When it comes to maintaining high-performance watercraft, a thorough grasp of engine components is essential. The intricate design of marine propulsion systems requires careful attention to each element, ensuring they work harmoniously. In this section, we will explore the vital aspects of these mechanisms, shedding light on their functions and interconnections.

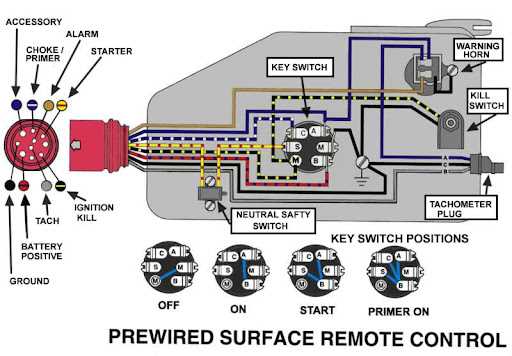

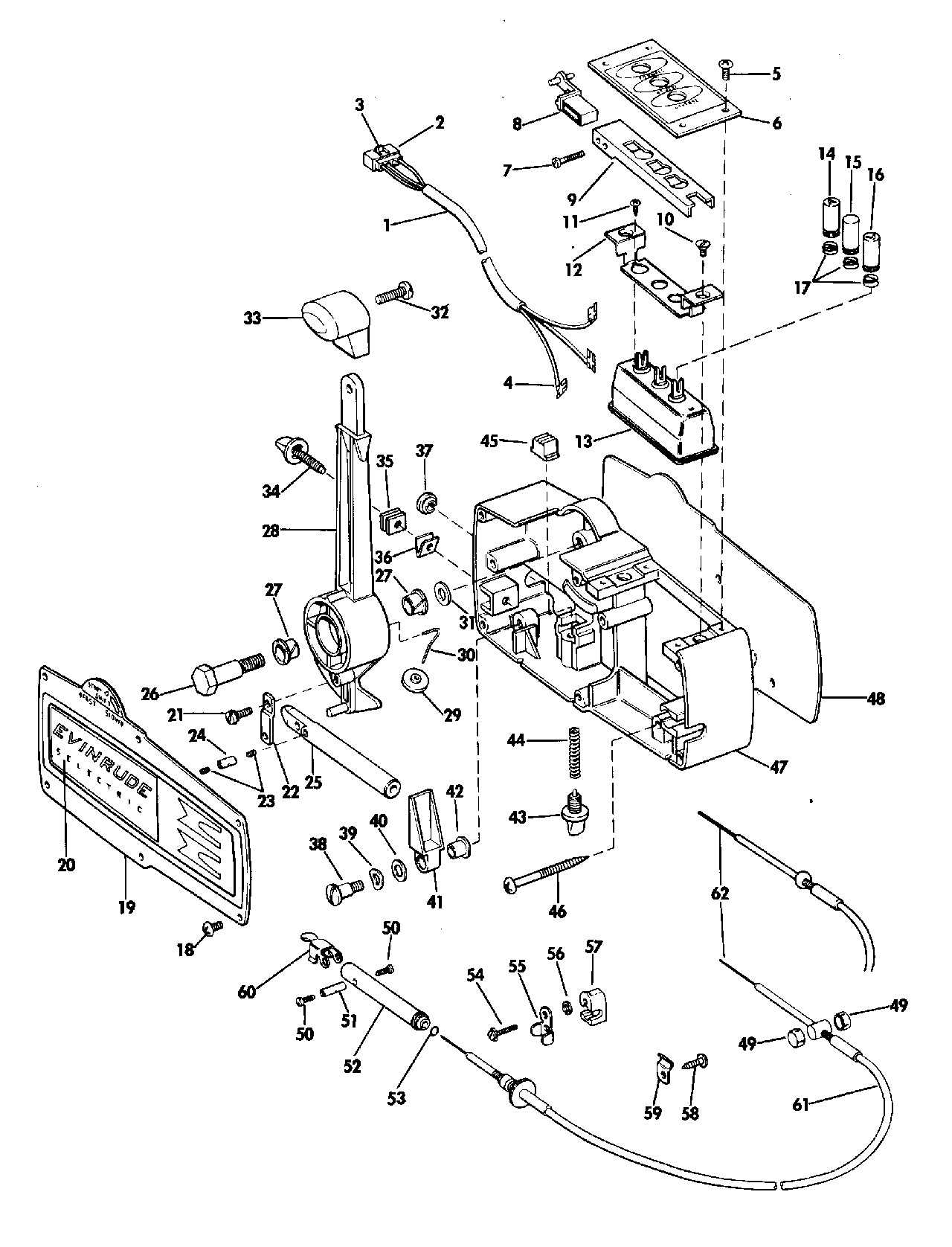

Visual aids play a crucial role in comprehending the assembly of these systems. By examining detailed representations, one can gain insights into the various elements that contribute to overall efficiency and reliability. This knowledge not only enhances maintenance practices but also empowers enthusiasts to tackle repairs with confidence.

