Traction Control: The elements of the drivetrain help distribute

Wheels and Tires Configuration

The setup of wheels and tires plays a critical role in ensuring stability, traction, and overall performance. Understanding the various options available and how to configure them correctly can significantly enhance handling and endurance across different terrains.

Choosing the Right Tire Type

Different environments demand specific tire types to maintain optimal grip and control. Off-road tires typically feature deeper treads, which provide enhanced traction on rough and uneven surfaces. On the other hand, slick or low-profile tires are better suited for flat, paved areas where speed and minimal friction are key factors.

Wheel Size and Offset

Wheel size impacts both the handling and the visual profile of the vehicle. Larger wheels may offer better stability, while smaller wheels provide quicker acceleration. Additionally, the offset of the wheel affects how it fits within the vehicle’s frame, influencing turning radius and clearance. Ensuring the correct configuration is crucial for avoiding unnecessary strain on suspension components and achieving balanced performance.

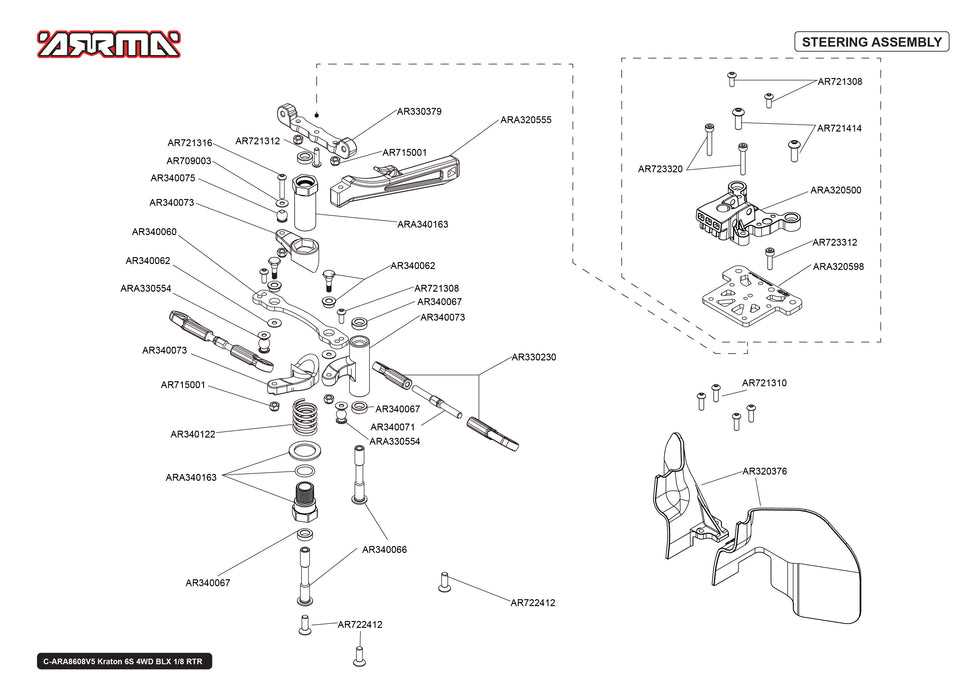

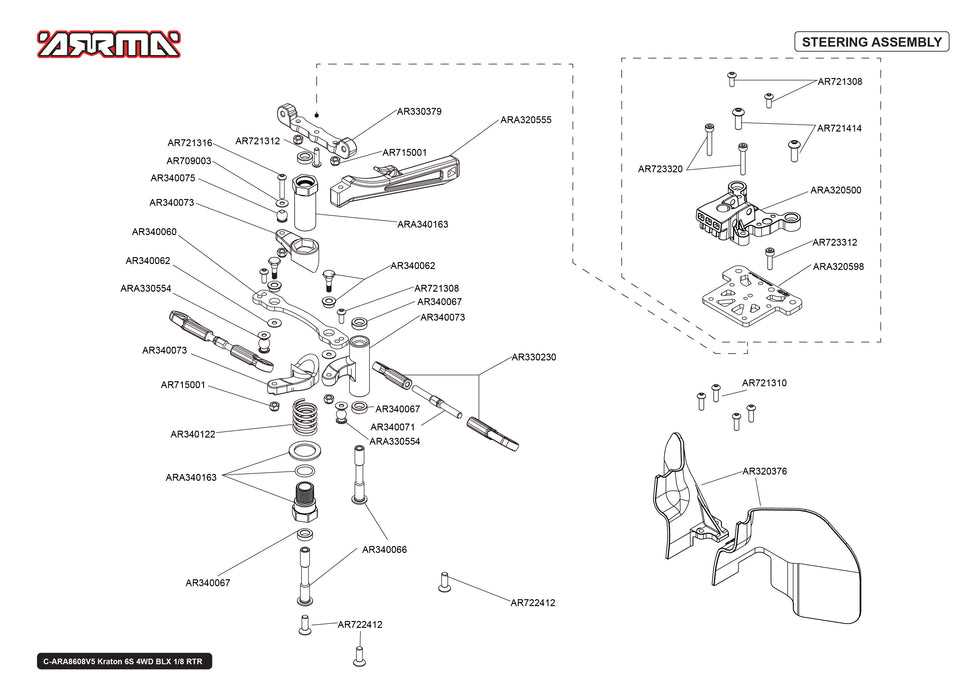

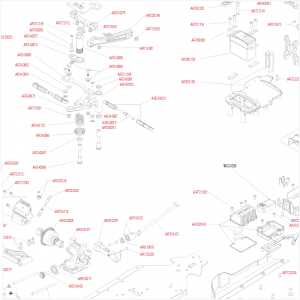

Steering Mechanism and Linkages

The steering system is a crucial component in any vehicle, allowing for precise control and navigation. It comprises various linkages that connect the steering wheel to the wheels, enabling smooth directional changes. Understanding the mechanics behind this system helps in enhancing performance and ensuring longevity.

At the heart of the steering assembly lies the servo, which translates the driver’s input into movement. This movement is transmitted through a series of linkages that include tie rods and steering arms. These elements work together to ensure that when the steering wheel is turned, the vehicle responds accurately and efficiently.

Furthermore, the geometry of the linkages plays a significant role in the overall handling characteristics. Adjustments to the angles and lengths of these components can greatly influence steering responsiveness and stability, especially during high-speed maneuvers or rough terrain navigation.

Regular maintenance of the steering mechanism is essential for optimal performance. Inspecting the linkages for wear and tear, ensuring proper alignment, and lubricating moving parts can prevent issues and enhance the driving experience. By understanding the intricate relationship between the steering components, enthusiasts can better appreciate the engineering behind their vehicles.

