When delving into the intricacies of small power units, one often encounters a wealth of information about their structure and functionality. These machines, essential in various applications, rely on a multitude of elements that work in harmony to ensure optimal performance. A comprehensive exploration of these components not only enhances understanding but also aids in effective maintenance and troubleshooting.

Within this context, visual representations serve as invaluable tools. They allow users to identify and comprehend the specific roles of each individual piece, facilitating easier repairs and modifications. By dissecting these illustrations, enthusiasts and professionals alike can gain insights into the arrangement and interrelationships of various elements, paving the way for more informed decisions.

Furthermore, familiarity with these representations can significantly streamline the process of sourcing replacements or upgrades. Whether one is a hobbyist or a seasoned technician, having a clear grasp of the configuration of these vital components can lead to improved efficiency and longevity of the equipment. Engaging with this information empowers users to enhance their expertise and tackle challenges with confidence.

Understanding the Tecumseh 5hp Engine

This section aims to provide insights into a widely utilized power unit known for its reliability and efficiency. Designed for various applications, this machine serves as a vital component in many outdoor devices, making it essential for enthusiasts and professionals alike.

Key Components: Every functional unit comprises several critical elements that work harmoniously. Familiarizing oneself with these components can significantly enhance maintenance and operational understanding.

Functionality: The operational principles are rooted in mechanics, where energy conversion plays a crucial role. Grasping these principles aids in troubleshooting and optimizing performance.

Applications: From lawn mowers to generators, this powerhouse finds its place in numerous settings. Its versatility is a testament to its design and engineering prowess.

Key Components of the Engine

Understanding the fundamental elements of a motor is essential for effective maintenance and repair. Each component plays a vital role in the overall functionality, ensuring optimal performance and longevity. Below are some of the primary features that contribute to the efficient operation of these mechanical systems.

- Crankshaft: This part converts linear motion into rotational motion, driving the other components.

- Piston: Responsible for compressing the fuel-air mixture and transmitting force to the crankshaft.

- Connecting Rod: Links the piston to the crankshaft, allowing for the transfer of energy.

- Cylinder Head: Houses valves and provides a sealing surface for combustion, essential for maintaining pressure.

- Valves: Control the intake of fuel and air, as well as the expulsion of exhaust gases.

- Ignition System: Produces the spark necessary for combustion, a critical aspect of operation.

- Fuel System: Delivers fuel to the combustion chamber, ensuring an appropriate mixture for efficient performance.

Each of these components interacts intricately, contributing to the overall efficacy of the motor. Regular inspection and understanding of these elements can significantly enhance performance and prevent potential failures.

Importance of Maintenance and Care

Regular upkeep and attention are crucial for ensuring optimal performance and longevity of machinery. Neglecting these aspects can lead to reduced efficiency, increased wear, and ultimately, costly repairs. By adhering to a structured maintenance routine, operators can prevent potential issues and enhance the overall functionality of their equipment.

Benefits of Consistent Maintenance

- Increased Reliability: Regular checks help identify problems before they escalate, ensuring consistent performance.

- Cost Savings: Preventive care often results in lower repair costs compared to addressing significant failures.

- Enhanced Lifespan: Proper treatment extends the working life of components, maximizing the return on investment.

- Safety Assurance: Routine inspections contribute to safer operation by minimizing risks associated with mechanical failures.

Key Maintenance Practices

- Regular Cleaning: Keeping surfaces free from debris and dirt prevents buildup that can lead to operational issues.

- Fluid Checks: Monitoring and replacing lubricants and coolants ensures smooth functioning and reduces friction.

- Inspection of Components: Periodically examining belts, hoses, and other critical elements helps identify wear and tear.

- Timely Repairs: Addressing minor issues promptly can prevent them from developing into major problems.

Common Issues with Tecumseh Engines

Small power sources often face a variety of challenges that can impact their performance and reliability. Understanding these typical problems can aid in effective troubleshooting and maintenance. This section delves into frequent concerns that users may encounter, enhancing the longevity and functionality of their machines.

Fuel Delivery Problems: One common issue is inadequate fuel flow, which can lead to poor operation or stalling. Clogged filters or lines can restrict fuel access, necessitating regular checks and maintenance.

Starting Difficulties: Engines may also exhibit trouble starting, often caused by issues in the ignition system or a weak battery. Ensuring proper spark and battery health is essential for reliable operation.

Overheating: Excessive heat can arise from insufficient lubrication or blocked air vents, potentially damaging internal components. Regularly monitoring oil levels and cleaning vents can help prevent this issue.

Wear and Tear: With time, parts can wear down, leading to decreased efficiency or failure. Routine inspections and timely replacements of worn components are vital for optimal performance.

Vibration and Noise: Unusual vibrations or sounds may indicate misalignment or loose fasteners. Addressing these concerns promptly can prevent further damage and enhance operational smoothness.

