In the world of outdoor machinery, having a clear grasp of how each element fits together is crucial for effective maintenance and repair. Whether you’re preparing for winter challenges or simply ensuring optimal performance, knowing the layout of your machine can save time and effort. Familiarity with each section allows users to troubleshoot issues with greater confidence.

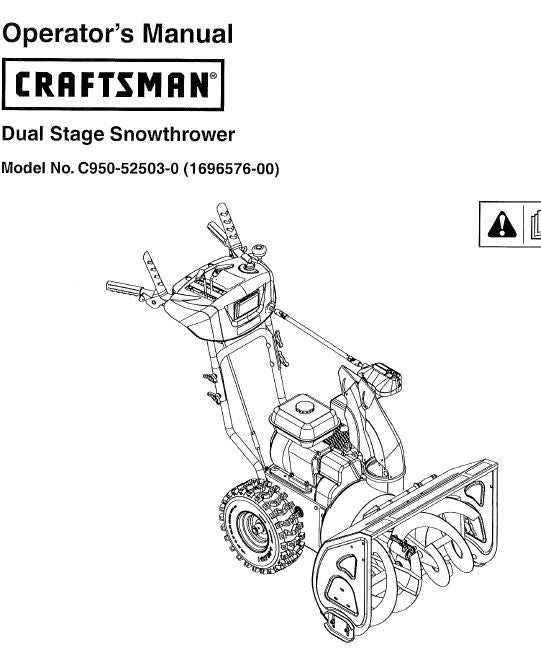

Moreover, visual representations can significantly enhance comprehension. These illustrations serve as valuable resources, enabling individuals to identify various components with ease. By using such references, even those with minimal experience can navigate complex machinery and execute repairs without the fear of making costly mistakes.

Ultimately, a thorough understanding of these mechanisms not only aids in routine upkeep but also contributes to the longevity of the equipment. With the right information at hand, you can tackle any task, ensuring that your outdoor tools are always ready to perform when needed.

Snow Removal Equipment Overview

This section provides a comprehensive examination of essential components for effective snow-clearing machinery. Understanding each element is crucial for maintaining optimal performance and ensuring longevity of your equipment. Familiarity with these parts aids in timely replacements and repairs, enhancing the overall efficiency during winter operations.

Key Components

- Engine: The powerhouse that drives the entire unit.

- Auger: Responsible for gathering and breaking up snow.

- Impeller: Helps propel the snow out of the chute.

- Chassis: The main frame that supports all other components.

- Skids: Adjustable features that control the height of the clearing mechanism.

- Chute: Directs the snow where it needs to go.

Maintenance Tips

- Regularly check and change the oil to ensure smooth engine operation.

- Inspect the auger for any signs of wear or damage.

- Clear debris from the impeller to maintain optimal performance.

- Adjust skids as necessary to adapt to varying snow conditions.

- Lubricate moving parts to prevent rust and corrosion.

Understanding Snowblower Components

Grasping the essential elements of a snow-clearing machine is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring optimal performance during harsh winter conditions. Familiarity with these parts enhances your ability to troubleshoot issues and perform necessary repairs.

Key Functional Elements

At the heart of any clearing device lies the mechanism responsible for propulsion and snow displacement. This includes the auger and impeller, which work together to break up and expel snow effectively. Understanding their functions allows users to recognize signs of wear and tear that could hinder performance.

Maintenance and Care

Regular upkeep of the various segments is essential for longevity. Components such as belts, filters, and spark plugs require periodic inspection and replacement. By delving into the specifics of each element, operators can ensure their machine remains in peak condition, ready to tackle the challenges of winter weather.

