In the world of heavy machinery, having a comprehensive overview of how each element fits together is crucial for effective maintenance and operation. This section focuses on the intricate arrangements that define the assembly of various machinery types, providing valuable insights into their functionality and upkeep.

By exploring these configurations, users can better grasp the relationship between different elements, leading to improved troubleshooting and repair processes. Each layout serves as a visual guide, helping operators and technicians identify specific components and their respective roles within the system.

Utilizing these illustrations not only enhances one’s understanding but also aids in planning maintenance schedules and ensuring optimal performance. This knowledge empowers users to make informed decisions when it comes to repairs and replacements, ultimately extending the lifespan of their equipment.

Overview of Bomag BT60 Components

This section provides a comprehensive look at the essential elements that make up a specific construction machine. Understanding these components is crucial for maintenance, operation, and troubleshooting. Each part plays a vital role in ensuring optimal performance and longevity of the equipment.

Key Elements

The primary components of this machinery include the engine, hydraulic system, and control mechanisms. The engine serves as the powerhouse, converting fuel into mechanical energy. The hydraulic system, on the other hand, facilitates the movement and operation of various attachments, enabling efficient functionality. Control mechanisms provide the operator with the ability to manage these systems effectively.

Maintenance Considerations

Regular upkeep of these critical components is essential for ensuring reliability and efficiency. Inspecting the engine for signs of wear, checking hydraulic fluid levels, and ensuring that control systems function correctly are all important practices. By prioritizing maintenance, operators can prevent costly repairs and extend the lifespan of the equipment.

Importance of Parts Diagrams

Visual representations of components are crucial for understanding the assembly and functionality of machinery. These illustrations serve as a valuable resource for technicians and engineers, enabling them to identify individual elements, their locations, and how they interact within the overall system. By providing a clear overview, these graphics facilitate efficient repairs and maintenance, reducing downtime and enhancing operational efficiency.

Enhancing Understanding

Having access to well-structured visuals significantly improves the comprehension of complex systems. Technicians can easily locate specific items and understand their roles, leading to quicker troubleshooting and resolution of issues. This clarity is particularly beneficial in training scenarios, where new personnel can familiarize themselves with the machinery without needing extensive verbal explanations.

Streamlining Maintenance

Accurate visual guides are essential for effective upkeep of equipment. They not only help in identifying replacement components but also ensure that the correct parts are used during repairs. This precision minimizes errors, increases safety, and prolongs the lifespan of the machinery, ultimately resulting in cost savings for organizations.

How to Read the Diagram

Understanding technical illustrations can significantly enhance your ability to identify components and their interrelations. These visuals serve as essential tools for maintenance and assembly, providing a clear overview of how various elements fit together. By mastering the interpretation of these schematics, you can efficiently troubleshoot issues and perform necessary repairs.

Key Elements to Focus On

When examining a technical illustration, pay attention to several critical components. First, identify the symbols used to represent different items, as these can vary between different types of schematics. Next, focus on the labeling, which typically includes numbers or letters corresponding to specific parts. Lastly, look for connections and pathways, as they indicate how various elements interact within the system.

Utilizing a Reference Table

A reference table can provide invaluable assistance in understanding the symbols and designations used in the schematic. This table typically matches each symbol with its corresponding part number and description, allowing for quick identification. Below is an example of how such a table might be structured:

| Symbol | Part Number | Description |

|---|---|---|

| 12345 | Adjustment Screw | |

| 67890 | Fastening Nut | |

| ️ | 54321 | Clamp Mechanism |

By familiarizing yourself with the symbols and their meanings, you will enhance your proficiency in navigating these illustrations, ultimately leading to more effective maintenance and repair processes.

Commonly Replaced Parts

In any machine, there are certain components that tend to wear out over time and require replacement to maintain optimal performance. Understanding which elements are frequently changed can help users effectively manage maintenance schedules and reduce downtime.

