The functionality and efficiency of modern farming equipment largely depend on the intricate assembly of various components. A comprehensive understanding of these elements is crucial for maintaining optimal performance and ensuring the longevity of the machinery. This section aims to provide a clear overview of the essential elements that constitute key agricultural machines.

Each machine is comprised of numerous individual pieces, each serving a specific role in the overall operation. From the engine systems that power the equipment to the transmission systems that facilitate movement, every component is integral to achieving seamless functionality. Recognizing how these parts interact and contribute to the machine’s performance can aid users in troubleshooting and performing effective maintenance.

In this guide, we will explore detailed representations of the various assemblies involved in these powerful machines. By familiarizing yourself with the arrangement and purpose of each element, you can enhance your understanding and efficiency in managing these vital tools on the farm.

This section aims to provide a comprehensive overview of a well-known agricultural machine, focusing on its essential components and their functions. Understanding the configuration of this vehicle can significantly aid in maintenance and repairs, ensuring optimal performance for various farming tasks.

- Introduction to the tractor’s significance in modern agriculture

- Key specifications and features of the model

- Overview of the engine system and its importance

- Understanding the transmission and drive mechanisms

- Details on the hydraulic system and its applications

- Exploring the electrical components and wiring layout

- Importance of the steering and suspension systems

- Maintenance tips for critical components

- Common issues and troubleshooting advice

- Conclusion emphasizing the value of proper upkeep

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide an organized layout that helps users understand the relationships between various elements, facilitating easier identification and management during servicing tasks.

These illustrations are essential for several reasons:

- Enhanced Understanding: Visual guides simplify complex systems, making it easier for operators to grasp the overall assembly and function of each element.

- Efficient Troubleshooting: When issues arise, these visuals enable technicians to quickly pinpoint the source of a problem, reducing downtime.

- Accurate Replacements: Knowing the exact shape and placement of each component aids in selecting the right replacements, minimizing errors during repairs.

- Time-Saving: Streamlined access to information saves valuable time for maintenance personnel, allowing for quicker resolution of mechanical issues.

In summary, visual aids are indispensable tools for anyone involved in machinery upkeep. They provide clarity and efficiency, ultimately leading to better performance and longevity of equipment.

Identifying Key Components

Understanding the essential elements of agricultural machinery is crucial for effective maintenance and operation. Recognizing these components not only aids in troubleshooting but also enhances the overall functionality of the equipment. This section will delve into the significant parts that contribute to the seamless performance of your machinery.

Primary Functional Elements

- Engine: The heart of the machine, responsible for generating power.

- Transmission: Facilitates the transfer of power from the engine to the wheels.

- Hydraulic System: Enables lifting and operating various attachments through fluid pressure.

- Chassis: The framework that supports all other components.

- Wheels: Essential for mobility, ensuring stability and traction.

Additional Essential Parts

- Fuel System: Delivers fuel to the engine for combustion.

- Cooling System: Maintains optimal operating temperature to prevent overheating.

- Electrical System: Powers lights, ignition, and other electronic components.

- Brake System: Ensures safety and control during operation.

- Control Panel: Provides the operator with information and control over the machinery.

Familiarity with these critical components allows for better management and efficient use of your agricultural machinery, ultimately leading to improved productivity.

Common Repairs and Maintenance

Regular upkeep and prompt repairs are essential for ensuring the longevity and efficiency of agricultural machinery. By addressing minor issues before they escalate, operators can save time and resources while maintaining optimal performance. This section outlines typical maintenance tasks and common repairs that may be required throughout the machinery’s lifespan.

Routine Maintenance Tasks

Conducting frequent checks and performing routine maintenance is crucial for preventing unexpected breakdowns. Tasks such as changing oil, replacing filters, and inspecting belts should be scheduled regularly. Cleaning air filters and ensuring fluid levels are adequate also play a significant role in enhancing operational efficiency. Following a detailed maintenance schedule can prolong the life of your equipment.

Common Repair Issues

Over time, certain components may wear down or become damaged, necessitating repairs. Common issues include leaks in hydraulic systems, which can lead to decreased performance and potential hazards. Additionally, engine overheating can occur if the cooling system is not functioning properly. Identifying and addressing these problems early can prevent more extensive damage and ensure reliable operation.

Understanding Hydraulic Systems

Hydraulic systems play a crucial role in the operation of various machinery, utilizing fluid mechanics to transmit power and facilitate movement. By harnessing the properties of pressurized fluids, these systems enable machines to perform a wide range of tasks with precision and efficiency. Their fundamental components include pumps, cylinders, valves, and fluid reservoirs, which work in harmony to achieve desired motions and force applications.

Components of Hydraulic Systems

The effectiveness of a hydraulic system largely depends on its individual components. Pumps are responsible for generating the necessary pressure, while cylinders convert hydraulic energy into mechanical movement. Valves regulate the flow and direction of the hydraulic fluid, ensuring that the system operates smoothly and efficiently. Each component must be maintained and serviced regularly to prevent breakdowns and ensure optimal performance.

