For any tool enthusiast or professional, having a clear understanding of the individual components that make up a device is essential for maintenance and repairs. Knowing how each part functions in unison ensures optimal performance and prolongs the tool’s lifespan. This guide offers insights into the various elements of a specific power tool, providing clarity on how these pieces fit together.

Accurate identification of each element is crucial when replacing or servicing the tool. Whether it’s a motor, blade, or other integral part, understanding their roles can save both time and money in repairs. This section breaks down the key components to help users easily locate what they need, ensuring a smooth maintenance process.

Efficiency and precision are the hallmarks of a well-maintained tool. By familiarizing yourself with the parts that contribute to its functionality, you can handle any issue that arises, ensuring that your equipment is always ready for the next job.

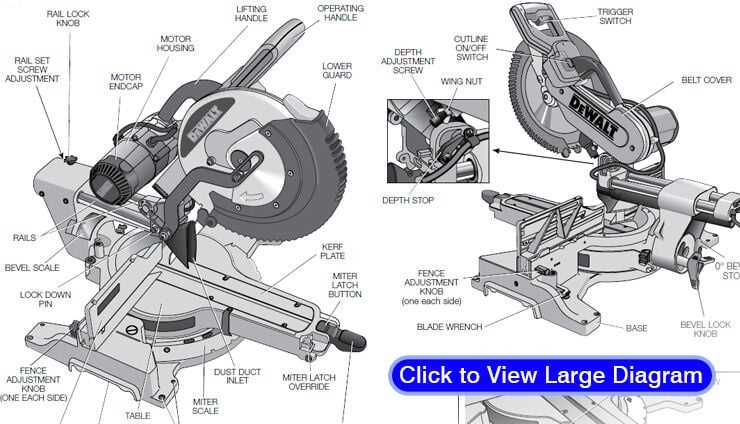

Dewalt DWS709 Parts Diagram Overview

Understanding the layout and components of a cutting tool is essential for proper maintenance and repair. A well-organized visual representation helps users identify individual elements and their interactions, ensuring smoother operations and fewer mistakes during assembly or disassembly.

Here are the key elements commonly highlighted in such a schematic:

- Motor assembly and its housing

- Blade and cutting mechanism components

- Adjustment knobs and settings for precision

- Safety features and protective casing

- Electrical wiring and connections

- Base and frame parts for structural support

By examining these components, you can gain a clearer insight into the tool’s functionality, which is vital for efficient upkeep and troubleshooting.

Key Components of Dewalt DWS709

The essential elements of a precision cutting tool play a critical role in its overall performance and reliability. These components ensure smooth operation, durability, and accuracy, all crucial for completing various tasks effectively. Understanding the primary sections helps in maintaining the tool and recognizing potential issues for repair or upgrades.

Among the main elements are the motor, which powers the tool, the blade assembly that handles the cutting process, and the adjustment mechanisms that provide versatility for different angles and depths. Additionally, the safety features and the structural framework ensure stability and user protection during operation.

