Discover the intricate mechanisms that drive modern residential heating systems. This section delves into the inner components responsible for maintaining optimal indoor comfort during colder months.

Explore how each element collaborates within the framework of a sophisticated heating appliance, ensuring efficient operation and reliable performance throughout its lifespan.

Uncover the intricacies of a device designed to provide warmth and comfort, examining the integration of components that collectively optimize energy utilization for residential heating needs.

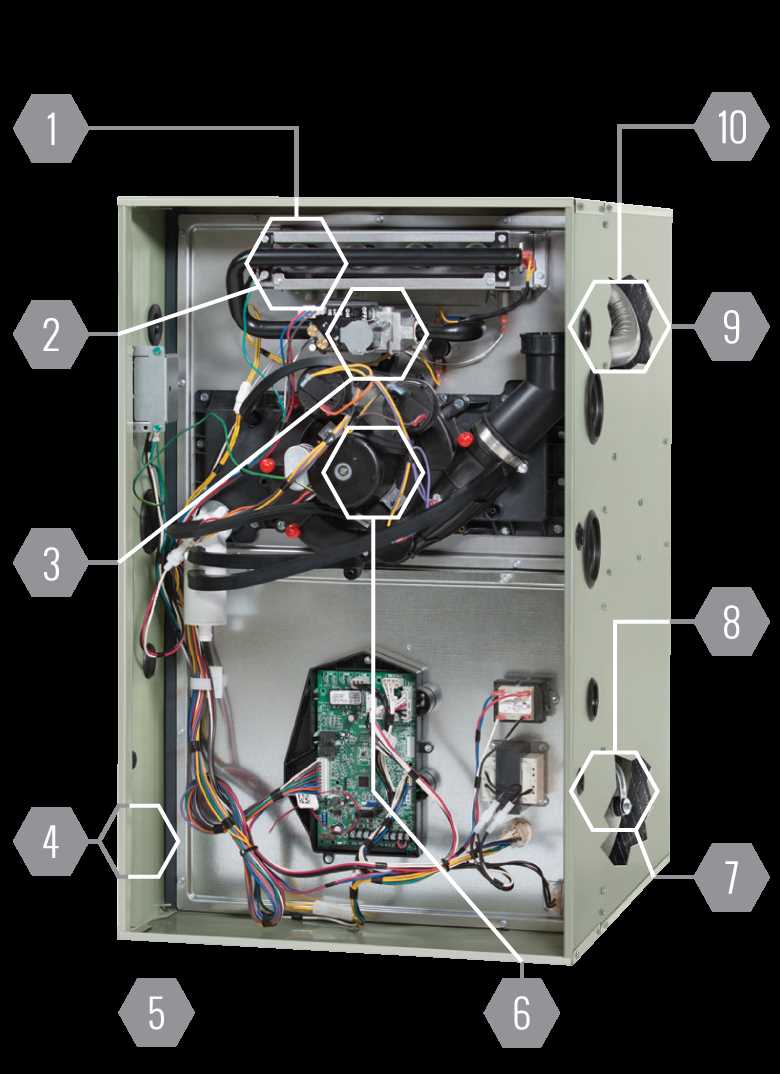

Trane XE90 Furnace Parts Diagram

This section provides an insightful overview of the essential components that contribute to the efficient operation of your heating unit. Understanding these elements is crucial for maintenance and troubleshooting, ensuring optimal performance throughout the heating season.

Key Components Overview

Every heating system consists of various critical elements that work in unison. Familiarity with these components can aid in identifying issues and ensuring longevity.

| Component | Description |

|---|---|

| Blower Motor | Circulates warm air throughout the space. |

| Heat Exchanger | Transfers heat from combustion to the air. |

| Thermostat | Regulates the temperature settings. |

| Ignitor | Initiates the combustion process. |

Importance of Regular Maintenance

Regular upkeep of these elements is vital to enhance the system’s efficiency and lifespan. Scheduling routine inspections can prevent unexpected failures and ensure a consistently warm environment.