Benefits of Hydraulic Technology

One of the primary advantages of hydraulic technology is its ability to transmit significant force through relatively compact systems. This allows for the design of powerful machinery that can accomplish heavy lifting and intricate tasks without requiring excessive physical space. Additionally, hydraulic systems are known for their reliability and ease of control, making them essential in various industries, from agriculture to construction.

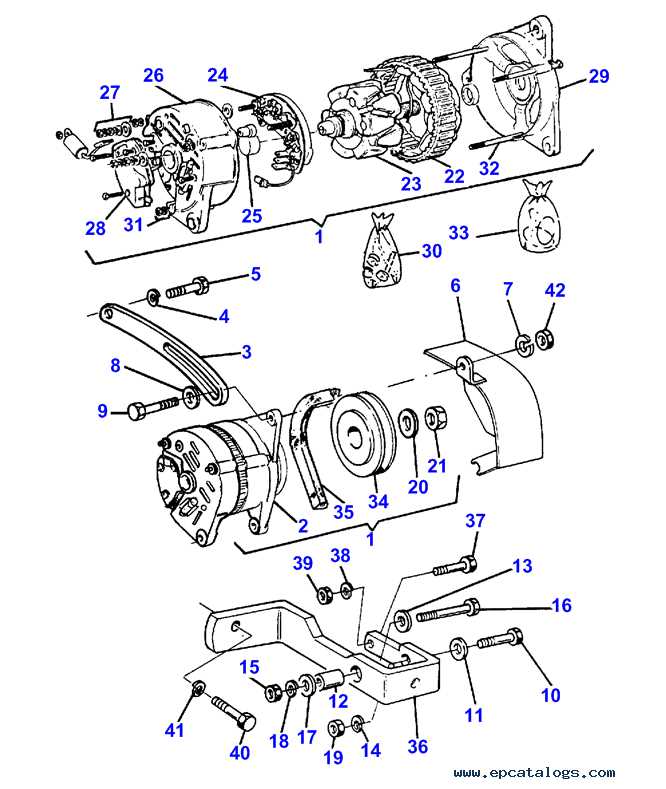

Electrical System Breakdown

The electrical framework of agricultural machinery is crucial for its overall functionality and efficiency. Understanding the components and their interconnections is essential for effective maintenance and troubleshooting. This section delves into the various elements that constitute the electrical system, providing insights into their roles and relationships.

- Battery: The primary source of power, supplying electrical energy to the entire system.

- Alternator: Converts mechanical energy into electrical energy, recharging the battery during operation.

- Starter Motor: Engages the engine, initiating its operation by drawing power from the battery.

- Wiring Harness: A network of wires that facilitates the flow of electricity between components.

- Fuses: Protect the system from overload by breaking the circuit when excessive current flows.

- Switches: Control the electrical flow, enabling or disabling various functions as needed.

Each of these components plays a vital role in ensuring the smooth operation of the machinery. Regular inspection and maintenance of the electrical system can prevent potential failures and enhance the longevity of the equipment.

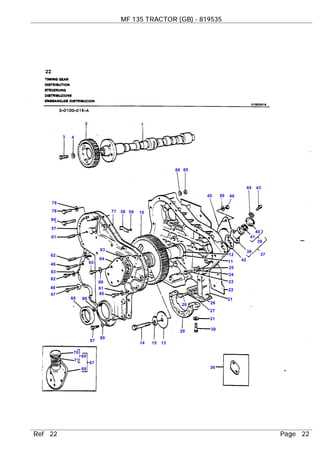

Engine Assembly Overview

The engine assembly is a crucial component of any agricultural machinery, serving as the powerhouse that drives the vehicle’s operations. This section provides an insight into the key elements and functions involved in the construction and operation of the engine assembly, highlighting its significance in ensuring optimal performance and reliability.

Key Components

Understanding the main components of the engine assembly is essential for effective maintenance and troubleshooting. Each part plays a specific role in the overall functioning of the engine, contributing to its efficiency and longevity.

| Component | Description |

|---|---|

| Cylinder Head | Houses the combustion chamber and valves, crucial for airflow and fuel mixture. |

| Crankshaft | Transforms linear motion from the pistons into rotational motion to power the vehicle. |

| Pistons | Move up and down within the cylinders, compressing the fuel-air mixture for combustion. |

| Timing Belt | Synchronizes the rotation of the crankshaft and camshaft for precise valve operation. |

| Oil Pan | Holds engine oil, providing lubrication to various moving parts for smooth operation. |

Assembly Process

The assembly process of the engine involves meticulous attention to detail, ensuring that each component is correctly positioned and secured. Proper alignment and torque specifications are vital for the engine’s overall functionality, impacting performance and reducing the risk of mechanical failures.

