In the world of heavy machinery, particularly in the field of compaction, having a clear overview of the internal workings and components is crucial. This understanding aids operators and technicians in maintaining equipment efficiency and ensuring longevity. A comprehensive visualization of these elements not only facilitates better repair practices but also enhances operational safety.

When it comes to exploring the intricacies of compaction units, various illustrations serve as invaluable resources. These detailed representations break down the assembly of critical mechanisms, providing insights into how each part interacts within the larger system. By studying these layouts, one can easily identify potential issues and streamline maintenance procedures.

Furthermore, recognizing the specific functions of individual components fosters a deeper appreciation for the technology at play. It empowers users to make informed decisions when it comes to replacements and upgrades, ultimately leading to improved performance on job sites. In this guide, we will delve into these layouts, shedding light on their significance in effective machinery management.

Understanding Bomag BW55E Components

Familiarity with the various elements of a compactor is essential for efficient operation and maintenance. Each component plays a vital role in ensuring optimal performance, contributing to the machine’s overall functionality. A comprehensive grasp of these parts allows operators to troubleshoot issues effectively and enhance productivity.

Key Elements of the Compactor

At the heart of this machinery lies the engine, responsible for powering the unit. Additionally, the vibratory system is crucial for achieving the desired compaction, utilizing force to consolidate materials. Understanding the interplay between these components is essential for maximizing efficiency.

Maintenance and Troubleshooting

Regular upkeep of these elements is necessary to prevent breakdowns and ensure longevity. Familiarity with the control mechanisms and hydraulic systems can help operators identify potential issues early, leading to timely interventions and maintaining peak performance.

Key Features of Bomag BW55E

This compact machine is designed for efficient soil compaction, showcasing several remarkable characteristics that enhance its performance in various applications. With a focus on user-friendliness and durability, it serves as a reliable choice for contractors and landscapers alike.

Powerful Engine: Equipped with a robust motor, this model ensures consistent performance, making it suitable for demanding tasks.

Compact Design: Its small footprint allows for easy maneuverability in tight spaces, ideal for residential projects and urban environments.

Operator Comfort: Featuring an ergonomic handle and vibration-damping technology, it provides a comfortable experience, reducing operator fatigue during extended use.

Enhanced Durability: Built with high-quality materials, it withstands harsh conditions, ensuring longevity and reduced maintenance costs.

Versatile Applications: Capable of tackling various surfaces, it is effective for compacting asphalt, gravel, and soil, making it a versatile tool for different projects.