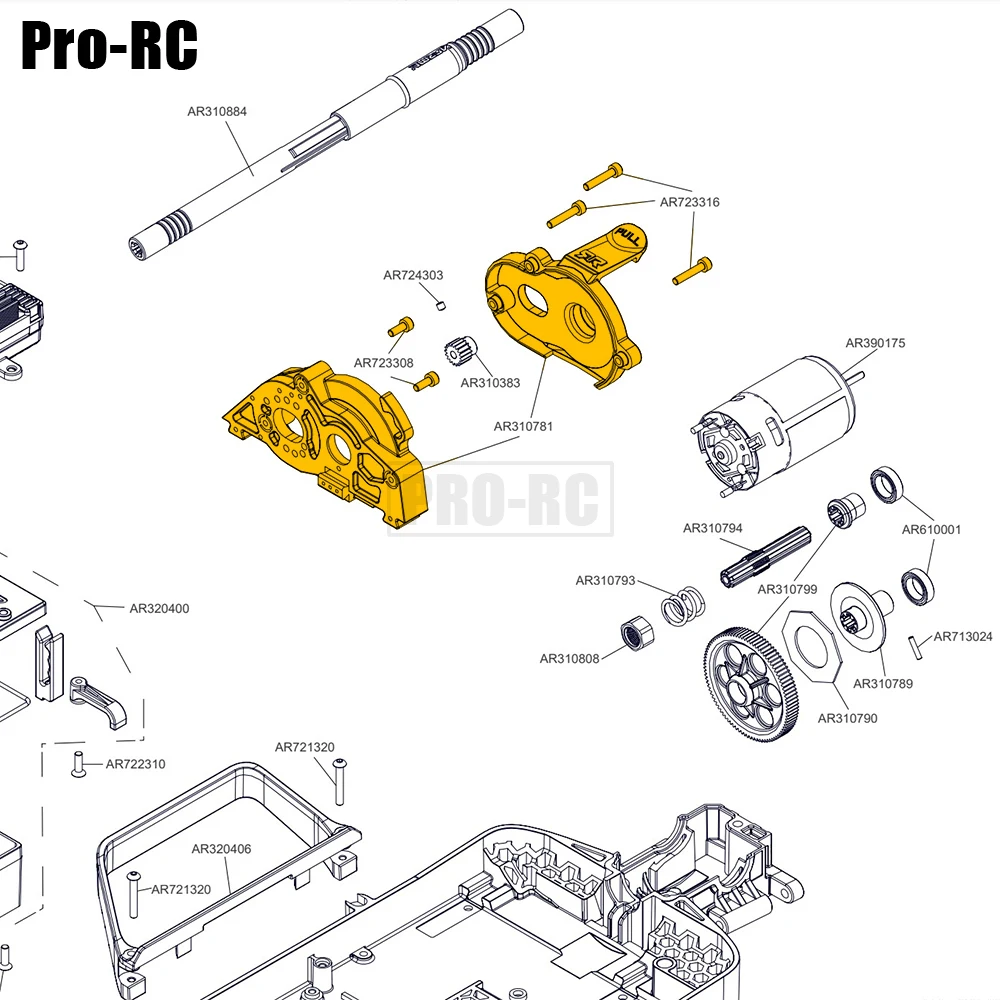

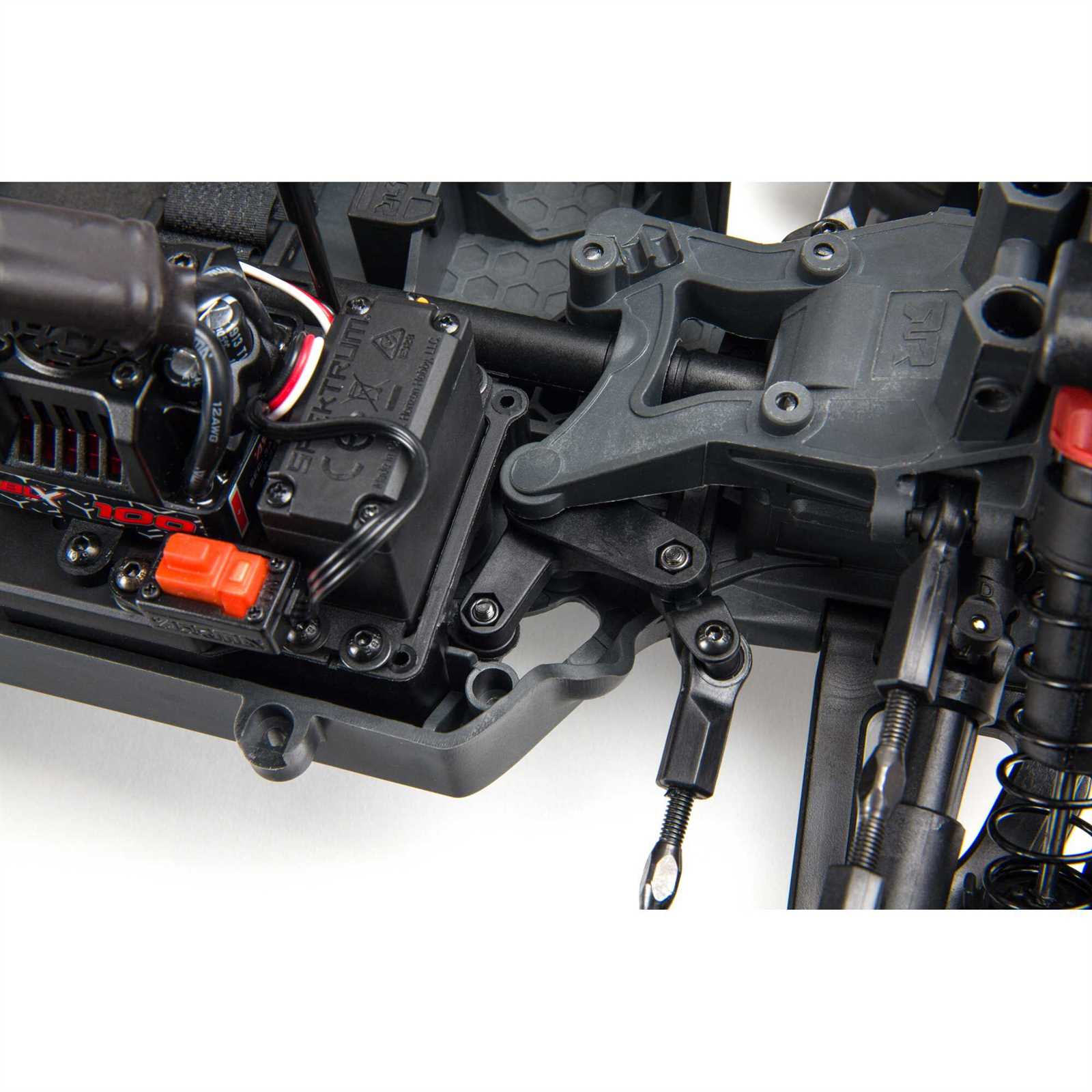

Motor and Power System Layout

The arrangement of the engine and power system is crucial for optimizing performance in remote-controlled vehicles. This section explores the fundamental components and their interconnections, emphasizing efficiency and functionality. A well-designed layout can significantly enhance the overall driving experience and ensure reliable operation under various conditions.

Engine Configuration

The engine serves as the heart of the vehicle, converting energy into motion. Its placement within the chassis affects weight distribution and handling characteristics. A balanced configuration minimizes unnecessary strain on the vehicle, promoting longevity and stability during operation.

Electrical Components

In addition to the engine, the electrical system plays a pivotal role in ensuring seamless power delivery. This includes the battery, speed controller, and wiring. Proper management of these elements is essential for maintaining optimal performance and preventing potential failures. Ensuring adequate connections and appropriate component ratings can significantly improve reliability and responsiveness during use.

Bumper and Skid Plate Details

The front protective component and the underlying shield play crucial roles in safeguarding the vehicle during operation. These elements are designed to absorb impacts and provide stability, ensuring that the chassis remains intact while navigating various terrains. Understanding their specifications and functionality can enhance performance and durability.

Functionality

The protective shield serves as the first line of defense against obstacles, preventing damage to vital components beneath the vehicle. It is engineered to withstand harsh conditions, ensuring reliable protection during rough rides. Meanwhile, the bumper not only contributes to the aesthetic appeal but also provides additional support and resilience during collisions.