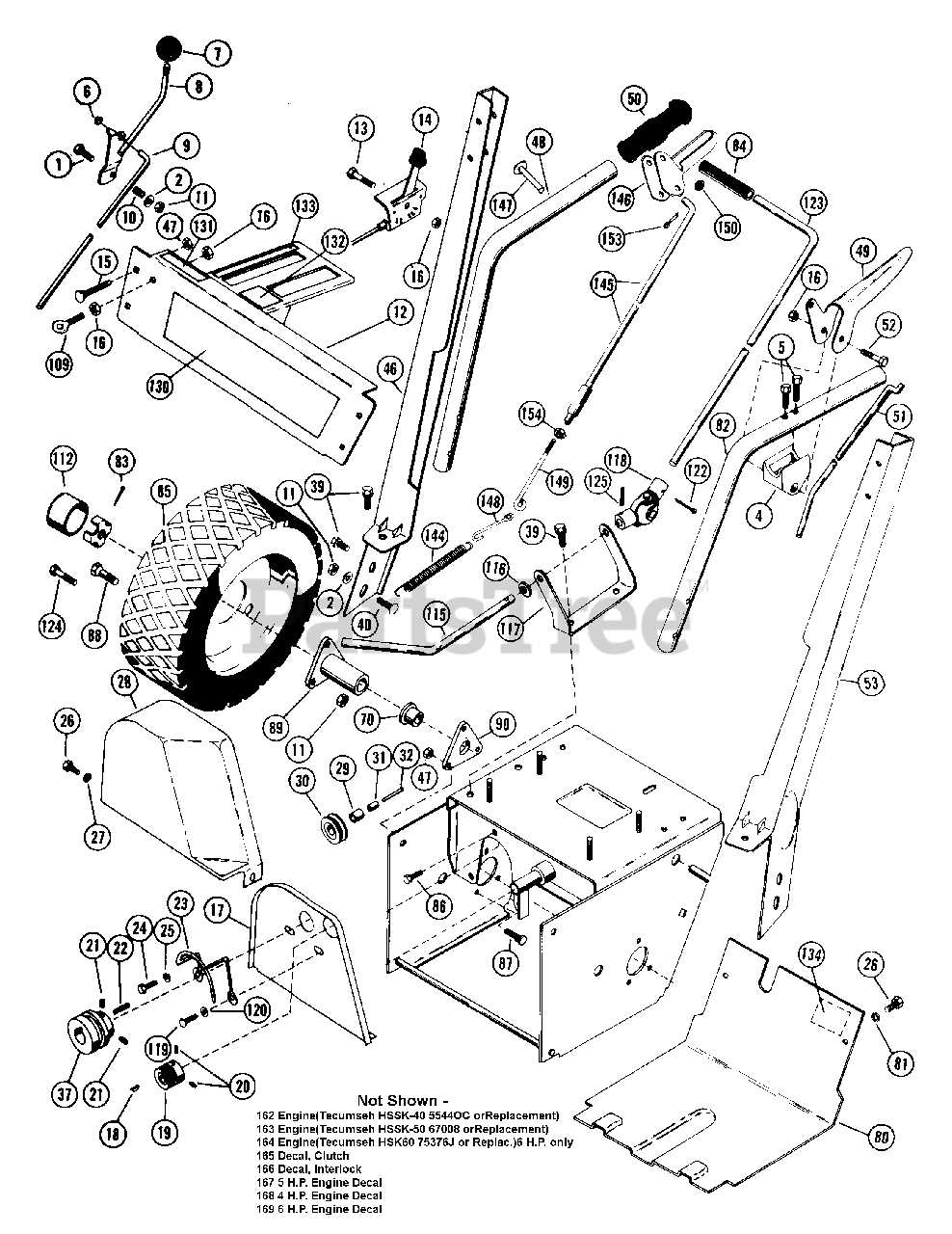

How to Read a Parts Diagram

Understanding a schematic representation is crucial for effective maintenance and repair of various machinery. These visual guides provide detailed information about the components, their relationships, and the assembly process. Familiarity with such illustrations can significantly enhance troubleshooting skills and facilitate efficient repairs.

Here are some key steps to help you navigate through a schematic:

- Identify Symbols: Each component is usually represented by a unique symbol. Familiarize yourself with common icons to understand what each part represents.

- Follow the Lines: Lines connecting the symbols indicate relationships or pathways. Pay attention to these connections, as they show how components interact with one another.

- Check for Labels: Many schematics include labels or numbers next to components. These often correspond to a list or key, providing further details about each part.

- Understand Scale: Be mindful of the scale used in the representation. Some diagrams provide a scale reference to indicate the size and proportion of components relative to one another.

- Refer to a Legend: If available, consult the legend or key accompanying the illustration. This can clarify symbols, color codes, or any specific notes relevant to the schematic.

By mastering these techniques, you can effectively interpret visual representations and ensure a successful approach to any repair or maintenance task.

Ordering Replacement Parts Online

When it comes to maintaining your machinery, securing the right components through online platforms can be both convenient and efficient. With a few clicks, you can access a wide range of options tailored to your specific needs.

- Start by identifying the exact component you need.

- Check the specifications to ensure compatibility.

- Visit reputable websites that specialize in mechanical components.