As we delve deeper, we will discuss the significance of specific components, highlighting their roles within the greater machinery. Understanding how each piece fits into the larger framework is key to ensuring optimal performance and longevity of your vessel’s engine.

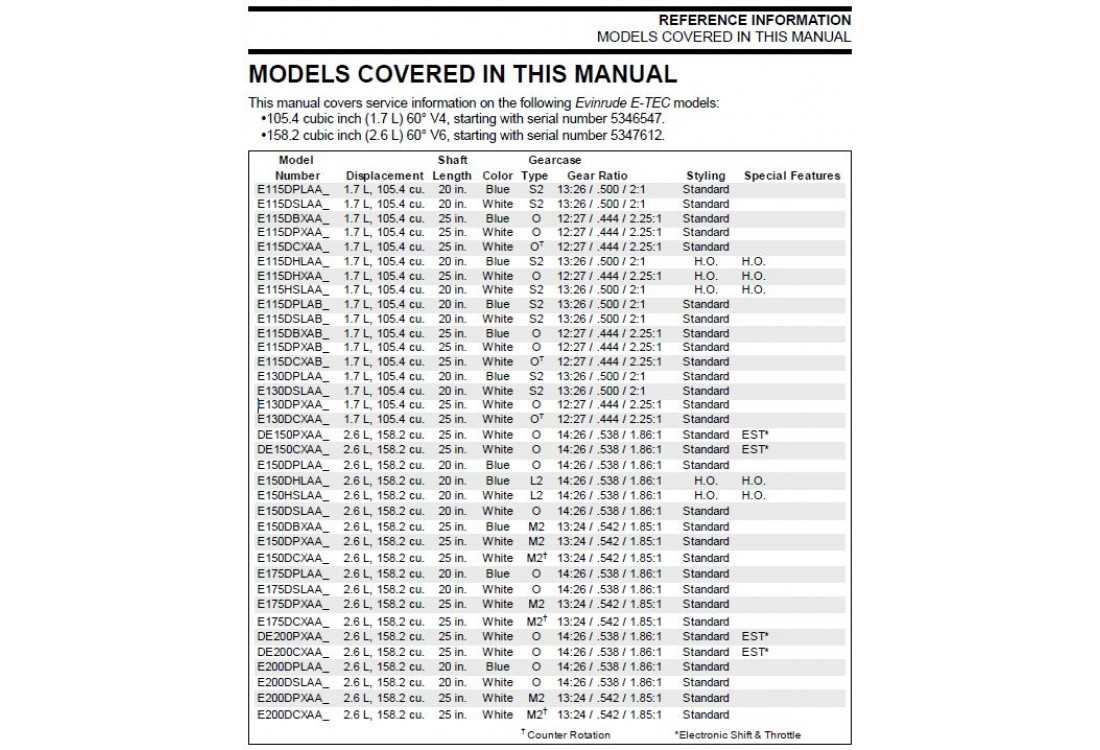

Evinrude 115 Parts Overview

This section provides an essential insight into the components of a specific outboard motor model, focusing on their roles and interrelationships. Understanding these elements is crucial for maintenance and repair, ensuring optimal performance and longevity of the engine.

