In the realm of crafting and design, having a comprehensive grasp of the essential elements that make up your cutting tool can significantly enhance your creative endeavors. Each component plays a pivotal role, ensuring that your projects come to life with precision and ease. This section delves into the intricate structure of these devices, providing insights into their functionalities and interconnections.

Knowing how each section contributes to the overall performance is crucial for both beginners and seasoned users. From the mechanisms that drive the blade to the sensors that ensure accuracy, understanding these features will empower you to optimize your crafting experience. Whether you are working with paper, fabric, or vinyl, a clear awareness of your machine’s anatomy will facilitate smoother operations.

Moreover, familiarizing yourself with the layout of these components can aid in troubleshooting and maintenance, prolonging the lifespan of your device. By exploring the various sections and their purposes, you’ll be better equipped to make informed decisions about upgrades and accessories that can elevate your crafting projects to new heights.

Cricut Maker Overview

This section provides a comprehensive look at a versatile crafting tool designed for various creative projects. It combines precision cutting technology with the ability to work with an extensive range of materials, making it an invaluable asset for hobbyists and professionals alike. Understanding its components and functionalities can enhance the crafting experience, leading to greater innovation and efficiency in project execution.

Key Features

The innovative device is equipped with several remarkable features that set it apart from traditional crafting tools. Here are some of the most notable attributes:

| Feature | Description |

|---|---|

| Multi-Material Compatibility | Can handle materials such as paper, fabric, vinyl, and more. |

| Precision Cutting | Offers intricate and detailed cuts for various designs. |

| Smart Technology | Includes advanced software integration for design and cutting. |

Applications

The multifunctional tool is ideal for a wide range of applications. Whether for crafting personalized gifts, home décor, or intricate designs for events, its capabilities open up endless possibilities. Users can unleash their creativity and produce unique items that stand out.