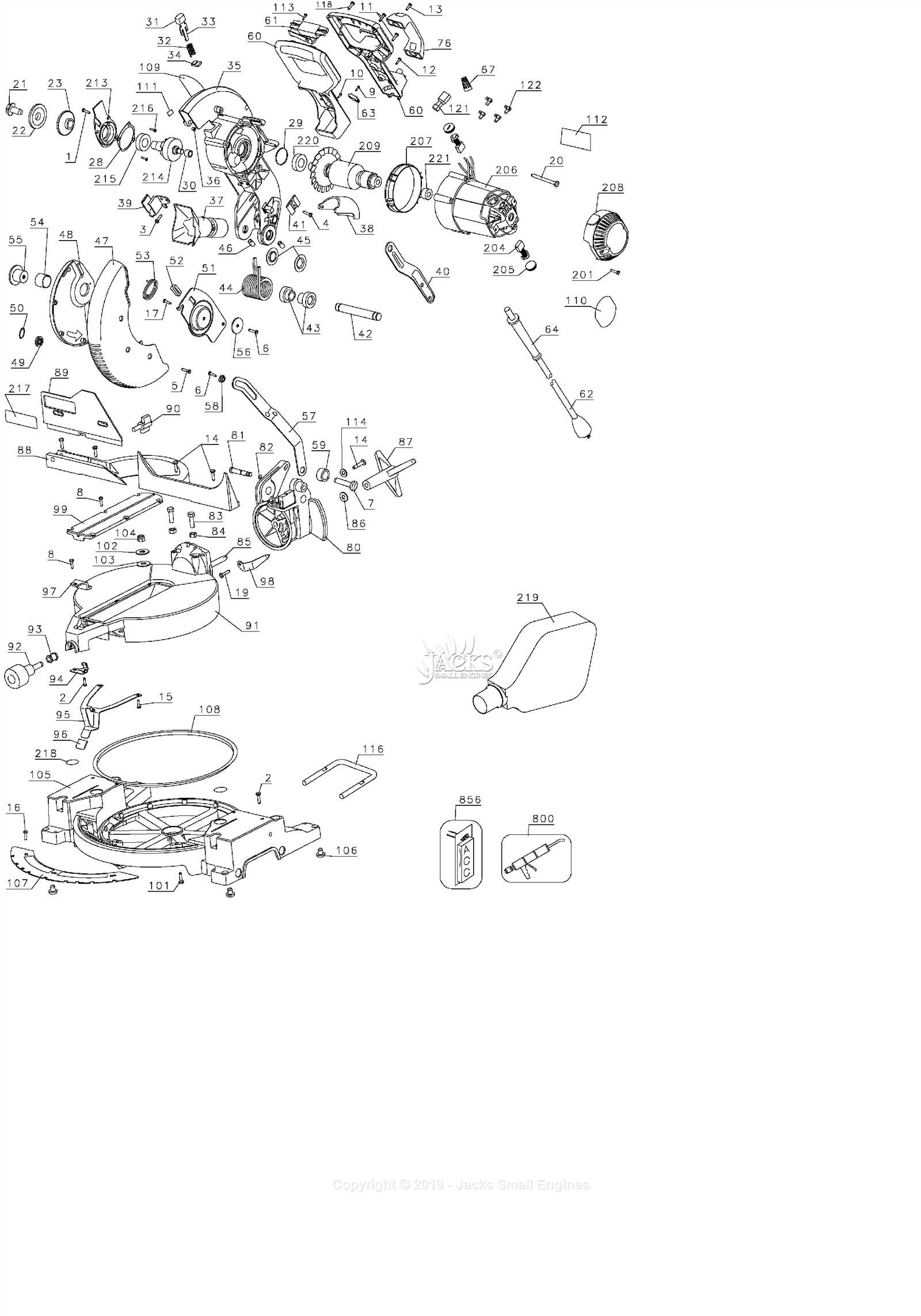

Understanding the Dewalt DWS709 Assembly

Grasping the assembly of power tools is essential for ensuring their proper functioning and maintenance. A well-organized structure not only contributes to the tool’s efficiency but also helps in troubleshooting and replacement of worn-out components.

These tools are comprised of several key components that work together in harmony. Each part plays a crucial role in the overall performance, and knowing how they fit and function can significantly extend the tool’s lifespan.

- Motor Assembly: The heart of the tool, responsible for generating the cutting power.

- Blade Mechanism: Ensures precise cutting action, typically integrated with a guide for accuracy.

- Housing and Frame: Provides structural integrity and houses the motor and other parts securely.

- Fence System: Ensures stability and guides the material during cuts for straight lines.

- Adjustment Features: Enable customization of cut angles and depths based on the task requirements.

By understanding the assembly, users can identify potential issues, maintain the tool more effectively, and ensure optimal performance over time.

How to Identify Dewalt DWS709 Parts

Identifying the components of your tool can enhance its maintenance and performance. Understanding the key elements and their functionality is essential for ensuring longevity and efficient operation. This process can be simplified by recognizing the visual and functional features of each part, allowing you to troubleshoot or replace them when necessary.

| Component | Visual Identification | Function |

|---|---|---|

| Motor Assembly | Large, centrally located housing with ventilation slots | Provides power to the tool for cutting operations |

| Blade Guard | Protective cover over the blade, often clear plastic | Prevents debris and protects the user from the rotating blade |

| Adjustment Knob | Small, often located near the blade or guide system | Allows fine-tuning of the cutting angle or depth |

| Fence | Flat surface aligned with the blade for accurate cutting | Supports the workpiece and ensures straight cuts |

| Dust Collection Port | A tube or port, usually on the side or back | Helps remove sawdust and debris during use, keeping the workspace clean |

Essential Tools for Dewalt DWS709 Maintenance

Regular upkeep of your equipment ensures optimal performance and extends its lifespan. To keep your tool functioning smoothly, certain essential instruments are required for routine maintenance and minor repairs. These tools help address issues, replace worn-out components, and ensure precision in operation.

