In the realm of agricultural equipment, comprehending the intricate elements that contribute to a machine’s functionality is essential for optimal performance. Each segment plays a pivotal role in ensuring seamless operation, making it vital for operators and technicians to familiarize themselves with these components.

Visual representations serve as invaluable tools for anyone seeking to navigate the complexities of mechanical systems. By examining these illustrations, one can gain insights into the relationships between various parts and how they interact within the larger assembly.

Furthermore, delving into the specifics of each element not only enhances understanding but also aids in troubleshooting and maintenance. This knowledge ultimately empowers users to make informed decisions, ensuring their equipment remains in peak condition.

Understanding Farm Pro 2425 Parts

Gaining insight into the components of agricultural machinery is essential for effective maintenance and operation. Each element plays a crucial role in ensuring optimal performance and longevity, making it important to familiarize oneself with their functions and interrelations.

Key Components Overview

Recognizing the primary elements can aid in troubleshooting and enhance operational efficiency. Below is a brief description of vital components commonly found in such machinery.

| Component | Description |

|---|---|

| Engine | Drives the overall functionality, converting fuel into mechanical energy. |

| Transmission | Transfers power from the engine to the wheels, enabling movement. |

| Hydraulics | Facilitates the operation of various attachments and implements through fluid power. |

| Chassis | Provides the structural framework, supporting all other components. |

Importance of Maintenance

Regular upkeep of these crucial elements ensures that the machinery operates at peak efficiency, minimizing downtime and enhancing productivity. Understanding the role of each component is the first step toward achieving this ultimate goal.

Key Components of the Tractor

Understanding the essential elements of a tractor is crucial for both operation and maintenance. Each component plays a vital role in ensuring optimal performance, contributing to the machine’s overall efficiency and longevity.

Engine: The heart of the machine, responsible for converting fuel into mechanical power. It determines the tractor’s performance capabilities.

Transmission: This system transmits power from the engine to the wheels, allowing for variable speed and torque, essential for different tasks.

Chassis: The structural framework that supports all other components, providing stability and durability while allowing for maneuverability.

Hydraulics: A critical system that enables various attachments and implements to function effectively, enhancing versatility in agricultural tasks.

Electrical System: This includes the battery, wiring, and controls that power lights, ignition, and various electronic components, ensuring smooth operation.

Wheels and Tires: These elements provide traction and stability, impacting the machine’s ability to navigate various terrains and conditions.

Importance of Regular Maintenance

Consistent upkeep of equipment is crucial for optimal performance and longevity. Neglecting this responsibility can lead to various issues that may compromise functionality and safety.

Key reasons for regular maintenance include:

- Enhancing efficiency and productivity.

- Preventing costly repairs and replacements.

- Ensuring safety for operators and users.

- Extending the lifespan of machinery.

By implementing a routine maintenance schedule, operators can significantly reduce downtime and ensure smooth operation. This proactive approach allows for early detection of potential problems, ultimately leading to a more reliable and efficient system.

Where to Find Replacement Parts

Locating components for agricultural machinery can be essential for maintaining efficiency and performance. Understanding where to seek these items can save time and ensure quality.

- Manufacturer’s Website: Start by checking the official site for the latest components and updates.

- Authorized Dealers: Reach out to local dealers who specialize in equipment sales and support.

- Online Marketplaces: Explore platforms like eBay or Amazon for a variety of new and used items.

- Specialty Retailers: Look for shops that focus specifically on agricultural equipment and its needs.

- Forums and Communities: Engage with online groups where enthusiasts share resources and recommendations.

By exploring these avenues, you can effectively find the necessary components for your machinery and ensure its optimal functionality.

Step-by-Step Parts Replacement Guide

This section provides a comprehensive approach to effectively substituting components in your equipment. By following a structured process, you can ensure that each element is replaced correctly, enhancing the performance and longevity of your machine.

Preparation Before Replacement

Before diving into the replacement procedure, it’s essential to gather all necessary tools and new components. This preparation helps streamline the process and minimizes downtime.