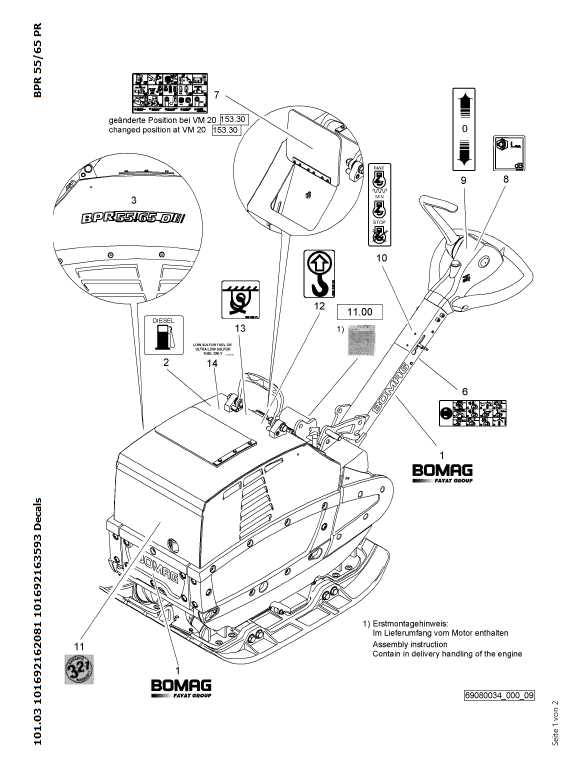

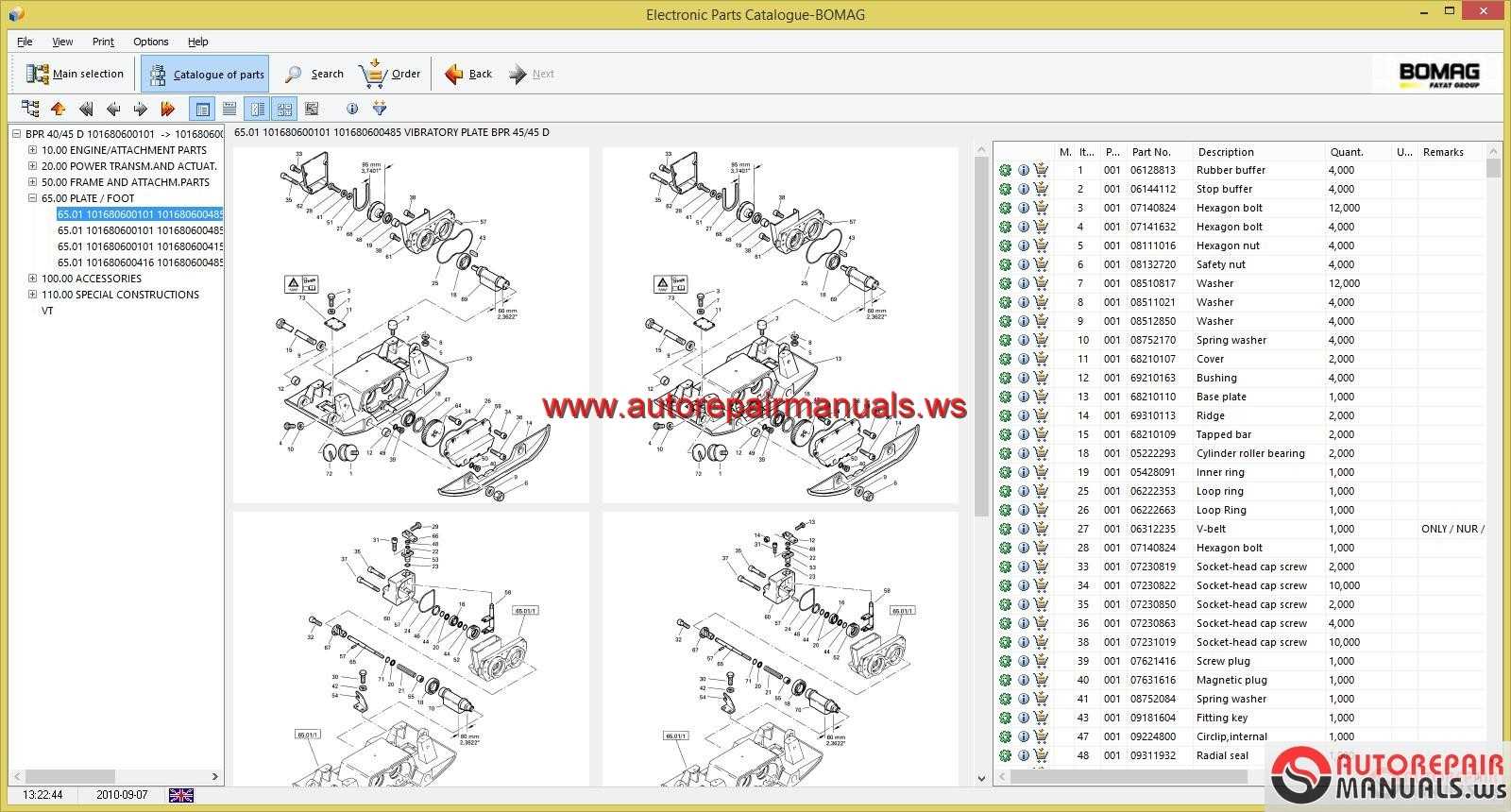

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding and maintaining machinery. These illustrations provide clear insights into how various elements fit together, enhancing comprehension for both operators and technicians. They serve as a valuable tool for troubleshooting, repair, and maintenance tasks.

Benefits of Visual Guides

- Clarity: They simplify complex assemblies, making it easier to identify each part’s location and function.

- Efficiency: Technicians can quickly locate the necessary components, reducing downtime during repairs.

- Accuracy: Accurate identification helps prevent errors during assembly and disassembly, ensuring proper functionality.

Applications in Maintenance

- Facilitating routine inspections by providing a checklist of components to examine.

- Assisting in the ordering of correct replacements, avoiding compatibility issues.

- Enhancing training for new employees by serving as a reference during hands-on experience.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as a roadmap, guiding users through the intricate network of elements within machinery. Familiarity with how to interpret these visuals can significantly enhance troubleshooting efficiency and simplify the ordering of necessary components.

Begin by identifying the key features of the visual. Often, these images will include a legend that explains symbols and numbers associated with each item. This reference is crucial for understanding the function of each piece. Pay attention to the layout, as it typically reflects the actual assembly of the parts, helping to visualize how they interact.

Next, look for any annotations that provide additional context, such as specifications or installation notes. These details can be invaluable when seeking to ensure compatibility or understanding how to properly install or replace a component. Additionally, note any groupings or sections that may indicate related items or assemblies, facilitating a more organized approach to repairs.