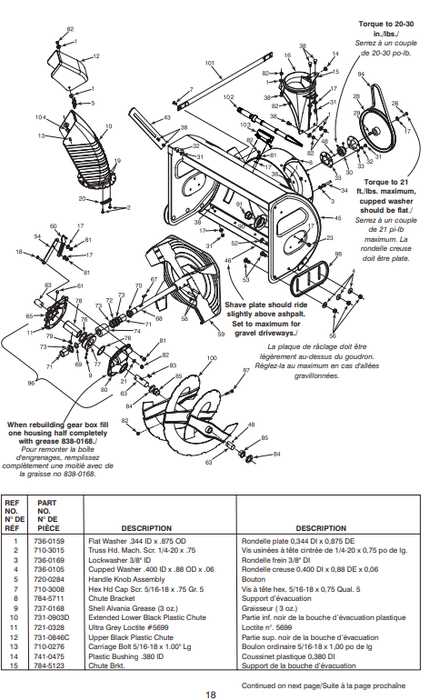

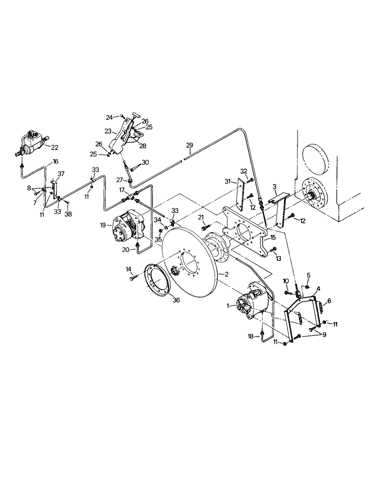

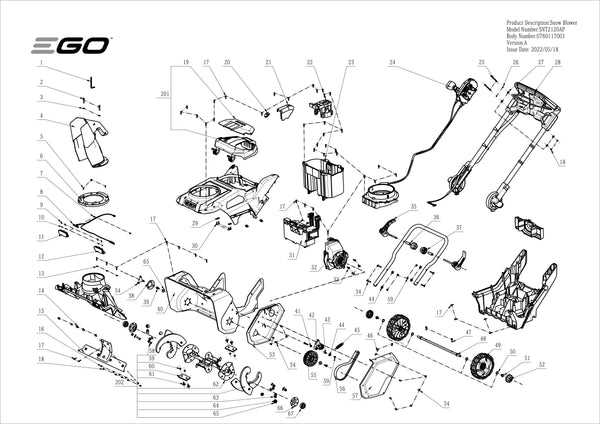

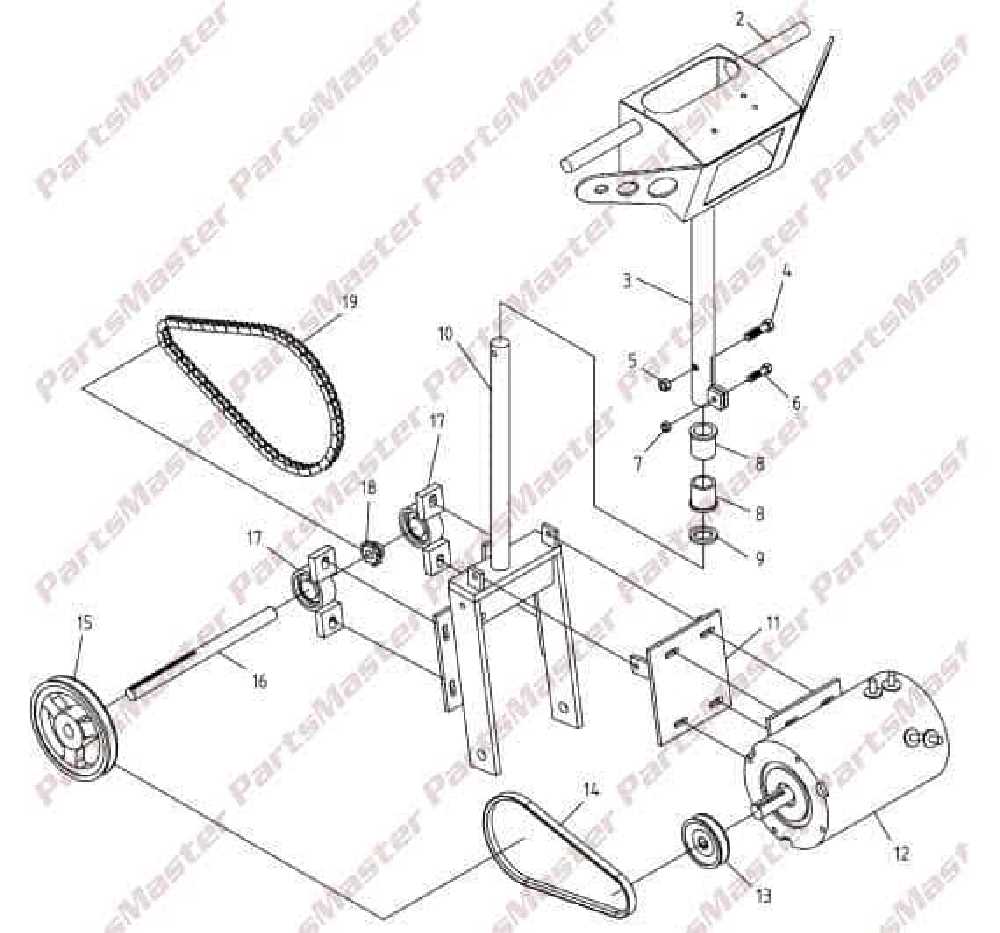

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair of equipment. These illustrations serve as a guide to help users identify and locate specific elements within a system, facilitating easier troubleshooting and replacement. By familiarizing oneself with the layout and symbols used, one can streamline the repair process and ensure that all necessary components are accounted for.