Basic Tools Required

The following tools are essential for general maintenance and minor adjustments:

| Tool | Purpose |

|---|---|

| Screwdrivers | Used for tightening and loosening screws for general repairs. |

| Allen Wrenches | For adjusting internal screws or bolts in tight spaces. |

| Wrenches | Helps in loosening or tightening nuts and bolts. |

| Lubricant | Ensures smooth movement of mechanical parts and reduces friction. |

Advanced Tools for Precision Maintenance

For more detailed or advanced repairs, the following tools are necessary:

| Tool | Purpose |

|---|---|

| Multimeter | Used to check the electrical components and diagnose issues. |

| Calipers | Essential for measuring precision parts and ensuring correct fit. |

| Blade Sharpening Tools | Helps maintain cutting efficiency by keeping blades sharp. |

Replacing the Blade on Dewalt DWS709

Changing the cutting blade on your tool is an essential maintenance task to ensure optimal performance and precision. Over time, blades can become dull or damaged, reducing the tool’s cutting efficiency. Replacing the blade is a simple yet important procedure that can significantly improve your project outcomes. Follow the steps below to safely and efficiently replace the cutting blade on your machine.

Tools and Preparation

Before starting the replacement process, gather the necessary tools. You will need a wrench or tool for loosening the blade arbor, a new blade compatible with your machine, and safety equipment such as gloves and eye protection. Make sure the machine is unplugged to avoid any accidents during the replacement.

Step-by-Step Blade Replacement

First, ensure the machine is completely powered off and disconnected from the power source. Secure the tool on a stable surface and use the wrench to loosen the arbor nut holding the blade in place. Carefully remove the old blade, making sure to handle it with care to avoid any injury. Install the new blade by aligning it with the arbor and tightening the nut securely. Double-check that the blade is positioned correctly before turning the machine back on.

Exploring the Electrical System of Dewalt DWS709

The electrical system in a power tool is crucial for its operation and efficiency. Understanding the layout and components of this system can help users maintain performance and troubleshoot issues effectively. From motors to wiring, each part plays an essential role in ensuring the tool operates smoothly under various working conditions.

Key Electrical Components

At the heart of the electrical setup are the motor and its connections to the power supply. The wiring is designed to ensure smooth current flow, allowing the motor to operate at peak efficiency. Additionally, circuit protection elements such as fuses or circuit breakers prevent damage from overloads or short circuits, ensuring longevity and safety during operation.

Maintenance and Troubleshooting

Regular maintenance of the electrical system can significantly reduce the risk of malfunctions. Inspecting the wiring for wear or corrosion, ensuring the motor is properly connected, and checking for any signs of electrical interference are all essential tasks. Identifying issues early can help avoid costly repairs and ensure the tool remains operational for longer periods.

How to Maintain Dewalt DWS709 Parts

To ensure the longevity and optimal performance of your tool, regular upkeep and careful attention to its components are essential. Routine checks and maintenance help prevent wear and tear, enhance accuracy, and avoid costly repairs. Below are key steps and best practices for keeping all components in good working order.

Cleaning and Inspection

Regular cleaning of the machinery is critical to remove dust, debris, and residues that may affect its efficiency. Always inspect the main components for any signs of damage or wear. Ensure that everything is tightly secured and operates smoothly.

- Clean the surface and mechanical parts after every use.

- Check for any loose screws or fastenings and tighten them.

- Inspect moving parts for smooth motion and proper lubrication.

Lubrication and Component Replacement

Lubrication of specific parts ensures smooth movement and reduces friction, extending the lifespan of the tool. Make sure to replace worn-out components to maintain peak performance.

- Use appropriate lubricant for metal and moving parts.

- Replace any worn-out or damaged components as soon as possible.

- Regularly replace consumable items like blades or cutting accessories to maintain cutting accuracy.

Troubleshooting Dewalt DWS709 Part Issues

When working with power tools, it’s important to ensure that all components are functioning properly to maintain performance and safety. Identifying and resolving malfunctions in various tool elements can help prevent more serious issues and ensure smooth operation. A thorough check-up can assist in pinpointing whether the problem lies in a specific part or its connection with other components.

Start by inspecting any visible signs of wear or damage, such as broken or misaligned parts, which can affect the tool’s precision and safety. If the tool is making unusual noises or not performing at full capacity, this often indicates a misalignment or failure of a particular component. Testing different settings and operations will provide further insight into the issue.

