The intricate design of utility vehicles encompasses a multitude of elements that work in harmony to ensure functionality and safety. This section delves into the essential components that contribute to the overall integrity and performance of these vehicles. By gaining insight into the arrangement of these elements, users can better appreciate the engineering behind their robust structures.

With a focus on specific assemblies, we aim to clarify the various components that play a critical role in enhancing usability. Each assembly is meticulously crafted to provide not only durability but also ease of access and maintenance. Understanding how these components interact will empower users to make informed decisions when it comes to repairs and upgrades.

This exploration will serve as a valuable resource for anyone seeking to enhance their knowledge about the intricate workings of utility vehicles. Through a comprehensive examination of the layout and functionality, individuals can ensure their vehicles remain in optimal condition, ready to tackle any task at hand.

Kubota RTV-X1100C Overview

This section provides a comprehensive look at a versatile utility vehicle designed for a variety of tasks in both agricultural and industrial settings. Known for its robust construction and reliable performance, this model is engineered to handle demanding environments while providing comfort and ease of use.

Key Features

The vehicle boasts an array of features aimed at enhancing functionality and user experience. With a powerful engine and efficient drivetrain, it delivers impressive torque and traction, making it suitable for off-road conditions. The spacious cabin offers ample storage and ergonomic seating, ensuring that operators can work efficiently for extended periods.

Applications

This robust vehicle is ideal for numerous applications, including landscaping, farming, and property maintenance. Its adaptability allows users to equip it with various attachments, maximizing its utility. Additionally, its all-terrain capability ensures reliable performance in diverse environments, making it a favorite among professionals in different industries.

