When working with professional painting equipment, it’s essential to know how different elements contribute to its smooth operation. In this article, we explore the key mechanisms that ensure the efficiency and longevity of a high-quality sprayer. Understanding these details can significantly enhance both performance and maintenance.

Proper knowledge of the inner workings helps you diagnose issues faster and make necessary adjustments or replacements. Whether you are a seasoned professional or a DIY enthusiast, gaining insight into these features will empower you to keep your equipment running at optimal capacity.

In the following sections, we will take a closer look at the critical elements that make up a reliable machine, ensuring you have a comprehensive understanding of how they work together for flawless performance.

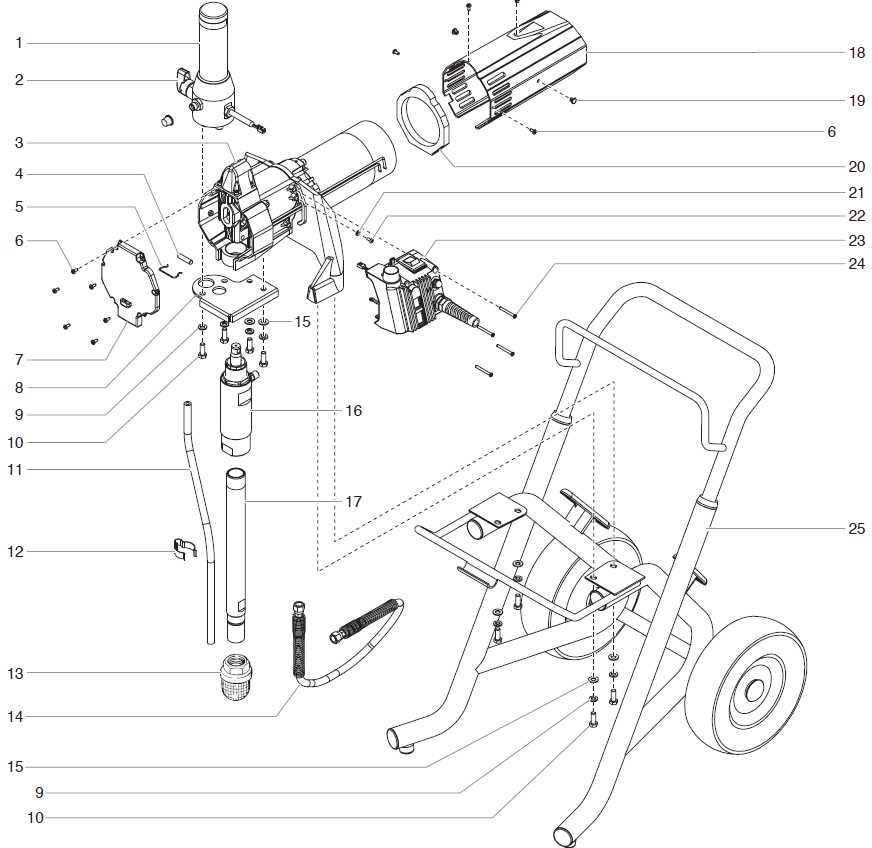

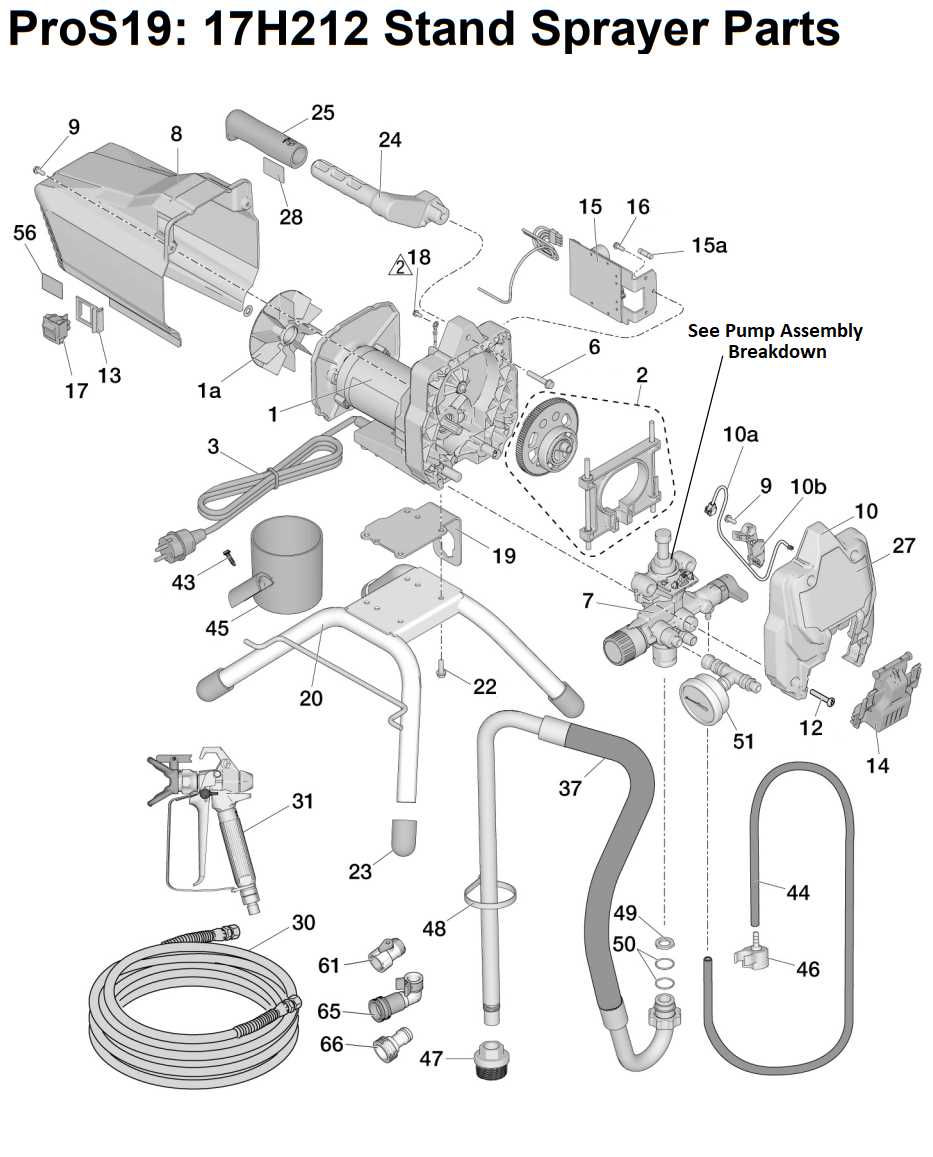

Graco 390 Parts Overview

This section provides a detailed look into the key components of a popular airless paint sprayer. Understanding how each element functions together is essential for maintaining optimal performance and ensuring longevity of the equipment. Regular inspection and replacement of worn-out elements can help in preventing potential issues and prolonging the sprayer’s operational life.

Main Components

