Understanding the layout of various components is crucial for anyone looking to maintain or repair machinery. Knowing where each element fits and how they interact allows for more efficient troubleshooting and upkeep. A clear and organized layout helps ensure that every piece is in its proper place, contributing to the smooth operation of the entire system.

Having access to accurate and detailed visuals of how different elements connect and work together can save time and prevent costly errors. Whether you’re addressing minor repairs or routine maintenance, a well-structured guide can provide the clarity needed to navigate the system effectively.

Familiarity with these layouts empowers users to approach technical challenges with confidence. It helps ensure that tasks are completed efficiently, reducing the risk of missteps and unnecessary replacements. By grasping the structure, you’re better equipped to make informed decisions regarding the care and upkeep of the machinery.

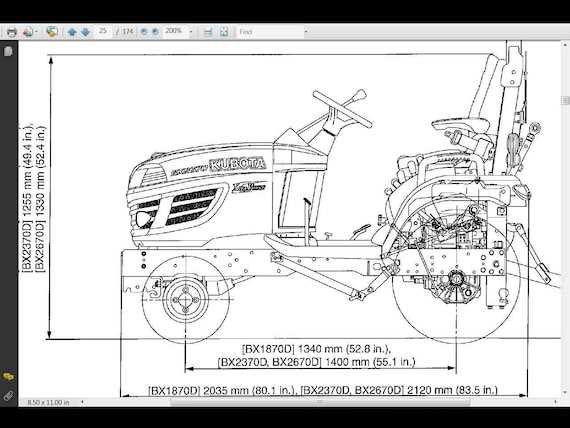

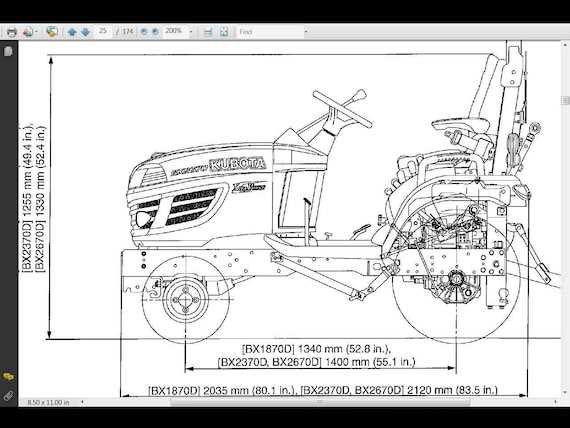

Kubota BX Parts Overview

In this section, we will take a closer look at the components that contribute to the efficient operation of this compact machine. Each element plays a crucial role in maintaining optimal performance, ensuring that the equipment remains reliable for various tasks.

- Engine Elements: The power unit drives the overall functionality, ensuring consistent energy flow and performance.

- Hydraulic System: Responsible for providing the necessary force to operate attachments and other moving parts.

- Transmission Components: These ensure smooth transitions and control over the machine’s speed and direction.

- Cooling Mechanism: Keeps the system at a stable temperature, preventing overheating during heavy use.

- Electrical Elements: These ensure proper communication between controls and various parts, maintaining overall efficiency.

By understanding how these sections work together, users can better maintain their equipment and address any operational challenges effectively.

