Understanding the intricate arrangement of elements within a traditional timekeeping mechanism is key to appreciating its functionality. These mechanical devices rely on a series of interlocking structures, each designed to contribute to the precise measurement of time. From delicate springs to gears of varying sizes, every part serves a unique role in ensuring accuracy and reliability.

In the following guide, we will explore the key elements that make up these devices, offering insight into their purpose and interaction within the broader system. Whether you are a novice or an expert, this overview will provide valuable information to enhance your knowledge of how these components work together harmoniously.

With attention to the layout and alignment of these mechanical structures, we aim to provide clarity on their interconnected functions, helping you gain a deeper understanding of the craftsmanship involved in assembling such systems.

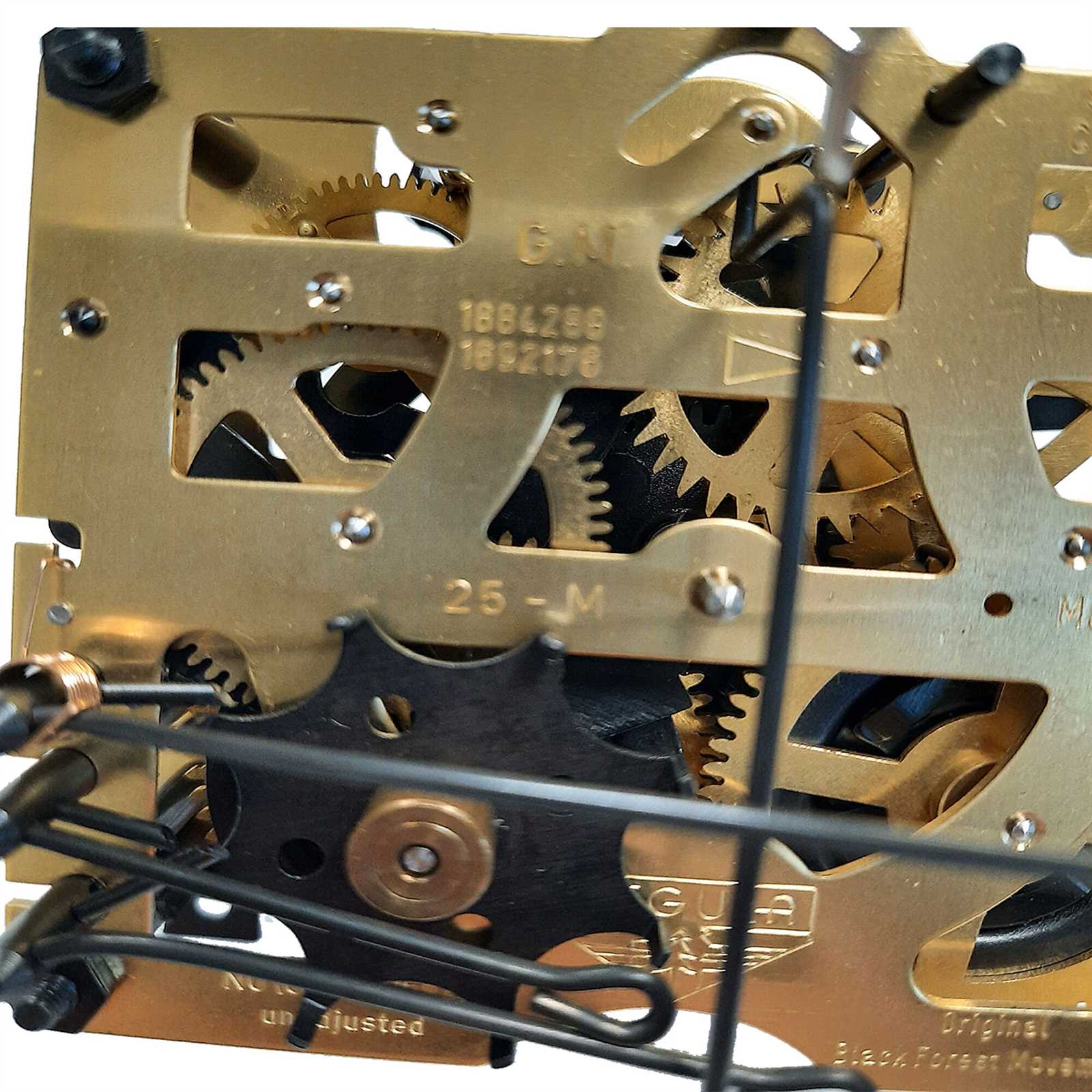

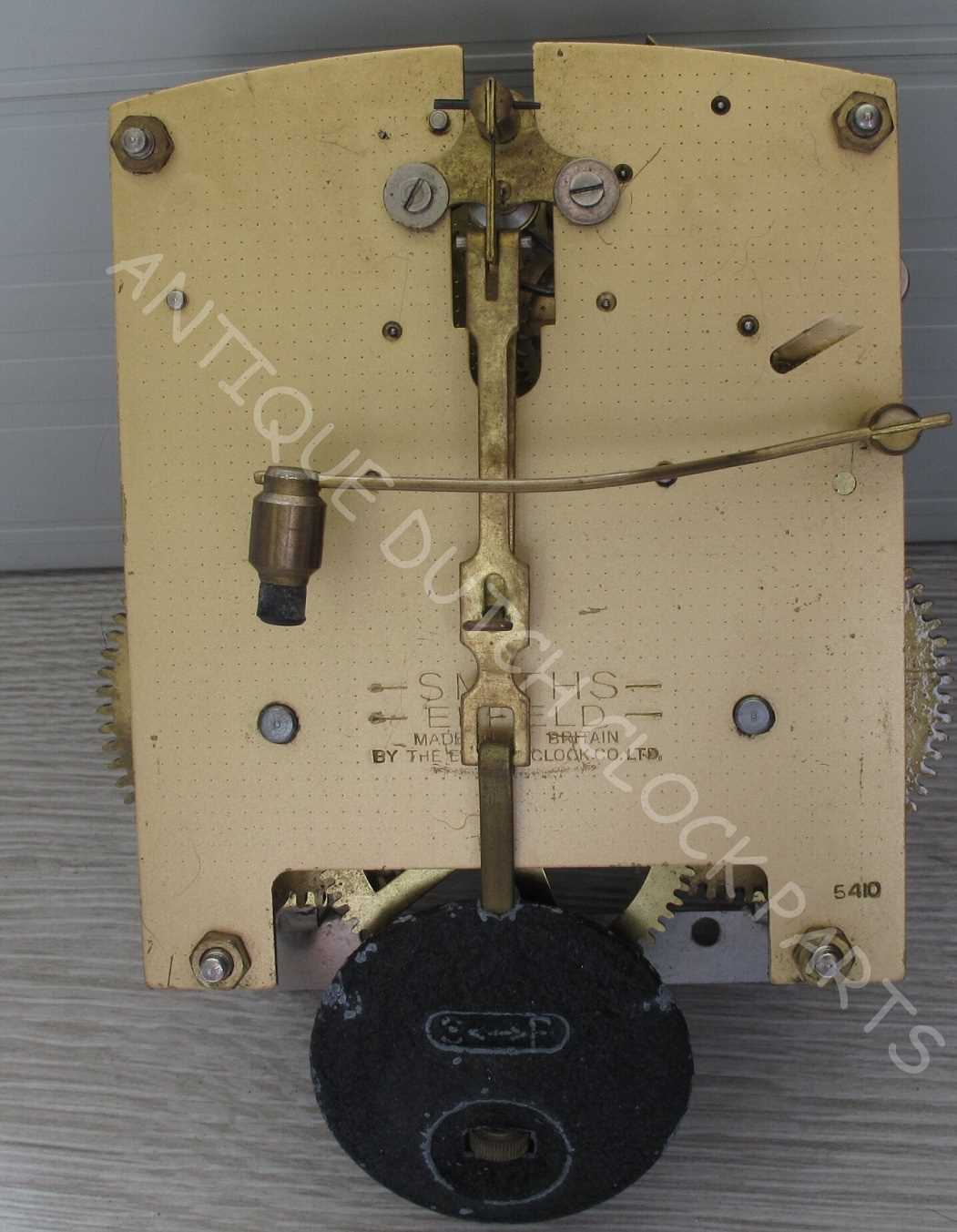

Regula 34 Movement Parts Overview

The intricate system consists of several essential components working together in perfect harmony. Each element plays a key role in ensuring smooth functionality and precision within the mechanism. Understanding how these pieces interact is crucial for anyone looking to maintain or repair this timekeeping device.