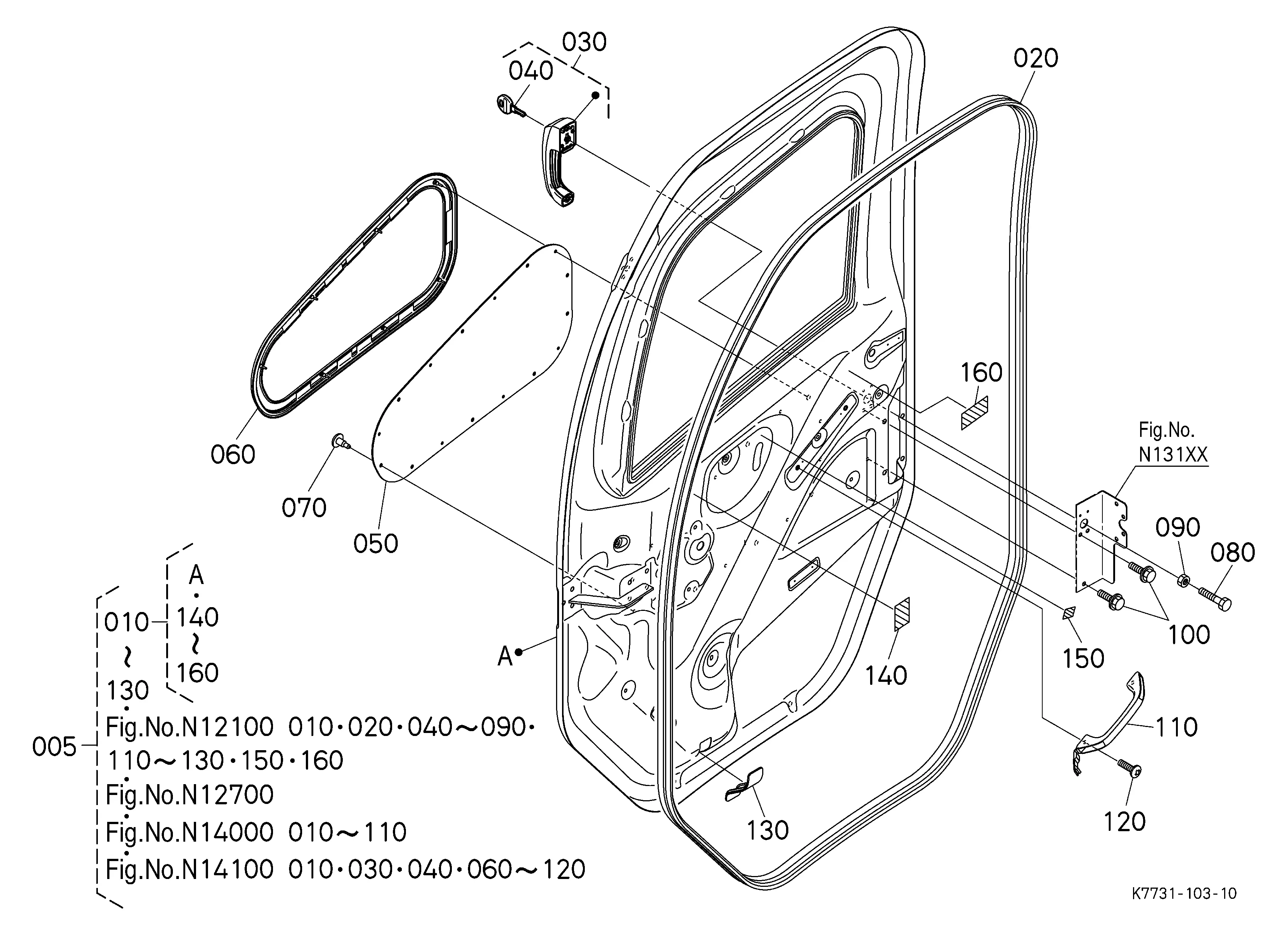

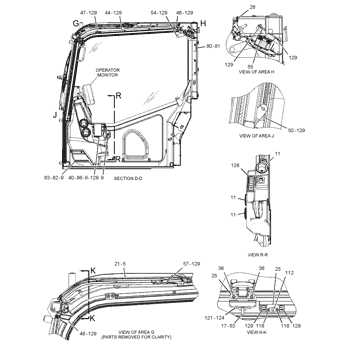

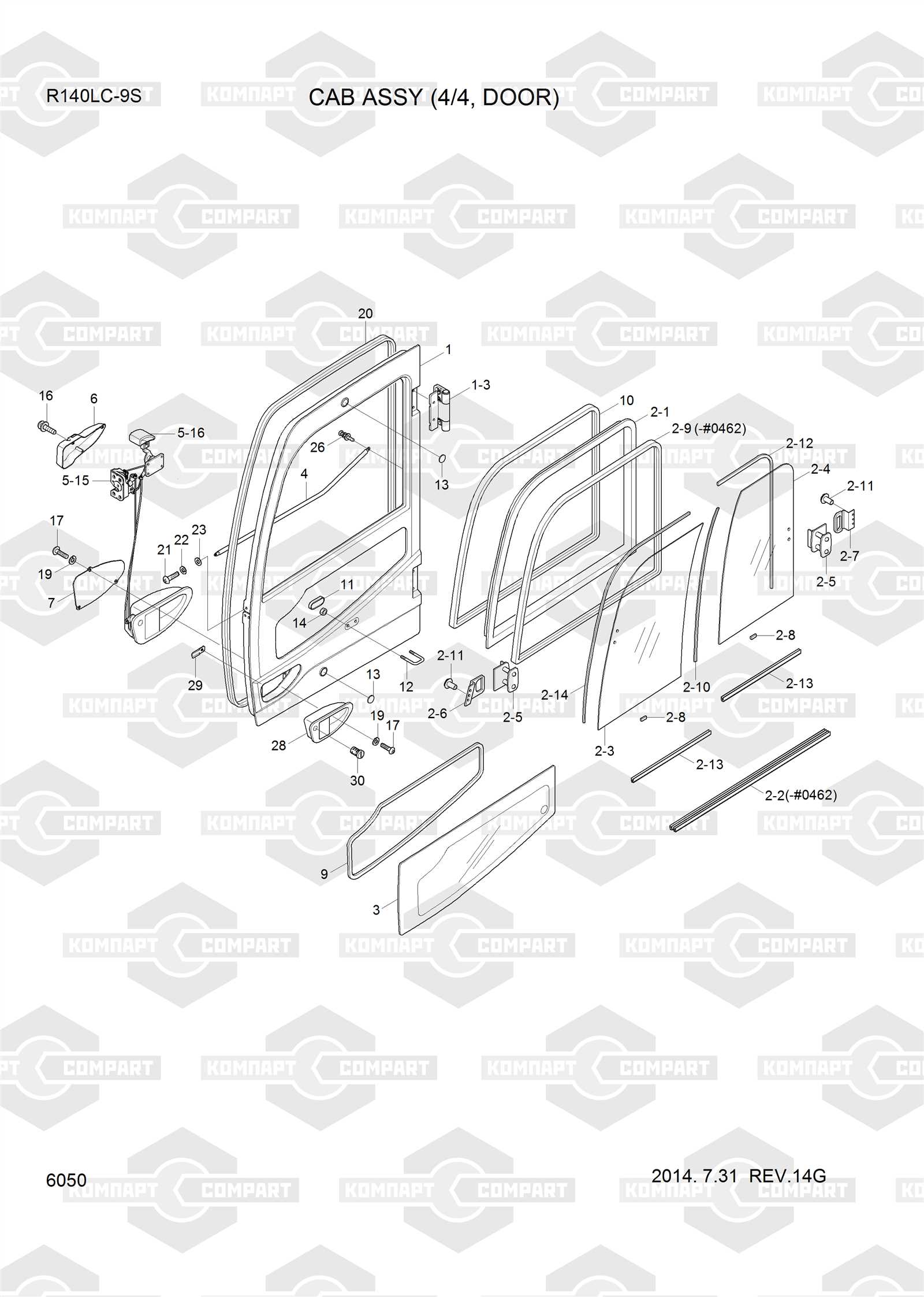

Understanding Door Components

The assembly of an entryway structure consists of various elements that play crucial roles in its functionality and safety. Each segment is designed to work in harmony, contributing to the overall performance and durability of the system. Familiarizing oneself with these elements can enhance maintenance efforts and facilitate repairs when necessary.

