When it comes to maintaining the efficiency of your climate control unit, having a clear understanding of its internal structure is essential. A comprehensive overview of the various elements involved can greatly enhance your ability to troubleshoot and perform necessary repairs. By familiarizing yourself with these components, you empower yourself to make informed decisions regarding maintenance and upgrades.

Each part plays a crucial role in the overall functionality, contributing to the seamless operation of the entire system. Recognizing how these elements interconnect allows for better insight into potential issues and their resolutions. This knowledge is not only beneficial for regular upkeep but also aids in optimizing performance.

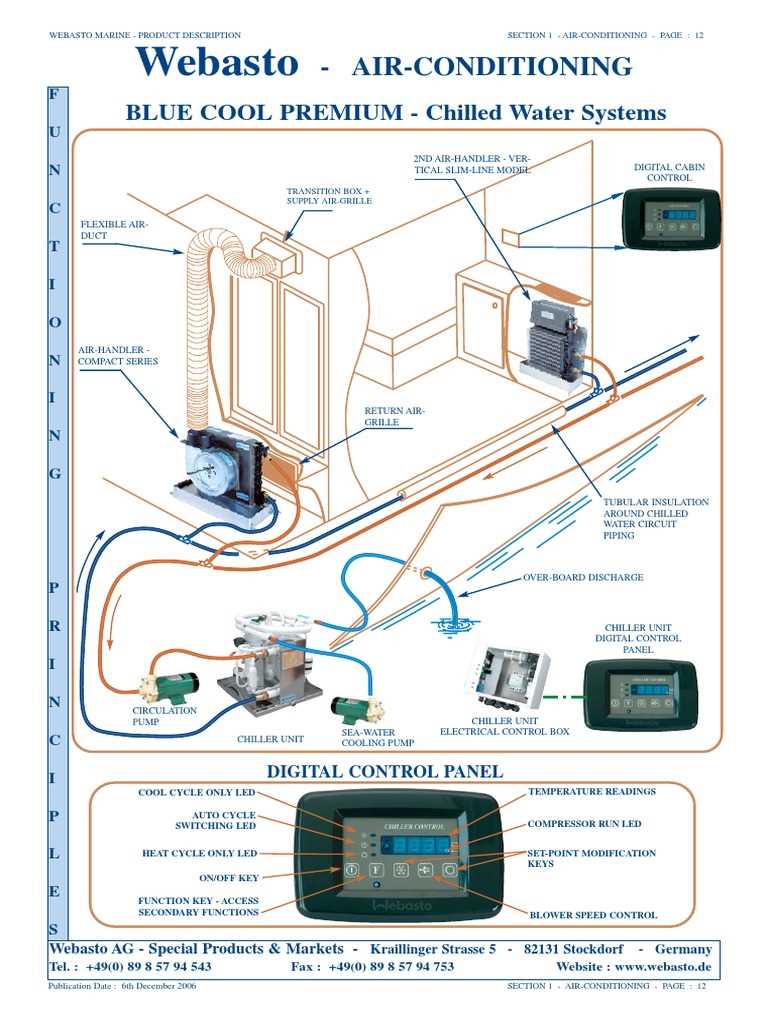

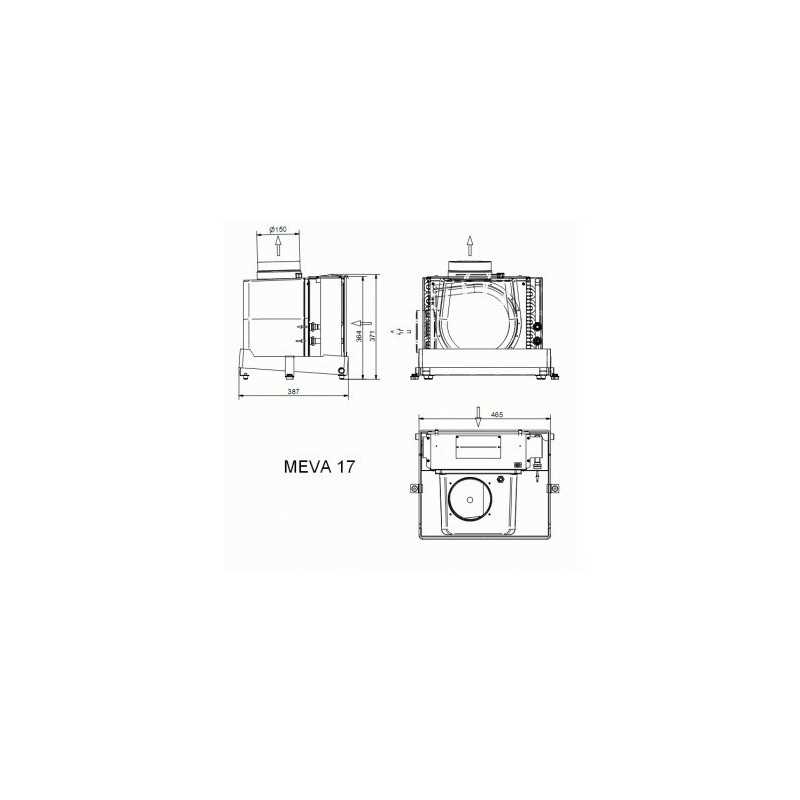

In this exploration, we will delve into the intricate relationships between these components, providing a visual representation that clarifies their functions. Understanding these connections is vital for anyone looking to enhance the longevity and reliability of their cooling apparatus.