Main elements include gears, levers, and springs, all meticulously designed to fit into the overall system. Each piece has a specific function, contributing to accurate timekeeping. The balance between these parts is what allows the mechanism to operate reliably over long periods.

One of the key features is the synchronization between these elements, ensuring that the device runs smoothly without interruption. Regular maintenance is important to keep all components in optimal condition.

Main Components of Regula 34 Mechanism

The intricate structure of this timekeeping device relies on several essential elements working in harmony. These components ensure the precision and functionality of the overall system, each playing a critical role in regulating the mechanism’s timing and motion.

| Component | Function |

|---|---|

| Escapement | Controls the release of energy and regulates the movement’s pace. |

| Mainspring | Stores and releases energy to power the mechanism. |

| Balance Wheel | Oscillates to maintain consistent timing intervals. |

| Gears | Transmit energy from the mainspring to other components. |

| Anchor | Locks and unlocks the escapement to regulate time intervals. |

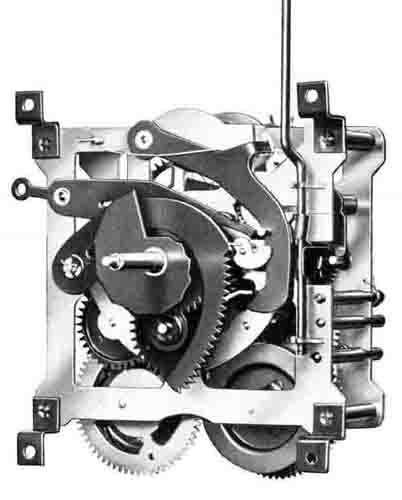

Detailed View of the Escapement System

The escapement is a vital mechanism that controls the release of energy in timed intervals, allowing for precise movement. It ensures that energy is transmitted in a regulated manner, providing accurate timekeeping by interacting with other components. Understanding its function gives a deeper insight into how timekeeping devices operate smoothly and consistently.

Key Components of the Escapement

At the heart of this system are the pallet fork and the escape wheel, working in harmony to regulate the release of energy. The escape wheel’s teeth engage with the pallet fork, creating a controlled and repetitive action. This interaction allows the system to “tick,” marking consistent intervals in time.

How the System Maintains Accuracy

The precise interaction between these components is essential for the overall functionality. The balance wheel, connected to the pallet fork, oscillates back and forth, ensuring that the intervals remain consistent. Any disruption or imbalance in this system could result in inaccurate time measurement, making its precise assembly and alignment critical.

