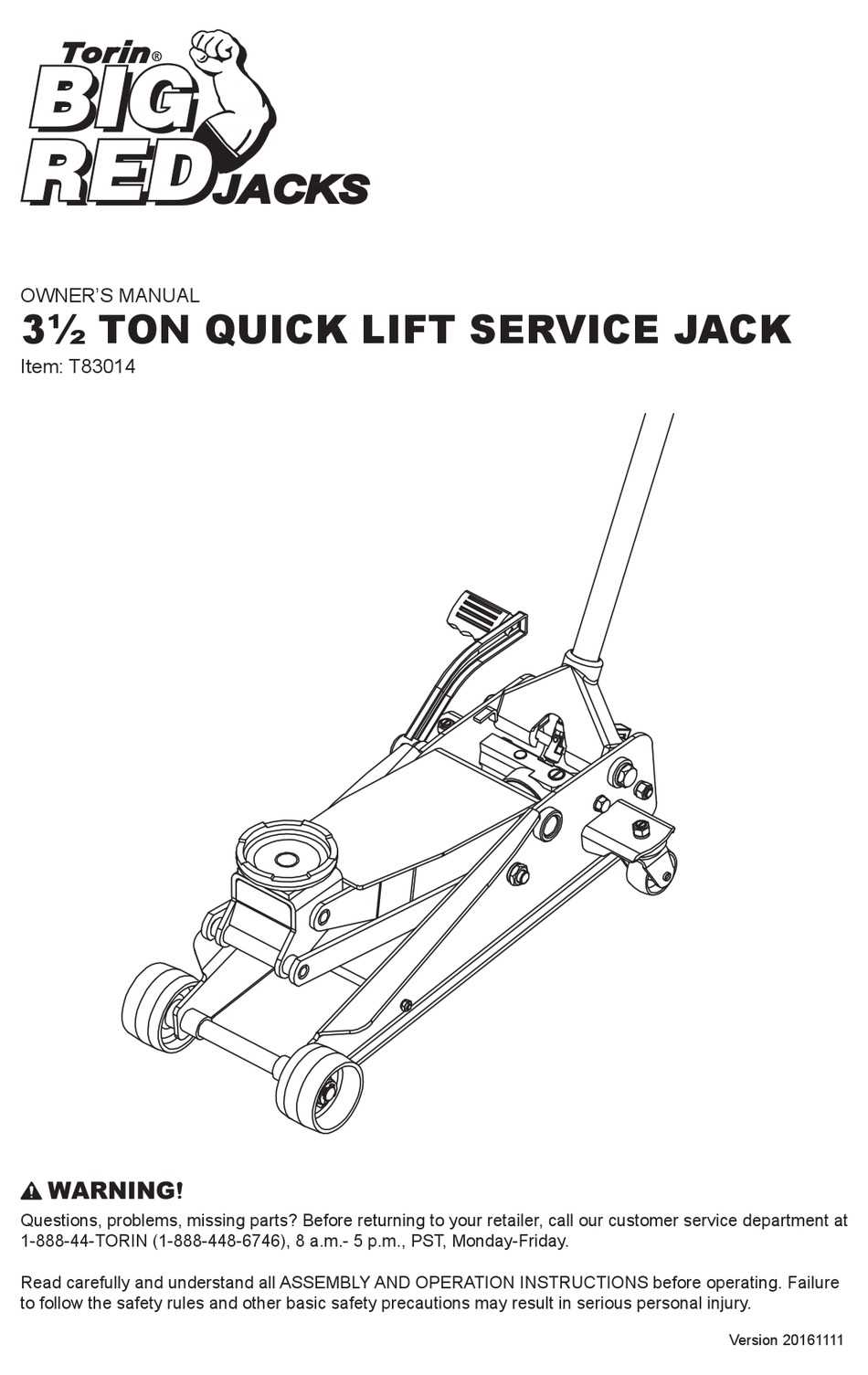

In the realm of mechanical tools designed for elevating heavy objects, a comprehensive understanding of the various components is essential. This knowledge not only aids in proper usage but also enhances maintenance practices. Grasping how each element functions in conjunction can significantly improve efficiency and safety during operation.

The exploration of an elevation mechanism’s assembly provides valuable insights into its design and functionality. By breaking down the intricate structure, users can better appreciate the craftsmanship involved. This examination is crucial for those who rely on such equipment for both personal and professional tasks.

Moreover, identifying the specific roles of each component empowers users to troubleshoot potential issues effectively. Awareness of how these elements interact facilitates more informed decisions when it comes to repairs or upgrades. Ultimately, a thorough comprehension of these mechanical aspects ensures longevity and reliability in any lifting endeavor.