Another crucial step is to examine the electrical system, ensuring that all connections are secure and there are no frayed wires or loose connectors. Any disruption in the power flow can lead to malfunction, reducing the tool’s effectiveness. If everything seems intact but problems persist, it may be necessary to consult a professional for more advanced diagnostics.

Locating Dewalt DWS709 Parts for Replacement

When repairing or upgrading a tool, finding the correct components is essential for ensuring optimal performance and longevity. To ensure the replacement parts fit and function properly, knowing where to look and what to search for is crucial. A detailed search strategy can save both time and money, allowing for smooth repairs.

Where to Begin Your Search

Start by identifying the specific components you need, whether it’s for general maintenance or replacing worn-out pieces. Accurate identification is key, as similar models might have slight differences in their internal mechanisms. Make use of official sources, such as the manufacturer’s website, to ensure you’re getting high-quality, compatible replacements.

Online Retailers and Marketplaces

For convenience, many users turn to online platforms that specialize in tool accessories and replacements. These platforms often provide a wide range of options and can deliver parts quickly. Be sure to check customer reviews and seller ratings to avoid potential issues with compatibility or quality.

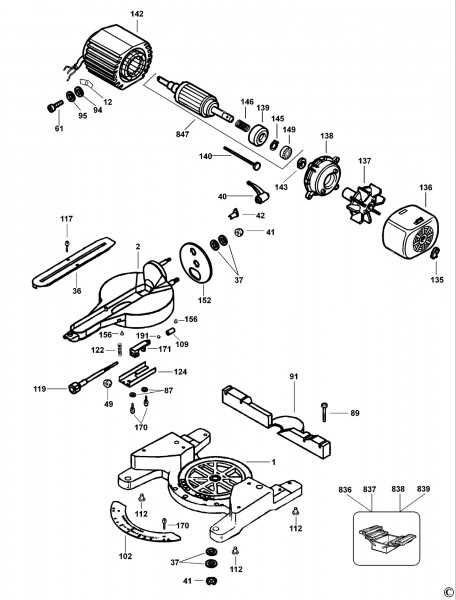

Understanding the Dewalt DWS709 Motor Assembly

The motor assembly is the heart of any power tool, driving its cutting performance and efficiency. It consists of several key components working in unison to provide the necessary force for precise operation. By understanding the structure and function of each element, users can better maintain and troubleshoot the tool, ensuring optimal performance over time.

At the core of the assembly lies the electric motor, which is responsible for converting electrical energy into mechanical motion. Surrounding this motor are the brushes and commutator, which facilitate smooth current flow, allowing the tool to operate efficiently. Additionally, the motor housing protects the internal components from dust and debris, preventing premature wear and tear.

Regular maintenance and understanding how each piece contributes to the overall function of the motor assembly are vital for extending the lifespan of the tool. Proper care ensures that the motor remains in good working order, minimizing the need for repairs and maximizing performance.

How to Disassemble the Dewalt DWS709

To effectively dismantle a compound miter saw, careful preparation and methodical steps are essential. This process allows for easy maintenance, repair, and cleaning of the device’s internal components. Follow the steps below to ensure a safe and efficient disassembly.

| Step | Action |

|---|---|

| 1 | Unplug the tool to ensure safety before starting any disassembly. |

| 2 | Remove the blade by loosening the central bolt using a wrench or appropriate tool. |

| 3 | Detach the fence and other external parts by unscrewing the bolts holding them in place. |

| 4 | Open the casing carefully, avoiding damage to the electrical components inside. |

| 5 | Take note of the arrangement of each part to assist in reassembly. |

Once disassembled, keep the components organized for reassembly. Make sure to check each part for wear or damage during the process, and replace anything that may affect the tool’s functionality.

Upgrade Options for Dewalt DWS709 Parts

Improving the performance of your cutting tool can significantly enhance both efficiency and precision. Whether you’re looking to upgrade certain components or invest in new accessories, there are several options available to tailor the machine to your specific needs. From smoother cuts to increased durability, the right enhancements can make a noticeable difference in your projects.

Key Upgrades for Enhanced Performance

Blade replacement is one of the most effective upgrades to improve cutting accuracy. High-quality blades can provide cleaner cuts and reduce the wear on the motor. Choosing a blade suited to your material and cutting style ensures better results and extends the lifespan of the tool.

Additional Accessories for Greater Versatility

For more versatility, consider adding laser guides or dust collection systems. Laser guides improve cutting precision by providing a clear visual marker, while a dust collection system keeps the workspace clean and improves air quality. These upgrades are practical for both professional and home users aiming to improve their cutting experience.