Cruisair Parts Overview

This section provides a comprehensive look at essential components involved in marine air conditioning systems. Understanding the different elements is crucial for effective maintenance and troubleshooting. Each unit consists of various mechanisms that work together to ensure optimal performance and comfort on board.

Key Components

The main elements typically include the compressor, evaporator, and condenser. Each plays a vital role in the refrigeration cycle, contributing to the overall efficiency and effectiveness of the system. Familiarity with these components can significantly enhance the maintenance process.

Maintenance Tips

Regular inspection of these crucial mechanisms is essential for longevity and performance. It is advisable to clean filters and check for any signs of wear and tear. Staying proactive can prevent larger issues and ensure the system operates smoothly.

Understanding Cruisair Components

Grasping the intricacies of marine air conditioning systems involves familiarizing oneself with the various elements that contribute to their functionality. Each component plays a vital role in ensuring optimal performance and efficiency, and recognizing their interactions can greatly enhance maintenance and troubleshooting efforts.

Core Elements: At the heart of these systems are several key units, including the compressor, evaporator, and condenser. The compressor is responsible for circulating refrigerant, while the evaporator absorbs heat from the cabin, and the condenser releases it outside. Understanding how these units work together is essential for effective operation.

Auxiliary Features: Beyond the primary components, there are additional features such as control panels, filters, and ducting systems. Control panels allow users to set desired temperatures, while filters ensure clean airflow. Proper maintenance of these auxiliary elements is crucial for sustaining performance and prolonging the lifespan of the overall system.

By comprehending the structure and function of these components, users can better appreciate their marine cooling systems, leading to improved maintenance practices and enhanced comfort while at sea.

Benefits of Using Diagrams

Utilizing visual representations significantly enhances comprehension and retention of complex information. By breaking down intricate concepts into easily digestible components, these illustrations serve as valuable tools for learning and reference.

Enhanced Understanding

Visual aids facilitate a deeper grasp of subjects by presenting data in a structured format. Here are some advantages:

- Clarity: Simplifies complex ideas.

- Focus: Highlights key elements effectively.

- Memory Aid: Supports better recall of information.

Improved Communication

Visual formats enhance dialogue among teams and stakeholders. Benefits include:

- Shared Understanding: Aligns perspectives.

- Efficient Discussions: Reduces ambiguity in communication.

- Quick Reference: Offers an accessible overview for quick consultations.

Key Parts of Cruisair Systems

This section explores the essential components of marine climate control units, emphasizing their roles in efficient operation and user comfort.

- Compressor: The heart of the system, responsible for circulating refrigerant and maintaining desired temperatures.

- Condenser: This element dissipates heat, converting refrigerant from gas to liquid form.

- Evaporator: Essential for absorbing heat, this component allows the refrigerant to vaporize and cool the air.

- Expansion Valve: Regulates the flow of refrigerant into the evaporator, ensuring optimal pressure and performance.

Understanding these fundamental elements can greatly enhance maintenance and efficiency, leading to an ultimate improvement in onboard comfort.

How to Read a Parts Diagram

Understanding the visual representation of components can significantly enhance your ability to navigate and identify essential elements in a system. This guide will provide insights on interpreting these illustrations effectively.

To begin, familiarize yourself with the key features:

- Legend: This section explains symbols and notations used in the visual.

- Labels: Each element is typically marked for easy identification.

- Groupings: Components are often organized into sections based on functionality.

Follow these steps for effective interpretation:

- Study the legend to understand symbols.

- Identify each labeled component.

- Observe groupings to grasp relationships between elements.

- Refer to accompanying documentation for detailed descriptions.

By mastering these techniques, you’ll enhance your comprehension and become adept at locating necessary components swiftly.

Common Issues with Cruisair Units

Air conditioning systems on boats are essential for comfort, but they can encounter various problems over time. Understanding these common challenges can help users maintain optimal performance and ensure a pleasant experience on the water.

-

Insufficient Cooling:

This issue often arises due to dirty filters, blocked air intakes, or low refrigerant levels. Regular maintenance and inspections are crucial.

-

Unusual Noises:

Strange sounds such as grinding or rattling may indicate loose components or wear in the system. Identifying the source early can prevent further damage.

-

Water Leakage:

Leaks can occur due to clogged drain lines or damaged seals. Prompt attention to these issues is essential to avoid water damage.

-

Electrical Problems:

Frequent tripping of circuit breakers or malfunctioning controls can signal electrical faults. Checking connections and circuits can help troubleshoot these problems.