Key Elements of the Assembly

Among the primary components are the frame, which provides the overall structure; the locking mechanism, essential for security; and the window sections that offer visibility and protection from the elements. Understanding the purpose of each component can aid in identifying potential issues that may arise over time.

Maintenance Tips

Regular inspection and care of each segment can prolong the life of the entire assembly. Ensuring that moving elements operate smoothly and that seals are intact will help prevent wear and tear. Additionally, keeping the locking mechanisms well-lubricated can enhance security and ease of use.

| Component | Description |

|---|---|

| Frame | The rigid structure that supports the entire assembly. |

| Locking Mechanism | Device that secures the structure, ensuring safety. |

| Window Section | Transparent area that provides visibility while offering protection. |

| Seals | Materials that ensure weather resistance and insulation. |

Benefits of Proper Door Maintenance

Regular upkeep of entryways significantly enhances their functionality and longevity. By addressing minor issues promptly, users can prevent more severe damage and ensure optimal performance. Proper care also contributes to safety, aesthetics, and energy efficiency, making it a crucial aspect of overall equipment maintenance.

One of the primary advantages of consistent maintenance is the reduction of wear and tear. Neglecting small repairs can lead to larger problems, resulting in costly replacements. Timely inspections allow for the identification of potential issues before they escalate, ensuring that mechanisms remain in good working order.

Additionally, well-maintained entryways provide enhanced security. Regular checks and repairs help to ensure locking mechanisms function correctly, safeguarding against unauthorized access. This peace of mind is invaluable, especially in environments where security is paramount.

Another benefit is improved energy efficiency. Proper sealing and insulation can reduce energy loss, leading to lower utility bills and a more comfortable environment. Maintaining seals and gaskets is essential for preventing drafts and leaks, making upkeep an investment in sustainability.

| Benefit | Description |

|---|---|

| Longevity | Extends the lifespan of entryway components by preventing significant damage. |

| Security | Ensures reliable operation of locking systems, enhancing safety. |

| Energy Efficiency | Reduces energy costs through better insulation and sealing. |

| Aesthetics | Maintains a polished appearance, contributing to the overall look of the equipment. |

In summary, consistent maintenance of entryways is essential for ensuring their efficiency, security, and appearance. By investing time and resources into proper care, users can enjoy a range of benefits that enhance both functionality and value.

Identifying Common Door Issues

Understanding the typical complications that can arise with entry barriers is essential for maintaining functionality and security. Various symptoms may indicate that the mechanisms or components of these barriers are not performing optimally. Early recognition of these problems can prevent more extensive repairs and ensure reliable operation.

Signs of Malfunction

Common indicators of issues include difficulty in opening or closing, unusual noises during operation, or visible damage to the frame or closure elements. If the entry does not align properly or is not securely latched, it may pose risks to both safety and performance.

Maintenance Recommendations

Regular inspections can help identify wear and tear before they escalate into significant concerns. It is advisable to check the seals and hinges for any signs of corrosion or degradation. Lubrication of moving parts can enhance smooth operation and extend the lifespan of the entire assembly.

Step-by-Step Repair Process

Undertaking a repair can seem daunting, but breaking it down into manageable steps can simplify the process. Whether you’re fixing a mechanism or replacing components, a structured approach will ensure that the task is completed efficiently and effectively.

1. Gather Necessary Tools and Materials: Before starting, collect all required tools and replacement elements. Having everything on hand will prevent interruptions during the repair.

2. Prepare the Workspace: Create a clean and organized work area. Adequate lighting and space will help you focus and minimize the risk of losing small components.

3. Remove the Existing Assembly: Carefully detach the damaged unit. Take your time and avoid using excessive force, as this can cause additional damage. Document the disassembly process with photos to aid reassembly.

4. Inspect and Clean: Once removed, inspect the surrounding area for any signs of wear or damage. Clean any dirt or debris that may have accumulated to ensure a proper fit for the new assembly.

5. Install the New Component: Position the replacement unit in place and secure it according to the manufacturer’s instructions. Ensure all connections are tight and properly aligned to avoid future issues.