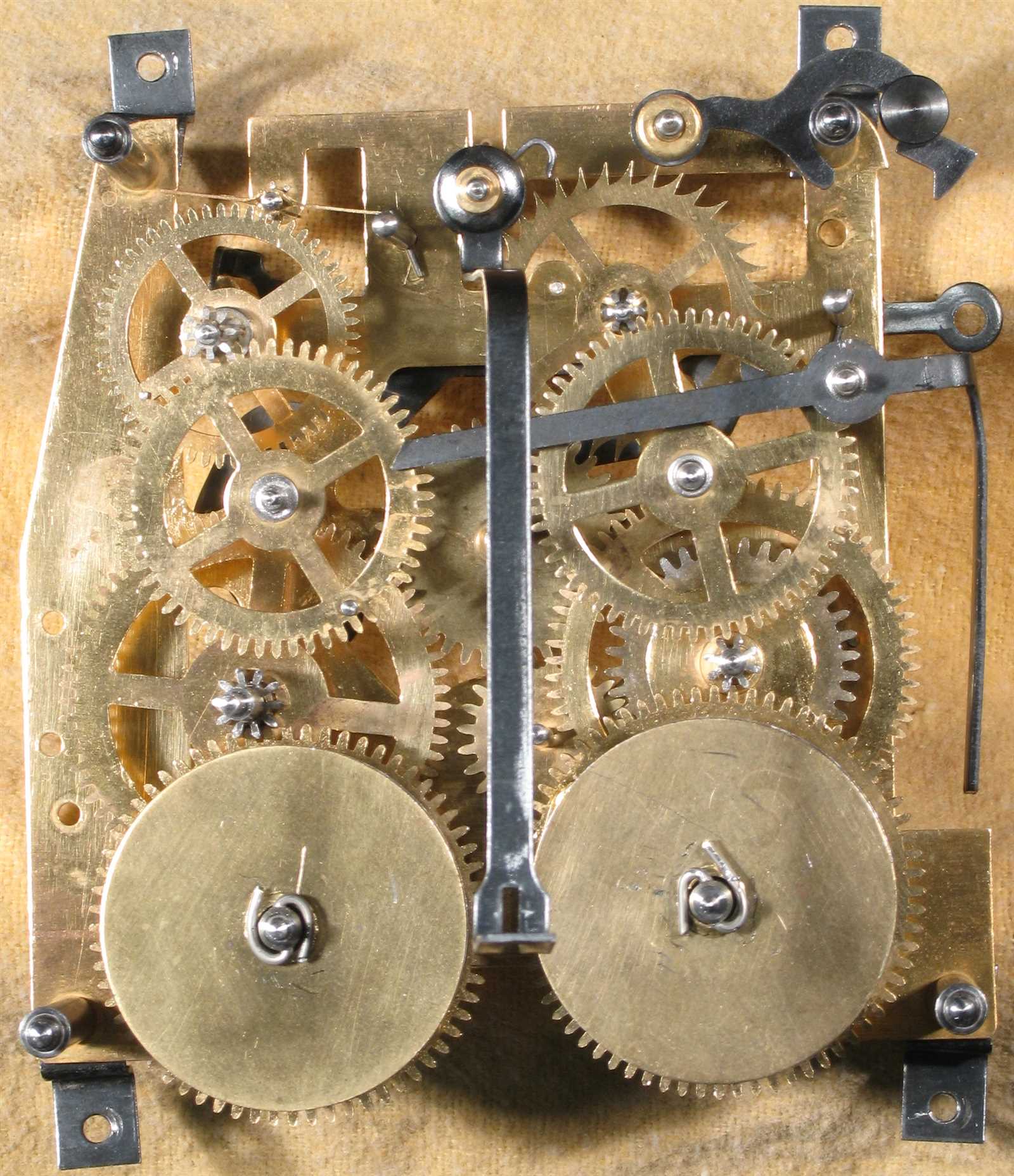

Gear Train Structure and Arrangement

The intricate design of the gear train plays a vital role in ensuring the seamless operation of mechanical timekeeping devices. This system of interconnected wheels transfers energy through the mechanism, controlling its pace and accuracy.

The arrangement of the gears follows a precise layout to efficiently transmit power. Each gear interacts with its neighboring component, forming a carefully orchestrated sequence.

- The primary gear drives the energy input.

- Intermediate gears adjust the speed and direction of the flow.

