In the realm of automotive engineering, a transmission plays a pivotal role in the overall performance and functionality of a vehicle. This complex assembly comprises various elements that work together to ensure smooth gear shifts and efficient power transfer from the engine to the wheels. Grasping the intricate layout and relationship between these elements is essential for anyone involved in maintenance or repair.

Knowledge of the internal structure is crucial for diagnosing issues and performing upgrades. Each element serves a specific function, contributing to the transmission’s efficiency and longevity. By familiarizing oneself with these components, individuals can make informed decisions regarding repairs, enhancements, or replacements.

Furthermore, understanding the configuration of these components aids in troubleshooting problems that may arise during operation. Whether it’s addressing performance issues or optimizing functionality, a clear comprehension of the assembly’s arrangement is invaluable. This guide delves into the specifics of these elements, shedding light on their interconnections and operational roles.

Understanding the 47RE Transmission

The 47RE unit is a vital component in many heavy-duty vehicles, designed to provide robust performance and reliability. This automatic transmission is engineered to handle significant power outputs while maintaining smooth gear shifts and optimal fuel efficiency. Its sophisticated design incorporates several key elements that work together to ensure dependable operation under various driving conditions.

Key Components and Their Functions

Each element within the transmission plays a crucial role in its overall functionality. Understanding these components can enhance your comprehension of how the system operates.

- Torque Converter: This device transmits power from the engine to the transmission, facilitating smooth acceleration.

- Planetary Gear Set: This assembly allows for different gear ratios, enabling the vehicle to change speeds effectively.

- Valve Body: The heart of the transmission, this unit regulates fluid flow and directs it to the appropriate clutches and bands.

- Clutch Packs: These are responsible for engaging and disengaging gears, contributing to the smooth transition between shifts.

Common Issues and Maintenance

Regular maintenance is essential for the longevity of the transmission. Here are some common issues and tips for upkeep:

- Check fluid levels regularly to prevent overheating and ensure proper lubrication.

- Look for signs of slipping or delayed engagement, which may indicate wear on the clutch packs.

- Inspect for leaks, as fluid loss can severely affect performance.

- Perform regular fluid changes to maintain cleanliness and effectiveness.