Transmission and Drive Parts

The functionality of any agricultural machinery heavily relies on the intricate system of components that manage the transfer of power. These elements are crucial for ensuring smooth operation and efficiency in various tasks, from tilling to harvesting.

Key Components: At the heart of the drive mechanism lies the transmission assembly, which plays a vital role in adjusting torque and speed to meet operational demands. The gears and shafts involved are designed to withstand significant stress while providing seamless transitions between different speeds.

Functionality: Each component within this assembly works in harmony to deliver optimal performance. The connections and linkages between the drive elements are engineered to facilitate precise control, allowing the operator to adapt to varying field conditions effectively.

Understanding the structure and role of these components is essential for maintaining and enhancing the reliability of the machinery. Regular inspections and timely replacements can significantly prolong the lifespan and operational efficiency of the entire system.

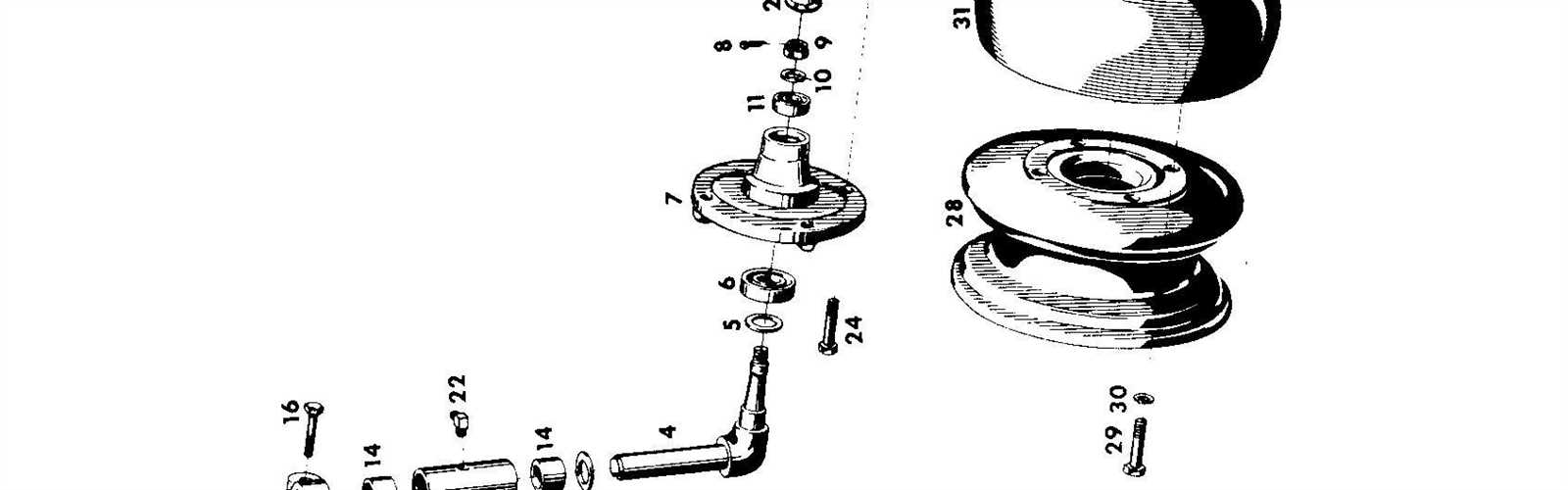

Visual Guides for Assembly

Effective assembly of machinery components can be significantly enhanced through the use of visual aids. These resources provide a clear representation of the various elements involved, ensuring that each piece is correctly positioned and fitted. Utilizing diagrams and illustrations allows operators to follow detailed steps easily, minimizing the chances of errors during the assembly process.

Benefits of Visual Aids

- Improved understanding of complex structures

- Step-by-step guidance reduces mistakes

- Enhanced efficiency in assembly operations

- Quick reference for troubleshooting during assembly

Types of Visual Resources

- Illustrated manuals that detail each step of the assembly process

- Exploded views that show how components fit together

- Color-coded charts that indicate various parts and their functions

Parts Sourcing and Availability

Finding components for machinery can often be a complex task, as it requires navigating various suppliers and understanding their stock levels. Ensuring the accessibility of essential elements is crucial for maintaining the functionality and performance of any equipment. By leveraging diverse resources and platforms, users can effectively secure the necessary items for repairs or upgrades, thereby minimizing downtime and enhancing productivity.

Exploring Supply Channels

To acquire the required components, one should explore multiple supply channels, including online marketplaces, specialized retailers, and local distributors. Utilizing online resources allows for easy comparison of prices and availability, while local distributors may offer faster delivery options. Engaging with a network of professionals in the industry can also yield valuable recommendations for reliable sources.

Evaluating Quality and Compatibility

When sourcing elements, it is vital to evaluate both quality and compatibility to ensure optimal performance. Selecting reputable suppliers who provide high-quality items can prevent future issues and promote the longevity of machinery. Additionally, verifying compatibility with existing equipment before making a purchase can save time and resources, leading to a more efficient maintenance process.