6. Test Functionality: After installation, test the new assembly to confirm that it operates as expected. Address any irregularities promptly to prevent complications down the line.

7. Reassemble and Clean Up: Once satisfied with the repair, reassemble any surrounding components. Clean up your workspace, disposing of any old parts responsibly.

Following these systematic steps will not only streamline the repair process but also enhance your confidence in handling similar tasks in the future.

Parts Replacement Tips

When it comes to maintaining your vehicle’s integrity, ensuring the right components are correctly swapped out is essential. This section provides valuable insights to help you navigate the replacement process effectively, ensuring optimal functionality and longevity of your equipment.

Assessing the Need for Replacement

Before proceeding with any substitutions, it’s crucial to evaluate the condition of the existing elements. Look for signs of wear, damage, or malfunction that may warrant a change. Conducting a thorough inspection allows you to prioritize which components require immediate attention, ultimately saving you time and resources.

Choosing Quality Components

Opt for high-quality replacements that match or exceed the original specifications. Utilizing reputable suppliers ensures you receive durable materials that can withstand various conditions. Consider consulting user reviews or expert recommendations to select components that offer the best performance and reliability.

Essential Tools for Door Repairs

When it comes to fixing entryways, having the right instruments can make all the difference. Proper tools not only enhance efficiency but also ensure a professional finish. Whether you’re replacing components or making adjustments, a well-equipped toolkit is crucial for a successful restoration.

Basic Toolkit

- Socket Set: Ideal for loosening and tightening bolts.

- Flathead and Phillips Screwdrivers: Essential for various screws encountered in assembly.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Utility Knife: Perfect for cutting materials with precision.

- Measuring Tape: Ensures accurate measurements for fittings and components.

Advanced Tools

- Torque Wrench: Ensures fasteners are tightened to the correct specifications.

- Drill and Drill Bits: For creating or enlarging holes in different materials.

- Angle Grinder: Useful for cutting metal or grinding down edges for a smooth finish.

- Sealant Gun: Essential for applying weatherproofing materials effectively.

- Heat Gun: Helpful for softening materials or removing old adhesive.

Having these tools on hand will not only facilitate repairs but also improve the overall outcome of your projects. A well-prepared technician can tackle any challenge that arises during the restoration process.

Exploring OEM vs. Aftermarket Parts

The choice between original equipment manufacturer (OEM) and alternative components can significantly impact the performance and longevity of your machinery. Understanding the differences between these options is crucial for ensuring optimal functionality and reliability. OEM components are typically designed to meet the exact specifications of the original design, while aftermarket options often provide a cost-effective alternative that may vary in quality and compatibility.

Advantages of OEM Components

Opting for OEM components offers several benefits, including guaranteed compatibility and adherence to the manufacturer’s standards. These parts are manufactured by the same company that produced the original equipment, ensuring a perfect fit and performance that aligns with factory specifications. Additionally, OEM components often come with warranties that provide peace of mind for users.

Benefits of Aftermarket Components

Aftermarket components can present various advantages, including cost savings and a wider selection of options. Many aftermarket manufacturers create enhanced versions of original designs, offering improved performance or features. However, it is essential to research the quality and reliability of these components to ensure they meet the required standards.