Replacement Process

Follow these steps to successfully replace the required components:

| Step | Description |

|---|---|

| 1 | Turn off the machine and disconnect power to ensure safety. |

| 2 | Identify the specific component that needs replacing. |

| 3 | Carefully remove any covers or protective elements. |

| 4 | Detach the faulty component using the appropriate tools. |

| 5 | Install the new component, ensuring all connections are secure. |

| 6 | Replace any covers or shields that were removed earlier. |

| 7 | Reconnect power and perform a test to confirm functionality. |

By adhering to these guidelines, you can effectively enhance the efficiency of your machinery, ensuring optimal operation for years to come.

Common Issues with Farm Pro 2425

Every piece of machinery can encounter its share of challenges over time. Understanding these common problems can help operators maintain their equipment effectively and minimize downtime. Here are several frequently observed issues that users may face with their machinery.

1. Hydraulic System Problems

One of the most prevalent concerns involves the hydraulic system. Users often report issues such as slow response times or complete failure of hydraulic functions. This can stem from fluid leaks, clogged filters, or low fluid levels. Regular checks and timely maintenance are essential to prevent these complications.

2. Electrical Failures

Another common issue pertains to electrical systems. Problems such as blown fuses, malfunctioning switches, or battery failures can hinder operation. Ensuring connections are secure and that components are in good condition can help avoid electrical disruptions.

3. Engine Performance

Operators may also experience difficulties with engine performance. Symptoms can include stalling, lack of power, or excessive noise. Regular oil changes, fuel system maintenance, and air filter replacements can contribute to smoother operation.

4. Transmission Issues

Transmission-related challenges can manifest as slipping gears or difficulty shifting. These issues may arise from worn components or insufficient fluid. It’s important to monitor transmission fluid levels and address any unusual behavior promptly.

5. Tire Wear

Excessive wear on tires can affect stability and performance. This can be due to improper inflation, misalignment, or uneven load distribution. Regular inspections and proper maintenance can extend tire life and enhance safety.

Addressing these common challenges promptly can enhance the longevity and reliability of your equipment, ensuring it remains a valuable asset in your operations.

Benefits of Using Genuine Parts

Choosing authentic components for machinery maintenance ensures optimal performance and longevity. These original items are specifically designed to meet the manufacturer’s standards, providing several advantages that counterfeit or generic options cannot match.

Enhanced Reliability

When utilizing genuine components, you can expect improved reliability in your equipment. Key benefits include:

- Consistent quality that meets strict specifications.

- Lower risk of malfunctions or breakdowns.

- Better compatibility with existing systems.

Long-Term Cost Savings

Investing in authentic components can lead to significant savings over time:

- Reduced need for frequent replacements.

- Minimized repair costs associated with inferior parts.

- Extended lifespan of the overall machinery.