Below are some of the components that are often replaced:

- Filters

- Seals and Gaskets

- Belts

- Hoses

- Bearings

Regular inspection and timely replacement of these elements can ensure the longevity and efficiency of the equipment.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of machinery requires diligent upkeep and proactive measures. Regular maintenance not only enhances performance but also extends the lifespan of equipment, minimizing the risk of unexpected breakdowns and costly repairs.

1. Regular Inspections: Conduct frequent checks to identify wear and tear early. Look for signs of damage or unusual noises that may indicate underlying issues.

2. Clean Components: Keeping all parts free from debris and dirt is essential. Accumulation of contaminants can lead to corrosion and malfunction. Use appropriate cleaning agents to maintain cleanliness.

3. Lubrication: Proper lubrication is critical for reducing friction and wear. Ensure that moving parts are adequately lubricated according to the manufacturer’s recommendations to ensure smooth operation.

4. Check Fluid Levels: Regularly monitor and maintain appropriate levels of fluids, such as oils and coolants. Low fluid levels can lead to overheating and damage to internal components.

5. Follow Operating Guidelines: Adhering to the operating guidelines provided by the manufacturer ensures optimal performance and safety. Avoid overloading equipment to prevent undue stress and potential failures.

6. Scheduled Maintenance: Implement a routine maintenance schedule. Regular service by qualified technicians can catch issues before they escalate and keep machinery in peak condition.

7. Store Properly: When not in use, ensure equipment is stored in a clean, dry environment. Protect it from environmental elements that may cause deterioration.

By adhering to these maintenance practices, users can significantly enhance the durability and efficiency of their machinery, ultimately leading to improved productivity and reduced operational costs.

Where to Find Replacement Components

When maintaining equipment like the Bomag BT60, locating the right replacement components is crucial for ensuring optimal performance and longevity. Here are some reliable sources for acquiring the parts you need:

- Specialized Dealers: Look for dealerships that specialize in construction machinery supplies. They often stock a variety of components suitable for compactors and similar equipment.

- Online Marketplaces: Websites dedicated to industrial equipment and parts can be a treasure trove. They offer a wide selection of components from various manufacturers, ensuring compatibility and quality.

- Manufacturer’s Official Channels: Check the official channels of the equipment’s manufacturer. They typically provide authentic parts that meet the original specifications, ensuring the best fit and performance.

- Local Distributors: Explore local distributors that cater to the construction industry. They may have the parts you need in stock or can order them quickly from their network.

- Equipment Repair Shops: Establishments specializing in machinery repair often have access to a range of parts and can provide guidance on sourcing specific components.

By utilizing these resources, you can efficiently procure replacement components for your Bomag BT60 or similar equipment, ensuring minimal downtime and reliable operation.

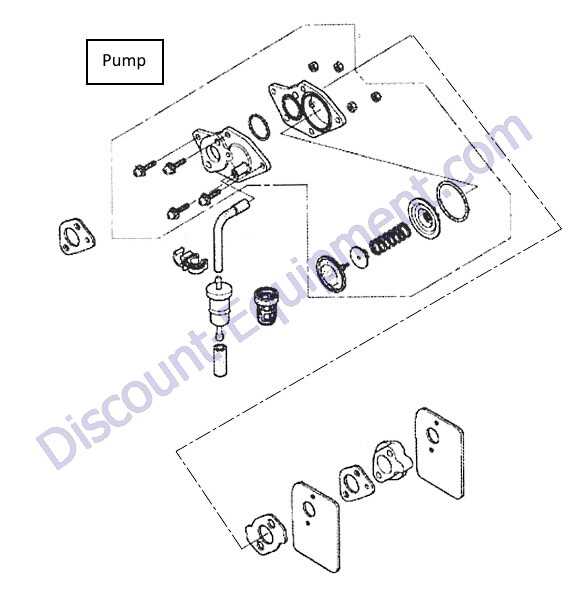

Understanding Hydraulic System Layout

The configuration of hydraulic systems plays a crucial role in the overall functionality and efficiency of machinery. A well-organized layout ensures that fluid flow is optimized, contributing to the seamless operation of various components. Understanding the arrangement and interaction of these elements is vital for effective maintenance and troubleshooting.