Main Components of Trane XE90

This section explores the essential elements that make up a high-efficiency heating system, focusing on how each part contributes to optimal performance and reliability. Understanding these components can help users appreciate their functionality and importance in maintaining a comfortable environment.

Key Elements

The primary components include a heat exchanger, blower assembly, and ignition system. The heat exchanger plays a crucial role in transferring heat, while the blower ensures that warm air circulates throughout the space. Additionally, the ignition system is vital for initiating the heating process safely and effectively.

Supporting Features

Other notable features encompass the control board and safety mechanisms. The control board acts as the system’s brain, regulating operations based on temperature settings. Safety mechanisms, such as limit switches and flame sensors, are essential for preventing hazards and ensuring efficient function.

Understanding the Blower Assembly

The blower assembly plays a crucial role in the efficient operation of heating systems. It is responsible for circulating air throughout the environment, ensuring that spaces maintain a comfortable temperature. This component works by drawing air in and pushing it out through ducts, making it essential for both comfort and energy efficiency.

Key elements of the blower assembly include the motor, wheel, and housing. Each of these parts contributes to the overall functionality and reliability of the system. Below is a table outlining these components and their primary functions:

| Component | Function |

|---|---|

| Motor | Drives the blower wheel to move air effectively. |

| Blower Wheel | Creates airflow by spinning rapidly to push air through the system. |

| Housing | Encloses the motor and wheel, guiding airflow and reducing noise. |

Understanding these components helps in diagnosing issues and performing maintenance. Regular checks on the blower assembly can prevent larger problems, ensuring that the system operates smoothly and efficiently throughout its lifespan.

Heat Exchanger Functionality Explained

A heat exchanger plays a critical role in transferring thermal energy between two or more fluids without them mixing. This essential device is widely used in various heating and cooling systems, ensuring efficient temperature regulation and enhancing overall performance. Understanding its operation is vital for comprehending how energy is conserved and optimized within these systems.

In essence, a heat exchanger operates by facilitating the flow of heated air or liquid through a series of coils or plates, allowing the heat to transfer to a cooler medium. This process occurs through conduction and convection, where thermal energy naturally moves from the hotter substance to the colder one. The design of the exchanger significantly influences its effectiveness, as factors such as surface area, material, and flow arrangement determine how efficiently heat is transferred.

Efficiency is paramount in these devices, as it directly impacts energy consumption and system performance. A well-functioning heat exchanger can improve energy utilization, leading to lower operational costs and a reduced carbon footprint. Regular maintenance and inspections are essential to ensure that the device operates at peak efficiency, preventing issues such as leaks or blockages that can hinder performance.

Moreover, the functionality of a heat exchanger is not only limited to heating applications. It is also critical in cooling processes, where it helps to dissipate unwanted heat, thereby maintaining optimal operating temperatures for various machinery and equipment. This versatility makes it an indispensable component across multiple industries, including residential, commercial, and industrial settings.

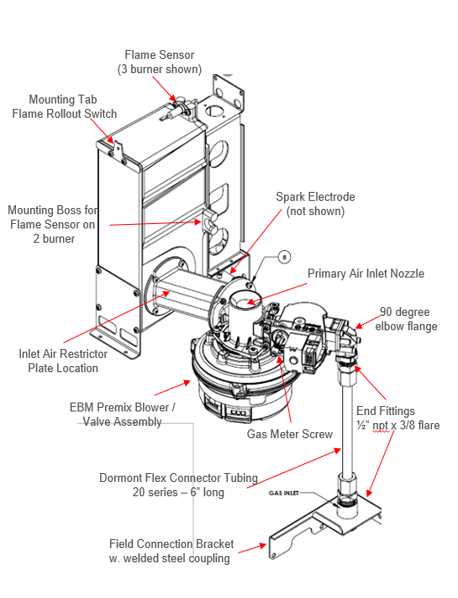

Identifying the Gas Valve Location

Understanding where the gas control component is situated is crucial for both maintenance and troubleshooting. This element plays a vital role in regulating the flow of gas, ensuring safe and efficient operation. Knowing its location can help in quickly addressing issues that may arise during usage.