The main elements of this sprayer system include the pump, motor, and control unit. These core sections work together to ensure a smooth and consistent paint flow. The motor powers the pump, while the control unit regulates pressure, ensuring the ideal amount of coating material is applied to surfaces.

Supporting Elements

In addition to the core components, the sprayer includes various supporting parts such as hoses, nozzles, and filters. These are crucial for guiding the paint and ensuring the spray remains clean and uninterrupted. Regular maintenance of these elements helps avoid clogs and ensures a uniform finish.

Key Components of the Graco 390

The primary elements of this spraying device play a crucial role in its efficient operation, ensuring smooth performance during painting tasks. Understanding these components can significantly enhance the longevity and effectiveness of the machine, making it easier to troubleshoot and maintain.

Main Functional Elements

- Pump unit – responsible for delivering a steady flow of material to the spray gun.

- Pressure control – allows for adjustments to the material flow to match the requirements of the surface being painted.

- Motor – powers the entire system, driving the pump and ensuring consistent operation.

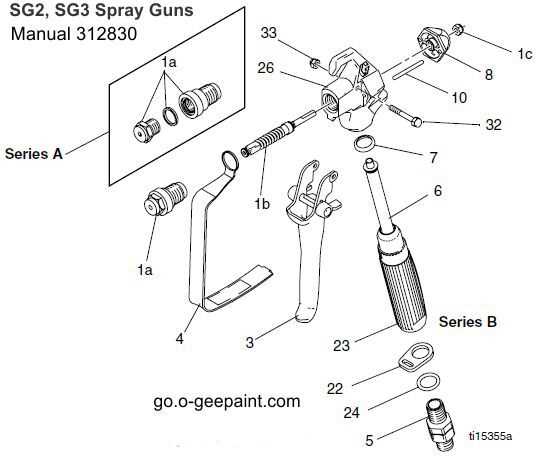

Essential Connections and Controls

- Hose assembly – connects the pump to the spray gun, allowing for flexible movement during application.