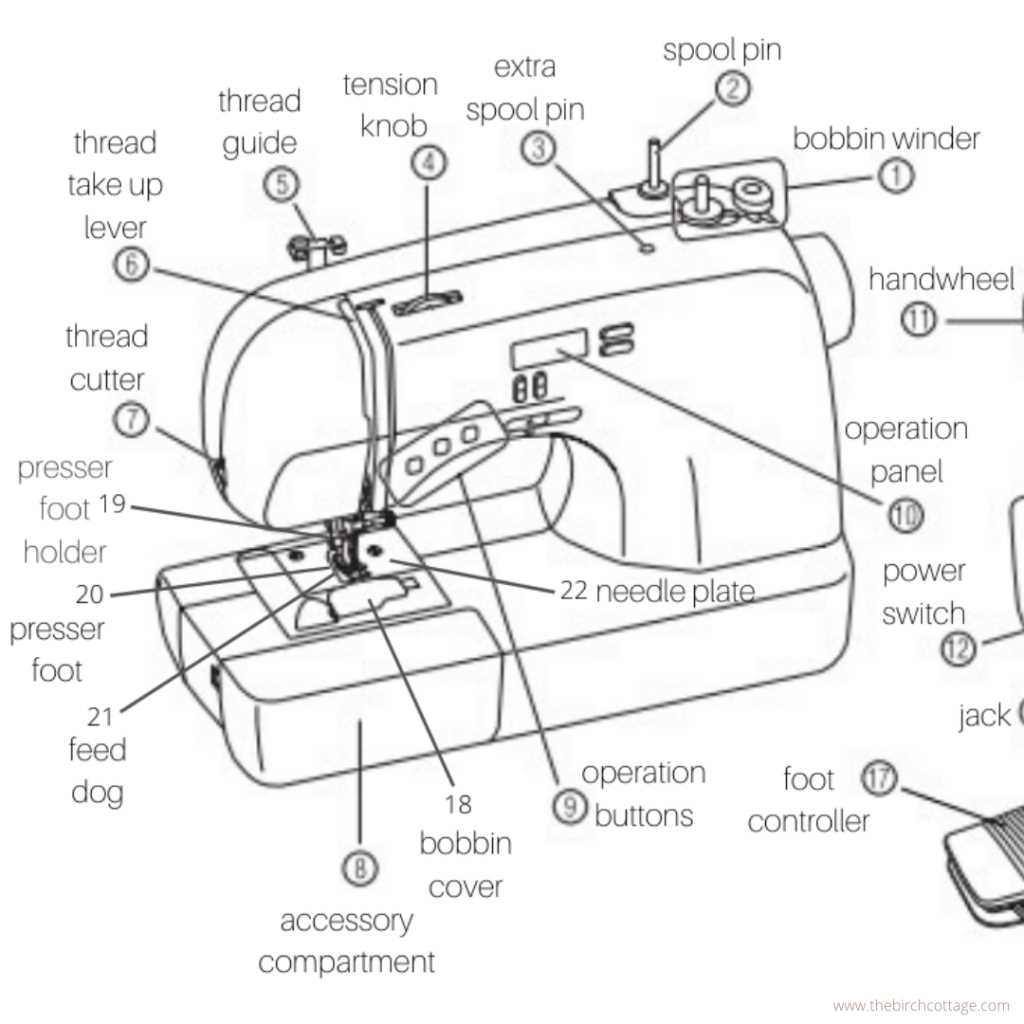

Understanding the Machine Components

Exploring the intricate elements of a crafting device reveals the synergy that enables creativity. Each component plays a vital role, working together to produce remarkable results in various projects. By familiarizing oneself with these elements, users can maximize the potential of their equipment.

Main Elements

- Blade Assembly: This component is crucial for precision cutting, designed for various materials.

- Carriage: Houses the blade and holds it in place while moving across the surface.

- Rollers: These facilitate the movement of the material being used, ensuring smooth feeding.

- Control Panel: The interface allows users to adjust settings and select functions easily.

- Power Supply: Provides the necessary energy for operation and functionality.

Understanding Their Functions

- Precision: The blade assembly determines the accuracy of cuts.

- Mobility: The carriage’s movement is essential for executing designs effectively.

- Material Handling: Rollers maintain consistent tension and alignment.

- User Interaction: The control panel enhances the user experience by simplifying adjustments.

- Stability: The power supply ensures consistent performance during extended use.

Importance of a Parts Diagram

Understanding the individual components of any machine is crucial for effective operation and maintenance. A visual representation of these elements not only aids in identifying each piece but also enhances troubleshooting and repair processes. When users are familiar with the layout and function of each part, they can ensure optimal performance and longevity of the equipment.

Having a detailed illustration serves multiple purposes. It simplifies the process of assembly and disassembly, making it easier to replace or repair components when necessary. Additionally, it can serve as a valuable reference for identifying issues or malfunctions, which is essential for both novice and experienced users alike.

| Benefit | Description |

|---|---|

| Enhanced Understanding | Visual aids help users comprehend the function of each element. |

| Streamlined Repairs | Quick identification of components leads to faster maintenance. |

| Improved Efficiency | Familiarity with parts promotes better handling and operation. |

| Informed Decision Making | Knowledge of components aids in selecting the right tools and materials. |

Key Features of the Cricut Maker

This versatile cutting machine offers an array of innovative functionalities that elevate crafting to new heights. Designed for both beginners and seasoned creators, it seamlessly combines precision with user-friendly features, allowing for a wide range of projects from simple to intricate.

Advanced Cutting Technology

Equipped with a sophisticated cutting system, this device can handle an extensive variety of materials, including paper, vinyl, fabric, and even thicker substances like wood and leather. The unique blade system adjusts automatically to ensure optimal results, providing consistent precision across every cut.

Smart Tools and Accessories

Featuring a range of interchangeable tools, this machine enhances creativity by allowing users to switch between cutting, writing, and scoring functions effortlessly. The adaptive tool system not only expands crafting possibilities but also ensures compatibility with future tools, making it a long-term investment for any enthusiast.

Main Tools Compatible with Cricut

When it comes to crafting with precision and creativity, having the right tools at your disposal is essential. Various implements enhance the functionality of cutting machines, allowing users to explore a wide range of projects, from intricate designs to practical applications. Understanding the tools that can be utilized with these devices opens up a world of possibilities for makers and hobbyists alike.

Cutting Blades

One of the most important accessories includes specialized cutting blades. These blades are designed for different materials, such as vinyl, paper, fabric, and even thicker materials like wood. Each blade type enables unique cutting capabilities, ensuring that every project is executed flawlessly.

Writing and Scoring Tools

In addition to cutting, writing and scoring tools enhance the creative process. Writing tools allow for personalized notes and artistic lettering, while scoring tools ensure clean folds for cards and boxes. These accessories provide versatility and add a professional touch to any crafted item.