| Aspect | OEM Components | Aftermarket Components |

|---|---|---|

| Compatibility | Perfect fit | Varies by manufacturer |

| Cost | Higher | Generally lower |

| Warranty | Often includes warranty | Varies; may have limited warranty |

| Performance | Standardized performance | Potential for enhanced features |

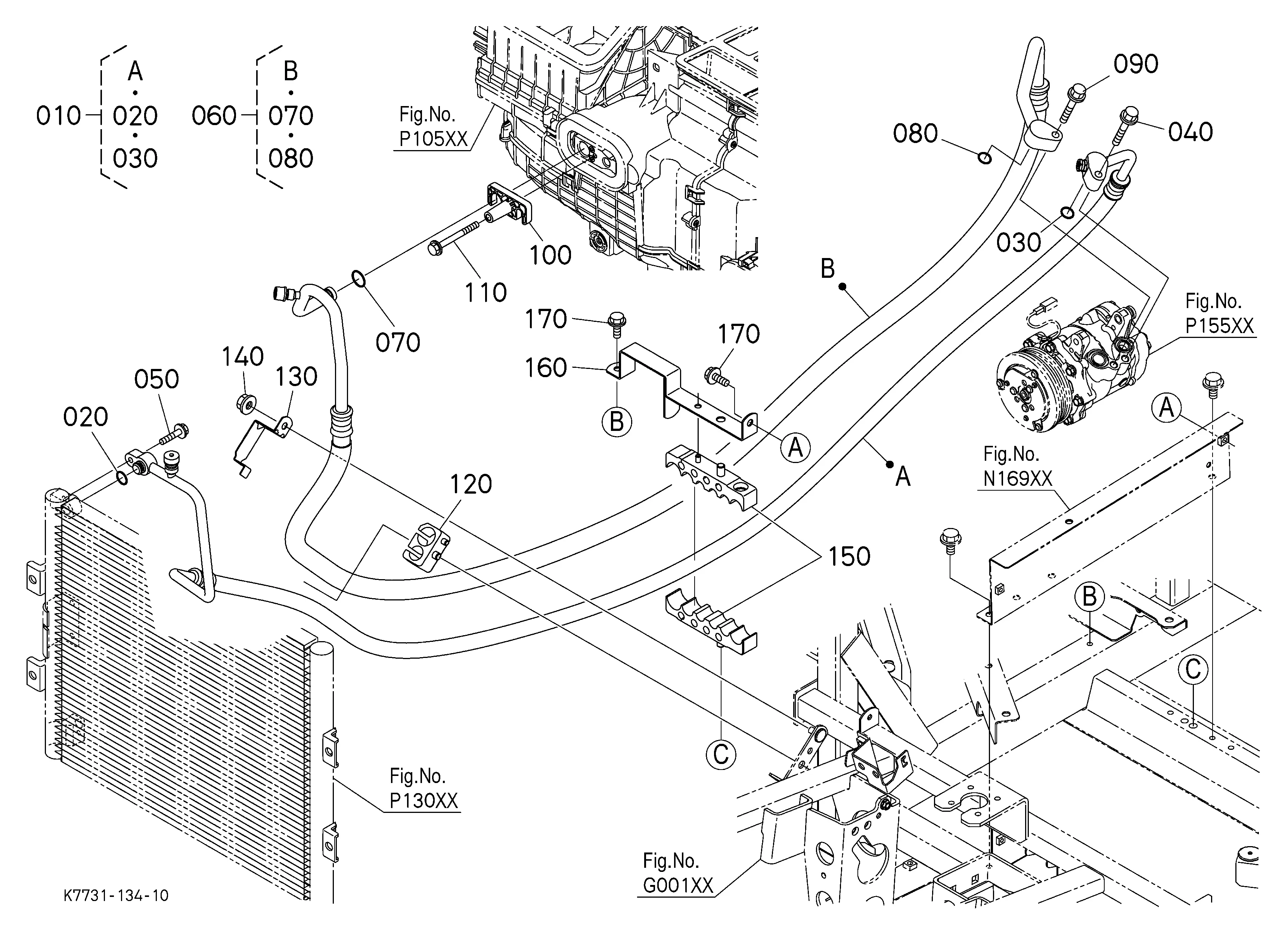

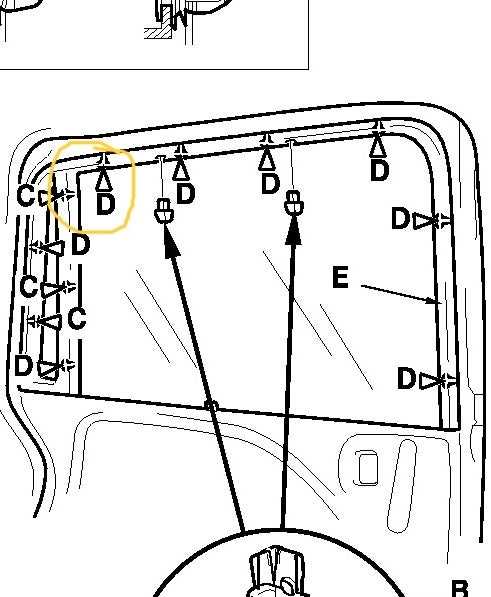