- Look for customer reviews to gauge product quality.

- Compare prices across different vendors for the best deal.

Once you’ve selected your items, proceed to checkout, ensuring that you enter your shipping information correctly to avoid delays.

Finally, keep an eye on delivery times and confirm that the products match your expectations upon arrival.

Differences Between Engine Models

Various motor variants exhibit distinct characteristics that cater to different applications and performance needs. Understanding these differences is crucial for selecting the appropriate model for specific tasks, as each version offers unique features and specifications that affect overall efficiency and functionality.

Performance Variations

One of the primary distinctions lies in the power output and torque delivery. Some models are engineered for higher performance, allowing for quicker acceleration and enhanced load capacity. In contrast, others prioritize fuel efficiency and smooth operation, making them ideal for lighter tasks.

Design and Build Quality

The construction materials and design techniques also vary significantly. Some versions utilize advanced composites for durability and weight reduction, while others might rely on traditional metals for robustness. Durability and maintenance considerations play a significant role in determining which model is best suited for specific environments.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks, having the right instruments is essential for a successful outcome. The appropriate tools not only facilitate the repair process but also ensure safety and efficiency. Below is a list of indispensable tools that will aid in various repair projects.

- Wrenches: A set of adjustable and socket wrenches is crucial for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers are needed for securing or removing screws.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping and manipulating small components.

- Torque Wrench: This tool is essential for applying the correct amount of force to fasteners.

- Hex Keys: Also known as Allen wrenches, these are vital for working with hexagonal screws.

In addition to these basic tools, consider the following items for more complex tasks:

- Multimeter: Useful for diagnosing electrical issues.

- Oil Filter Wrench: Helps in removing and installing oil filters with ease.

- Parts Cleaner: A solvent or cleaning solution that assists in keeping components free of debris.

- Safety Gear: Always wear gloves, goggles, and other protective equipment to ensure personal safety.

Equipping yourself with these tools will enhance your ability to perform repairs effectively and confidently.

Tips for Troubleshooting Problems

When dealing with mechanical issues, a systematic approach can make all the difference. Identifying the root cause of a malfunction often requires careful observation and methodical testing. This section provides practical strategies to help you diagnose and resolve common challenges effectively.

Start by gathering information about the symptoms. Note any unusual sounds, vibrations, or performance issues. Keeping a log of these observations can aid in pinpointing the problem more accurately. Next, inspect the unit thoroughly for visible signs of wear or damage. Look for loose connections, leaks, or cracked components that could affect operation.

Testing the functionality of individual elements is crucial. Use appropriate tools to check electrical connections, fuel supply, and airflow. Each system plays a vital role in overall performance, so ensure that each part is operating correctly. If the issue persists, consult the manufacturer’s guidelines or seek assistance from knowledgeable sources to gain insights on less obvious problems.

Finally, don’t overlook the importance of regular maintenance. Keeping everything clean and well-lubricated can prevent many issues from arising in the first place. Establish a routine check-up schedule to ensure long-lasting and reliable performance.

Exploring Aftermarket Parts Options

When seeking alternatives to original components, it’s essential to evaluate various aftermarket solutions that can enhance performance and longevity. These options often provide greater flexibility, allowing users to customize their equipment according to specific needs and preferences.

Benefits of Aftermarket Solutions

Cost-effectiveness is a significant advantage, as many alternatives are available at lower prices without compromising quality. Additionally, users may discover enhanced features that are not present in factory-issued components, leading to improved functionality.

Considerations When Choosing Alternatives

Quality should always be a priority. Researching reputable suppliers ensures that the selected replacements will perform reliably. Moreover, compatibility with existing machinery must be confirmed to avoid any potential issues.

Resources for Tecumseh Engine Owners

For enthusiasts and users of small machinery, having access to reliable information and support is essential for optimal maintenance and repair. This section aims to provide a collection of valuable resources that will assist owners in ensuring their equipment operates smoothly and efficiently.

Online Forums and Communities

Joining online platforms dedicated to small machinery can be a great way to connect with fellow users. These communities often share tips, troubleshooting advice, and personal experiences that can be incredibly beneficial. Participating in discussions can help you gain insights and solutions to common issues.

Manufacturer Manuals

Obtaining the original manuals is crucial for understanding the specifications and maintenance requirements of your unit. These documents often include essential information about assembly, maintenance schedules, and troubleshooting guides that can aid in preserving the longevity of your equipment.

Video Tutorials

Many creators produce informative videos that visually demonstrate repairs and maintenance procedures. Platforms like YouTube are rich with content, providing step-by-step instructions that can simplify complex tasks and enhance your repair skills.

Local Repair Shops

Establishing a relationship with a nearby repair shop that specializes in small machinery can provide you with professional assistance when needed. These experts can offer personalized advice and service, ensuring that your equipment remains in peak condition.

Replacement Suppliers

Identifying reputable suppliers for replacement components is key. Whether you prefer online shopping or local stores, having access to high-quality replacements ensures that your machinery continues to function effectively. Look for suppliers that offer warranties and customer support for added peace of mind.