Assembling the lift requires careful attention to each component and step to ensure a safe and efficient setup. The following instructions will guide you through the process, helping you put together the lift with minimal effort.

- Prepare the Components: Begin by organizing all the individual parts. Make sure all items are accounted for and ready for assembly.

- Assemble the Base: Start by attaching the base supports to the main frame. Secure the bolts tightly, ensuring the foundation is stable and well-aligned.

- Install the Hydraulic Mechanism: Attach the hydraulic system to the frame according to the manual. Make sure the hydraulic cylinder is aligned and properly connected to the lifting arm.

- Attach the Lifting Arm: Position the lifting arm onto the base, connecting it with the provided pins and securing it with locking clips. Double-check all connections for stability.

- Test the Lift: Once fully assembled, test the functionality by operating the lift up and down. Check for smooth movement and ensure there are no loose bolts or fittings.

With these steps, the lift will be ready for safe and reliable use. Make sure to regularly inspect and maintain the equipment to ensure it operates correctly over time.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential to ensure the long-term reliability of any mechanical tool. By following simple guidelines, you can prevent wear and tear, ensuring the device continues to function effectively over time. Consistent maintenance helps avoid unexpected breakdowns, increases safety, and prolongs the lifespan of your equipment.

Lubrication: Regularly applying the appropriate lubricant to moving components reduces friction, preventing unnecessary strain and damage. Make sure all the pivot points are well-oiled for smooth operation.

Inspection: Periodically checking for loose bolts, worn-out components, or any visible damage is crucial. Tighten any loose connections and replace worn-out parts as soon as they are identified to avoid further deterioration.

Cleaning: Dirt, grime, and debris can accumulate over time and affect the performance of mechanical devices. Cleaning the surfaces and mechanisms after each use ensures that no foreign materials hinder the functionality of the equipment.

By incorporating these simple maintenance practices, you ensure that your tool remains reliable and efficient for years to come.

Common Issues and Solutions

When working with hydraulic lifting devices, certain challenges may arise over time due to frequent use and environmental factors. These obstacles can lead to difficulties in the equipment’s functionality, affecting its reliability and performance. Understanding the common problems and addressing them promptly can extend the lifespan of your tool and ensure smooth operation.

Hydraulic Fluid Leaks

One of the most frequent issues encountered is hydraulic fluid leakage. This can occur when seals or gaskets wear out or become damaged. If fluid levels drop significantly, the device may fail to lift efficiently or at all. Regular inspection of seals and timely fluid replacement can prevent these issues.

Slow Lifting Speed

Another common problem is a noticeable decrease in lifting speed. This may result from air trapped within the hydraulic system, leading to inefficient pressure buildup. Bleeding the system to release trapped air or checking for blockages in the hydraulic lines can help restore normal speed and performance.