Typical Placement of the Gas Control Unit

The gas valve is usually located near the burner assembly, typically on the front or side of the heating unit. It is designed to be accessible for regular inspections and service. Depending on the model, the layout may vary slightly, but it generally remains within close proximity to the ignition system to facilitate proper function.

Visual Cues for Identification

When attempting to locate this component, look for the gas supply line leading into the appliance. The valve often features a knob or lever for manual control, along with indicator markings for operational status. Additionally, there may be safety features or sensors nearby that can assist in identifying its exact position. Regular familiarity with these elements can enhance safety and efficiency in operation.

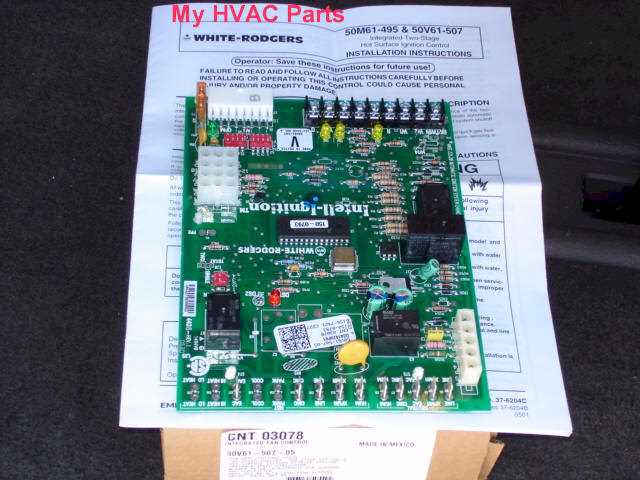

Role of the Control Board

The control board serves as the central hub for managing and coordinating the operation of heating systems. It ensures seamless communication between various components, enabling efficient functionality and response to environmental changes.

This critical component processes signals from sensors and thermostats, directing the system to activate or deactivate as needed. By doing so, it maintains optimal performance while prioritizing safety and energy efficiency.

Moreover, the control board often features diagnostic capabilities, allowing technicians to troubleshoot issues swiftly. This ultimately enhances the longevity and reliability of the entire heating apparatus.

Examining the Inducer Motor

The inducer motor plays a crucial role in the overall efficiency and safety of heating systems. This component is responsible for creating a proper airflow, which is essential for the combustion process. By ensuring that exhaust gases are expelled effectively, the inducer motor helps maintain optimal operation and prevents hazardous conditions within the system.

Functionality of the Inducer Motor

The primary function of the inducer motor is to draw in air from the atmosphere and push it through the heat exchanger. This process is vital for maintaining the right pressure and ensuring that the combustion process occurs smoothly. A well-functioning inducer motor not only improves efficiency but also enhances the lifespan of the entire system.

Common Issues and Maintenance

| Common Issues | Symptoms | Solutions |

|---|---|---|

| Blockage in airflow | Decreased efficiency | Clear obstructions |

| Motor failure | Unusual noises | Replace motor |

| Wiring problems | System not starting | Inspect and repair wiring |

Proper Filter Placement Guide

Ensuring optimal air quality and system efficiency relies heavily on the correct positioning of air filters. This guide provides essential insights into the best practices for filter installation, which can significantly enhance the performance and longevity of your heating and cooling systems.

1. Identify the Filter Location: Begin by locating the designated area where the filter is meant to be installed. This is typically situated within the air intake section of your unit.

2. Ensure Correct Orientation: Pay attention to the arrows on the filter frame. These indicate the direction of airflow; the filter must be positioned accordingly to function effectively.

3. Maintain a Tight Seal: Once in place, check that the filter fits snugly without gaps. Air leakage can lead to reduced efficiency and dirt accumulation within the system.

4. Regularly Inspect and Replace: Establish a routine for checking the condition of the filter. Regular replacements are vital to ensure maximum airflow and system efficiency.

By following these guidelines, you can help maintain a clean environment while promoting the ultimate performance of your heating and cooling systems.