Key Components

The motor consists of various crucial elements that contribute to its functionality. Each part plays a significant role in the overall operation, from propulsion to fuel management.

| Component | Description |

|---|---|

| Cylinder Block | The core structure housing the pistons and combustion chambers. |

| Crankshaft | Transforms linear motion from the pistons into rotational motion for the propeller. |

| Fuel Pump | Delivers fuel from the tank to the engine at the required pressure. |

| Ignition System | Generates the spark necessary to ignite the air-fuel mixture. |

| Exhaust Manifold | Directs exhaust gases away from the engine, enhancing efficiency. |

Maintenance Considerations

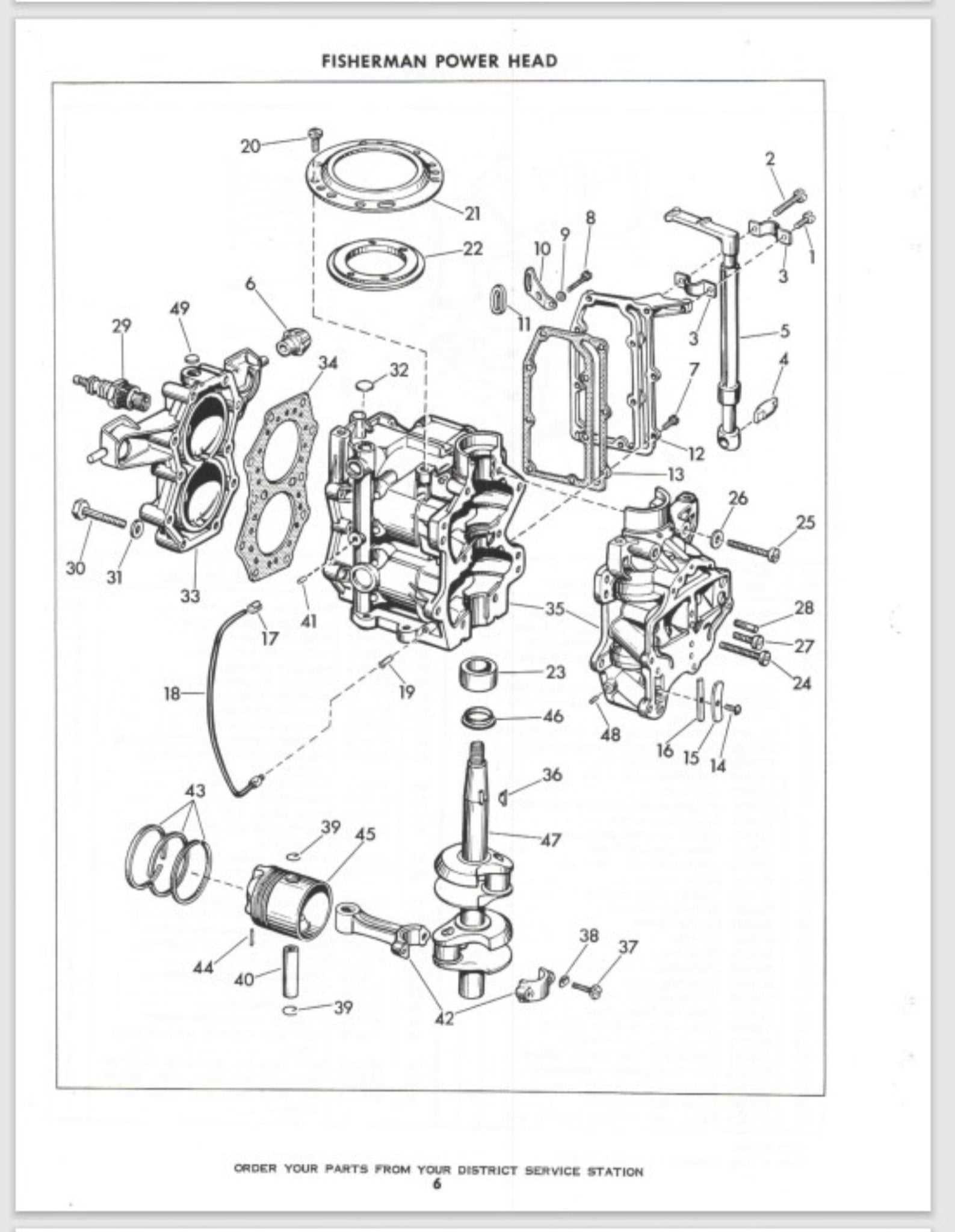

Understanding the Engine Components

Engines are intricate systems made up of various elements that work together to create power and efficiency. Grasping the function of each component is essential for proper maintenance and troubleshooting. This section will explore the fundamental parts that contribute to the overall performance of a marine propulsion system.