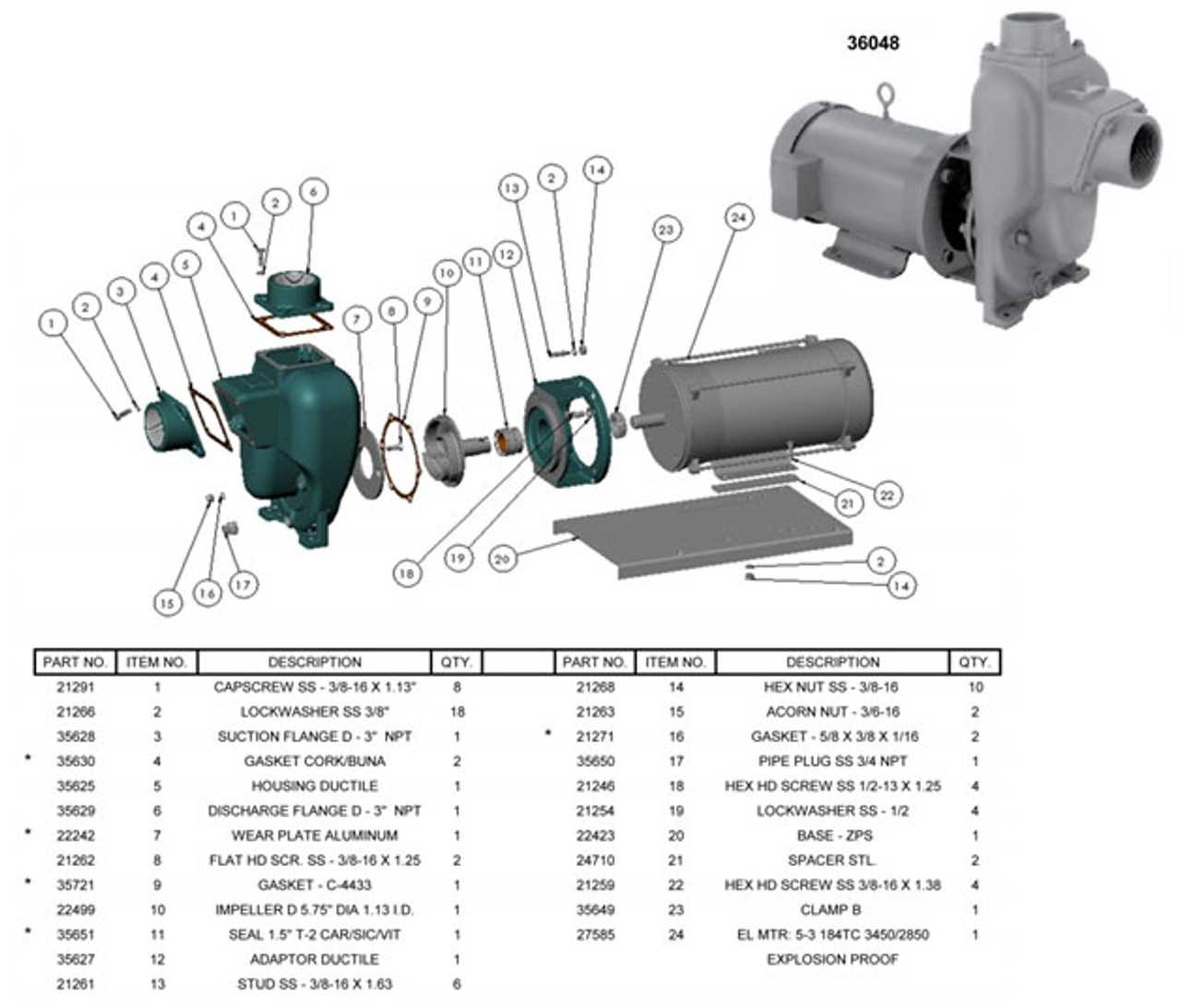

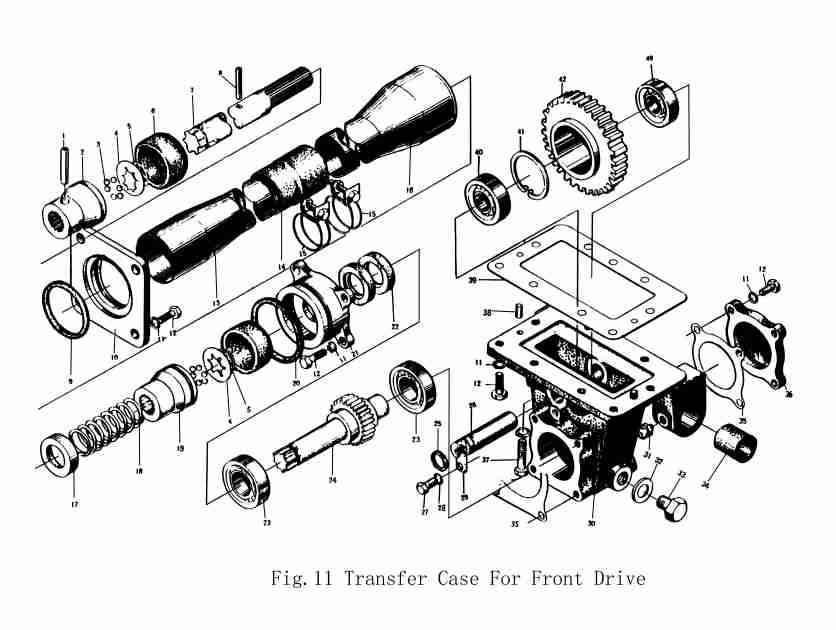

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a systematic way to identify various elements and their relationships within a machine, ensuring that users can accurately address issues and perform replacements.

Familiarize Yourself with Symbols

Each visual representation often employs specific symbols to denote various components. Learning these symbols helps in quickly locating the necessary items and understanding how they fit together, ultimately streamlining the repair process.