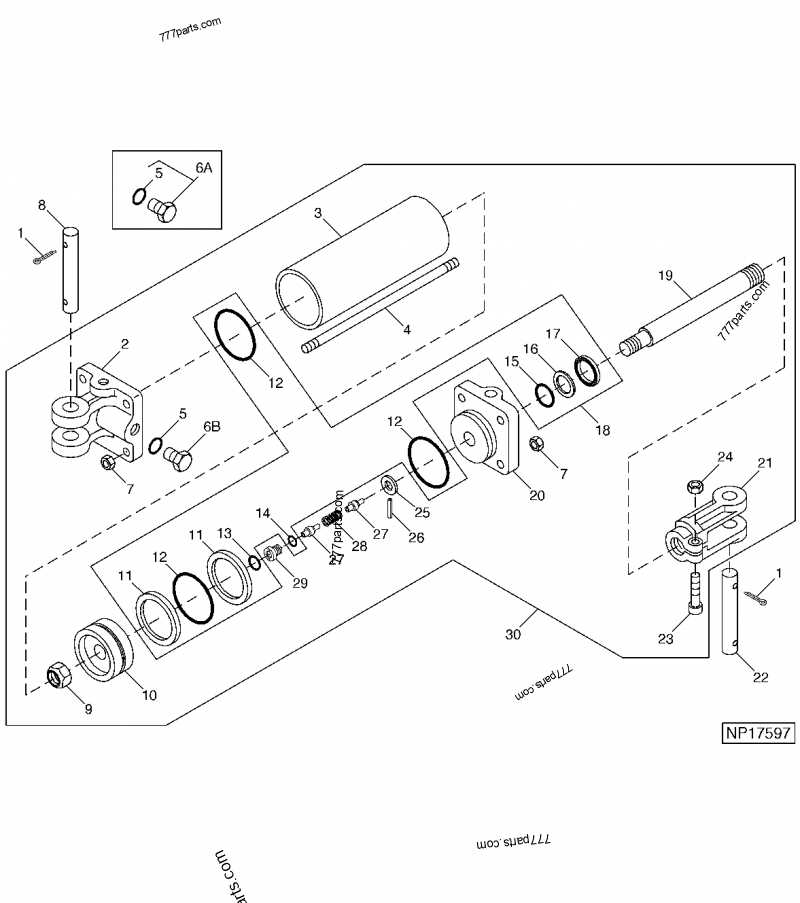

How to Identify Replacement Parts

Recognizing the right components for repair or replacement is crucial for maintaining the functionality of any mechanical system. It’s important to carefully examine the structure and understand how each element contributes to the overall operation. By doing so, you can ensure that the correct items are selected to restore optimal performance.

Examine the Structure

Start by closely inspecting the mechanism. Look for markings, labels, or unique characteristics that can help you differentiate between various components. These visual cues often provide valuable information about the specifications of each element.

Use Reference Guides

Consult manuals or detailed guides for insights on how the system is constructed. These resources can help you cross-reference specific components with those listed in technical documentation, ensuring accurate identification.

Tip: When in doubt, bring the component to a professional who can assist with identifying the exact item needed for replacement. This step helps avoid mismatches and ensures compatibility.

Safety Precautions When Using the Lift

Ensuring safety is essential when operating any type of lifting equipment. Following specific precautions can prevent accidents and protect both the operator and the vehicle. Always prioritize safety measures to ensure a secure working environment.

Proper Setup and Inspection

- Position the lift on a flat, stable surface to prevent imbalance during use.

- Inspect the lifting device for any visible damage or wear before every operation.

- Ensure all components are clean and free from debris that may interfere with its function.

Safe Operation Guidelines

- Always check the load capacity and never exceed the maximum weight the lift can support.

- Secure the vehicle in place before lifting to avoid unintended movement or slipping.

- Remain clear of the area underneath the vehicle while it is elevated.

- Lower the lift slowly and steadily to maintain control over the vehicle’s descent.

By adhering to these guidelines, you can ensure the safety of everyone involved and prolong the lifespan of the equipment.

Comparing Torin Models and Options

When it comes to selecting lifting equipment, various models offer different features and specifications to cater to specific needs. Whether you’re looking for a compact solution for smaller tasks or a more robust tool for heavy-duty operations, there are numerous options available. Understanding the differences between each model can help ensure that you choose the one that fits your requirements perfectly.

Capacity is one of the most important factors to consider. Each model is designed to handle a certain weight, so it’s crucial to match the tool with the task at hand to avoid safety issues and ensure efficiency.

Design and Durability also play significant roles. Some models are built with reinforced materials for more demanding environments, while others focus on portability and ease of use. Consider the conditions under which the tool will be used when comparing these aspects.

Additional Features like lifting height, handle ergonomics, and mobility options can further differentiate each variant. For those seeking specific performance enhancements, it’s worth exploring these additional characteristics to find the most suitable choice for your needs.

Customer Reviews and Feedback

Feedback from users provides valuable insights into the overall performance and usability of the equipment. By sharing their experiences, customers help potential buyers make informed decisions and highlight the strengths and areas for improvement in the product.

Positive Experiences

- Many users praised the durability and reliability of the product, noting its ability to handle frequent use without issues.

- Several customers appreciated the straightforward setup and easy handling, making it a convenient choice for everyday tasks.

- Affordability was another aspect often highlighted in reviews, with users finding it to be a cost-effective option for its quality.

Suggestions for Improvement

- Some customers expressed a desire for improved instructions, suggesting that clearer guidance could enhance the overall experience.

- In a few cases, users mentioned that certain components could benefit from sturdier materials to ensure even longer-lasting performance.

- There were also occasional comments about the packaging, with recommendations for better protection during shipping.

Where to Buy Genuine Parts

Finding authentic components for your lifting device is essential for maintaining its performance and safety. Utilizing reliable sources ensures you acquire high-quality materials that meet industry standards and prolong the lifespan of your equipment.

Here are some recommended avenues for purchasing genuine replacements:

- Authorized Dealers: Always check with licensed distributors who specialize in your equipment brand. They typically offer a wide range of genuine components.

- Manufacturer’s Website: Visit the official website of the manufacturer to find information about available products and purchase options.

- Local Repair Shops: Many repair facilities are equipped with genuine components. Inquire about their stock and availability.

- Online Retailers: Numerous reputable online platforms offer authentic items. Be sure to read reviews and check for seller ratings.

By sourcing from these channels, you can ensure the reliability and effectiveness of your equipment through genuine materials.