Specifications

| Feature |

Description |

| Material |

High-strength polymer for impact resistance |

| Weight |

Lightweight construction for improved handling |

| Design |

Aerodynamic shape to reduce drag |

| Installation |

Easy to mount with standard tools |

Body Shell and Mounting Options

The protective covering and its attachment methods play a crucial role in enhancing the durability and performance of a remote-controlled vehicle. A well-designed exterior not only safeguards the internal components but also contributes to the overall aesthetics and aerodynamics. Understanding the various options available for body shells and their mounting techniques is essential for optimizing the vehicle’s functionality and appearance.

When selecting a shell, enthusiasts have a range of materials and styles to consider, each offering unique benefits. From lightweight polycarbonate to more robust alternatives, the choice can significantly influence handling and protection. Furthermore, the mounting options determine how securely the shell is attached to the chassis, impacting both performance during operation and ease of maintenance.

| Body Shell Material |

Benefits |

Considerations |

| Polycarbonate |

Lightweight, flexible, impact-resistant |

Can scratch easily, requires careful handling |

| ABS Plastic |

Durable, resistant to deformation |

Heavier, less flexible than polycarbonate |

| Fiberglass |

Highly durable, customizable |

More expensive, heavier |

| Carbon Fiber |

Strongest option, lightweight |

Very expensive, requires specialized tools for modifications |

For securing the shell, various mounting techniques exist, ranging from traditional clips to advanced pin systems. Each method offers distinct advantages in terms of ease of installation and reliability. Choosing the right mounting option not only enhances the aesthetic appeal but also ensures the shell remains intact during rigorous use.