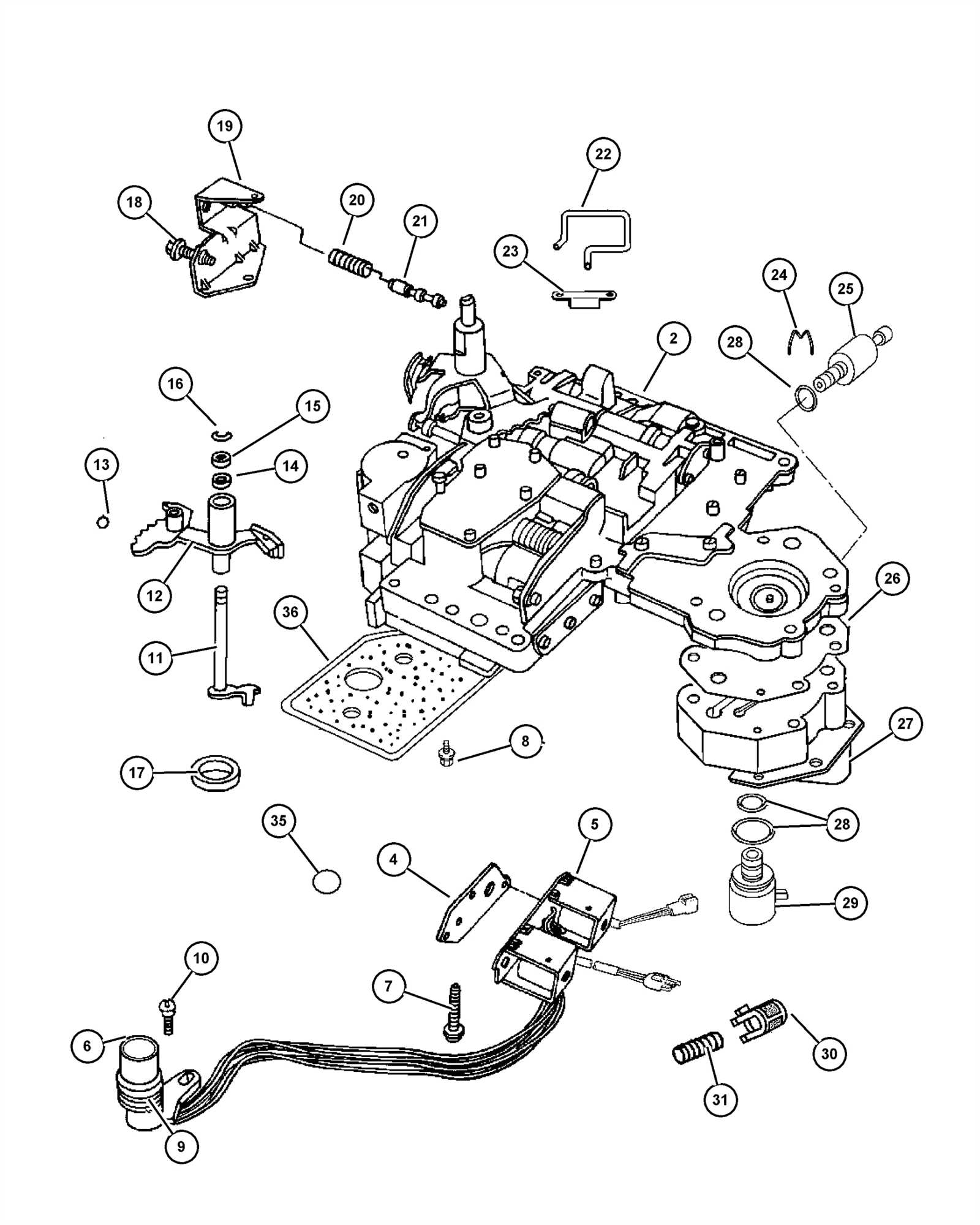

Key Components of 47RE Assembly

The assembly of a specific transmission comprises several critical elements that work in unison to ensure optimal performance and reliability. Understanding these components is essential for effective maintenance and repair. Each part serves a distinct function, contributing to the overall efficiency and functionality of the unit.

Main Elements

- Torque Converter: This component plays a vital role in transferring engine power to the transmission while allowing for smooth acceleration.

- Planetary Gear Set: A series of gears that enables different gear ratios, providing the necessary speed and torque for various driving conditions.

- Clutches and Bands: These elements engage and disengage the gear sets, allowing for smooth shifting and control over the vehicle’s speed.

- Valve Body: Often referred to as the brain of the transmission, it controls fluid flow and determines which clutches and bands engage based on input from the driver and vehicle sensors.

- Oil Pump: This essential component circulates transmission fluid, ensuring that all moving parts are lubricated and operate smoothly.

Supportive Elements

- Filter: Keeps contaminants out of the transmission fluid, prolonging the life of the assembly.

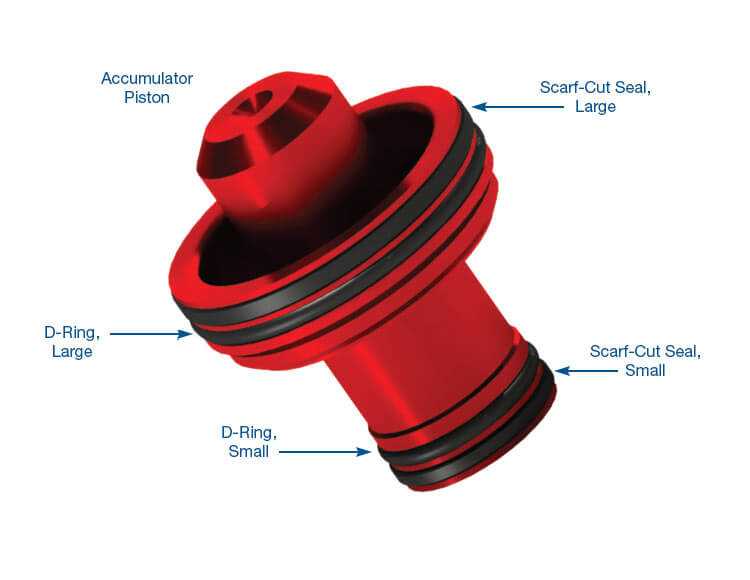

- Gaskets and Seals: Prevent fluid leaks and ensure that the transmission maintains proper pressure and fluid levels.