In hydraulic systems, several key components work together to create the necessary force for movement and operation. The layout typically includes elements such as pumps, valves, actuators, and reservoirs. Each component has a specific function, and their proper arrangement can significantly influence performance and reliability.

| Component | Function |

|---|---|

| Pump | Generates flow and pressure in the system. |

| Valve | Controls the direction and flow of hydraulic fluid. |

| Actuator | Transforms hydraulic energy into mechanical movement. |

| Reservoir | Holds hydraulic fluid and allows for expansion and contraction. |

By examining these components and their interactions, operators can gain insights into how to optimize system performance and extend equipment lifespan. Regular inspections and understanding the layout help in identifying potential issues before they escalate, ensuring efficient operation.

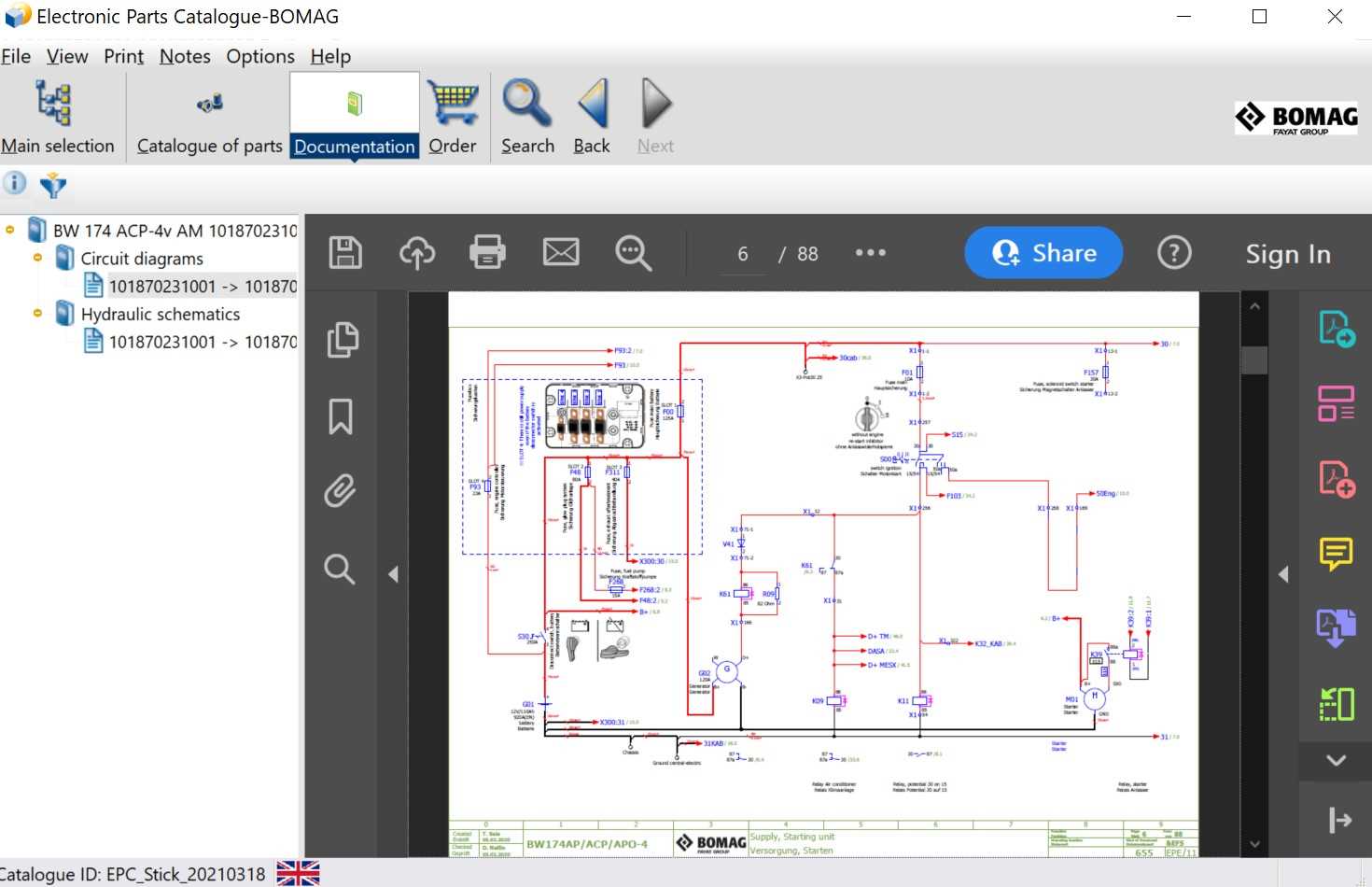

Electrical Components Explained

Understanding the various electrical components in machinery is essential for effective maintenance and troubleshooting. These elements play a crucial role in ensuring that the equipment operates smoothly and efficiently. Each component serves a specific function that contributes to the overall performance of the system.

Wiring harnesses connect different electrical parts, allowing them to communicate and work together. They are designed to withstand environmental factors while providing reliable connections. Switches control the flow of electricity, enabling operators to manage the equipment easily. Whether they are toggle or push-button switches, their design ensures user-friendly operation.

Fuses protect the system from overloads by breaking the circuit when excessive current flows, preventing potential damage to other components. Similarly, relays act as switches operated by an electromagnetic coil, allowing for remote control of circuits and enhancing safety in operations. Understanding these elements helps users maintain the integrity and efficiency of their machinery.

