Install the new unit, ensuring it is positioned correctly and secured tightly.

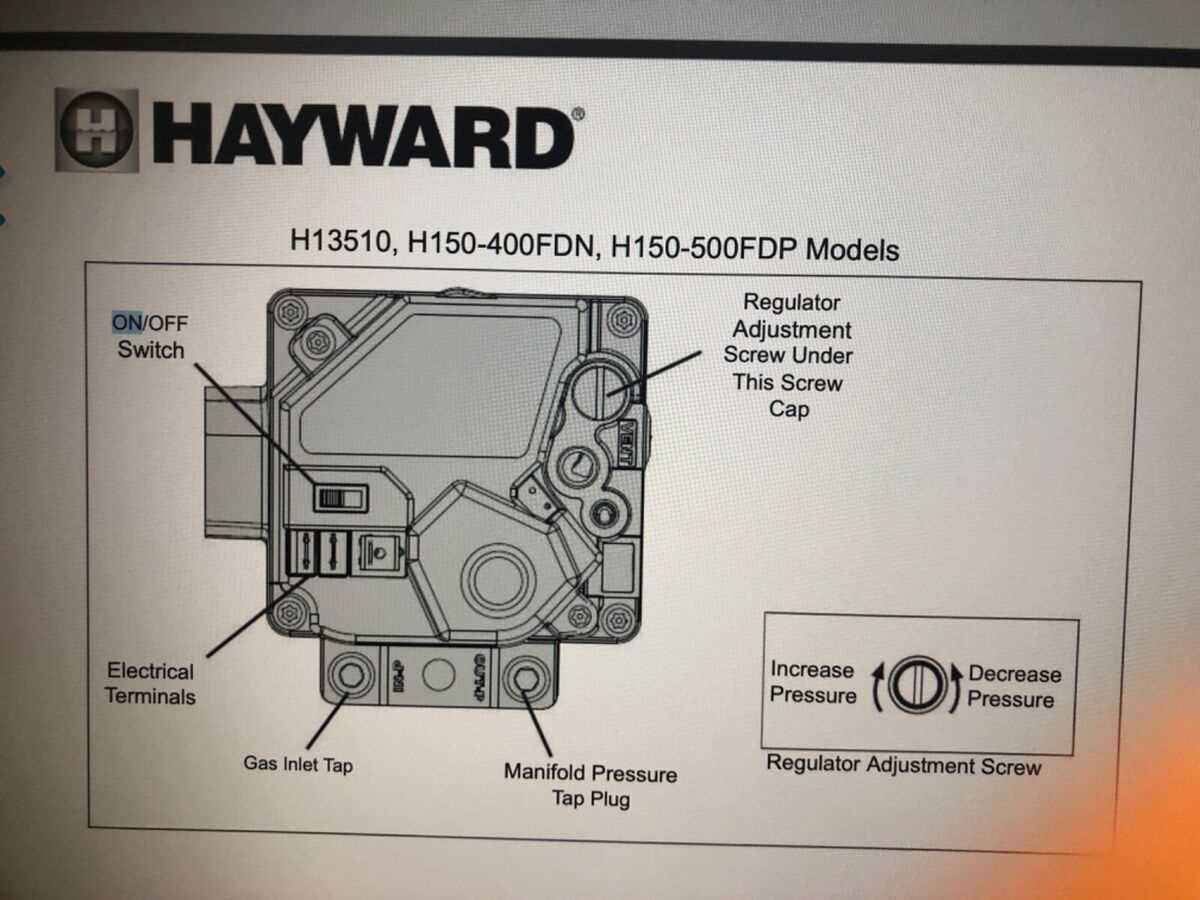

Guide to the Control Panel Functions

The control panel serves as the central interface for managing and adjusting various settings of your equipment. By familiarizing yourself with its functions, you can ensure optimal performance and tailor the system to your specific needs. Understanding the key elements of the panel will allow for seamless operation and troubleshooting when necessary.

Temperature Settings: The temperature controls enable users to adjust the desired output, ensuring comfort and energy efficiency. It’s crucial to monitor the current levels to maintain ideal conditions.

System Modes: The panel allows for easy switching between different operational modes, such as normal, energy-saving, or standby. Each mode is designed for specific scenarios, providing flexibility in how the system is used.

Error Notifications: The display will show error codes or alert messages if the system detects any issues. These indicators are essential for prompt identification of malfunctions or maintenance requirements.