- Electrical Components: Sensors and solenoids that monitor and adjust the performance of the assembly based on real-time data.

Common Issues with 47RE Parts

When dealing with automatic transmissions, several frequent challenges can arise that impact performance and reliability. Understanding these issues can help in maintaining smooth operation and extending the lifespan of the system.

- Fluid Leaks: One of the most prevalent problems is fluid leakage, which can stem from worn seals or gaskets. Regular inspection is crucial to identify and address these leaks promptly.

- Overheating: Excessive heat can lead to significant damage. Insufficient cooling or inadequate fluid levels are often the culprits behind this issue.

- Shifting Problems: Difficulty in changing gears, whether it’s slipping or hard shifts, can indicate internal wear or electrical issues that require immediate attention.

- Noise: Unusual sounds during operation may signal problems within the assembly. Grinding or whining noises should not be ignored as they often indicate internal damage.

Addressing these common issues through regular maintenance and timely repairs can significantly enhance the durability and efficiency of the automatic transmission system.

Maintenance Tips for Longevity

Ensuring the durability of your transmission requires a proactive approach to maintenance. Regular attention to essential components and fluid management can significantly enhance performance and extend the lifespan of the system. By implementing a few key practices, you can prevent common issues and ensure reliable operation over time.

Regular Fluid Checks

Monitoring and maintaining the proper fluid levels is crucial. The transmission fluid serves multiple functions, including lubrication, cooling, and cleaning. Regular checks will help you identify any leaks or degradation in the fluid quality.

| Fluid Type | Recommended Change Interval | Signs of Degradation |

|---|---|---|

| Synthetic Fluid | Every 30,000 miles | Dark color, burnt smell |

| Conventional Fluid | Every 15,000 miles | Low level, contaminants present |

Component Inspection

Regularly inspect essential components for wear and tear. This includes checking seals, gaskets, and electrical connections. Addressing minor issues before they escalate can save time and costs in the long run.