-

Poor Airflow:

This can be caused by blocked ducts or failing fans. Ensuring that vents are clear and fans are operational is key to maintaining good airflow.

By recognizing these typical challenges and addressing them promptly, users can enhance the reliability and efficiency of their onboard cooling systems.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your equipment requires regular care and attention. By adopting a proactive approach to upkeep, you can prevent issues and enhance efficiency, ultimately prolonging the lifespan of your system.

Regular Inspections

- Conduct frequent visual checks for any signs of wear or damage.

- Examine seals and connections to ensure proper function.

- Look for leaks or unusual sounds during operation.

Routine Cleaning

- Clean filters regularly to maintain airflow and efficiency.

- Remove dust and debris from components to prevent overheating.

- Utilize appropriate cleaning solutions for different materials.

Replacement Parts Availability

Ensuring the availability of essential components is crucial for maintaining the efficiency and longevity of any system. Access to high-quality replacements can significantly impact performance and reliability, making it imperative to explore various sources for procurement.

Sources for Acquisition

- Authorized Dealers: Certified vendors often offer genuine components with warranties.

- Online Retailers: E-commerce platforms provide a wide range of options and competitive pricing.

- Local Distributors: Nearby suppliers may have immediate availability for quick replacements.

- Aftermarket Suppliers: Alternative sources can offer cost-effective solutions, though quality may vary.

Considerations for Selection

- Quality Assurance: Verify the credibility of the source to ensure component reliability.

- Compatibility: Ensure that the replacement matches specifications for seamless integration.

- Warranty Terms: Evaluate the warranty offered to protect against defects or failures.

- Customer Support: Check for assistance options in case of issues with the acquired items.

Installation Guidelines for Components

Proper installation of system elements is crucial for optimal performance and longevity. Following these guidelines ensures that each part functions effectively, contributing to the overall efficiency of the unit.

Before beginning the installation process, it is essential to gather all necessary tools and components. Ensure that the work area is clean and organized to avoid any distractions or mistakes.

| Step | Description |

|---|---|

| 1 | Review the installation manual thoroughly to understand specific requirements. |

| 2 | Identify the location for each component, ensuring compatibility and accessibility. |

| 3 | Securely fasten each part according to specifications, using the appropriate tools. |

| 4 | Conduct a final inspection to verify that all elements are correctly installed and connected. |

Adhering to these steps will lead to a successful installation, paving the way for efficient operation and reducing the likelihood of future issues.

Comparison of OEM and Aftermarket Parts

When considering components for your system, the choice often lies between original manufacturer offerings and alternative options. Each category presents unique advantages and drawbacks, impacting performance, reliability, and cost. Understanding these distinctions can guide you toward making an informed decision that best suits your needs.

Original equipment manufacturer solutions are designed specifically for compatibility and performance, ensuring a precise fit and adherence to quality standards. This often translates to enhanced longevity and efficiency, making them a preferred choice for those seeking ultimate reliability.

In contrast, alternative options frequently offer lower prices and broader availability, appealing to budget-conscious consumers. However, variations in quality and compatibility may arise, necessitating careful consideration. Delving into user reviews and warranty offerings can provide additional insights into these alternatives.

Ultimately, the decision between these two types hinges on individual priorities, such as cost, performance, and long-term satisfaction. Assessing both options in relation to your specific circumstances will lead to the best outcome for your system’s needs.

DIY Repairs: What You Need to Know

Embarking on home repairs can be both rewarding and challenging. Understanding the essentials can significantly enhance your experience, making it more efficient and less daunting.

Before diving into any project, consider the following points:

- Assess Your Skills: Be honest about your capabilities. Know when to tackle a task and when to seek professional help.

- Gather Tools: Ensure you have the necessary equipment ready. Common tools include screwdrivers, wrenches, and pliers.

- Research: Utilize online resources, tutorials, and forums to gain insights on your specific repair.

Here are steps to guide you through the process:

- Identify the Issue: Understand what needs fixing to avoid unnecessary work.

- Gather Materials: Purchase or find the required supplies for the job.

- Follow Instructions: Adhere to guides or manuals closely to ensure accuracy.

- Test the Repair: After completing your work, test the area to ensure functionality.

With patience and diligence, you can achieve satisfying results in your repair endeavors.

Seeking Professional Help: When to Call

Recognizing when to reach out to an expert can significantly impact the longevity and efficiency of your equipment. There are specific indicators that suggest it may be time to consult with a qualified technician rather than attempting a DIY solution.

Signs It’s Time to Call a Professional

- Persistent issues that reoccur despite troubleshooting efforts.

- Unusual noises or smells that indicate potential malfunction.

- Visible damage or wear that requires specialized tools or knowledge.

Benefits of Professional Assistance

- Expert diagnosis that ensures accurate problem identification.

- Access to specialized tools and parts that may not be available to the general public.

- Long-term savings through proper repair versus frequent temporary fixes.