Reset and Diagnostics: The reset function is available to restart the system if necessary, while built-in diagnostic tools assist in identifying problems, allowing for efficient troubleshooting and repair.

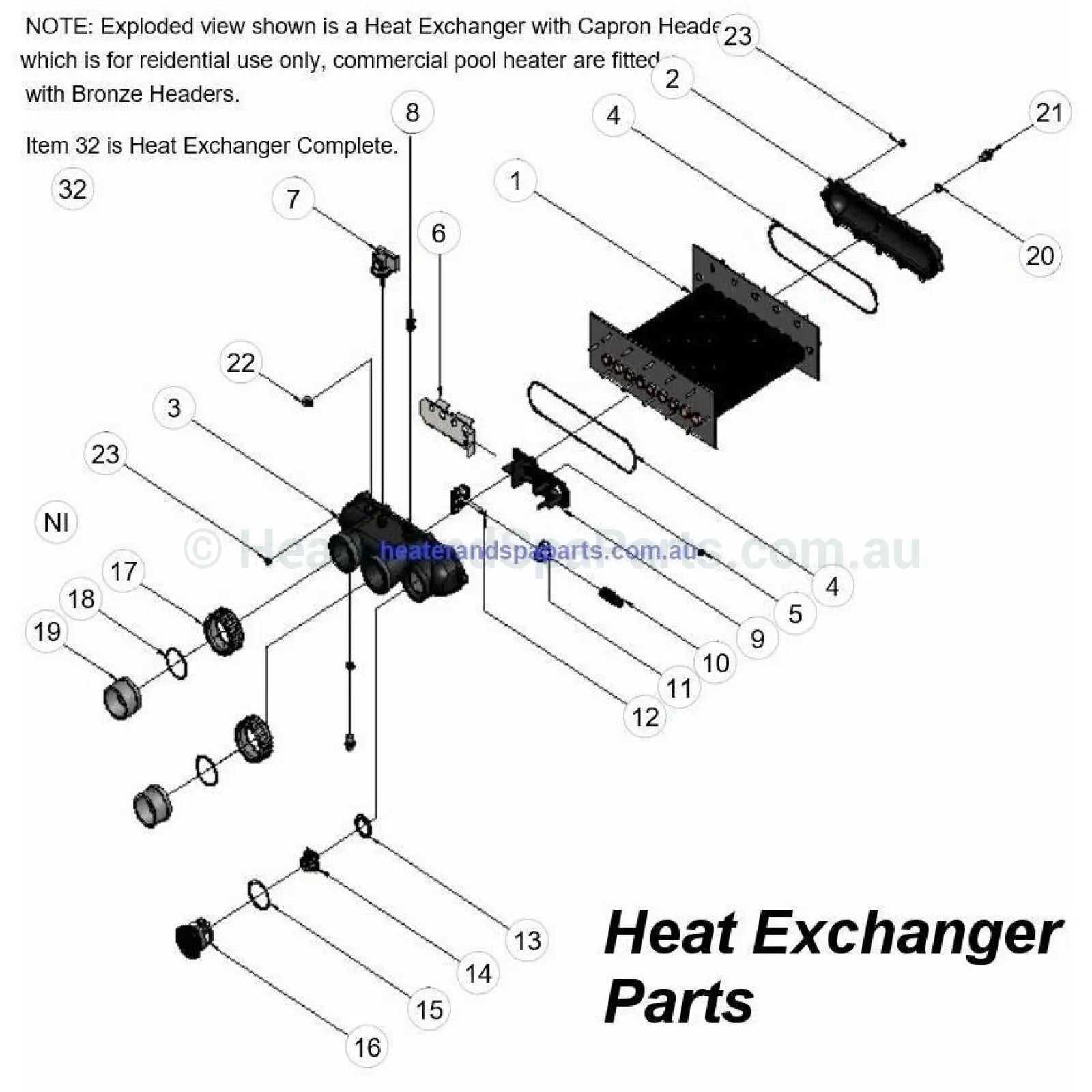

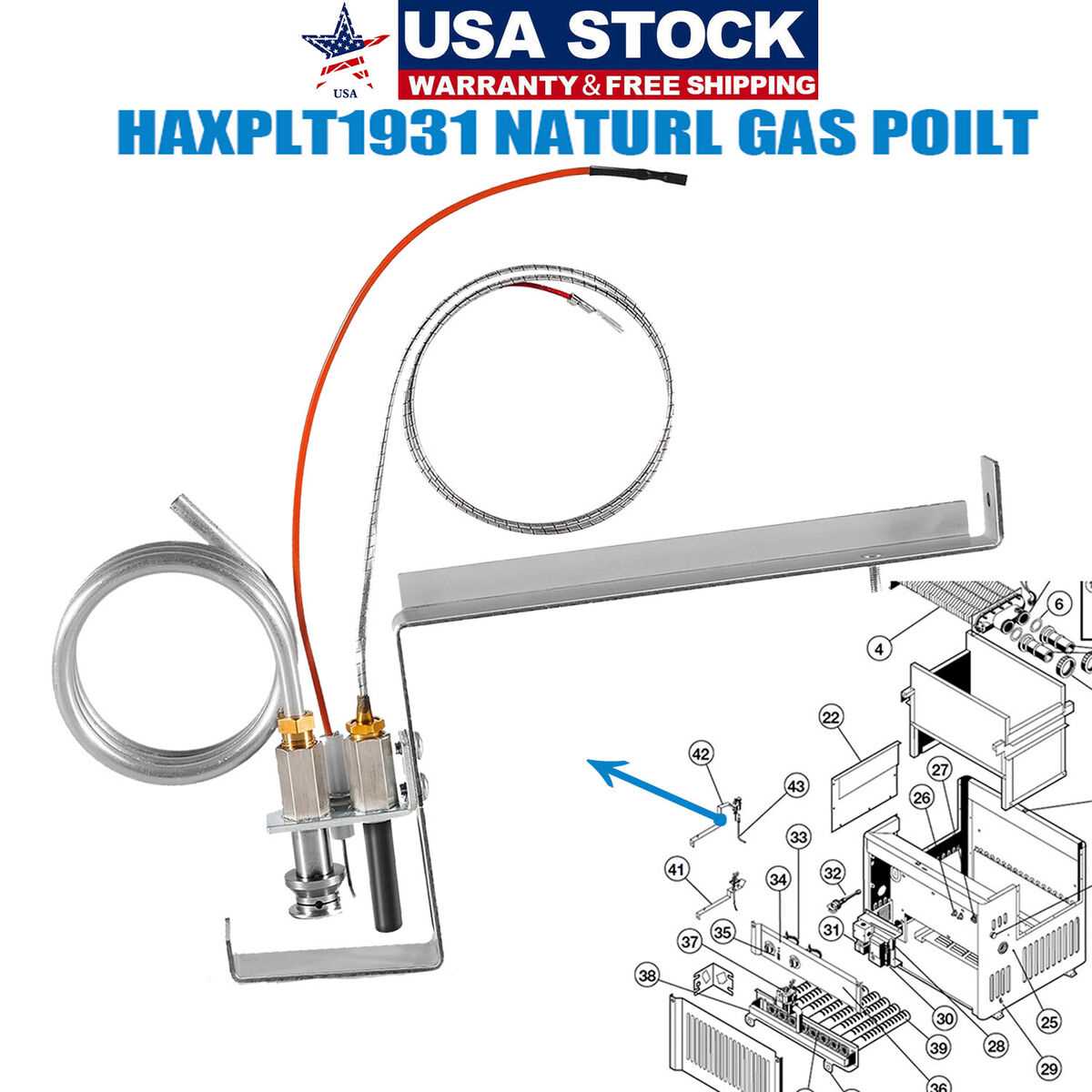

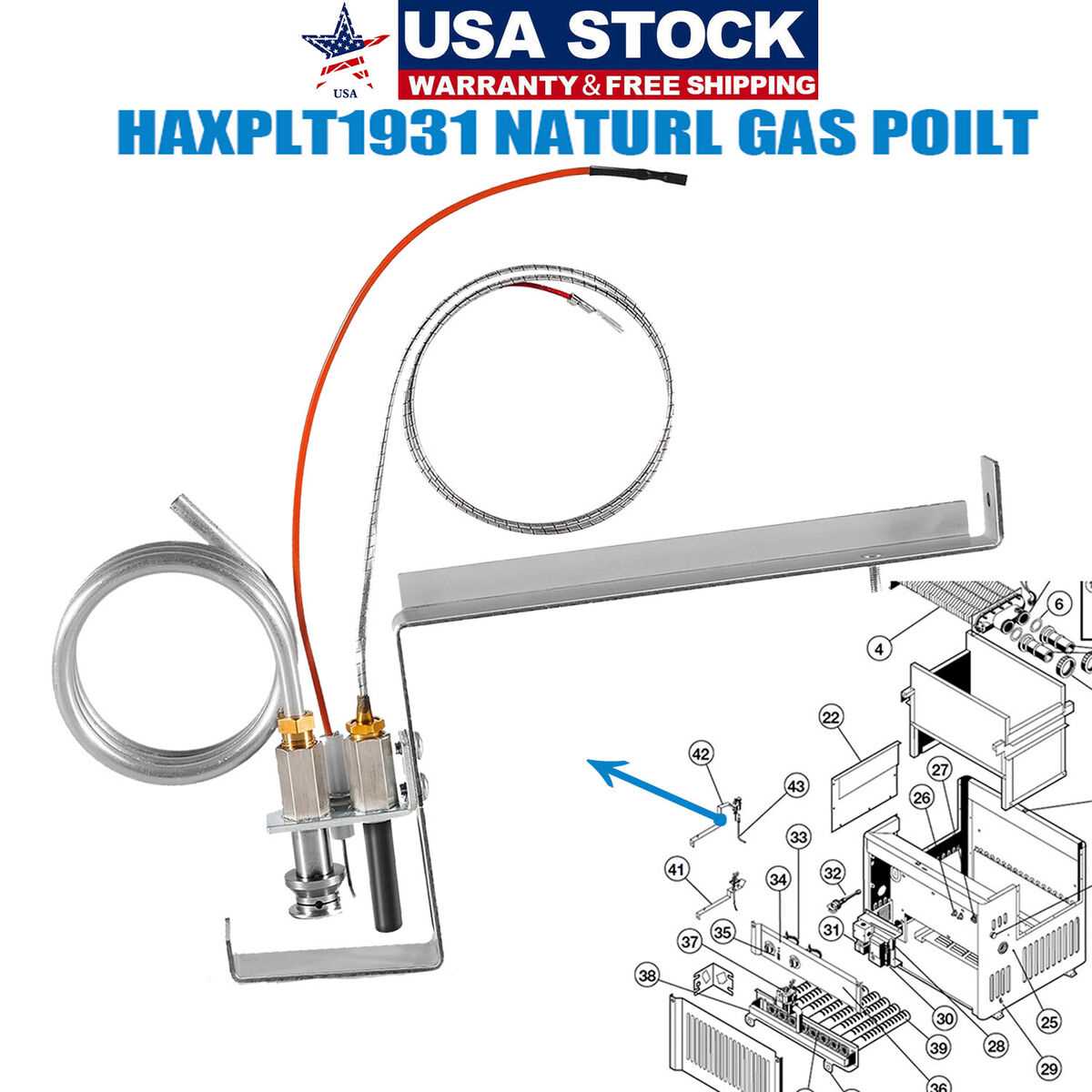

Commonly Worn-Out Parts in the H150

Over time, certain components of heating systems are more prone to wear and tear due to frequent use and exposure to harsh conditions. Regular maintenance and timely replacement of these elements can help prolong the lifespan of the unit and ensure efficient performance.

- Heat Exchanger: One of the most critical elements, the heat exchanger is subjected to continuous high temperatures, which can cause scaling, corrosion, or leaks.

- Burner Assembly: The burner is responsible for generating the flame that heats the water. Over time, debris buildup and wear can reduce its efficiency, leading to poor heating performance.

- Ignition System: The ignition module or pilot assembly can wear out due to frequent ignitions, resulting in difficulties starting the unit.

- Pressure Switch: This safety device ensures that the system has the correct water pressure before operation. It can degrade over time, causing the system to shut down or fail to start.

- Control Panel: The electronic control board is essential for managing the unit’s settings and operation. Continuous use can lead to malfunctions or failure in response.

