liquid and cleaning solution is crucial for maintaining optimal performance in cleaning devices. These components work together to ensure that the appropriate amount of fluid is released onto surfaces, enhancing the cleaning process. Understanding the roles of these mechanisms is essential for proper maintenance and troubleshooting.

Reservoir and Pump System: The reservoir holds the cleaning solution, while the pump system facilitates the movement of liquid from the container to the cleaning mechanism. A malfunction in either of these elements can hinder the overall functionality.

Hoses and Connectors: Flexible tubing and connectors are vital for transporting the solution from the reservoir to the cleaning head. Regular inspection is necessary to prevent leaks or blockages that can disrupt the dispensing process.

Spray Nozzles: These components are responsible for dispersing the liquid onto the surface being cleaned. Ensuring that the nozzles are clear and functioning correctly is key to achieving an even application of the solution.

The Role of Filters in Operation

In any cleaning device, filters play a crucial part in ensuring effective performance and longevity. They are designed to trap dust, debris, and other particles, preventing them from circulating back into the air or contaminating the water used in the cleaning process. By maintaining cleanliness within the system, filters contribute to a more efficient operation and improved results.

Effective Filtration is essential for maintaining the integrity of the cleaning solution. When dirt and impurities are filtered out, the appliance can work optimally, allowing for better cleaning results on various surfaces. Regular maintenance and replacement of these components are vital to ensure that they function correctly, preventing clogs that can hinder performance.

Maintaining Filters is a key aspect of appliance upkeep. Users should be aware of the recommended replacement intervals and perform routine checks to ensure filters are free from buildup. This proactive approach not only enhances the cleaning effectiveness but also extends the life of the device, making it a worthwhile investment for any household.

Breakdown of the Hose and Attachments

This section delves into the various components associated with the flexible tubing and its accessories used in cleaning devices. Understanding these elements is essential for effective maintenance and optimal performance.

The flexible tubing and its attachments play a crucial role in the cleaning process. Here’s a closer look at these components:

- Flexible Hose: This part allows for easy maneuverability while cleaning various surfaces.

- Attachment Tools: Specialized implements that assist in targeted cleaning tasks. Common types include:

- Brush Tool: Ideal for removing dirt from carpets and upholstery.

- Crevice Tool: Perfect for reaching tight spaces and corners.

- Stain Tool: Designed for treating stubborn stains on various surfaces.

Regular inspection and proper care of these components can enhance the overall functionality of the cleaning unit.

Motor Configuration and Functionality

The internal structure and operation of a cleaning device’s motor are crucial for its overall performance. This section explores how the motor is designed, the various components involved, and their specific roles in facilitating efficient cleaning. Understanding these elements is essential for troubleshooting and maintenance, ensuring optimal functioning.

Key Components

The motor typically consists of several essential elements, including the rotor, stator, and brushes. The rotor, which rotates when electrical energy is applied, is responsible for generating the necessary force to drive the device. The stator, on the other hand, remains stationary and produces a magnetic field that interacts with the rotor. Additionally, brushes are used to maintain electrical contact between the rotating rotor and the power source, ensuring smooth operation.

Operational Mechanics

When the device is powered on, electrical current flows through the motor, creating a magnetic field in the stator. This magnetic field interacts with the rotor, causing it to spin rapidly. The rotation of the rotor drives various mechanical components, enabling tasks such as suction and agitation. Regular maintenance of the motor, including cleaning and inspection of the brushes and rotor, can significantly enhance the longevity and effectiveness of the cleaning apparatus.

How to Replace Key Parts

Maintaining your cleaning device is essential for optimal performance, especially when certain components wear out over time. This section outlines the steps to effectively swap out crucial elements, ensuring your machine runs smoothly and efficiently.

Identifying Components for Replacement

Before beginning the replacement process, it is important to determine which components need attention. Commonly replaced items include:

- Hoses

- Filters

- Brushes

- Water tanks

Steps for Replacing Components

Follow these steps to replace the identified components:

- Unplug the Device: Ensure the machine is turned off and disconnected from the power source.

- Remove the Affected Component: Gently detach the worn or damaged part from the machine. Refer to the user manual for specific instructions.

- Install the New Component: Align the new piece correctly and secure it in place. Make sure it fits snugly.

- Test the Device: Once everything is reassembled, plug the machine back in and conduct a test run to confirm proper functionality.

Regularly checking and replacing components not only extends the lifespan of your cleaning equipment but also enhances its efficiency.

Maintenance Tips for Long-Lasting Use

To ensure the durability and efficiency of your cleaning device, proper upkeep is essential. Regular maintenance not only enhances performance but also extends the lifespan of the machine. By following a few simple guidelines, you can keep your equipment in excellent condition for years to come.

Regular Cleaning: It is crucial to keep the machine clean after each use. Remove any debris or residue that may accumulate in the tanks and brushes. Wipe down the exterior to prevent dust buildup.

Check Components: Periodically inspect all components for wear and tear. Pay close attention to brushes and filters, as these parts can significantly affect performance. Replace any worn items promptly to maintain optimal functionality.

Store Properly: When not in use, store the device in a cool, dry place. Avoid exposure to extreme temperatures or humidity, which can damage internal parts. Proper storage helps preserve the integrity of the machine.

Follow Manufacturer Guidelines: Always refer to the manufacturer’s instructions for specific maintenance recommendations. Adhering to these guidelines ensures that you are using the device correctly and taking the necessary steps for its care.

By implementing these simple maintenance practices, you can enjoy efficient operation and a longer lifespan for your cleaning equipment.

Troubleshooting Common Mechanical Issues

When dealing with a cleaning device, understanding the typical mechanical challenges can enhance performance and prolong its lifespan. Identifying and resolving these issues requires a systematic approach to ensure optimal functionality.

Identifying Performance Problems

Devices may exhibit reduced suction or inconsistent operation due to clogged components or worn-out mechanisms. Regularly inspecting the hoses, brushes, and filters for blockages or damage is crucial. Cleaning or replacing these parts can significantly improve performance.

Addressing Noise and Vibration

Unusual noises or excessive vibrations can indicate underlying problems within the unit. These may arise from loose screws, misaligned components, or debris caught in moving parts. Tightening connections and ensuring all parts are properly aligned can help mitigate these issues.