The efficient functioning of a heating system relies on the intricate arrangement of its elements. Each component plays a vital role, contributing to the overall performance and reliability of the system. Grasping how these elements interact can significantly enhance maintenance practices and troubleshooting processes.

In this section, we will explore the specific configuration and relationships between various parts of a heating unit. By examining these connections, users can gain insight into the functionality and potential areas for improvement. This knowledge serves as a foundation for effective operation and care of the equipment.

Whether you’re a technician or an enthusiast, familiarizing yourself with the layout of these crucial components will empower you to make informed decisions. Understanding the intricacies involved not only aids in routine maintenance but also in identifying and resolving issues swiftly.

This section provides a comprehensive understanding of a specific heating device designed for efficient fuel combustion. Its key components play crucial roles in ensuring optimal performance and reliability, making it essential for various applications.

- Functionality and purpose of the device

- Importance of each element in the system

- Common applications in heating solutions

The following details will cover the essential features, advantages, and typical use cases, allowing readers to grasp the significance of this equipment in modern heating technologies.

Key Components of the Burner

The efficient operation of a combustion device relies on several crucial elements that work together to ensure optimal performance. Understanding these essential components is vital for maintenance and troubleshooting. Each part plays a unique role, contributing to the overall functionality of the system.

Main Functional Elements

Among the various components, certain elements are critical for the ignition, fuel delivery, and heat management processes. These key features are designed to operate harmoniously, maximizing efficiency and safety.

Component Specifications

| Component | Description |

|---|---|

| Fuel Pump | Responsible for delivering fuel to the combustion chamber at the required pressure. |

| Ignition Transformer | Generates the spark needed to ignite the fuel-air mixture. |

| Air Fan | Facilitates the necessary airflow for combustion efficiency. |

| Control Unit | Monitors and regulates the operation of the system, ensuring safe performance. |

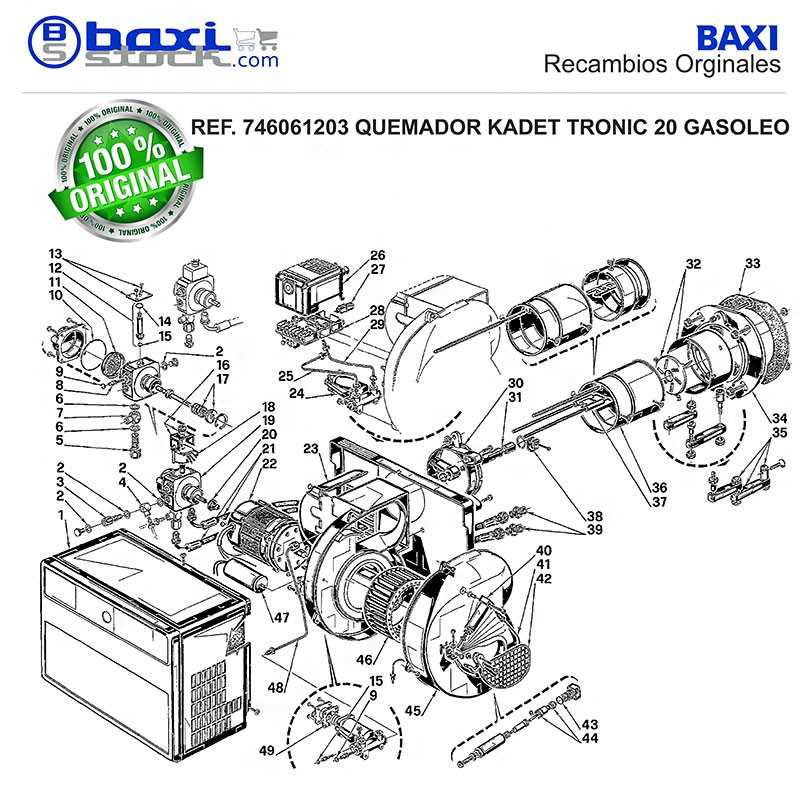

Understanding the Parts Diagram

This section aims to provide clarity on the components and their arrangement within the equipment. A thorough comprehension of the assembly is essential for effective maintenance and troubleshooting.

Analyzing the configuration of various elements allows users to identify specific functions and the interrelationship between them. Here are some key benefits of familiarizing oneself with the schematic:

- Improved maintenance practices

- Enhanced troubleshooting capabilities

- Informed decision-making for repairs

By exploring the layout, one can gain insights into operational efficiency and potential areas for improvement. Understanding each element’s role contributes to overall performance and reliability.

To make the most of this information, consider the following steps:

- Familiarize yourself with each component’s name and function.

- Identify how each part interacts with others in the system.

- Keep notes on any common issues related to specific components.

By following these guidelines, users can achieve a deeper understanding of their equipment and ensure optimal operation.