Lastly, take time to cross-reference the visual with any accompanying documentation or manuals. This step can provide further insights into the assembly process and potential issues, ultimately leading to more effective maintenance practices. Mastering the skill of reading these representations will empower you to navigate repairs with confidence and precision.

Common Replacement Parts Overview

When maintaining heavy machinery, understanding essential components that may require frequent substitution is crucial for optimal performance. This section highlights key elements that are commonly exchanged to ensure the equipment operates smoothly and efficiently.

Key Components

Several elements of machinery are prone to wear and tear due to constant use. Regular inspection and timely replacement of these components can significantly extend the lifespan of the equipment.

Replacement Schedule

Establishing a replacement schedule based on usage and environmental conditions can help in preventing unexpected breakdowns. Here are some commonly replaced elements:

| Component | Description | Frequency of Replacement |

|---|---|---|

| Hydraulic Filters | Essential for maintaining fluid cleanliness and preventing system damage. | Every 500 hours |

| Drive Belts | Critical for power transmission; can wear out over time. | Every 1000 hours |

| Seals and Gaskets | Prevent leaks and ensure proper sealing of components. | Annually or as needed |

| Brake Pads | Vital for safe operation; must be monitored regularly. | Every 600 hours |

Staying proactive about replacing these crucial components not only enhances performance but also ensures safety and reliability in operation.

Maintenance Tips for Bomag BW55E

Regular upkeep is essential for maximizing the lifespan and efficiency of your equipment. Implementing a systematic maintenance routine not only ensures optimal performance but also helps prevent unexpected breakdowns. Understanding the key aspects of care will allow operators to keep their machinery in top condition.

Start with routine inspections to identify any wear or damage. Check fluid levels regularly, including oil and hydraulic fluid, and replace them as necessary. Clean the air filters and ensure that all components are free from debris to maintain airflow and prevent overheating.

Pay close attention to the roller’s surface and undercarriage. Inspect for cracks, rust, or other signs of deterioration, and address any issues promptly. Keeping these areas clean can significantly enhance the machine’s operational efficiency.

Lubricate all moving parts according to the manufacturer’s specifications to minimize friction and wear. It’s also advisable to replace worn components with high-quality alternatives to maintain performance standards.

Finally, consider maintaining a log of all maintenance activities. This practice not only helps track the condition of your machinery but also aids in identifying patterns that may indicate larger issues, allowing for timely intervention.

Identifying Faulty Components

Recognizing malfunctioning elements in machinery is crucial for maintaining efficiency and safety. By systematically assessing each component, operators can prevent minor issues from escalating into significant failures. Understanding common indicators of wear and dysfunction can aid in timely interventions.

| Component | Signs of Failure | Recommended Action |

|---|---|---|

| Hydraulic System | Leaking fluid, inconsistent pressure | Inspect hoses and connections; replace as needed |

| Engine | Unusual noises, decreased power | Check oil levels; consider a thorough diagnostic |

| Drive Mechanism | Slipping, vibrations | Examine belts and gears; replace worn parts |

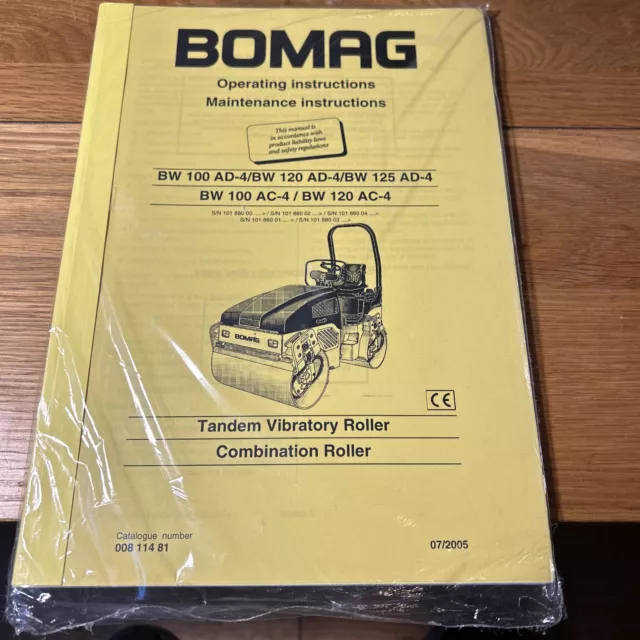

Where to Find OEM Parts

Locating high-quality original components for your machinery is essential for maintaining optimal performance and longevity. Reliable sources ensure that the parts meet the manufacturer’s specifications, providing peace of mind and efficiency.