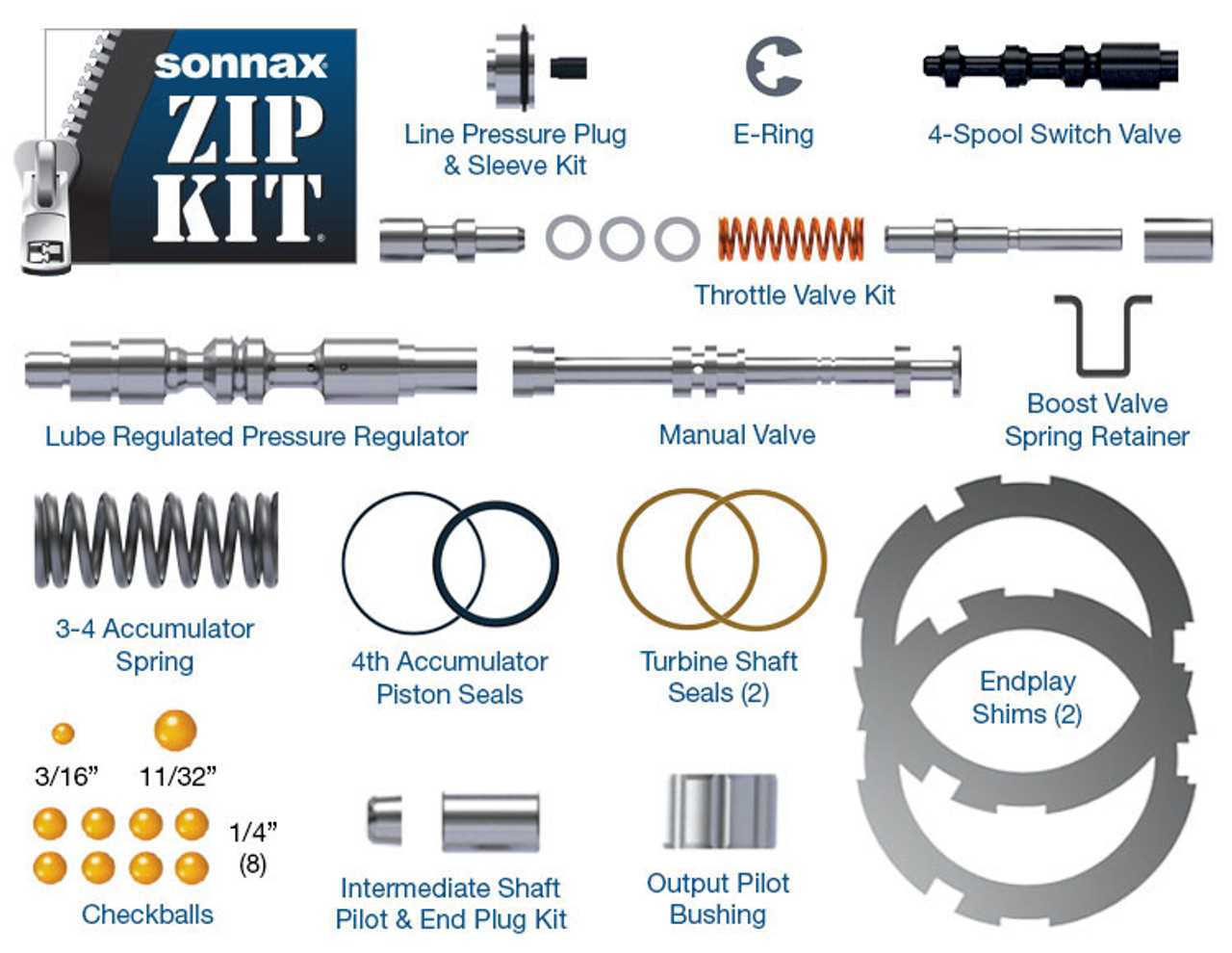

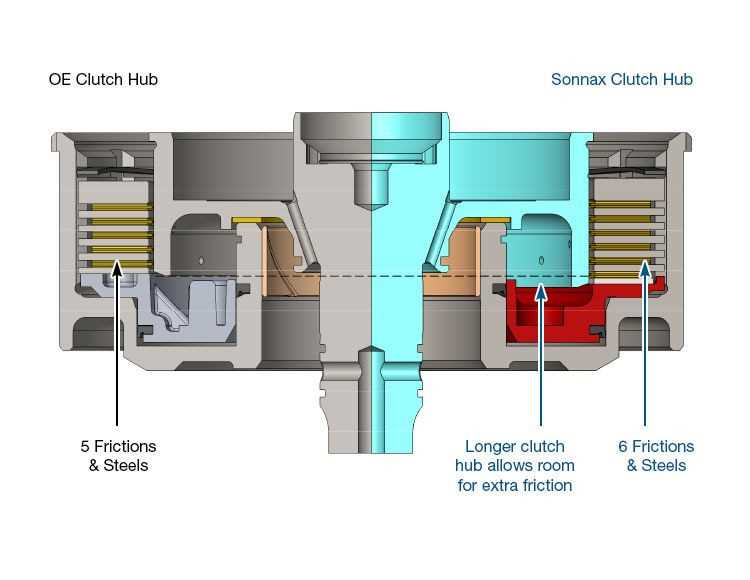

Upgrading Your 47RE Transmission

Enhancing the performance and reliability of your vehicle’s transmission system can significantly improve driving experience and longevity. By focusing on key components and integrating advanced technologies, you can achieve a more robust setup that meets your specific needs.

Choosing Quality Components: Selecting high-quality elements is crucial for ensuring durability and efficiency. Investing in upgraded clutches, torque converters, and valve bodies can lead to better power handling and smoother operation.

Improving Cooling Systems: Adequate cooling is vital for maintaining optimal temperatures during operation. Consider installing an external cooler or enhancing existing cooling features to prevent overheating, which can lead to premature wear.