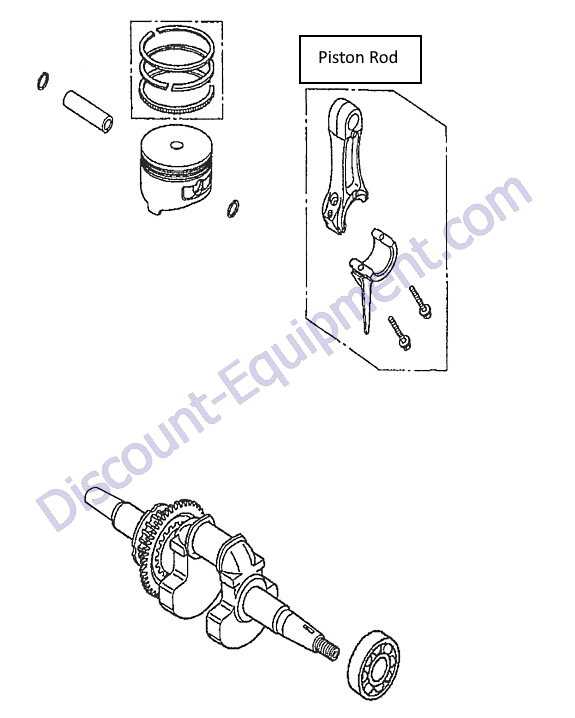

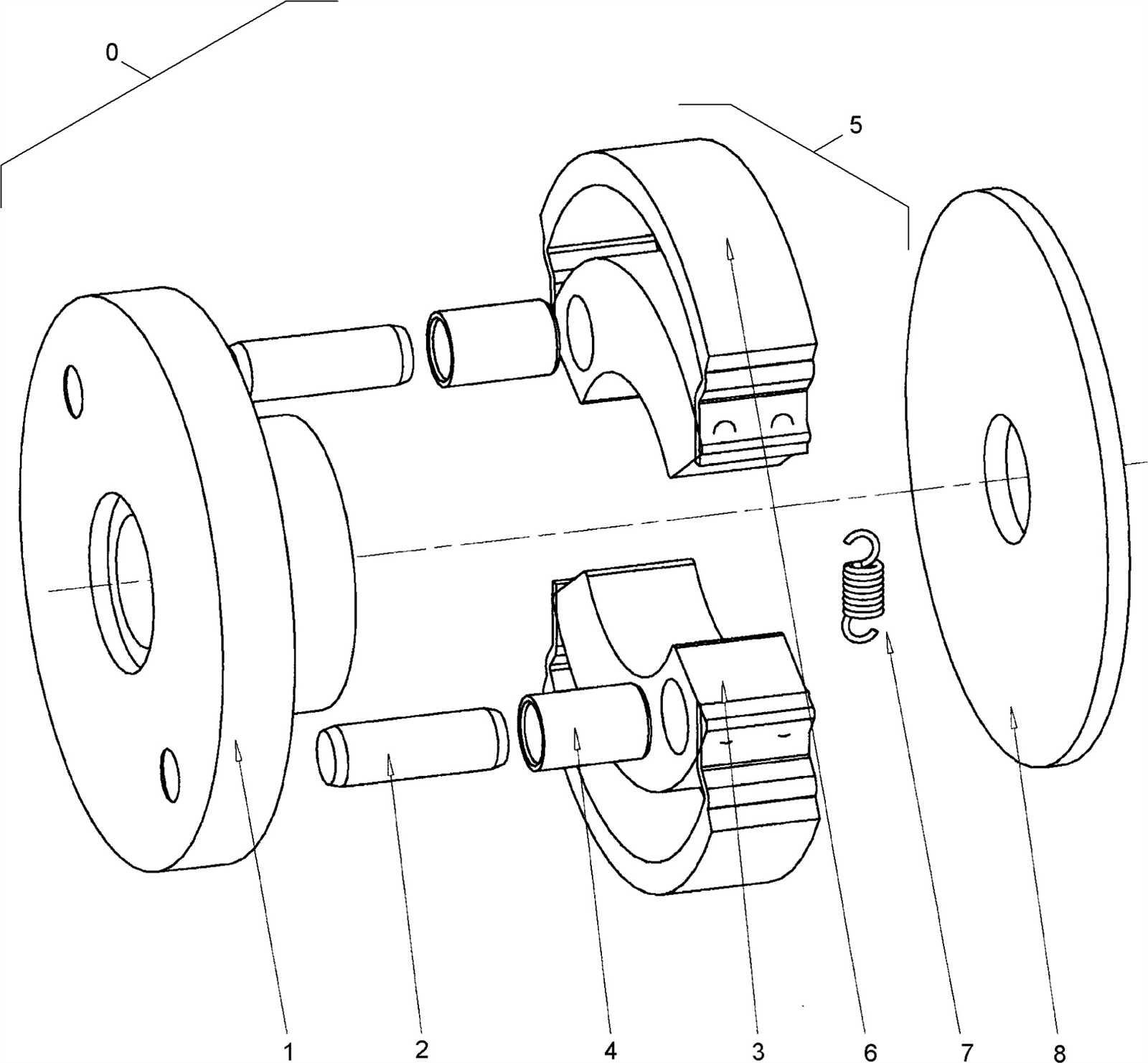

Identifying Mechanical Assemblies

In this section, we delve into recognizing the intricate components that comprise the operational machinery, focusing on the structural elements that ensure seamless functionality. Understanding these integral parts allows for precise maintenance and effective troubleshooting, contributing to enhanced operational longevity.

Exploring Key Components

Delving deeper, we examine the core elements that form the mechanical framework, emphasizing the interconnectedness and roles they play in the overall system. Each component contributes uniquely to the smooth operation, necessitating meticulous identification for targeted maintenance.

