Exploring the layout and connections of tool components is essential for effective maintenance and troubleshooting. By familiarizing oneself with the structure, it becomes easier to identify where each element fits and how various mechanisms interact. This knowledge can significantly enhance the efficiency of repair and upkeep tasks.

Recognizing the different sections and their functions allows for a more in-depth understanding of the equipment’s construction. It becomes possible to pinpoint areas that may require attention and anticipate the necessary steps for servicing. Additionally, knowing how each component is organized contributes to a smoother assembly or disassembly process.

Equipped with insights into the arrangement of internal and external elements, users can approach tasks with greater confidence. This awareness not only helps in resolving issues but also in preventing future complications through proper handling and routine inspection.

Ridgid 700 Tool Overview

This section provides a general insight into a versatile power tool designed for heavy-duty tasks, commonly used in plumbing and construction. It offers robust performance and durability, making it a popular choice for professionals who need to perform tasks like threading, tightening, and loosening. The tool’s design focuses on efficiency and ease of use, allowing operators to handle demanding jobs with less effort.

- Heavy-duty construction ensures reliability and long-term use in challenging environments.

- The ergonomic design provides comfort during prolonged usage, reducing operator fatigue.

- Suitable for various applications, including pipe fitting, maintenance, and installation tasks.

- Compact and portable, allowing easy transport and use in confined spaces.

- Equipped with features that facilitate quick and safe operation for different tasks.

The tool’s capabilities extend beyond basic usage, offering advanced functionalities that cater to different job requirements. It is engineered to accommodate a range of accessories, enhancing its versatility for specialized tasks. This adaptability makes it an essential tool for professionals seeking a reliable solution for diverse working conditions.

Understanding the Tool’s Main Features

When working with heavy-duty equipment, it’s essential to grasp the core functions that make the tool effective and efficient. This section outlines the primary capabilities, providing insight into its usability and overall performance.

- Power and Torque: The tool is designed to handle demanding tasks, delivering high levels of force to tackle tough materials effortlessly. Its robust construction ensures consistent power output for various applications.

- Versatility: Compatible with a range of accessories, the tool can be adapted for multiple functions, making it suitable for diverse tasks in different work environments. This adaptability enhances its value in professional settings.

- Ergonomic Design: The tool features a user-friendly design that reduces strain during extended use. Its handle and control layout are crafted to provide a comfortable grip, allowing for precise operation without fatigue.

- Durability: Constructed from high-quality materials, the tool is built to withstand challenging conditions. Its components are designed for long-term use, ensuring reliability even in the toughest working environments.

- Safety Mechanisms: Equipped with various safety features, the tool helps prevent accidental activation and ensures secure operation. These safeguards contribute to a safer and more controlled working experience.

Understanding these key features can help users maximize the tool’s potential, ensuring it meets the demands of any project.