Follow the Flow of the Illustration

Pay attention to the layout and flow of the visual. Typically, components are arranged in a logical order that reflects their assembly or operational sequence. By tracing this flow, you can gain insights into how the machine operates and identify potential problem areas more efficiently.

Upgrading Your Tractor’s Performance

Enhancing the capabilities of your agricultural vehicle can significantly impact efficiency and productivity. By focusing on key components and modifications, you can achieve improved power, better fuel efficiency, and increased durability. This section explores various strategies to elevate your machine’s operational prowess.

One of the ultimate approaches is to optimize the engine’s performance through advanced tuning techniques. Adjustments to the fuel-air mixture and ignition timing can lead to noticeable gains in horsepower and torque. Additionally, upgrading to a high-performance exhaust system can enhance airflow, reducing back pressure and improving overall engine response.

Another important aspect is the suspension and tire system. Installing high-quality tires designed for specific terrain can greatly improve traction and handling. Alongside this, reinforcing the suspension can ensure stability and comfort, especially when navigating uneven surfaces.

Lastly, investing in modern technology such as GPS-guided systems and precision farming tools can enhance operational efficiency. These innovations allow for better monitoring and management of resources, ultimately leading to smarter farming practices and reduced operational costs.

Identifying Parts by Model Number

Understanding how to pinpoint components through their specific identification numbers is crucial for efficient maintenance and repair. This process simplifies locating the correct elements, ensuring compatibility and performance. By utilizing model identifiers, users can navigate through various options with ease.

Importance of Model Numbers

Model identifiers serve as unique markers that distinguish one item from another. They provide essential information regarding size, functionality, and design variations. Familiarity with these codes can streamline the selection process, saving time and resources.

How to Find Model Numbers

Typically, model identifiers can be found on the device itself, often stamped or labeled in a visible area. Additionally, user manuals and official websites may provide listings for easy reference. Ensuring accurate identification is key to obtaining the right components.

| Identification Method | Location |

|---|---|

| Label on Equipment | Front or Side Panel |

| User Manual | Introduction or Index Section |

| Manufacturer’s Website | Support or Parts Section |

Resources for DIY Repairs

Engaging in hands-on repairs can be a rewarding experience that empowers individuals to take charge of their maintenance tasks. Whether you’re a novice or seasoned enthusiast, access to the right materials and guidance is crucial for effective troubleshooting and restoration.

Online Communities

Joining forums and social media groups focused on mechanical repairs can provide valuable insights. Experience-sharing and advice from fellow DIYers can enhance your knowledge and confidence.

Instructional Videos

Utilizing platforms that offer video tutorials can be incredibly beneficial. Visual guidance helps in understanding complex processes, making it easier to follow along and achieve successful results.

Comparing Aftermarket vs. OEM Parts

When it comes to equipment maintenance and repair, the choice between alternative and original components can significantly impact performance and longevity. Understanding the distinctions between these options is essential for making informed decisions that affect both functionality and cost-effectiveness.

Quality and Performance

Original components are typically designed to meet specific standards set by manufacturers, ensuring compatibility and reliability. In contrast, alternative options may vary in quality, with some exceeding OEM standards while others may fall short. Evaluating the intended use and required durability can help determine the best fit.

Cost Considerations

Alternative components often present a more budget-friendly option, appealing to those seeking to minimize expenses. However, it’s crucial to weigh the initial savings against potential long-term implications, such as increased wear or the need for more frequent replacements, which could negate any upfront cost benefits.

Tips for Effective Tractor Maintenance

Regular upkeep of your agricultural machinery is essential to ensure longevity and optimal performance. Implementing a few straightforward practices can prevent unexpected breakdowns and enhance efficiency during operations. By paying attention to various components, you can maintain the reliability of your equipment and avoid costly repairs.

Routine Inspections

Conducting frequent assessments of your machinery is crucial. Check fluid levels, tire pressure, and overall cleanliness. Look for any signs of wear or damage that may need immediate attention. Addressing minor issues promptly can prevent them from escalating into major problems.

Scheduled Servicing

Establish a regular servicing schedule based on the manufacturer’s recommendations. This should include oil changes, filter replacements, and checks on the cooling system. Keeping a log of all maintenance activities helps track performance and assists in identifying recurring issues, ensuring your equipment remains in top condition.