- The final gear outputs the regulated motion to control the system’s timing.

Proper alignment and positioning of these components are essential for maintaining functionality and ensuring consistent performance.

Balance Wheel and Timekeeping Function

The balance wheel plays a crucial role in maintaining the accuracy of a timekeeping mechanism. This component oscillates back and forth, regulating the release of energy to ensure consistent operation. Without precise control over its movement, the entire mechanism would lose synchronization, leading to incorrect timekeeping.

| Component | Function | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Balance Wheel | Oscillates to regulate energy flow | ||||||||||

| Escapement | Controls the release of energy to the balance wheel | ||||||||||

| Spring | Returns the balance wheel

Power Source and Winding MechanismThe energy source and winding system are crucial components that ensure the functionality and longevity of timekeeping devices. These elements work in harmony to provide accurate time measurement and reliable operation. Power is typically derived from one of two sources:

The winding mechanism plays a significant role in the operation of these timepieces:

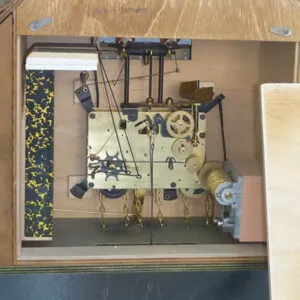

Understanding the interplay between the power supply and the winding system is essential for appreciating how these intricate devices maintain their accuracy and reliability over time. Strike Mechanism and Bell Assembly

The striking system is a crucial element in clock design, responsible for producing auditory signals at designated times. This mechanism consists of various components that work in unison to ensure precise operation, providing not only functionality but also enhancing the aesthetic appeal of the timepiece. Within this framework, the bell assembly plays a pivotal role, serving as the auditory output for the striking sequence. The integration of these elements is vital for achieving accurate chimes, contributing to the overall harmony of the clock’s operation. The striking mechanism typically includes a series of levers and gears that activate the striking hammer. When the clock reaches the set time, this assembly engages, allowing the hammer to strike the bell, producing a clear and resonant sound. The efficiency of this system is paramount for the reliability of the clock’s timekeeping and alert functions. Pendulum Suspension and Regulation

The concept of pendulum support and adjustment plays a vital role in achieving precise timekeeping. This mechanism utilizes a swinging weight, which serves as a stabilizing element, allowing for consistent oscillations that are essential for accuracy. Mechanism OverviewThe suspension system consists of a series of components that work together to ensure smooth motion. At its core, the arrangement allows the pendulum to swing freely, with minimal friction or obstruction. This design is crucial for maintaining a steady rhythm, which is fundamental to time measurement. Adjustment Techniques

To optimize performance, fine-tuning methods are often employed. Adjusting the length of the pendulum can directly influence the rate of oscillation, while calibrating the weight provides additional control over the timing. These adjustments help to counteract external factors that may affect precision, ensuring reliable operation. Lubrication Points for Optimal PerformanceMaintaining proper lubrication is essential for ensuring the efficient operation of any mechanical system. Regular application of suitable lubricants at designated locations can significantly enhance functionality and longevity. Identifying these critical zones allows for proactive maintenance and prevents premature wear and tear. Key Areas to Consider:

Implementing a structured lubrication schedule will not only improve efficiency but also extend the lifespan of the equipment. Regular checks and timely reapplication are crucial for maintaining peak performance. Common Parts Requiring Replacement

Maintenance of timekeeping devices often necessitates the replacement of certain components to ensure optimal functionality. Various elements may wear out or become less effective over time, leading to performance issues. Identifying these components is essential for proper upkeep and longevity. Frequently Replaced Components

Signs of Wear and Tear

Adjustment Tips for Accurate Movement

Achieving precision in timekeeping requires careful calibration and fine-tuning of various components. Proper adjustments ensure that the mechanism operates smoothly and maintains reliable performance over time. Here are some key strategies to enhance the accuracy of the system:

|