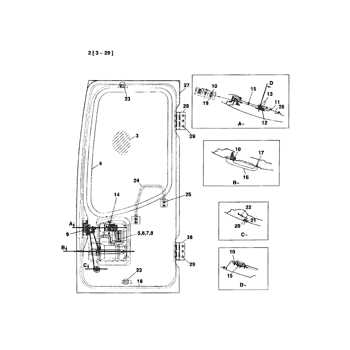

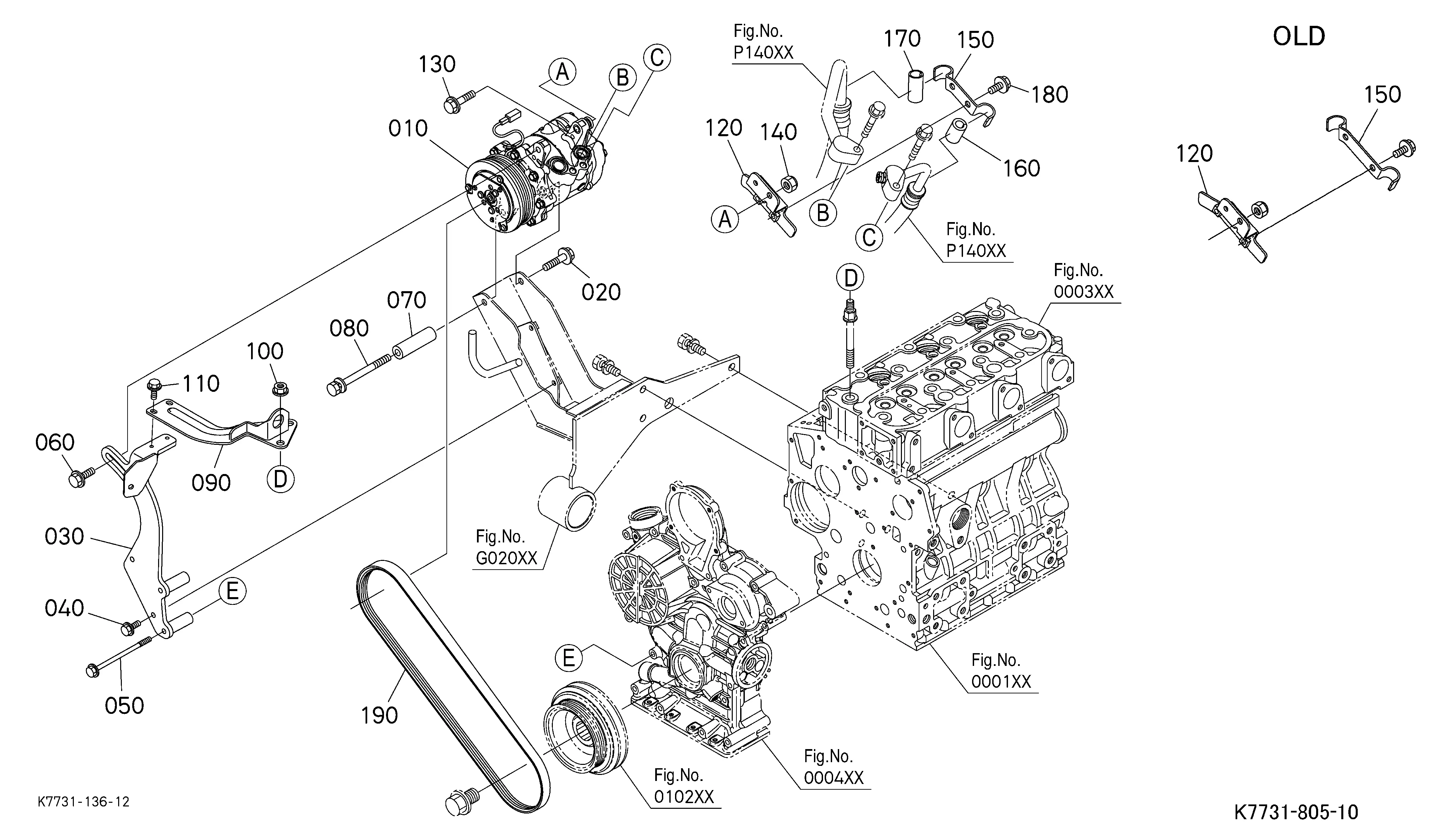

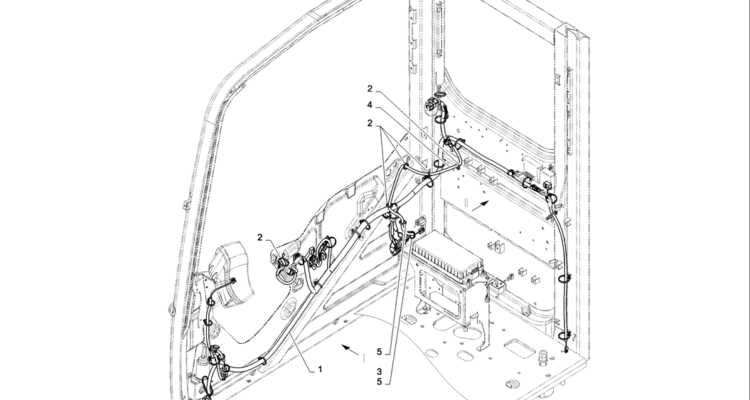

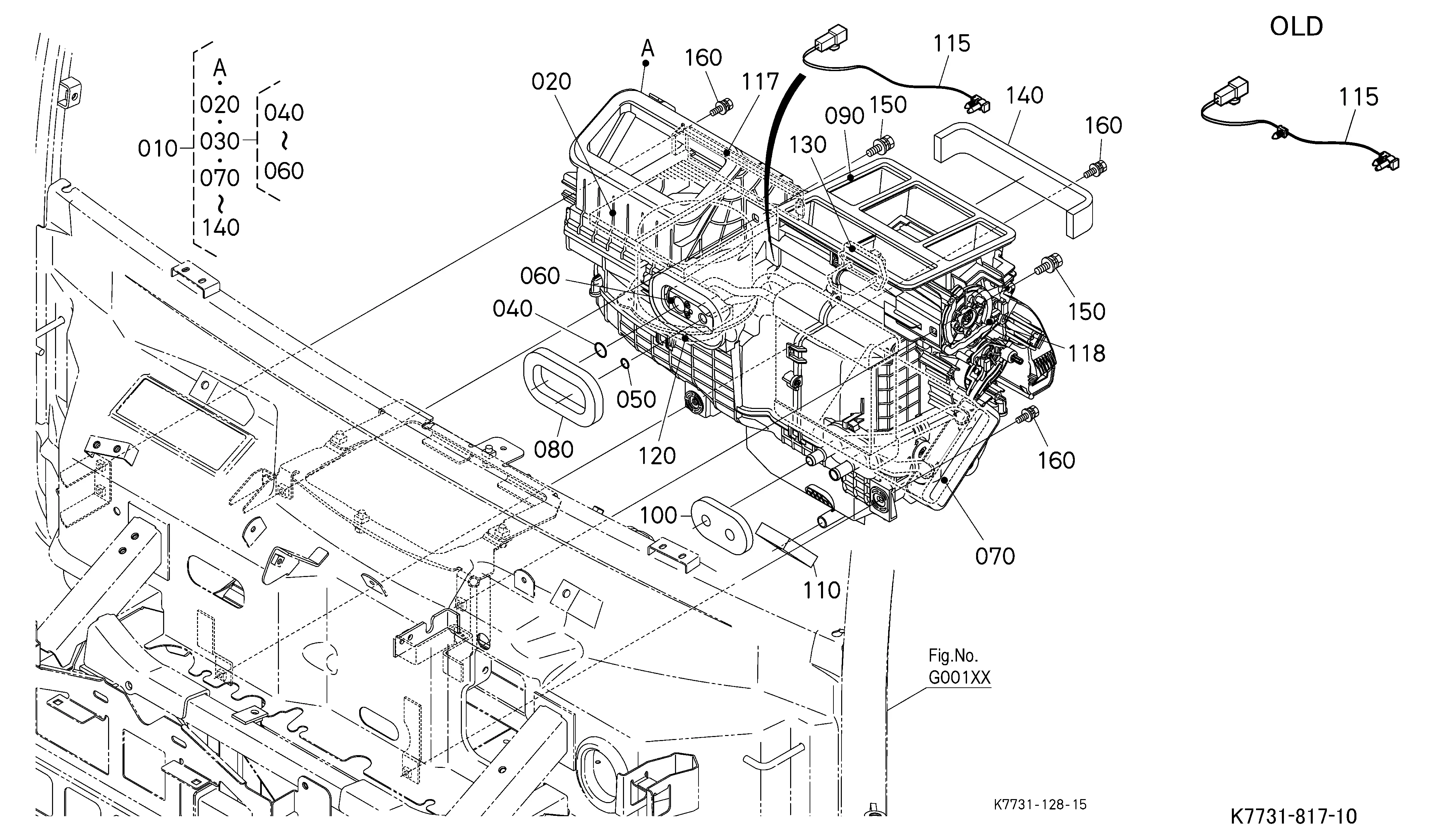

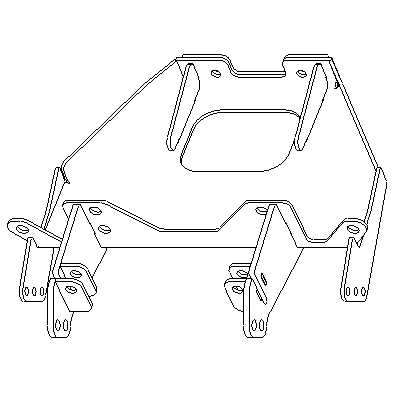

Detailed Parts Diagram Explanation

This section provides a comprehensive overview of the various components and their configurations within the specified vehicle model. Understanding how each element interrelates can enhance maintenance and repair processes, ensuring optimal functionality and longevity.

Component Identification

The first step in grasping the assembly is to familiarize oneself with the distinct elements involved. Each segment serves a unique role in the overall system, contributing to performance and safety. Familiarity with these units can significantly aid in troubleshooting issues and conducting replacements when necessary.