Functionality of Each Component

This section explores the role and significance of various elements within a combustion system, highlighting their individual contributions to overall performance and efficiency. Understanding how each component interacts is crucial for optimal operation and maintenance.

Fuel Delivery System: This element is responsible for transporting the fuel from the storage tank to the combustion chamber. Its design ensures precise flow control, promoting efficient energy production.

Ignition Mechanism: The ignition system initiates the combustion process by providing the necessary heat to ignite the fuel-air mixture. Its reliability is vital for smooth startups and consistent operation.

Air Supply Unit: This unit manages the intake of air, mixing it with fuel to create the ideal combustion environment. Proper airflow is essential for maximizing efficiency and minimizing emissions.

Control System: The control unit monitors and regulates various parameters such as temperature, pressure, and fuel flow. It ensures that the system operates within safe and efficient limits, providing automated responses to changing conditions.

Exhaust Management: This component facilitates the removal of combustion gases from the system, ensuring safe discharge and preventing the accumulation of harmful substances. Effective exhaust management is crucial for compliance with environmental standards.

Safety Features: These include mechanisms designed to prevent malfunctions and hazardous situations. From flame sensors to pressure switches, these features are essential for ensuring safe operation.

Common Issues with Burner Parts

Understanding the frequent challenges encountered with heating units is essential for efficient operation. These complications often arise from various components and can affect overall functionality, leading to decreased performance or malfunctions.

Typical Problems

Several issues are commonly observed in heating systems, primarily stemming from wear and tear, improper maintenance, or environmental factors. Recognizing these can help in timely interventions.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Inconsistent heating | Uneven temperatures, frequent shutdowns | Check for obstructions, ensure proper airflow |

| Excessive noise | Loud operational sounds, vibrations | Tighten loose components, inspect for damage |

| Fuel leakage | Visible spills, unpleasant odors | Inspect seals and connections, replace as necessary |

Maintenance Tips

Regular upkeep is crucial to mitigate these issues. Routine inspections and timely replacements of worn components can significantly enhance the longevity and efficiency of the system.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of heating equipment requires a proactive approach to care and upkeep. Regular maintenance not only enhances efficiency but also extends the lifespan of your unit, preventing unexpected breakdowns.

- Regular Inspections: Schedule routine check-ups to identify any potential issues early.

- Cleaning: Keep all components free of dust and debris to promote optimal operation.

- Fuel Quality: Use high-quality fuel to reduce wear and enhance combustion efficiency.

- Check Seals and Gaskets: Inspect and replace any worn seals to prevent leaks and ensure proper function.

- Temperature Monitoring: Regularly monitor operational temperatures to ensure they stay within recommended ranges.

Implementing these practices can significantly enhance the reliability and efficiency of your heating equipment, ultimately saving you time and money.