- Spray gun – the end component that applies material evenly across surfaces.

- Filters – help in preventing debris from clogging the system, ensuring smooth operation.

Identifying Essential Graco 390 Parts

Understanding the key components of your equipment is crucial for efficient maintenance and long-term performance. By familiarizing yourself with the core elements, you can ensure smooth operation and quickly address any potential issues.

Main Components Overview

The primary elements of this model include the pump, motor, and various control units. Each of these plays a vital role in the overall functionality of the machine, ensuring it operates seamlessly. Regular inspection of these parts will help to maintain optimal performance.

Ensuring Compatibility and Performance

It is important to use only original or high-quality replacements when servicing your machine. This guarantees compatibility and prevents premature wear, reducing the risk of breakdowns. Proper care and maintenance will extend the life of each component.

Common Wear and Tear Components

Over time, certain components of equipment are subject to natural wear and require periodic replacement. Understanding which elements experience the most stress can help with maintenance and extend the lifespan of your machinery.

Hoses and Seals

Flexible hoses and seals are often exposed to high pressures, causing them to deteriorate over time. Regular inspections and timely replacements ensure that no leaks or malfunctions occur, keeping the system running smoothly.

Pump and Valves

The pump and its associated valves are integral parts of fluid systems, and they face consistent use, leading to wear. Regular maintenance of these components can prevent performance issues, maintaining operational efficiency.

Maintenance Tips for Essential Components

Regular upkeep of mechanical equipment ensures optimal performance and longevity. A well-maintained device can function efficiently, reducing the need for costly repairs. The key to extending the lifespan of machinery is to follow a few essential maintenance practices consistently.

Regular Cleaning and Inspection

One of the most critical steps in maintaining your equipment is regular cleaning. Dust and debris can accumulate, causing friction and wear on moving parts. Make sure to clean surfaces thoroughly and inspect for signs of damage or corrosion. If any components show wear, replace them immediately to avoid further issues.

Lubrication and Tightening

Proper lubrication is essential to keep moving components operating smoothly. Ensure that all necessary joints and mechanisms are well-lubricated to prevent friction. Additionally, check for any loose screws or bolts, and tighten them to maintain the structural integrity of the equipment.