Key Features to Look For

- Numbering System: Each item is often labeled with a unique number corresponding to a list of components, which makes it easy to reference specific parts.

- Symbol Definitions: Familiarize yourself with common symbols used to represent different elements, such as fasteners, housing, and functional components.

- Exploded View: This perspective displays the parts separated, illustrating how they fit together, providing clarity on assembly and disassembly.

Steps for Effective Interpretation

- Begin by examining the overall layout, noting the main sections and how they relate to one another.

- Refer to the accompanying list to understand the function of each labeled item.

- Pay attention to any additional notes or annotations that may provide insight into specific installation or maintenance tips.

Common Issues and Solutions

When operating outdoor equipment for clearing snow, users often encounter a variety of challenges that can impede performance. Understanding these common problems and their corresponding solutions can enhance the efficiency of the machinery and extend its lifespan. This section outlines typical issues and practical remedies that can be easily implemented.

Engine Starting Difficulties

A frequent concern is the engine failing to start. This can result from several factors, including fuel issues, stale gasoline, or a faulty spark plug. To resolve this, ensure that fresh fuel is being used and that the spark plug is clean and properly connected. Regular maintenance checks can prevent this issue from recurring.

Improper Movement or Stalling

Another common issue is the machine stalling or not moving smoothly. This may be due to clogs in the auger or drive system. Inspecting and clearing any blockages, along with ensuring that the drive belts are in good condition, can significantly improve operation. Regular cleaning and maintenance are essential for optimal functionality.

Finding the Right Replacement Parts

Choosing appropriate components for your outdoor equipment is crucial for maintaining its functionality and efficiency. When seeking replacements, it is essential to understand the specific requirements of your machine to ensure optimal performance. This guide provides valuable insights into how to identify and select the correct items.

To begin, consider the following steps:

- Identify Your Equipment: Know the make and model of your machine to find suitable replacements.

- Check the Owner’s Manual: Refer to the manual for details on compatible components and specifications.

- Measure Components: Take measurements of existing items to ensure the new ones will fit correctly.

- Research Compatible Alternatives: Look for reputable brands that offer high-quality substitutes that meet industry standards.

Once you have gathered all necessary information, you can proceed to source the replacements through various channels:

- Visit authorized retailers or online marketplaces that specialize in outdoor equipment.

- Consult local repair shops for expert advice and recommendations on reliable alternatives.

- Utilize forums or community groups where enthusiasts share their experiences and suggestions.

By following these guidelines, you can ensure a smooth process in obtaining the right components for your machinery, thereby extending its lifespan and enhancing its performance.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your outdoor equipment requires regular care and attention. By following a consistent maintenance routine, you can extend the lifespan of your machine and improve its overall performance. This section provides essential tips to keep your equipment operating smoothly for years to come.

Regular Inspections

Conducting frequent checks on your machinery is crucial for identifying potential issues before they escalate. Look for signs of wear, loose components, and any fluid leaks. Addressing these concerns promptly can prevent costly repairs and enhance functionality.

Proper Storage Practices

Storing your equipment correctly can significantly impact its longevity. Always keep it in a dry and sheltered area, away from extreme weather conditions. If possible, cover the machinery to protect it from dust and debris. This simple practice can help maintain its integrity and readiness for use.

| Maintenance Task | Frequency |

|---|---|

| Check fluid levels | Every use |

| Inspect belts and cables | Monthly |

| Clean the exterior | After each use |

| Sharpen blades | Seasonally |

| Change filters | Annually |

Tools Needed for Repairs

When tackling maintenance tasks, having the right tools is essential for ensuring efficiency and effectiveness. Proper equipment can make the difference between a smooth repair process and a frustrating experience. Familiarizing oneself with the necessary instruments can lead to successful outcomes and prolong the lifespan of the machinery.

Essential tools typically include a variety of wrenches and sockets for loosening and tightening fasteners. Screwdrivers of different types and sizes are also crucial for handling screws found in various components. A reliable set of pliers can assist in gripping, bending, and cutting wires or other materials as needed.

In addition to hand tools, power equipment may be beneficial for more extensive repairs. Electric drills or impact wrenches can expedite the removal and installation of parts, saving valuable time. Safety gear, such as gloves and goggles, should not be overlooked, as they protect users from potential hazards during the repair process.

Having an organized toolbox is vital for maintaining efficiency. By keeping tools easily accessible, one can quickly find what is needed, minimizing downtime. Regularly inspecting tools for wear and tear ensures that they remain in optimal condition, ready for any repair task that arises.