Battery Compartment and Connections

The battery compartment plays a crucial role in the functionality of the vehicle, housing the power source and facilitating connections that ensure optimal performance. Proper understanding and maintenance of this area are essential for efficient operation and longevity of the model.

Location and Accessibility

The designated area for the power supply is typically located at the rear or under the chassis. This strategic positioning allows for easy access when replacing or charging the battery. Ensuring that this compartment is clean and free from debris can significantly enhance the connection quality and overall performance.

Connections Overview

The connections within the battery compartment are vital for transmitting power effectively. Users should be familiar with the types of connectors used and their respective functionalities. Regular inspection of these connections helps prevent electrical issues and ensures a stable power flow.

| Component |

Description |

| Battery Type |

The specific type of battery compatible with the model, impacting performance and runtime. |

| Connector Type |

Details the connectors used to link the battery to the power system, affecting ease of installation. |

| Mounting Points |

Locations where the battery is secured within the compartment, ensuring stability during operation. |

Shock Absorbers and Springs Setup

The proper configuration of dampers and coil springs is crucial for optimizing vehicle performance. This section delves into the fundamentals of setting up these components to enhance handling, stability, and overall ride quality. A well-balanced suspension system can significantly impact your vehicle’s capability on various terrains, ensuring a smoother and more controlled driving experience.

Understanding the Components

Before adjusting your dampers and springs, it’s essential to grasp their roles:

- Shock Absorbers: These elements control the rate of compression and rebound in the suspension system, ensuring that the vehicle maintains contact with the ground.

- Coil Springs: These provide the necessary support for the vehicle’s weight and absorb shocks from bumps and irregularities in the surface.

Adjustment Tips

To achieve the desired performance, consider the following setup strategies:

- Assess the current damping settings and adjust them according to your driving style and terrain.

- Experiment with different spring rates to find the balance between comfort and responsiveness.

- Regularly inspect the components for wear and tear to maintain optimal functionality.

By fine-tuning these elements, you can significantly improve your vehicle’s handling characteristics, making it more responsive to various driving conditions.