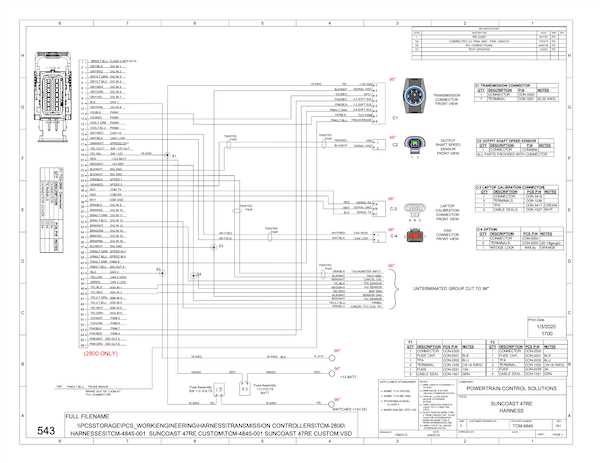

Optimizing Transmission Control: Upgrading the control module can provide more precise shifting and enhanced adaptability to driving conditions. This can result in improved response times and overall performance, contributing to a more enjoyable driving experience.

Regular Maintenance: Keep in mind that consistent upkeep is essential for any upgraded system. Regular fluid changes, inspections, and adjustments will help maintain peak performance and extend the lifespan of the components.

By implementing these enhancements, you can transform your vehicle’s transmission into a more efficient and reliable system, tailored to your driving style and requirements.

Essential Tools for Disassembly

When undertaking a complex project involving the dismantling of machinery or components, having the right equipment is crucial for a smooth and efficient process. Each tool plays a vital role in ensuring that every piece is handled properly, reducing the risk of damage and enhancing overall productivity.

Basic Hand Tools

The foundation of any disassembly task begins with basic hand tools. These typically include screwdrivers, wrenches, and pliers, which allow for the loosening and removal of various fasteners. A well-stocked toolkit with different sizes ensures that users can tackle a range of components without encountering limitations.

Specialized Equipment

In addition to standard tools, specialized equipment can significantly aid the disassembly process. Items like torque wrenches and impact drivers are invaluable when dealing with stubborn bolts or assemblies requiring precise torque settings. Employing these tools not only makes the task easier but also helps maintain the integrity of the components involved.

Comparing 47RE to Other Models

This section explores the differences and similarities between a specific transmission system and its counterparts in the automotive industry. Understanding these distinctions is essential for enthusiasts and professionals who wish to make informed decisions regarding performance and compatibility. Key aspects to consider include design, functionality, and application across various vehicle platforms.

Design Features

Each transmission system exhibits unique characteristics that cater to different driving needs. Notable design elements include:

- Gear ratios and their impact on performance.

- Type of torque converter used and its efficiency.

- Overall weight and size, influencing vehicle dynamics.

Functional Performance

The effectiveness of a transmission can be evaluated based on several performance metrics. Important factors include:

- Shifting responsiveness and smoothness during operation.

- Durability under high-stress conditions.

- Fuel efficiency and impact on engine performance.

By analyzing these components, one can appreciate how this specific system aligns with or diverges from other options available in the market.

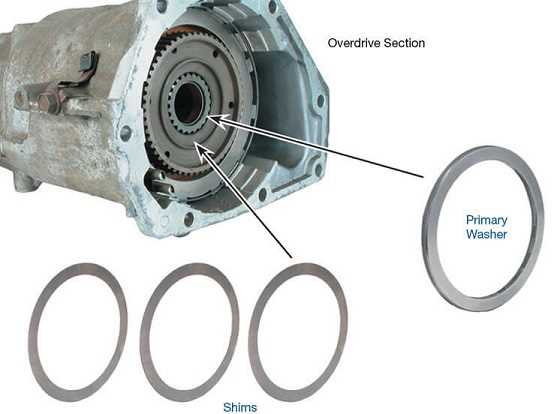

Replacing Worn-Out Components

Over time, certain elements within a mechanical system may experience deterioration, leading to diminished performance and potential failures. Regular maintenance and timely replacement of these degraded components are essential to ensure optimal functionality and longevity of the entire assembly.

Identifying Signs of Wear

Before proceeding with replacements, it’s crucial to recognize indicators that suggest specific components have become worn. Common signs include unusual noises, vibrations, or a noticeable decline in operational efficiency. Addressing these issues promptly can prevent further damage and costly repairs.