Ignition System Details

The ignition mechanism in heating units is crucial for efficient operation, ensuring that the combustion process initiates reliably. Understanding its components and functions can enhance maintenance and troubleshooting efforts, leading to improved performance and longevity of the equipment.

Key Components

This system typically comprises several essential elements, including the igniter, flame sensor, and control module. The igniter is responsible for producing the initial spark, while the flame sensor monitors the presence of a flame, ensuring safe operation. The control module orchestrates the entire process, making adjustments as needed.

Operational Insights

During the ignition sequence, the control module activates the igniter, which heats up and ignites the gas. Once a flame is detected by the sensor, the system continues to operate. Regular inspections of these components can prevent malfunctions and ensure efficient energy use.

Importance of the Limit Switch

The limit switch plays a crucial role in maintaining safety and efficiency within heating systems. Its primary function is to monitor and regulate temperature levels, ensuring that the equipment operates within safe parameters. By preventing overheating, it not only protects the system from damage but also enhances energy conservation.

Safety Mechanism

This component acts as a safeguard, cutting off power to the heating elements when temperatures exceed specified thresholds. This function is vital in preventing potential hazards such as fires or equipment failure. In essence, the limit switch serves as a first line of defense, ensuring a reliable and secure operation of the heating unit.

Energy Efficiency

In addition to safety, the limit switch contributes to the overall energy efficiency of the system. By regulating temperature effectively, it helps maintain optimal performance and minimizes unnecessary energy consumption. This not only reduces operational costs but also promotes a more sustainable use of resources.

Thermostat Wiring Connections Overview

Understanding the wiring connections for a temperature control device is crucial for maintaining optimal performance and efficiency in your heating system. Properly connecting the wires ensures accurate temperature regulation and enhances the longevity of the system.

Common Connection Types

Typically, connections can be categorized into several types based on their function. R wire usually powers the unit, while the W wire signals heating demands. Other connections, such as Y for cooling and G for fan control, play important roles in the overall operation.

Importance of Correct Wiring

Ensuring that each wire is correctly placed is essential to avoid operational issues. Incorrect wiring may lead to malfunctioning components or inefficient performance. Always consult the manufacturer’s guidelines or a professional when dealing with wiring to guarantee safety and reliability.

Understanding the Flame Sensor

The flame sensor plays a crucial role in ensuring the safe and efficient operation of heating systems. This component detects the presence of a flame, allowing the system to function properly and preventing potential hazards.

Here are key points to consider about flame sensors:

- Function: The primary purpose of the flame sensor is to confirm that combustion is occurring. It sends a signal to the control board to maintain operation.

- Types: There are various types of flame sensors, including:

- Infrared sensors

- Ultraviolet sensors

- Thermocouples

- Maintenance: Regular maintenance is essential to ensure that the flame sensor operates effectively. Dust and debris can interfere with its function.

- Signs of Failure: If the flame sensor malfunctions, it may lead to:

- Frequent system shutdowns

- Delayed ignition

- Inconsistent heating

Understanding the importance of the flame sensor can enhance safety and improve the overall performance of heating systems. Regular checks and prompt replacements can prevent issues and ensure reliable operation.

Trane XE90 Safety Features Overview

In modern heating systems, safety is paramount to ensure the well-being of occupants and the efficiency of the unit. Advanced mechanisms are integrated to monitor performance and prevent potential hazards. Understanding these features can enhance user confidence and promote responsible usage.

One critical aspect of safety is the presence of flame sensors. These components detect the presence of a flame and shut down the system if an anomaly occurs, preventing the risk of gas leaks. Additionally, limit switches are employed to monitor temperature levels, ensuring that the system operates within safe parameters.

Another essential feature is the use of robust venting systems. Proper exhaust pathways are vital to prevent harmful gases from entering living spaces. Safety shut-off valves further contribute by interrupting the gas supply in case of irregularities, providing an extra layer of protection.

Regular maintenance is also a crucial factor in ensuring these safety mechanisms function correctly. Routine inspections and prompt repairs can significantly reduce the risk of malfunctions, thereby enhancing the overall reliability of the heating system.