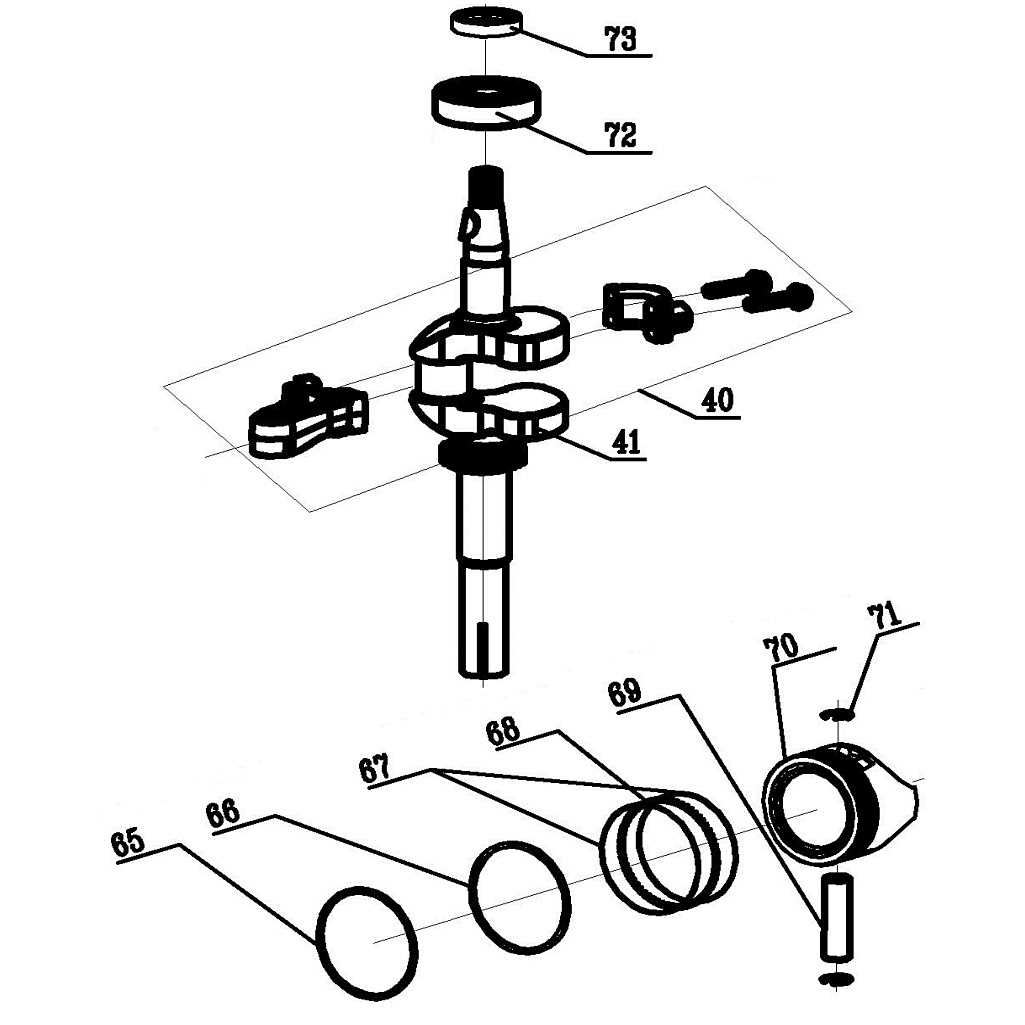

Replacing the Graco 390 Pump

When the pumping mechanism in your sprayer fails to operate efficiently, it may be time for a replacement. Understanding the process of swapping out the old unit with a new one can significantly enhance your machine’s performance and extend its lifespan. This section outlines the necessary steps to successfully complete this task, ensuring you can resume your projects with minimal downtime.

Preparation for Replacement

Before starting the replacement process, gather the required tools and safety equipment. Ensure the sprayer is powered off and disconnected from any power source. Reviewing the user manual can provide useful insights into specific procedures and safety precautions. Having a clean workspace will help you stay organized and make the installation smoother.

Steps for Installation

Begin by removing the old pumping unit carefully, following the manufacturer’s guidelines. Take note of how the components are assembled for easier reinstallation. Once the old pump is detached, place the new one in the same position, ensuring all connections align correctly. Tighten any screws or fasteners securely to prevent leaks during operation. After installation, conduct a test run to verify proper functionality and check for any signs of malfunction.

Electrical System Breakdown

The electrical system in high-performance equipment plays a critical role in ensuring optimal functionality and reliability. Understanding the components and their interconnections is essential for efficient troubleshooting and maintenance. This section delves into the various elements that constitute the electrical framework, highlighting their functions and importance in the overall operation.

Key Components

At the heart of the electrical system are several key components that work in unison. These include the motor, power supply, and control circuitry. The motor drives the main functions, while the power supply ensures that adequate energy is provided. The control circuitry is responsible for managing the interactions between these components, facilitating seamless operation.

Troubleshooting Tips

To maintain the performance of the electrical system, regular inspections are vital. Check for loose connections, worn wires, and signs of corrosion. If the system exhibits irregular behavior, refer to the wiring schematics to identify potential faults. Ensuring that all components are functioning correctly can prevent costly downtime and extend the lifespan of the equipment.

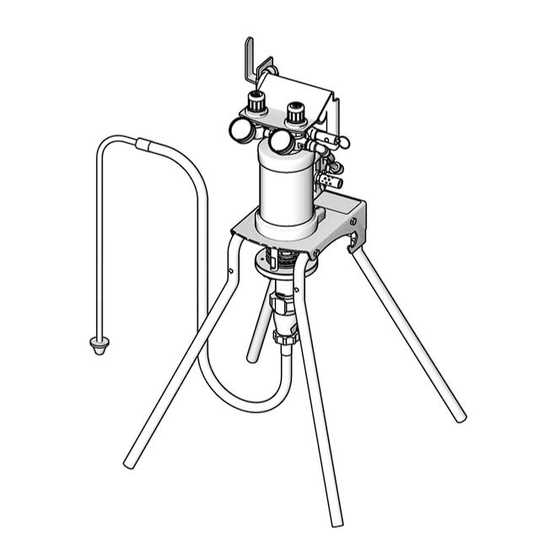

How to Clean Graco 390 Parts

Keeping your equipment in top condition is essential for optimal performance and longevity. Regular maintenance involves thorough cleaning of all components to prevent buildup and ensure smooth operation. This section outlines effective methods for cleaning your devices, ensuring they function efficiently for years to come.