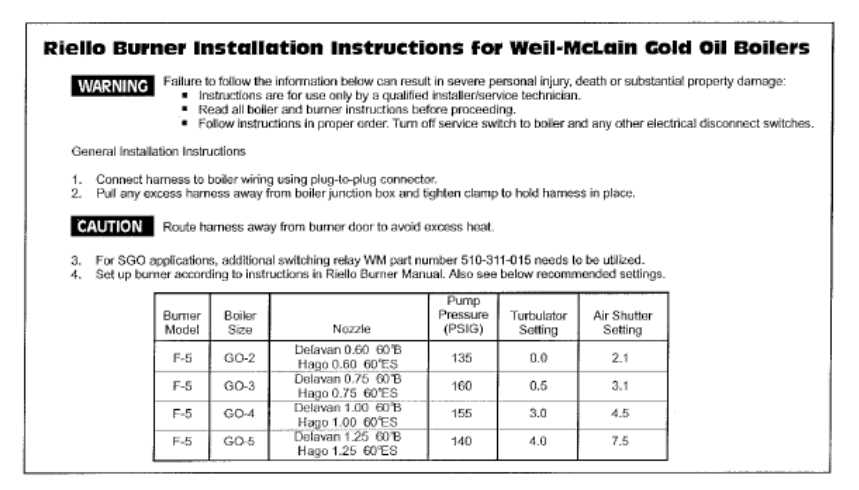

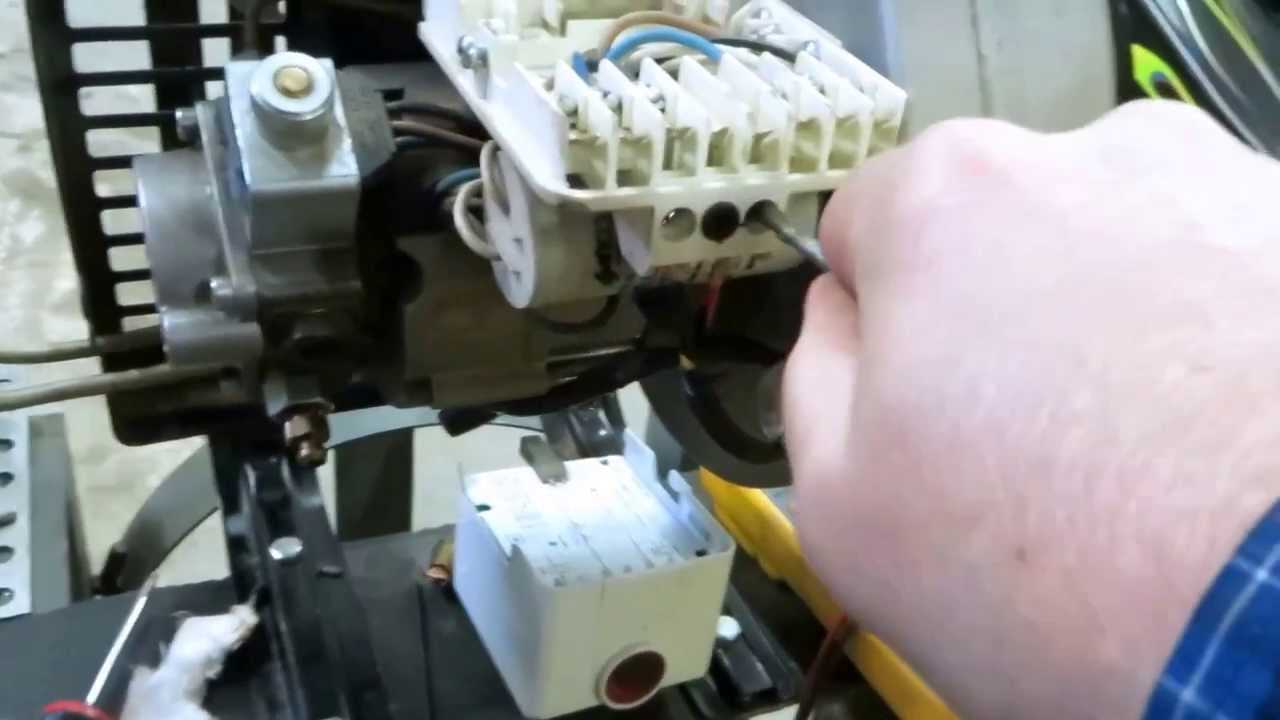

Replacement Procedures for Key Parts

This section outlines essential methods for exchanging critical components in heating mechanisms, ensuring optimal functionality and longevity. Understanding the correct approach to replacement can significantly enhance performance and safety during operation.

Essential Tools and Preparations

Before starting the replacement process, gather necessary tools such as wrenches, screwdrivers, and safety equipment. Ensure the system is completely powered down and cool to prevent any accidents. Preparing the workspace by clearing clutter will facilitate a smoother operation.

Step-by-Step Replacement Guide

Begin by identifying the component requiring replacement. Carefully detach any connections, making note of their arrangement for reinstallation. Utilize appropriate force to remove the component without damaging surrounding areas. After placing the new item, reverse the disassembly steps to reattach all connections securely. Finally, conduct a thorough inspection to confirm everything is properly aligned before powering the system back on.

Finding Authentic Replacement Parts

When it comes to maintaining heating equipment, securing genuine components is crucial for optimal performance and longevity. Ensuring the authenticity of replacements helps prevent malfunctions and guarantees safety during operation.

To effectively locate reliable alternatives, consider the following steps:

- Research reputable suppliers known for their quality offerings.

- Verify that the vendor provides documentation confirming the authenticity of their products.

- Check customer reviews to assess the reliability and reputation of the seller.

- Consult with professionals who have experience with the specific equipment to get recommendations.

Additionally, understanding the specifications of your original components can aid in making informed decisions when searching for suitable replacements. This knowledge empowers you to identify trustworthy options that align with your system’s requirements.

Improving Burner Efficiency

Enhancing the performance of heating equipment is crucial for optimizing energy consumption and reducing operational costs. Various strategies can be implemented to achieve higher efficiency, leading to improved overall functionality and lower emissions.

Key Factors to Consider

- Regular Maintenance: Consistent upkeep of components ensures optimal operation and longevity.

- Proper Air-Fuel Ratio: Achieving the correct mixture is vital for efficient combustion.

- Quality of Fuel: Using high-grade fuel can significantly affect the efficiency of the system.

- System Design: An appropriately designed system minimizes energy loss and enhances performance.

Strategies for Improvement

- Conduct routine inspections to identify and address wear and tear on vital components.

- Utilize advanced control systems that adjust the air-fuel mixture dynamically based on operating conditions.

- Implement insulation measures to reduce heat loss in the system.

- Consider retrofitting with modern technology that enhances efficiency and reduces environmental impact.