Essential Components of Ridgid 700

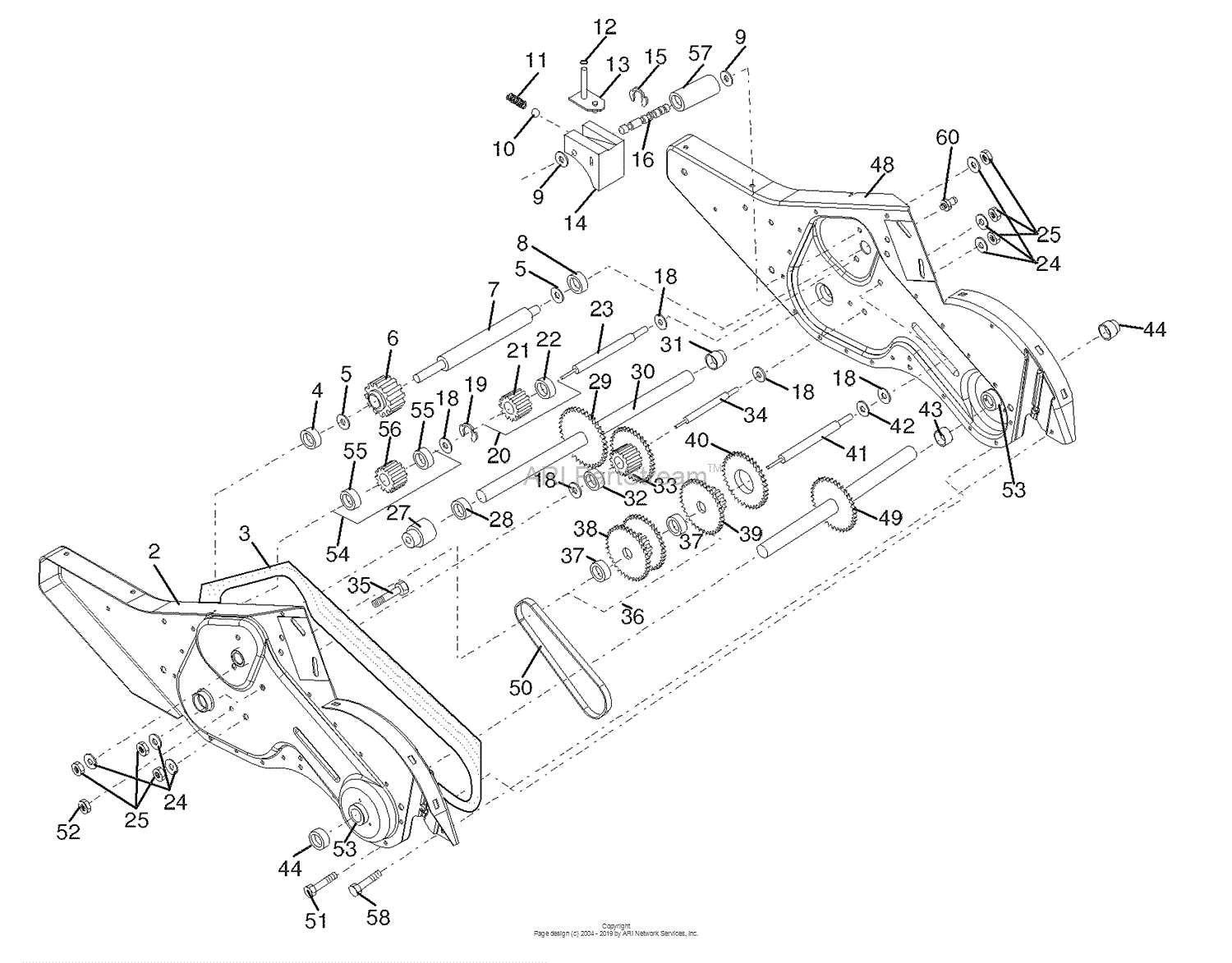

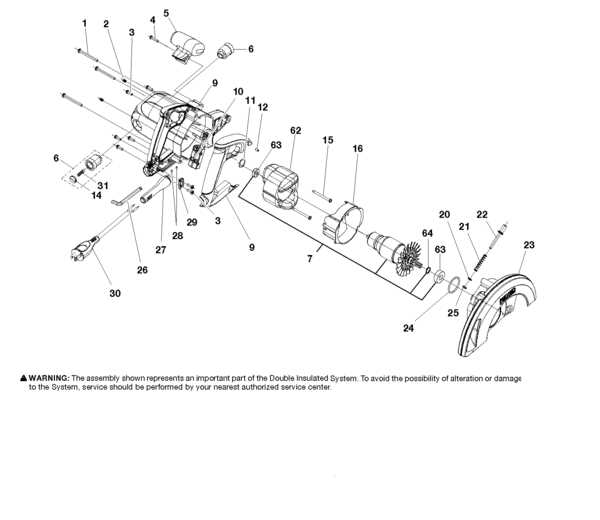

Understanding the key elements of this tool is crucial for ensuring its proper functioning and maintenance. Each part works in harmony, contributing to the tool’s overall performance and efficiency. Below is an overview of the most important elements that make up the device, helping users identify what to look for when performing upkeep or troubleshooting.

Main Structural Elements

The primary frame forms the backbone, providing a sturdy base for other components. It’s built to withstand substantial force, ensuring durability during heavy-duty tasks. Coupled with the body are the grips, which offer a comfortable hold, allowing for better control and maneuverability during use. The alignment of these structural pieces plays a critical role in reducing fatigue and enhancing precision.

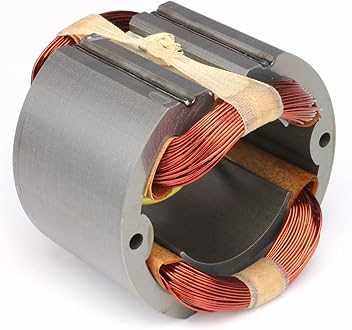

Power Transmission Features

Another set of essential features involves the mechanisms responsible for transmitting force. The internal motor drives the motion, working in conjunction with the transmission system to deliver consistent torque. Gears within the assembly transfer energy smoothly, while the connectors link different sections, ensuring that the tool operates seamlessly under varying conditions. Regular inspection of these elements is important to maintain optimal functionality.