Follow these steps for a comprehensive cleaning process:

-

Gather Necessary Supplies:

- Cleaning solution suitable for your equipment

- Soft cloths or rags

- Brushes (soft and stiff bristle)

- Water

- Protective gloves

-

Disassemble Components:

Carefully take apart the unit according to the manufacturer’s instructions. Ensure you keep track of each piece to facilitate reassembly.

-

Soak Removable Parts:

Submerge detachable elements in a cleaning solution for a specified duration, usually around 15-30 minutes. This helps to dissolve dirt and grime.

-

Scrub and Rinse:

Use brushes to gently scrub each part, paying extra attention to crevices and hard-to-reach areas. After scrubbing, rinse thoroughly with clean water to remove any residue.

-

Dry Completely:

Use soft cloths to dry all parts thoroughly. Ensure no moisture remains to prevent corrosion or malfunction.

-

Reassemble the Unit:

Once all parts are dry, carefully reassemble the equipment. Follow the initial disassembly steps in reverse order to ensure proper alignment and functionality.

Regular cleaning of your device not only enhances its performance but also extends its lifespan. Implement these steps periodically for the best results.

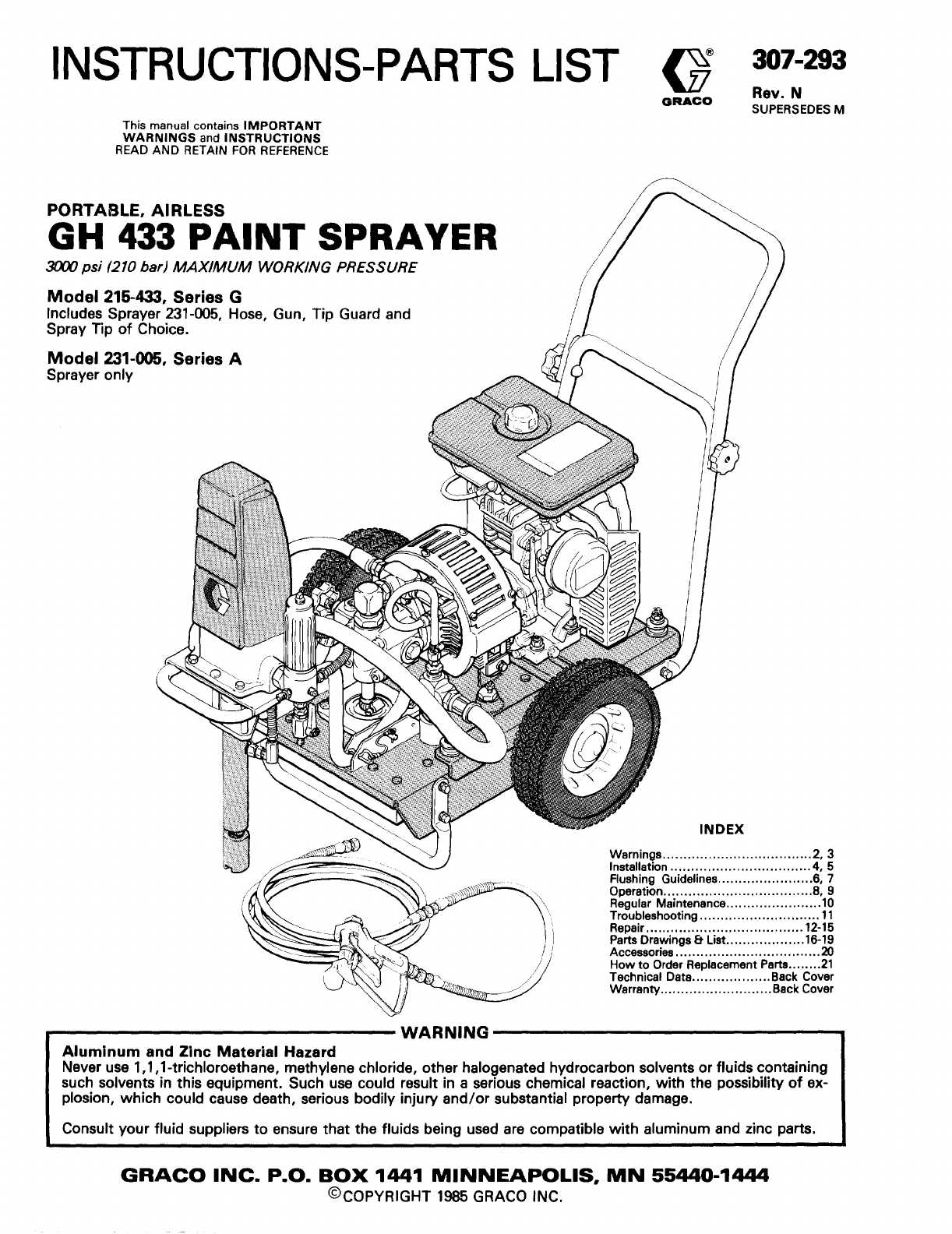

Graco 390 Fluid Section Diagram

This section provides an overview of the fluid assembly components essential for optimal operation in various applications. Understanding these elements is crucial for efficient maintenance and performance. A well-structured breakdown enhances clarity and aids users in recognizing the functionalities of each part.

- Fluid Inlet: This is where the liquid enters the assembly, facilitating a smooth transition into the system.

- Fluid Outlet: The exit point for the material, designed to ensure proper flow to the intended area.

- Check Valve: A critical component that prevents backflow, ensuring that the liquid moves in the desired direction.

- Filter: This part removes impurities, maintaining the cleanliness of the fluid and protecting internal mechanisms.

- Pump Housing: Encloses the pumping mechanism, providing support and protection while enabling efficient liquid movement.

By familiarizing oneself with these components, users can ensure that their systems function effectively and identify any potential issues that may arise over time. Regular checks and maintenance of these elements contribute to longevity and reliability.

Troubleshooting Common Parts Issues

Addressing issues with components is essential for maintaining optimal performance of your equipment. Recognizing and resolving these common challenges can prevent downtime and ensure efficient operation. Here are some common problems and their potential solutions.

- Inconsistent Operation:

- Check for blockages in the flow pathways.

- Inspect seals and gaskets for wear and tear.

- Ensure that all connections are secure and properly fitted.

- Noisy Performance:

- Examine for loose components that may be rattling.

- Look for signs of wear on moving parts that might need lubrication.

- Identify if any foreign objects are obstructing the operation.

- Leaking Fluids:

- Inspect hoses and fittings for cracks or damage.

- Ensure that all connections are tight and leak-proof.

- Replace worn seals or gaskets that may cause leaks.

- Reduced Efficiency:

- Check filters for clogs that may impede flow.

- Calibrate pressure settings to meet the manufacturer’s specifications.

- Ensure that the motor and drive systems are functioning properly.

By systematically addressing these issues, you can maintain the reliability and efficiency of your machinery, minimizing the risk of future complications.

Filters and Seals Guide

This section provides an overview of essential components designed to ensure optimal performance and longevity of equipment. Proper filtration and sealing mechanisms are crucial in preventing contaminants from entering the system and maintaining the integrity of various assemblies.

Understanding Filters: Filters play a vital role in trapping impurities and particles, thus enhancing the efficiency of the operation. Regular inspection and timely replacement of these elements are necessary to avoid clogs and ensure smooth functioning.

Importance of Seals: Seals are critical in preventing leaks and maintaining pressure within the system. They protect sensitive parts from damage caused by exposure to external elements. Ensuring that seals are intact and properly fitted is essential for maintaining optimal functionality.

Maintenance Tips: Regular maintenance checks should include examining both filters and seals for signs of wear or damage. Adhering to a consistent maintenance schedule can greatly extend the lifespan of equipment and enhance overall performance.

Ordering and Finding Spare Parts

When maintaining equipment, sourcing the correct replacement components is crucial for optimal performance. Whether you need to repair a malfunction or upgrade functionality, understanding how to locate and procure necessary elements can streamline the process.

Here are some effective strategies for obtaining the right components:

- Official Retailers: Check authorized dealers or manufacturers’ websites for reliable options.

- Online Marketplaces: Utilize platforms like Amazon or eBay, which often have a wide range of items available.

- Local Supply Stores: Visit nearby hardware or specialty shops that may stock what you need.

- Community Forums: Engage with online communities or user groups where members can recommend sources or share experiences.

Additionally, ensure you have the correct specifications and details regarding the components to avoid compatibility issues. Keeping a record of part numbers or model information can significantly aid in the search.

Lastly, consider contacting customer support if you’re uncertain about which items to order. They can provide guidance and clarify any doubts you may have.