Assembly Relationships

Examining the interactions between different units reveals how they work together to create a cohesive structure. Understanding these relationships is crucial for efficient repairs and upgrades. Recognizing which elements are dependent on each other allows for informed decision-making during maintenance tasks.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring personal safety and the security of the equipment is of utmost importance. Proper precautions help prevent accidents and injuries, enabling a smooth and efficient repair process. By following a few essential guidelines, individuals can significantly reduce the risks associated with repair work.

- Always wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and sturdy footwear, to safeguard against potential hazards.

- Ensure that the work area is well-ventilated to prevent inhalation of harmful fumes or dust.

- Disconnect the power source or remove the battery before beginning any repairs to prevent accidental starts.

- Use the correct tools for the job to avoid injuries caused by improper equipment.

- Keep the workspace organized and free from clutter to minimize the risk of tripping or other accidents.

Additionally, it is crucial to familiarize oneself with the machinery being serviced. Understanding the layout and functions of various components can aid in identifying potential dangers. Always consult the manufacturer’s guidelines for specific safety instructions and maintenance procedures.

Finally, if unsure about any repair process, seek assistance from a qualified professional. Taking the time to ensure safety not only protects individuals but also prolongs the lifespan of the equipment being serviced.

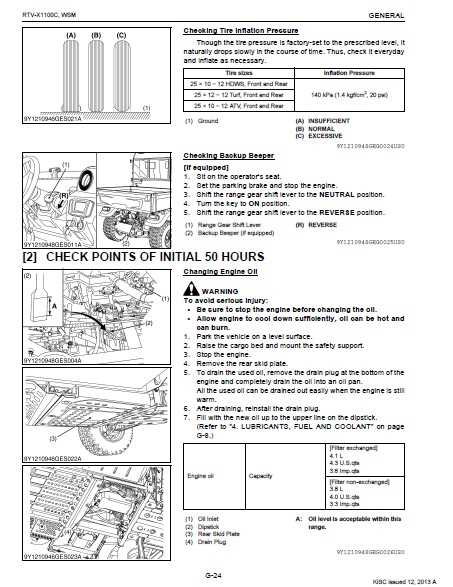

Routine Inspection Guidelines

Regular evaluation of your vehicle’s components is crucial to ensure optimal performance and longevity. Establishing a systematic approach to examining the various elements can help identify potential issues before they escalate, thereby enhancing overall safety and functionality.

Follow these key guidelines during your inspections:

- Visual Checks:

- Examine the exterior for any signs of damage or wear.

- Inspect seals and gaskets for cracks or deterioration.

- Look for any leaks around the hinges or latch mechanisms.

- Functional Testing:

- Open and close the access points to ensure smooth operation.

- Test any locking mechanisms to verify they engage properly.

- Check for unusual noises during operation that may indicate misalignment.

- Maintenance Tasks:

- Lubricate moving parts to prevent friction and wear.

- Clean surfaces to remove dirt and debris that can hinder function.

- Replace any worn or damaged components promptly to maintain integrity.

By adhering to these routine inspection guidelines, you can ensure that all mechanisms function correctly, ultimately extending the lifespan of your equipment and ensuring safety for users.

Upgrading Door Features

Enhancing the functionality and convenience of entryways in utility vehicles can significantly improve the overall user experience. Modern advancements offer a range of options that not only boost comfort but also elevate safety and accessibility. By incorporating innovative elements, operators can enjoy increased efficiency and ease of use while navigating various terrains.

Innovative Locking Mechanisms

One of the primary upgrades to consider is the implementation of advanced locking systems. Enhanced security features can provide peace of mind, especially in remote environments. Keyless entry systems, for instance, streamline access while minimizing the risk of lockouts. Additionally, smart locking mechanisms can offer remote control capabilities, allowing users to manage access with their smartphones.

Improved Insulation and Weather Resistance

Another vital enhancement involves enhancing insulation and weatherproofing features. Upgraded sealing materials and designs can significantly reduce noise and protect against harsh elements. This not only creates a more comfortable interior but also ensures that the vehicle remains operational in a variety of weather conditions. Improved insulation can contribute to energy efficiency by maintaining optimal temperatures within the cabin.

Frequently Asked Questions

This section aims to address common inquiries related to the assembly and functionality of certain components in utility vehicles. Here, we provide insights to assist users in understanding essential features and resolving typical concerns.

What should I do if a component is damaged?

If any element becomes compromised, it’s crucial to assess the extent of the damage. For minor issues, replacement may be possible with compatible substitutes. In severe cases, professional assistance is recommended to ensure proper installation and safety.

How can I maintain the functionality of these components?

Regular inspections and maintenance are key to extending the lifespan of any component. Keep the area clean, check for wear and tear, and lubricate moving parts as necessary. Following the manufacturer’s guidelines can significantly enhance performance.