Safety Features in Bomag BT60

Ensuring the security of the equipment during operation is a critical factor for any construction tool. Various mechanisms are designed to minimize the risk to the operator, as well as prevent damage to the machine. These security systems are carefully integrated into the machine to ensure both durability and user protection.

Operator Protection Mechanisms

Several features are implemented to safeguard the user from potential hazards. Key mechanisms are in place to reduce exposure to vibration, prevent accidental activation, and enhance stability during operation. These functions work in tandem to ensure a safe and controlled environment for the operator.

Preventive Safety Functions

Various preventive systems are embedded in the machine to address potential risks. From automatic shut-off systems to emergency controls, these safety mechanisms are vital to ensuring continuous safe usage. The equipment also incorporates indicators and warnings that notify the operator of potential issues, helping to avoid accidents before they happen.

| Feature | Function |

|---|---|

| Anti-Vibration System | Reduces the impact of prolonged usage on the operator’s hands and arms. |

| Automatic Shut-off | Prevents the tool from running unattended or in case of malfunction. |

| Emergency Stop | Allows the operator to quickly halt the machine in hazardous situations. |

| Stability Control | Enhances balance during operation, reducing the risk of tipping over. |

Upgrades and Modifications Available

Enhancing the performance and extending the life of construction equipment is essential for maximizing its utility and efficiency. Numerous improvements can be applied to enhance its functionality, durability, and ease of use, ensuring better results on the job site.

Performance Enhancements

- Upgrading the engine to a more fuel-efficient model can significantly improve operational efficiency.

- Enhanced shock absorption systems help reduce wear and tear, providing smoother operation.

- Improved air filtration systems ensure longer engine life by reducing contaminants.

Durability Modifications

- Reinforced materials for key components can extend equipment longevity in harsh environments.

- Weatherproofing upgrades protect the machine from extreme conditions, such as rain or excessive dust.

- Anti-corrosion treatments on exposed surfaces prevent rust and prolong the overall lifespan.

These upgrades and modifications ensure that your equipment remains reliable and effective, even in the toughest working conditions.

Comparing with Other Bomag Models

In this section, we will explore how this specific equipment stands in relation to other similar options available. Each model serves unique purposes and offers distinct advantages based on its construction, power, and application areas. Understanding these differences can help in selecting the most suitable variant for various types of tasks, ensuring maximum efficiency and reliability.

- Engine performance varies across models, providing different levels of power and fuel efficiency.

- Weight distribution and handling affect ease of operation, with some models offering more balanced or lightweight designs for tighter spaces.

- The design and durability of key components may differ, with certain versions featuring reinforced structures for demanding environments.

- Some models focus on specialized functionalities, offering additional features for specific tasks, improving precision or speed.

Overall, comparing these machines provides insight into their optimal usage scenarios, helping users choose the right equipment for their needs.

Frequently Asked Questions

In this section, we will cover the most common questions that arise regarding the maintenance, functionality, and troubleshooting of certain machinery components. Whether you are a seasoned operator or a new user, these insights can help you get a clearer understanding of how to handle your equipment effectively.

What are the key maintenance steps?

Regular upkeep is essential to ensure optimal performance. Make sure to follow routine checks, including lubrication, cleaning, and inspection of wear-prone elements. Refer to your user manual for detailed intervals and instructions on these tasks.

How can I identify issues with the equipment?

Unusual noises, vibrations, or loss of power are common indicators that something might be wrong. It’s important to investigate these signs promptly to avoid further damage. Checking for loose connections or worn-out components is often a good place to start.

| Question | Answer |

|---|---|

| What should I do if the engine won’t start? | First, verify that all safety switches are engaged. Then, check fuel levels and electrical connections to ensure everything is in order. |

| How often should I service the machinery? | Servicing should be done at regular intervals as outlined in the user manual. Typically, after a set number of operational hours or based on the manufacturer’s recommendations. |