Replacement Procedure

When replacing damaged components, following a systematic approach is vital. Here is a step-by-step process:

| Step | Description |

|---|---|

| 1 | Gather the necessary tools and replacement parts for the specific components that need attention. |

| 2 | Carefully remove the affected parts, ensuring to follow safety protocols to avoid injury or damage to the surrounding assembly. |

| 3 | Install the new components, making sure they are correctly aligned and securely fastened. |

| 4 | Test the assembly to confirm that the new parts are functioning properly and that the overall system operates as intended. |

By adhering to these guidelines, the efficiency and reliability of the mechanical system can be significantly enhanced, ensuring a smoother operation and extending its lifespan.

Importance of Quality Replacement Parts

Using high-quality components for vehicle repairs is crucial for maintaining optimal performance and longevity. When replacing critical elements, selecting items that meet or exceed original specifications ensures reliability and reduces the risk of future failures. Quality replacements not only enhance the efficiency of the system but also provide peace of mind for the vehicle owner.

Benefits of Choosing Superior Components

- Enhanced Durability: High-grade materials are engineered to withstand harsh conditions, minimizing wear and tear over time.

- Improved Performance: Superior components often contribute to better functionality, resulting in a smoother operation.

- Cost-Effectiveness: While the initial investment may be higher, quality replacements can save money in the long run by reducing maintenance and replacement frequency.

- Safety Assurance: Reliable elements are essential for maintaining safety standards, preventing accidents caused by component failure.

Considerations When Selecting Components

- Brand Reputation: Choose well-known manufacturers with a history of producing durable and reliable products.

- Compatibility: Ensure that the selected items are suitable for your specific vehicle model and system requirements.

- Warranty: Look for items that come with a warranty, indicating the manufacturer’s confidence in their quality.

- Reviews and Recommendations: Research user feedback and consult professionals to gauge the effectiveness of specific components.