Powerhead serves as the heart of the mechanism, housing critical components such as the cylinders and the crankshaft. It is responsible for converting fuel into energy, and understanding its operation is vital for anyone looking to optimize performance.

Fuel System plays a crucial role in delivering the right mixture of fuel and air to the combustion chamber. Components like the fuel pump and carburetor are essential in ensuring that the engine runs smoothly. Recognizing their function can aid in diagnosing common issues related to power loss or inefficient fuel consumption.

Cooling System prevents the engine from overheating, which can lead to serious damage. This system typically includes water pumps and thermostats, which regulate temperature and maintain optimal operating conditions. Knowledge of how this system works can help in identifying overheating problems before they escalate.

Ignition System is responsible for igniting the fuel-air mixture within the engine. Components such as spark plugs and ignition coils are integral to this process. Understanding how these parts interact can provide insight into starting issues and misfires that may arise.

Exhaust System is crucial for directing gases produced during combustion away from the engine. It helps maintain performance by ensuring that back pressure is minimized. Awareness of its components can assist in addressing performance issues related to exhaust blockage or leaks.

By familiarizing oneself with these core elements, users can enhance their understanding of engine functionality and improve maintenance practices, ultimately leading to a more reliable and efficient operation.

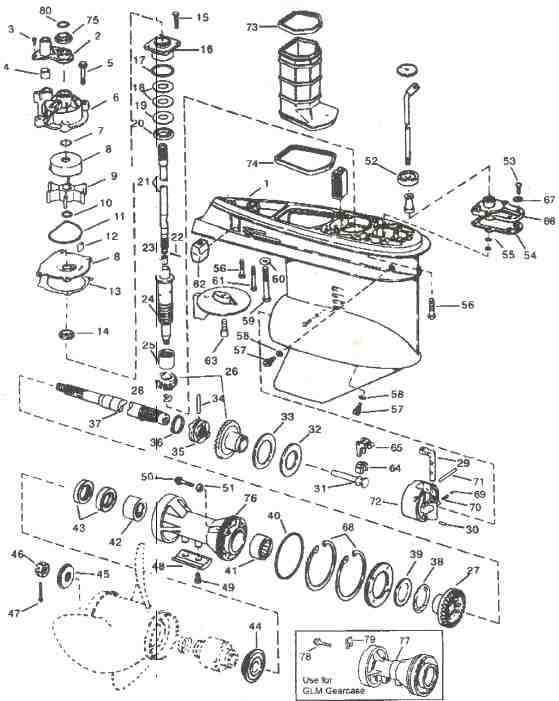

Importance of Accurate Diagrams

Having precise visual representations is crucial in the realm of mechanical components. These illustrations serve as vital resources for understanding the intricate relationships and functions of various elements within a system. When these images are accurate, they facilitate smoother repairs and maintenance, ensuring that users can easily identify and locate necessary components.

Moreover, clarity in these representations helps reduce the risk of errors during assembly or disassembly processes. This is particularly important for individuals who may not possess extensive technical knowledge. Accurate visuals empower users to navigate complex machinery confidently, enhancing both safety and efficiency.

| Benefits of Accurate Visuals | Description |

|---|---|

| Enhanced Understanding | Clear visuals allow users to grasp the configuration and function of components more easily. |

| Reduced Errors | Precision in illustrations minimizes mistakes during repairs, leading to better outcomes. |

| Time Efficiency | Quick identification of parts speeds up the repair process, saving time and effort. |

| User Empowerment | Users gain confidence in their ability to work with complex systems when equipped with reliable diagrams. |

Common Replacement Parts for Evinrude

Maintaining the longevity and performance of your outboard engine often requires the replacement of essential components. Understanding which items typically need to be replaced can help ensure smooth operation and enhance overall efficiency. This section outlines the frequently swapped elements that contribute to optimal performance.