Step-by-Step Repair Process

The process of restoring a malfunctioning outdoor equipment requires a systematic approach to ensure efficiency and effectiveness. This section outlines a clear, sequential method to troubleshoot and fix common issues, helping users regain the optimal functionality of their machinery.

Begin by assessing the problem. Identify the symptoms displayed by the equipment, whether it is not starting, running unevenly, or experiencing reduced power. Documenting these observations can provide valuable insights during the repair process.

Gather necessary tools and materials. Ensure you have all essential instruments on hand, such as wrenches, screwdrivers, and replacement components. Having everything prepared beforehand will streamline the repair process and reduce downtime.

Disassemble carefully. Start by removing the outer casing or any protective covers. Pay attention to the order of disassembly, as this will facilitate reassembly later. Taking photographs during this stage can serve as a helpful reference.

Inspect and identify damaged components. Look for signs of wear or breakage in the internal parts. Replace any damaged items with suitable alternatives that match the original specifications to maintain performance integrity.

Reassemble the equipment. Follow the documented steps from the disassembly phase, ensuring that all parts fit snugly and securely. Double-check the connections and fastenings to prevent any potential issues during operation.

Test the repaired machinery. Once reassembled, conduct a thorough test to verify that the equipment operates as intended. Monitor its performance closely for any irregularities, and make adjustments if necessary.

By adhering to these guidelines, users can effectively troubleshoot and resolve issues with their machinery, ensuring its longevity and reliable performance.

Upgrading Your Snowblower Features

Enhancing the capabilities of your winter machinery can significantly improve its performance and efficiency. By implementing various upgrades, you can optimize its operation, ensuring it meets your specific needs during harsh weather conditions. Whether you are looking for increased power or improved usability, there are several options to consider.

Investing in a more powerful engine can lead to better performance in challenging conditions. Higher horsepower models provide the ability to tackle heavier snowfalls and maintain speed without sacrificing effectiveness. Additionally, upgrading the transmission system can enhance maneuverability, allowing for smoother navigation through your property.

Another effective modification involves the addition of improved clearing technology. Upgrading to a model with advanced augers can facilitate better snow removal, ensuring thorough clearance of your pathways. You might also consider incorporating heated handles or ergonomic controls to enhance comfort and usability during prolonged operations.

Lastly, enhancing your equipment with high-quality tires or tracks can significantly affect its traction and stability. Opting for specialized winter tires or heavy-duty tracks can provide superior grip on icy surfaces, making your machinery more reliable. With these enhancements, you will experience a more efficient and user-friendly operation throughout the winter season.

Where to Purchase Mtd Parts

Finding components for your outdoor equipment can enhance its performance and extend its lifespan. Numerous options are available for acquiring the necessary items, catering to various preferences and budgets.

Here are some popular avenues to explore:

- Authorized Dealers: These locations often provide genuine items, ensuring compatibility and quality. Visit your nearest authorized retailer for reliable service.

- Online Retailers: Many websites specialize in outdoor equipment supplies. They often offer a vast selection, competitive pricing, and the convenience of home delivery.

- Local Hardware Stores: Many hardware stores stock common components. This option allows you to inspect items in person and receive immediate assistance.

- Salvage Yards: For budget-conscious consumers, salvage yards can be a goldmine for used items. You may find perfectly functional components at a fraction of the cost.

Whichever option you choose, ensure to verify the specifications to guarantee a proper fit for your equipment.

Online Resources for DIY Repairs

In today’s digital age, finding information for do-it-yourself repairs has never been easier. Numerous online platforms offer valuable insights and instructions for maintaining and fixing various machines. These resources can empower users to troubleshoot issues, locate necessary components, and perform repairs confidently without relying solely on professional services.

Useful Websites

Several websites cater to DIY enthusiasts, providing tutorials, videos, and user forums. These platforms often feature step-by-step guides that simplify the repair process, making it accessible to individuals with varying skill levels. Below is a table showcasing some popular online resources:

| Resource | Description | Features |

|---|---|---|

| RepairClinic | Comprehensive guide for home repairs | Video tutorials, parts lookup, and customer support |

| YouTube | Video-sharing platform with DIY content | Tutorials from various creators, community feedback |

| Forums | Online communities for sharing advice | Peer support, troubleshooting tips, and part suggestions |

Community Engagement

Engaging with online communities can enhance the DIY experience. Forums and social media groups allow individuals to share their experiences and seek advice from others. This collaborative approach not only fosters a sense of belonging but also provides diverse perspectives on repair strategies, making it easier to find effective solutions.