Key Parts and Their Functions

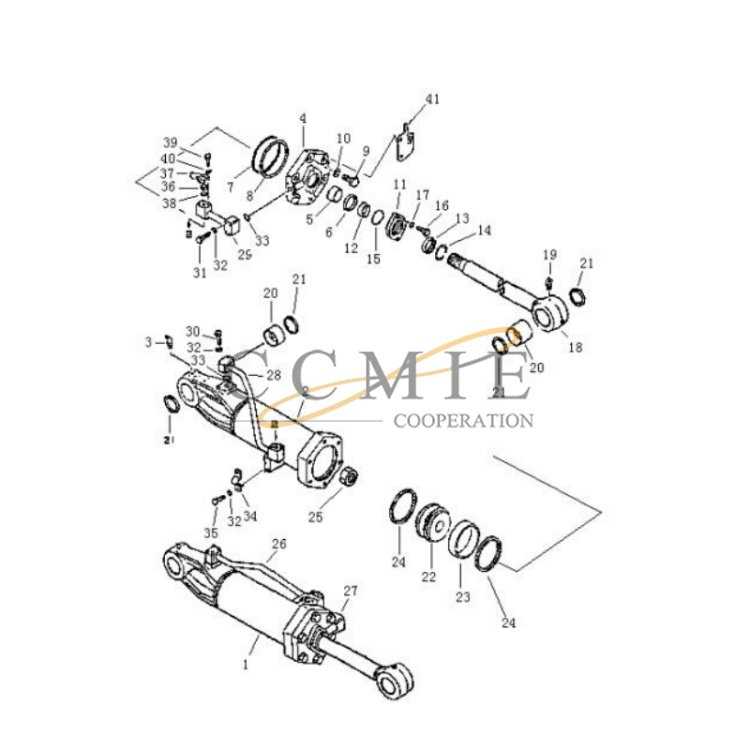

The following section provides an overview of the essential components used in mechanical equipment, explaining how each element contributes to the overall operation. Understanding these functions can help maintain efficiency and ensure proper upkeep of the device.

Main Operational Components

Various components are responsible for different mechanical tasks. Some elements generate movement, while others control or transfer power. The interaction between these parts ensures the smooth functioning of the entire system. Regular inspection and maintenance are essential for preventing wear and damage.

Supporting Elements and Accessories

Aside from the main operational components, several supporting elements play crucial roles in safety and stability. These may include fasteners, protective covers, and connectors that help secure the device and maintain safe operation under various conditions.

| Component | Function | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Motor | Generates the necessary force to drive the equipment, allowing for rotation or linear motion. | ||||||||||||||||||||||||||||||

| Transmission | Transfers the generated force to specific areas, ensuring controlled and effective movement. | ||||||||||||||||||||||||||||||

| Housing |

Exploded View of Ridgid 700An exploded illustration offers a detailed representation of the internal and external components of the tool. This visual guide helps to understand how each element fits together, making it easier to identify and locate individual pieces within the assembly. The exploded layout shows a clear breakdown of each part, allowing users to grasp the overall structure and positioning of the various sections. The diagram typically presents the tool in a disassembled state, where all elements are separated but aligned to indicate their correct placement. This approach provides insight into the mechanical relationships and connections between different sections, enabling easier troubleshooting and maintenance. By following the labeled sections and numbered references, users can quickly pinpoint specific components for inspection, repair, or replacement. The visual breakdown also aids in familiarizing oneself with the tool’s structure, contributing to a better understanding of its operation and assembly process. Detailed Breakdown of Each ComponentThis section provides a comprehensive analysis of the individual elements that make up the device. Understanding each component’s role and functionality is essential for proper maintenance and troubleshooting. By dissecting the various parts, users can gain insights into the overall performance and reliability of the equipment. Understanding Key ElementsEach part plays a crucial role in the operational efficiency of the machine. For instance, the power source is vital for driving the entire system, while connectors ensure seamless interaction between different parts. Recognizing how these elements work together can significantly enhance the user experience. Maintenance and Replacement ConsiderationsRegular inspections and timely replacements of worn-out components are critical for sustaining optimal performance. Components such as filters and gaskets require periodic checks, as their condition directly impacts the functionality of the overall system. Users should refer to the appropriate guidelines for specific maintenance schedules. Maintenance Tips for Ridgid 700Proper upkeep of your equipment is crucial for optimal performance and longevity. Regular maintenance not only enhances the efficiency of your tools but also ensures safety during operations. Following a systematic approach to care will help prevent breakdowns and costly repairs. Regular InspectionConducting periodic inspections is vital to identify any wear or damage early on. Look for signs of corrosion, loose components, or unusual noises during operation. Addressing these issues promptly can prevent more significant problems in the future. Cleaning and LubricationKeeping your equipment clean is essential to maintain its functionality. Dust and debris can accumulate and interfere with moving parts. Regularly clean the exterior and interior components. Additionally, ensure that all moving parts are adequately lubricated to reduce friction and wear.