Key Components for Replacement

Several crucial elements are known for their wear over time and may require timely substitution. Here are some of the most common:

| Component | Description |

|---|---|

| Fuel Filter | Essential for keeping the fuel system clean and free from contaminants. |

| Spark Plug | Vital for igniting the air-fuel mixture, contributing to engine performance. |

| Water Pump Impeller | Ensures proper cooling by circulating water through the engine. |

| Propeller | Helps in propulsion; regular inspection and replacement are crucial for efficiency. |

| Thermostat | Regulates engine temperature for optimal operation. |

Importance of Regular Maintenance

Frequent inspection and timely replacement of these critical components can prevent significant issues and costly repairs. By staying proactive about maintenance, you can enhance the reliability and performance of your marine equipment, ensuring that it remains in peak condition for many outings to come.

Where to Find Parts Diagrams

Locating visual references for components can be essential for maintenance and repairs. Understanding the layout and assembly of various items can save time and ensure accuracy. Here are several reliable sources to help you access these valuable illustrations.

Online Resources

- Manufacturer Websites: Many manufacturers provide detailed illustrations on their official sites. Look for a support or resources section.

- Online Retailers: Websites specializing in aftermarket components often include schematics for reference when purchasing parts.

- Forums and Communities: Enthusiast groups and discussion boards can be a treasure trove of information, where members share links and files.

Printed Manuals

- Service Manuals: Purchasing a service manual specific to your equipment can provide comprehensive diagrams and assembly instructions.

- Library Resources: Many local libraries have manuals available for borrowing, offering a cost-effective option for obtaining detailed references.

- Second-Hand Bookstores: Often, you can find used manuals at a fraction of the cost, which may include helpful illustrations.

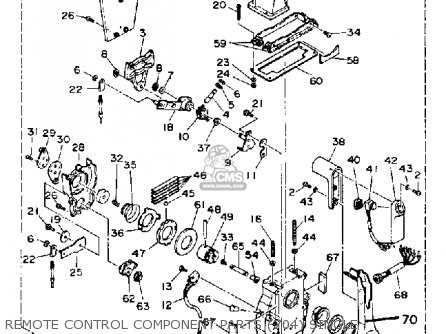

Interpreting the Parts Diagram Effectively

Understanding an assembly illustration can significantly enhance your ability to maintain and repair equipment. These visual guides provide crucial information about the components and their arrangement, allowing for better identification of parts and understanding of how they function together. Mastering this skill will enable you to troubleshoot issues more efficiently and carry out repairs with greater confidence.

Start by familiarizing yourself with the overall layout. Take note of how components are grouped and the logical flow of assembly. Often, similar items are clustered together, which can simplify your search for specific elements. Pay attention to any labels or numbers accompanying the visuals, as these are key to cross-referencing with manuals or parts lists.

When analyzing the illustration, focus on the connection points between different components. Understanding how pieces interact can reveal potential failure points and inform you about the required maintenance procedures. It is also essential to recognize any additional tools or materials indicated in the guide, which might be necessary for a complete assembly or disassembly.

Lastly, don’t hesitate to refer to supplemental resources, such as service manuals or online forums, to deepen your understanding. Engaging with a community of enthusiasts can provide valuable insights and tips that enhance your interpretation of these visual aids. By honing your skills in reading these illustrations, you’ll be well-equipped to manage your equipment effectively.

Tools Required for Maintenance

Proper upkeep of marine engines necessitates a range of essential instruments. Utilizing the correct tools not only ensures efficiency but also prolongs the life of the equipment. Familiarizing oneself with the necessary implements can make maintenance tasks more manageable and effective.

Essential Tools List

The following table outlines the fundamental tools needed for regular servicing:

| Tool | Purpose |

|---|---|

| Wrench Set | For tightening and loosening bolts and nuts. |

| Screwdriver Set | For fastening and removing screws. |

| Socket Set | For more efficient bolt manipulation. |

| Torque Wrench | To ensure proper tension on fasteners. |

| Fuel Line Wrench | For specialized fuel line adjustments. |

Additional Considerations

In addition to basic tools, having safety gear and specialized instruments can enhance the maintenance experience. Safety goggles, gloves, and a first aid kit are crucial for protection during any mechanical work. Investing in quality tools will pay off in terms of durability and performance during maintenance tasks.

Step-by-Step Maintenance Guide

This guide provides essential steps for maintaining your outboard motor to ensure optimal performance and longevity. Regular upkeep is crucial for avoiding costly repairs and enhancing the efficiency of your vessel.