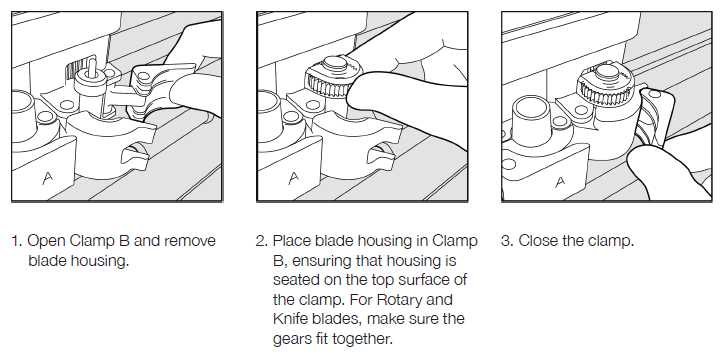

How to Replace Worn Parts

Maintaining your cutting machine is essential for optimal performance. Over time, certain components may experience wear and tear, impacting the device’s efficiency. Knowing how to identify and replace these elements will ensure that your equipment continues to operate smoothly and produce high-quality results.

Identify the Components: Start by carefully inspecting the machine for any signs of damage or excessive wear. Look for frayed belts, dull blades, or worn-out rollers. Familiarizing yourself with the different components will help you determine which ones need replacement.

Gather the Necessary Tools: Before beginning the replacement process, collect the required tools. Commonly needed items include screwdrivers, pliers, and replacement components. Having everything on hand will streamline the process and minimize downtime.

Follow the Instructions: Refer to the manufacturer’s guidelines for specific instructions on how to safely remove and replace the worn components. Each machine may have unique steps, so following the provided manual is crucial to avoid damage.

Test the New Components: Once you have installed the new parts, conduct a test run to ensure everything is functioning correctly. Pay attention to any unusual sounds or movements, as these could indicate improper installation.

Regular maintenance and timely replacement of worn elements will enhance the longevity and performance of your cutting machine, allowing you to continue your creative projects without interruption.

Troubleshooting Common Issues

When working with cutting machines, users may encounter a variety of challenges that can hinder their projects. Understanding common problems and their solutions can significantly enhance the crafting experience. This section aims to provide insights into frequent complications and how to effectively resolve them.

Common Problems and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Machine not powering on | Power supply issue | Check the power cable and outlet; ensure a secure connection. |

| Incorrect cuts | Blade misalignment | Recalibrate the blade and ensure it is properly installed. |

| Material not feeding | Feed rollers dirty | Clean the rollers with a lint-free cloth. |

| Design not transferring | Software settings incorrect | Verify the design settings and ensure they match the selected material. |

Preventive Measures

To minimize the occurrence of issues, regular maintenance is key. Ensure that the machine is cleaned after each use, check for software updates, and always refer to the user manual for troubleshooting tips. By being proactive, users can enjoy a smoother crafting experience.

Maintenance Tips for Longevity

Proper upkeep of your crafting device can significantly extend its lifespan and enhance performance. Regular attention to detail and mindful usage will ensure that it remains a reliable tool in your creative endeavors. Below are essential practices to maintain the functionality and durability of your machine.

Regular Cleaning

Keeping your equipment clean is vital for its efficiency. Dust and debris can accumulate and affect performance.

- Wipe down surfaces with a soft cloth after each use.

- Use compressed air to remove dust from hard-to-reach areas.

- Clean the cutting blade and housing regularly to prevent build-up.

Proper Storage

How and where you store your device can influence its condition.

- Store in a dry, temperature-controlled environment to avoid damage.

- Keep it covered to protect against dust and potential scratches.

- Avoid placing heavy objects on top to prevent physical harm.

Implementing these simple maintenance tips will help ensure that your device remains in optimal condition, allowing you to enjoy your crafting activities for years to come.

Visual Guide to Machine Layout

This section provides an illustrative overview of the arrangement and components within the crafting device. Understanding the setup is crucial for efficient use and optimal results. By familiarizing yourself with the layout, you can navigate through the various features and functionalities seamlessly.

Main Components Overview

The primary elements of the device include the cutting area, control panel, and feed mechanism. Each of these sections plays a vital role in the overall operation, ensuring that materials are processed accurately and efficiently. The cutting area is where the action happens, while the control panel offers user interface options for adjustments and settings.

Proper organization of tools and accessories is essential for maintaining workflow. Various compartments are designed to hold blades, mats, and other implements, making it easy to switch between tasks. Keeping these items readily accessible not only enhances productivity but also minimizes downtime during projects.