Authorized Dealers

One of the most trustworthy avenues is through authorized dealers, who offer a wide range of genuine items. These vendors are recognized by the manufacturer and provide the assurance of authenticity and proper fit.

Online Marketplaces

Additionally, numerous online platforms specialize in original equipment items. Look for websites that emphasize quality and customer reviews, as these factors can help you make informed decisions about your purchases. Always verify the seller’s credibility to avoid counterfeit options.

Aftermarket Parts vs. OEM Parts

The choice between alternative components and original manufacturer items can significantly influence performance and maintenance costs. Understanding the differences between these options is essential for making informed decisions in equipment care.

Alternative components often provide a more budget-friendly solution, appealing to those looking to save money without sacrificing quality. Many of these products are designed to meet or exceed the specifications of the originals, offering a viable substitute for various applications.

In contrast, original manufacturer items are crafted to precise standards set by the creator of the machinery. This ensures compatibility and reliability, which can be crucial for maintaining optimal functionality over time. However, they typically come at a higher price point.

Ultimately, the decision hinges on factors such as cost, reliability, and individual preferences. Evaluating the long-term benefits and potential risks of each option can guide users toward the best choice for their specific needs.

Repair Techniques for Bomag Equipment

Effective maintenance and restoration of machinery require a systematic approach to ensure optimal performance and longevity. Understanding the common issues and employing appropriate methods can significantly enhance operational efficiency.

| Technique | Description |

|---|---|

| Preventive Maintenance | Regularly scheduled inspections and servicing to prevent breakdowns. |

| Component Replacement | Identifying worn parts and replacing them promptly to avoid further damage. |

| Lubrication | Ensuring all moving parts are adequately lubricated to reduce friction and wear. |

| Diagnostic Testing | Utilizing diagnostic tools to assess machinery performance and identify faults. |

| Calibration | Adjusting settings to align machinery performance with manufacturer specifications. |

Cost Considerations for Replacement Parts

When it comes to maintaining machinery, financial factors play a crucial role in decision-making. Understanding the various expenses associated with acquiring new components can significantly impact the overall budget. This section explores key considerations to keep in mind when evaluating the costs linked to essential replacements.

Quality vs. Price

One of the primary dilemmas is balancing quality with cost. While lower-priced components might seem attractive, they can lead to increased expenses over time due to frequent replacements or maintenance needs. Investing in higher-quality alternatives can result in long-term savings, as they often offer better durability and performance.

Availability and Sourcing

Another important aspect is the availability of these components. Sourcing from reputable suppliers can sometimes come with a higher price tag but ensures reliability. Additionally, shipping costs and delivery times should be factored in, as delays can lead to downtime and lost productivity. Evaluating local versus online vendors may also influence overall expenditures.

In summary, taking a holistic approach to the costs associated with essential replacements can lead to more informed and financially sound decisions, ultimately enhancing operational efficiency.

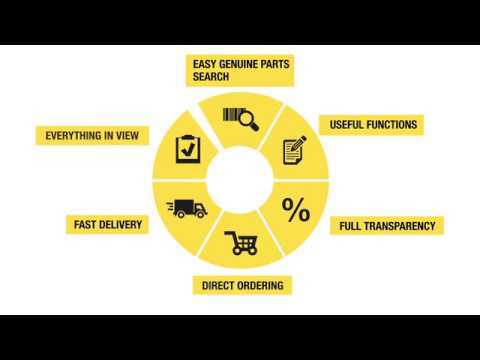

Resources for Parts Diagrams Online

Accessing detailed visual resources for machinery components can significantly enhance the efficiency of maintenance and repairs. A variety of online platforms provide comprehensive illustrations that help users identify and locate specific elements within their equipment. These resources are invaluable for both professionals and enthusiasts looking to ensure optimal functionality.

Online Platforms for Visual Resources

Several websites cater specifically to individuals seeking schematics and breakdowns of machinery parts. These platforms often feature user-friendly interfaces, enabling quick searches and easy navigation through various models.

| Website | Description |

|---|---|

| PartsTree | Offers extensive diagrams and detailed breakdowns for a wide range of machinery, along with ordering options for components. |

| OEMParts | A reliable source for original equipment manufacturer illustrations, ensuring accurate identification of parts and their functions. |

| ManualsLib | Provides access to a vast library of user manuals, which often include valuable schematic representations and part numbers. |

Community Forums and Support

In addition to dedicated websites, community forums offer a wealth of knowledge and shared experiences. Users can seek advice, share tips, and even obtain diagrams from fellow machinery owners, making these platforms an excellent supplement to traditional resources.