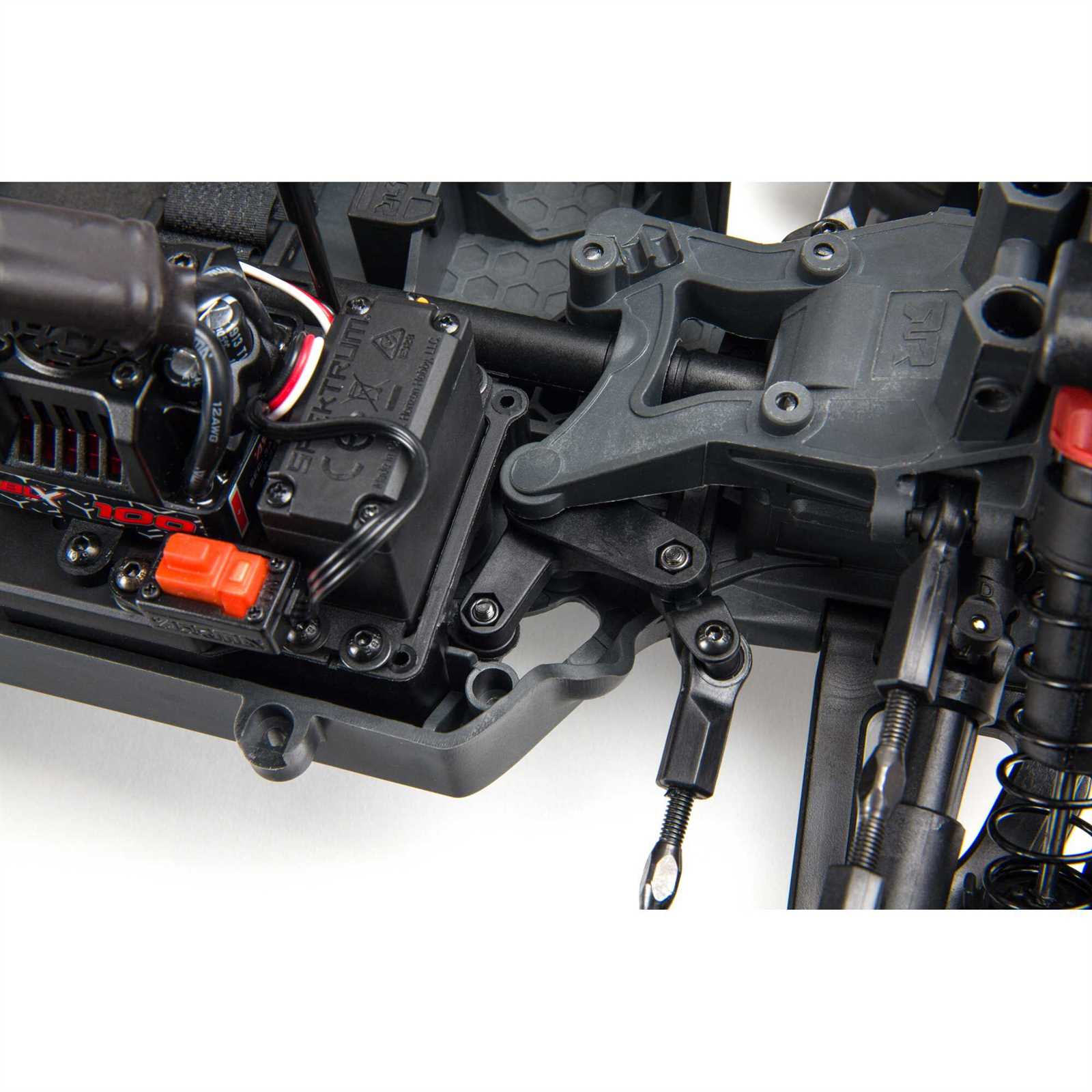

Electronics and Receiver Placement

Proper positioning of electronic components and receivers is crucial for optimal performance and reliability in remote-controlled vehicles. Ensuring that these elements are securely installed and well-organized not only enhances functionality but also minimizes the risk of damage during operation. A well-thought-out layout can lead to better signal reception and improved control, ultimately enhancing the overall experience for the user.

Securing the Receiver

The receiver is a vital component, as it interprets signals from the transmitter. It should be mounted in a location that is protected from vibrations and potential impacts. A secure fit is essential to prevent disconnections or damage. Using double-sided tape or Velcro can provide a reliable solution, allowing for easy access if adjustments are needed.

Organizing Wiring

Maintaining a tidy arrangement of wires is important for both aesthetics and functionality. Disorganized wiring can lead to interference with moving parts and increase the likelihood of entanglement. Utilizing cable ties or clips can help manage the wires effectively, ensuring that they remain clear of any rotating mechanisms. Additionally, proper insulation of exposed wires protects against short circuits, contributing to the longevity of the electronic systems.

Upgrade Options for Arrma Big Rock

Enhancing the performance and durability of your remote-controlled vehicle can significantly elevate your driving experience. By incorporating various enhancements, enthusiasts can optimize their machines for speed, agility, and resilience against wear and tear. This section explores several possibilities that can be considered to boost the functionality of your model, ensuring it meets both recreational and competitive demands.

Performance Enhancements

To achieve superior speed and control, consider upgrading the motor and electronic speed controller (ESC). A high-performance motor can provide more torque and increased RPMs, while an advanced ESC can ensure smoother acceleration and better response times. Additionally, improved suspension components can enhance handling and stability, allowing for better navigation over rough terrain.

Durability Improvements

Strengthening the frame and body can make a significant difference in durability. Reinforced chassis and high-quality shock absorbers can withstand impacts better. Upgrading to more robust tires can also improve traction and reduce the risk of punctures. These enhancements not only prolong the lifespan of the vehicle but also contribute to a more enjoyable driving experience.

| Upgrade Type |

Description |

Benefits |

| Motor |

High-performance motors for increased speed and torque. |

Improved acceleration and top speed. |

| ESC |

Advanced electronic speed controllers for smoother operation. |

Enhanced responsiveness and control. |

| Suspension |

Upgraded shock absorbers and springs for better handling. |

Increased stability and comfort on rough terrain. |

| Tires |

High-quality tires designed for various surfaces. |

Improved grip and reduced risk of punctures. |