Upgrading Cricut Maker Accessories

Enhancing your crafting experience can be achieved by exploring various complementary tools and equipment that elevate functionality and creativity. With a wide range of available enhancements, it’s essential to choose accessories that suit your specific needs and projects.

Benefits of Upgrading

- Improved Efficiency: Advanced tools can streamline your workflow, allowing for quicker project completion.

- Increased Versatility: New accessories can enable a broader range of materials and techniques.

- Enhanced Creativity: Innovative tools inspire new ideas and elevate your designs.

Recommended Accessories

- Cutting Blades: Invest in premium blades designed for different materials to achieve cleaner cuts.

- Tool Sets: Specialized tools for weeding, scoring, and engraving can significantly improve your crafting precision.

- Material Rollers: These can help manage larger sheets and rolls, ensuring smooth feeding during the cutting process.

- Storage Solutions: Organizing your supplies with dedicated storage can enhance your workspace and keep everything easily accessible.

By thoughtfully selecting and upgrading your accessories, you can transform your crafting projects and maximize your creative potential.

How Parts Impact Performance

The functionality of a crafting machine is significantly influenced by its various components. Each element plays a crucial role in determining how effectively the device performs its intended tasks. A well-designed assembly can enhance precision, speed, and overall user experience, while deficiencies in any segment may lead to suboptimal results.

Quality and Material are pivotal in the performance of any device. High-grade materials not only ensure durability but also contribute to smoother operation and less wear over time. In contrast, inferior materials can lead to frequent breakdowns and inconsistent outcomes.

Design and Engineering also play a vital role. Thoughtful arrangements of the internal mechanisms can enhance efficiency and minimize friction, allowing for faster processing and improved accuracy. An innovative layout can lead to better integration of functions, making the overall experience more seamless.

Maintenance is another critical factor. Regular upkeep of components ensures that they remain in optimal condition, reducing the likelihood of malfunctions. Neglecting this aspect can result in decreased performance and a frustrating experience for the user.

Ultimately, the interplay between quality, design, and maintenance of the individual elements determines the overall capability of the machine, affecting everything from ease of use to the quality of the final product.

DIY Repairs and Modifications

Engaging in hands-on repairs and enhancements can significantly extend the life of your crafting equipment while also boosting its functionality. Many enthusiasts find that personalizing their machines not only improves performance but also adds a unique touch to their creative process. This section explores various ways to address common issues and implement upgrades, enabling you to make the most of your tools.

Understanding Common Issues is the first step toward successful repairs. Many users encounter similar challenges, such as inconsistent cutting or malfunctioning components. By identifying these problems early, you can avoid more significant setbacks and costly replacements. Consider documenting any issues you face to help pinpoint trends and solutions.

Essential Tools and Materials are crucial for any repair project. Stocking up on basic supplies like screwdrivers, pliers, and replacement elements can prepare you for a variety of fixes. Additionally, utilizing online resources, such as forums or video tutorials, can provide guidance and tips for your specific model.

Modification Projects can also enhance the capabilities of your device. From upgrading blades to improving software, there are numerous ways to tailor your equipment to better suit your needs. Experimenting with new accessories or techniques can lead to exciting results and broaden your creative possibilities.

In conclusion, embracing DIY repairs and modifications not only fosters a deeper understanding of your tools but also empowers you to take control of your crafting experience. With the right approach and resources, you can ensure that your equipment remains a reliable partner in your creative endeavors.

Resources for Parts and Support

Having reliable resources for components and assistance is essential for maintaining optimal functionality and performance of your crafting machine. Various platforms offer helpful information, spare components, and expert guidance to ensure smooth operation.

- Official Website: The manufacturer’s website typically features a comprehensive support section, including manuals, troubleshooting tips, and access to official components.

- Community Forums: Online forums and discussion groups can be invaluable for connecting with fellow users. You can find solutions to common issues and share experiences.

- Social Media Groups: Joining dedicated groups on platforms like Facebook or Reddit can provide quick answers and insights from a large community of enthusiasts.

- Retail Outlets: Authorized retailers often stock essential components and can offer professional advice on maintenance and repairs.

- Instructional Videos: Many creators share detailed tutorials and repair guides on platforms like YouTube, which can be beneficial for visual learners.

By leveraging these resources, users can enhance their experience and ensure their crafting tools remain in excellent working condition.