Addressing these issues early can prevent major breakdowns and ensure smooth

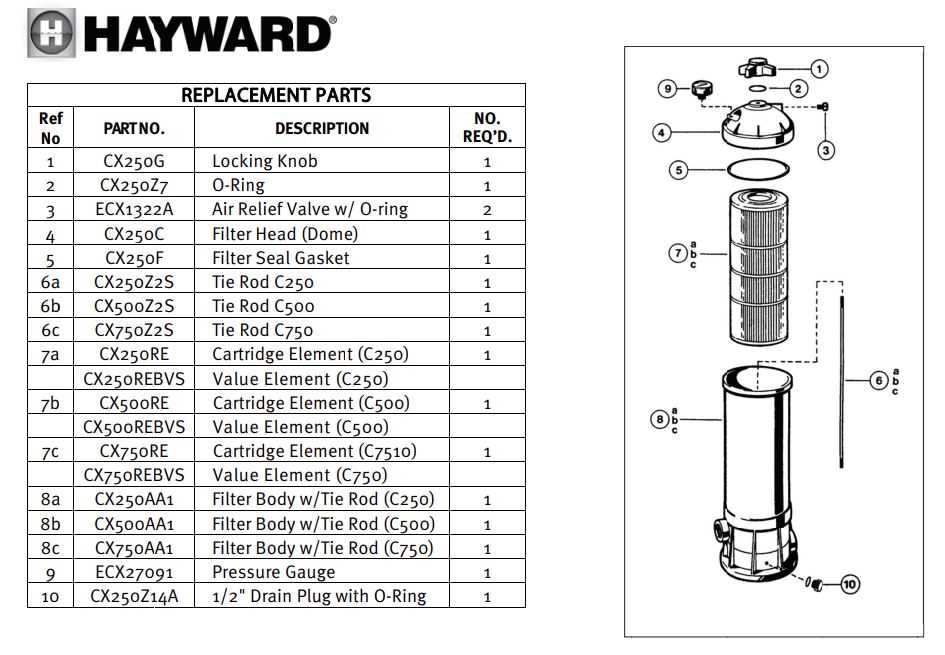

How to Maintain Your Hayward H150

Proper upkeep of your heating unit is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents potential issues that could arise from neglect. By following a few simple guidelines, you can ensure that your heating system operates smoothly throughout its lifespan.

Start by inspecting the unit periodically for any visible signs of wear or damage. Look for cracks, rust, or corrosion that may indicate underlying problems. Cleaning the exterior and ensuring that ventilation areas are free from debris will help maintain proper airflow and efficiency.

Next, check the filters and replace them as needed. Dirty filters can restrict airflow, causing the system to work harder than necessary. Regularly cleaning or replacing these components can significantly improve performance.

Additionally, it’s important to verify that all connections and seals are secure. Loose connections can lead to leaks or inefficient operation. Tighten any fittings and replace worn seals to maintain the integrity of the unit.

Lastly, consider scheduling professional maintenance at least once a year. A qualified technician can perform a thorough inspection and address any issues that may not be immediately apparent. Investing in regular professional check-ups will extend the lifespan of your heating unit and ensure optimal performance.

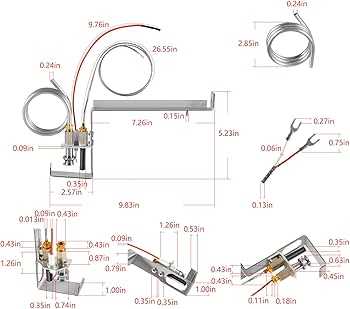

Troubleshooting Issues with the Ignition System

Identifying and resolving complications within the ignition mechanism is crucial for ensuring optimal performance of heating units. Various factors can contribute to ignition failures, ranging from faulty components to improper configurations. Understanding these elements can facilitate effective troubleshooting and restore functionality.

Common Symptoms of Ignition Problems

- No heat output despite operational indicators.

- Delayed ignition or difficulty starting.

- Frequent shutdowns during operation.

Steps for Effective Troubleshooting

- Check the power supply: Ensure the unit is receiving adequate voltage and that connections are secure.

- Inspect the ignition component: Examine for any visible damage or wear.

- Test the flame sensor: Clean or replace the sensor if it shows signs of corrosion or malfunction.

- Examine gas supply: Verify that gas flow is consistent and there are no obstructions in the line.

- Review control settings: Ensure that the thermostat and operational settings are appropriately configured.

By systematically addressing these areas, users can enhance the reliability of the ignition system and improve overall heating efficiency.

Understanding the Plumbing Connections in the H150

The plumbing connections play a crucial role in ensuring the efficient operation of heating equipment. Properly configured pipes facilitate the seamless flow of water, allowing the system to maintain optimal temperature levels while minimizing energy consumption. This section delves into the various plumbing elements, highlighting their functions and the significance of correct installation.

Inlet and Outlet Connections: The primary connections for water flow are the inlet and outlet ports. The inlet serves as the entry point for cold water, which is then heated before being directed out through the outlet. Ensuring these connections are securely fastened is essential to prevent leaks and maintain pressure.