1. Gather Necessary Tools: Start by collecting all required tools such as wrenches, screwdrivers, and replacement components. Having everything ready will streamline the process.

2. Inspect Fluids: Check the oil and fuel levels, ensuring they meet recommended specifications. Clean any filters and replace fluids if they appear dirty or degraded.

3. Examine the Propeller: Remove the propeller and inspect for damage or debris. Clean it thoroughly and replace it if there are signs of wear or bending.

4. Test Electrical Connections: Inspect wiring and battery connections for corrosion or loose fittings. Ensure all electrical components function properly.

5. Clean Cooling System: Flush the cooling system with fresh water to remove salt, dirt, and debris. This helps maintain efficient temperature regulation.

6. Check Belts and Hoses: Look for any cracks or wear on belts and hoses. Replace them as needed to prevent failure during operation.

7. Final Run Test: After completing the maintenance, conduct a test run. Pay attention to performance and listen for any unusual sounds.

Following these steps will help maintain the reliability of your motor, ensuring it operates smoothly when you need it most.

Troubleshooting Common Issues

Addressing common challenges that arise in marine engines is essential for optimal performance and longevity. By identifying and resolving these issues, boaters can ensure smooth operation and enhance their overall experience on the water.

Common Symptoms and Solutions

- Engine Won’t Start:

- Check the fuel supply and connections.

- Inspect the battery for sufficient charge.

- Examine ignition components for wear.

- Overheating:

- Verify the cooling system for blockages.

- Ensure water intake is clear.

- Check for proper thermostat operation.

- Unusual Noises:

- Identify the source of any rattling or grinding sounds.

- Inspect for loose parts or misalignments.

- Listen for changes during operation to pinpoint issues.

Preventive Measures

- Regularly maintain fuel and oil levels.

- Perform routine inspections of key components.

- Follow recommended service intervals for replacement parts.

Tips for Ordering Parts Online

When shopping for components online, ensuring accuracy and efficiency can greatly enhance your experience. A systematic approach not only saves time but also minimizes the risk of ordering incorrect items. Here are some helpful guidelines to streamline the process.

- Research Before You Buy: Take the time to investigate the specific components you need. Familiarize yourself with the specifications and compatibility requirements to avoid confusion.

- Utilize Diagrams: Look for visual references that detail the components and their arrangement. These can provide clarity and assist in identifying the exact items you require.

- Check Seller Reputation: Before making a purchase, verify the credibility of the online retailer. Read customer reviews and ratings to ensure a trustworthy transaction.

- Compare Prices: Don’t settle for the first option you find. Browse multiple websites to compare prices and shipping options, ensuring you get the best deal.

- Look for Warranties: Ensure that the components come with a warranty or guarantee. This provides peace of mind in case of defects or dissatisfaction.

By following these steps, you can enhance your online shopping experience, ensuring that you receive the right components for your needs with minimal hassle.

Impact of Regular Maintenance

- Improves efficiency and performance.

- Extends the lifespan of equipment.

- Reduces the likelihood of unexpected breakdowns.

- Enhances safety during operation.

Incorporating a routine maintenance schedule can yield significant benefits, making it an ultimate priority for anyone seeking to protect their investment.

Expert Recommendations for DIY Repairs

Engaging in self-repairs can be both satisfying and economical, provided that you approach the task with the right knowledge and tools. This section offers valuable insights to enhance your do-it-yourself efforts, ensuring that your projects are executed with confidence and precision.

Essential Tools and Materials

Before starting any repair work, it’s crucial to gather the appropriate tools and materials. Having everything on hand will streamline the process and prevent unnecessary delays. Below is a list of recommended items:

| Tool/Material | Purpose |

|---|---|

| Screwdriver Set | For removing and tightening screws |

| Wrench Set | To adjust and secure nuts and bolts |

| Multimeter | For electrical diagnostics |

| Replacement Gaskets | To ensure proper sealing in joints |

| Lubricants | To reduce friction and wear |

Steps for Successful Repairs

To ensure a smooth repair process, follow these fundamental steps:

- Identify the issue clearly and research potential solutions.

- Refer to manuals or online resources for specific guidance.

- Take your time and work methodically to avoid mistakes.

- Test the repairs thoroughly before putting the equipment back into full operation.