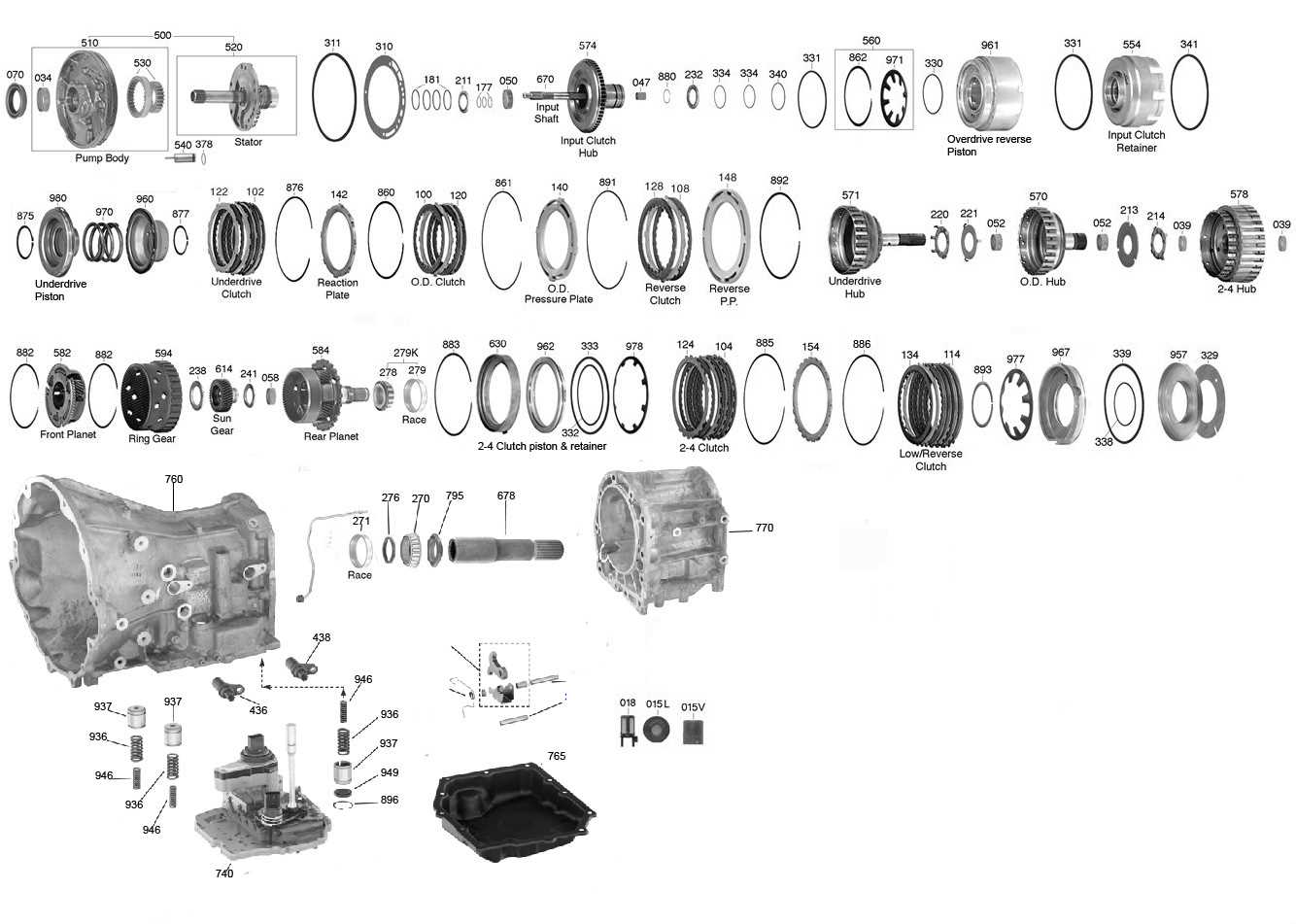

Diagram Analysis for Troubleshooting

Understanding the visual representation of components is crucial for effective diagnostics and repairs. This approach enables technicians to identify potential issues by examining the interconnections and functions of various elements within the assembly. A thorough examination can reveal not only the normal operational relationships but also common failure points that may arise during usage.

In-depth scrutiny of the schematic allows for the pinpointing of specific areas that might lead to malfunction. By mapping out the layout and connections, one can discern which segments are critical for proper functionality and where interruptions may occur. Such an analysis empowers users to isolate problems and formulate targeted solutions.

Furthermore, familiarity with the layout enhances the ability to foresee issues that may develop over time, allowing for proactive maintenance strategies. By prioritizing key components based on their significance in the overall system, technicians can efficiently allocate resources to prevent breakdowns.

Identifying OEM vs. Aftermarket Parts

When it comes to vehicle components, distinguishing between original equipment manufacturer (OEM) and aftermarket options is crucial for ensuring quality and performance. OEM items are designed and produced by the vehicle’s manufacturer, adhering to specific standards and specifications. In contrast, aftermarket alternatives are created by third-party companies and may vary significantly in terms of quality, performance, and compatibility.

Understanding the differences between these two types can significantly impact the longevity and functionality of your vehicle. OEM offerings often come with a warranty and are manufactured to the same standards as the original components, ensuring a reliable fit and function. However, they typically carry a higher price tag.

On the other hand, aftermarket solutions can provide cost savings and a broader range of options. While some aftermarket products may be of high quality, others might not meet the same stringent requirements as their OEM counterparts. Therefore, it’s essential to research the manufacturer and product reviews before making a decision.

In conclusion, whether opting for OEM or aftermarket, understanding the nuances between them is vital for making informed choices that will benefit your vehicle in the long run.

Resources for Further Research

To deepen your understanding of the components and functionality of automatic transmission systems, exploring additional materials and resources is essential. A wide range of literature, online platforms, and community forums can provide valuable insights and technical knowledge that enhance your expertise.

Recommended Literature

Books and manuals focusing on automotive mechanics often contain detailed sections on transmission systems. Look for comprehensive guides that cover general maintenance, troubleshooting, and rebuilding techniques. Technical manuals from manufacturers can also serve as invaluable references for specific models.

Online Communities and Forums

Participating in online forums dedicated to automotive repair and modification can connect you with experienced enthusiasts and professionals. These platforms often feature discussions, troubleshooting tips, and shared experiences related to various transmission systems. Websites like Transmission Repair Forum and Bob Is The Oil Guy can be excellent starting points for community engagement and knowledge exchange.