Bypass Valve: A bypass valve is an important component that allows for the redirection of water flow. This feature is useful for maintaining desired temperatures and can help in preventing overheating during periods of low demand. Understanding its placement and function is vital for effective system management.

Return Lines: The return lines carry heated water back to the source, completing the cycle. Proper insulation and sealing of these lines can enhance energy efficiency and reduce heat loss. Regular inspections should be conducted to ensure that all connections remain intact and functional.

Drainage System: A well-designed drainage system is necessary for removing excess water and preventing overflow. This includes drain plugs and valves that must be easily accessible for maintenance. Familiarity with the drainage setup contributes to effective troubleshooting and longevity of the equipment.

Overall, a comprehensive understanding of these plumbing connections is essential for anyone looking to maintain or troubleshoot heating systems. Proper attention to detail in these areas can lead to improved performance and reliability.

Proper Installation of a New Pressure Switch

Installing a new pressure switch is a crucial task that ensures the optimal functioning of your system. A correctly installed switch maintains the desired pressure levels, promoting efficiency and preventing potential damage. This section provides essential guidelines for successfully setting up the new component.

1. Gather Necessary Tools and Materials: Before starting, ensure you have all required tools at hand, such as a screwdriver, adjustable wrench, and any sealing tape or compound. Having everything ready will streamline the installation process.

2. Turn Off Power: Safety is paramount. Always disconnect the power supply to avoid electrical hazards while working on the system. Confirm that the power is off by testing the circuits.

3. Remove the Old Switch: Carefully detach the existing pressure switch from its mounting position. Take note of the wiring configuration for accurate reconnection later. If needed, label the wires to avoid confusion.

4. Install the New Switch: Position the new pressure switch in place, ensuring it aligns properly with any existing mounting hardware. Secure it with screws or bolts, ensuring a snug fit without over-tightening, which could cause damage.

5. Reconnect Wiring: Refer to the notes or labels made earlier to reconnect the wires correctly. Double-check the connections for any loose or exposed wires, as proper contact is essential for effective operation.

6. Test the Installation: Once everything is securely in place, restore the power supply and conduct a test run. Monitor the system to ensure the pressure switch operates as expected, responding correctly to pressure changes.

Following these steps will help ensure a successful installation, contributing to the longevity and performance of your system.

Identifying Electrical Components of the H150

Understanding the electrical elements of a heating unit is crucial for effective maintenance and troubleshooting. Each component plays a vital role in ensuring the system operates efficiently and reliably. This section will delve into the essential electrical parts, highlighting their functions and significance within the overall assembly.

Key Electrical Elements

Among the primary components are the thermostat, which regulates temperature settings, and the control board, responsible for managing operations. Additionally, the power supply unit provides the necessary voltage for operation, while various sensors monitor different parameters, ensuring safety and performance.

Understanding Component Functions

Each of these elements interacts to create a seamless heating experience. For instance, the thermostat communicates with the control board to adjust the heating output based on user preferences. Furthermore, sensors provide real-time data, allowing the unit to respond promptly to changes, enhancing overall functionality and safety.

Best Practices for Seasonal Storage of the H150

Proper care and preparation are essential when storing heating units during the off-season. Ensuring the longevity and efficiency of your device requires a few critical steps to protect it from potential damage caused by environmental factors. Adopting effective strategies for seasonal storage not only preserves functionality but also saves you time and resources in the long run.

1. Clean Thoroughly: Before storing your unit, it’s vital to clean it meticulously. Remove any debris, dirt, or residues that may accumulate. Use a gentle cleaner and a soft cloth to wipe down surfaces, ensuring that all components are free from contaminants.

2. Drain Fluids: To prevent freezing and potential damage, make sure to drain all water and fluids from the system. This step is crucial in colder climates where temperatures may drop significantly.

3. Store in a Dry Environment: Choose a storage location that is dry and well-ventilated. Excess moisture can lead to rust and corrosion, adversely affecting the performance of your equipment. Using a storage bag or cover can provide additional protection from dust and humidity.

4. Disconnect Power Supply: Always unplug the unit from any electrical sources before storing. This measure enhances safety and helps avoid accidental activation during storage.

5. Regular Checks: Throughout the storage period, periodically inspect the unit for any signs of wear or damage. Early detection of issues can prevent costly repairs and ensure your device is ready for use when the season returns.