Keeping Your Tool in Top Shape

Maintaining your equipment in optimal condition is essential for ensuring longevity and reliability. Regular upkeep not only enhances performance but also prevents unexpected breakdowns that could lead to costly repairs. Adopting a systematic approach to care can greatly improve your tool’s efficiency. Here are some essential practices to consider for effective maintenance:

By following these simple yet effective maintenance steps, you can ensure that your equipment remains efficient and ready for use whenever you need it. Common Issues with Ridgid 700When using power tools, operators may encounter several typical challenges that can affect performance and usability. Understanding these common problems is essential for effective troubleshooting and maintenance. Identifying the issues early on can significantly extend the lifespan of the equipment and improve overall efficiency. Frequent Mechanical MalfunctionsOne of the most prevalent issues is mechanical failure, often stemming from wear and tear over time. Users might experience difficulties with the tool’s ability to grip securely, resulting in inconsistent performance. Regular inspections can help detect any signs of damage, ensuring timely repairs before they escalate into more significant problems. Electrical ConcernsElectrical complications can also arise, particularly in older models. Common symptoms include intermittent power loss or failure to start, which may indicate wiring issues or faulty connections. Keeping the electrical components clean and regularly checking the connections can help mitigate these risks. Identifying and Fixing Frequent Problems

In any tool or machinery, common issues may arise over time due to wear and tear or improper use. Recognizing these problems early can help in maintaining efficiency and prolonging the lifespan of the equipment. This section will discuss typical malfunctions, their symptoms, and possible solutions to ensure optimal performance. One of the most frequent challenges faced is improper functioning, often manifesting as unusual noises or reduced power output. These issues can stem from various sources, including worn components or inadequate lubrication. Regular inspections and timely replacements can mitigate these concerns.

Replacement Parts Guide for Ridgid 700This section provides an essential overview of essential components for maintenance and repair of your equipment. Understanding the significance of each element will ensure optimal performance and longevity of your device. Whether you’re looking to enhance efficiency or replace worn-out items, having a comprehensive guide will facilitate informed decisions. Identifying Components: Familiarize yourself with the various elements that make up your device. By recognizing each component’s function, you can better determine which items require replacement. This knowledge is vital for troubleshooting and ensuring smooth operation. Acquiring Quality Replacements: When seeking new components, prioritize sourcing from reputable suppliers. High-quality replacements contribute to the overall durability and reliability of your equipment. Always verify compatibility with your specific model to avoid issues during installation. Installation Tips: Proper installation is crucial for the functionality of new components. Follow detailed instructions provided by the manufacturer or consult professional services if needed. Taking the time to ensure everything is fitted correctly will prevent future problems. Maintenance Practices: Regular maintenance is key to extending the lifespan of your device. Develop a routine that includes inspecting components and replacing them as necessary. This proactive approach will save time and resources in the long run. Finding the Right Spare Parts

When it comes to maintaining tools and equipment, identifying the correct replacement components is crucial for ensuring optimal performance and longevity. A systematic approach to sourcing these elements can greatly enhance the efficiency of repairs and replacements, minimizing downtime and restoring functionality. First and foremost, it is essential to consult the manufacturer’s resources to obtain an accurate list of compatible elements. Many brands provide detailed catalogs or online databases that can assist in pinpointing the specific components needed for a particular model. Utilizing these resources will not only simplify the search process but also guarantee the compatibility of the selected items. Additionally, reaching out to authorized dealers or reputable retailers can provide valuable insights. These professionals often possess extensive knowledge about the equipment and can guide you in choosing the right replacements. Moreover, exploring online forums or user groups dedicated to the equipment can yield useful recommendations and experiences from fellow users. Lastly, always consider quality when selecting replacement components. Opting for genuine or high-quality alternatives can prevent further issues and ensure the tool operates effectively. Investing time in thorough research will ultimately lead to a smoother maintenance experience and extend the lifespan of your equipment. Compatibility of Ridgid 700 Parts

Understanding the interchangeability of components within a particular model is crucial for maintenance and repair. Many users seek to ensure that the elements they choose will function seamlessly together, promoting optimal performance and longevity of the equipment. Key Factors for Compatibility

Commonly Used Compatible Components

|