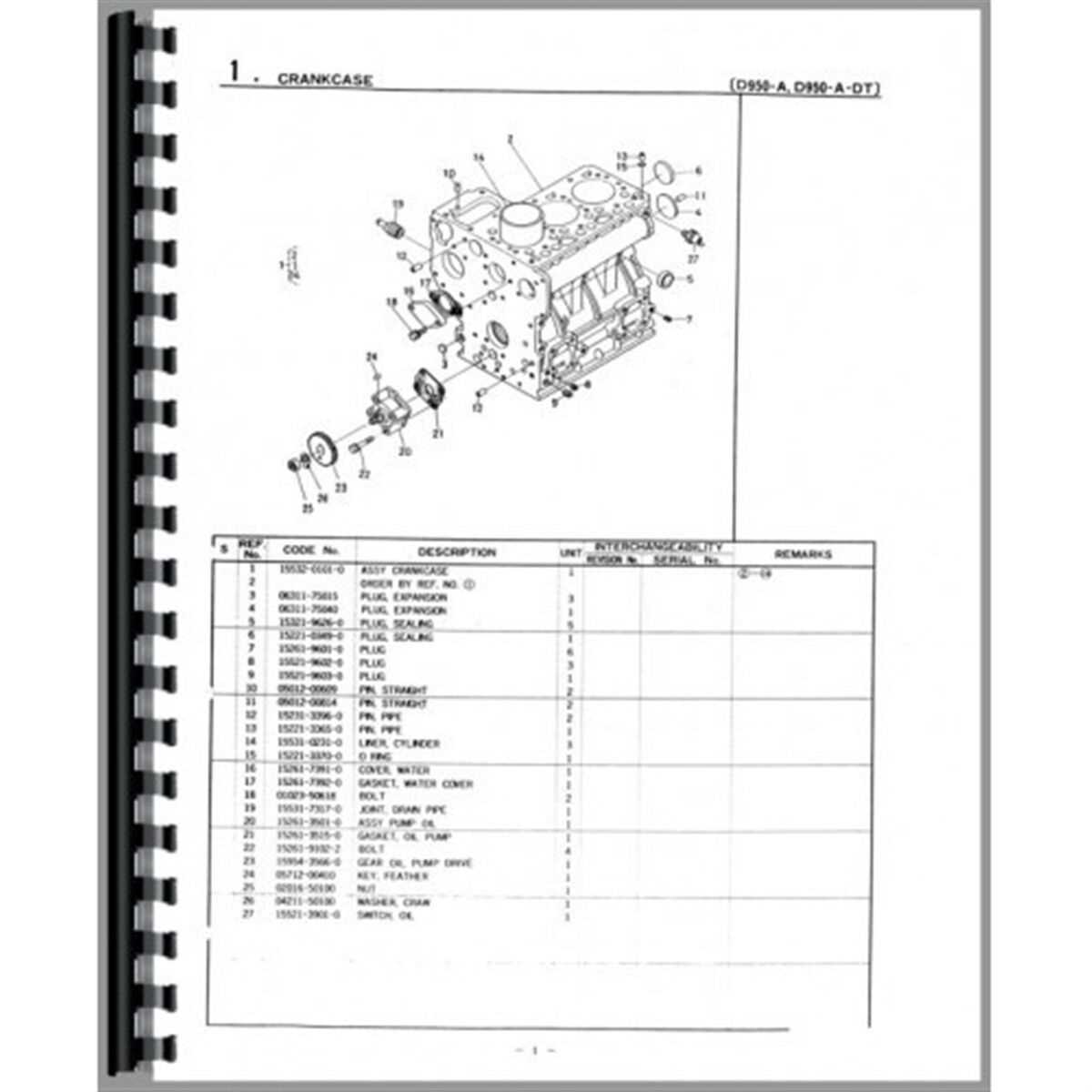

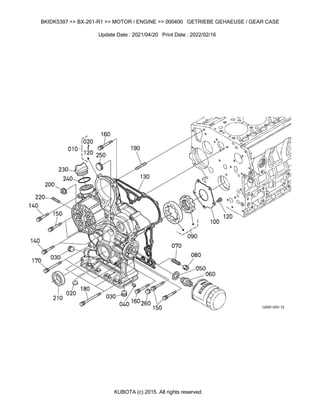

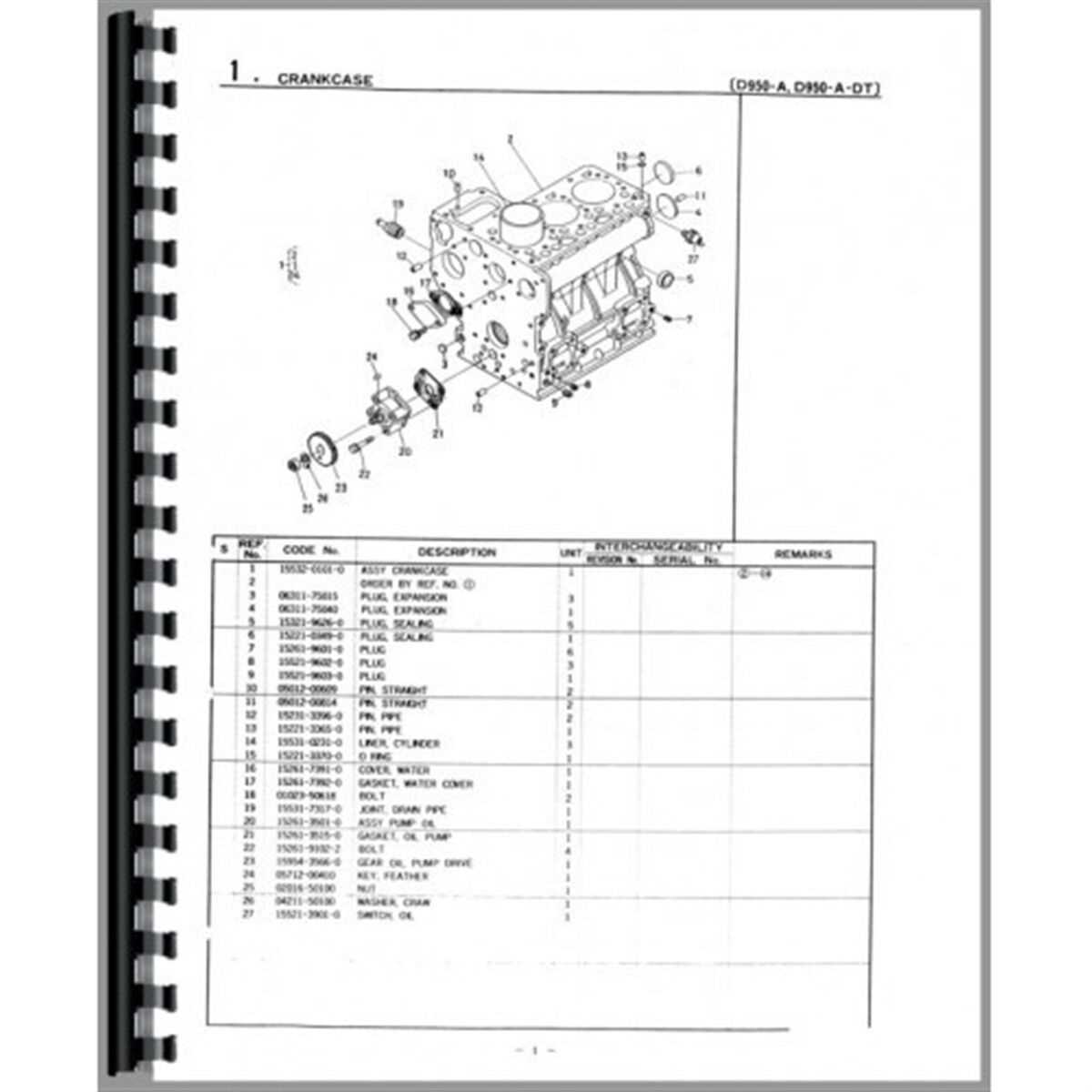

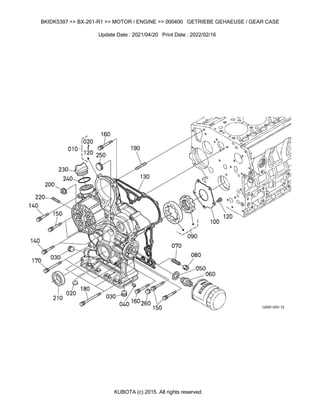

Engine Components Breakdown

The internal structure of an engine consists of various crucial elements working together to ensure smooth operation. These elements are carefully designed to handle different tasks, from powering the vehicle to maintaining efficiency during extended use. Understanding how these pieces interact can help in identifying potential issues and maintaining the system effectively.

Main Functional Units

Among the core components, several units play a significant role in driving the engine’s functionality. These include elements responsible for combustion, cooling, and regulating the internal mechanics. Each part is engineered for durability and performance under varying conditions.

Supporting Mechanisms

Apart from the primary units, there are smaller mechanisms that assist in the overall operation. These support systems ensure the engine runs efficiently by optimizing airflow, fuel delivery, and temperature control. Maintaining these aspects helps in prolonging the life of the machine.

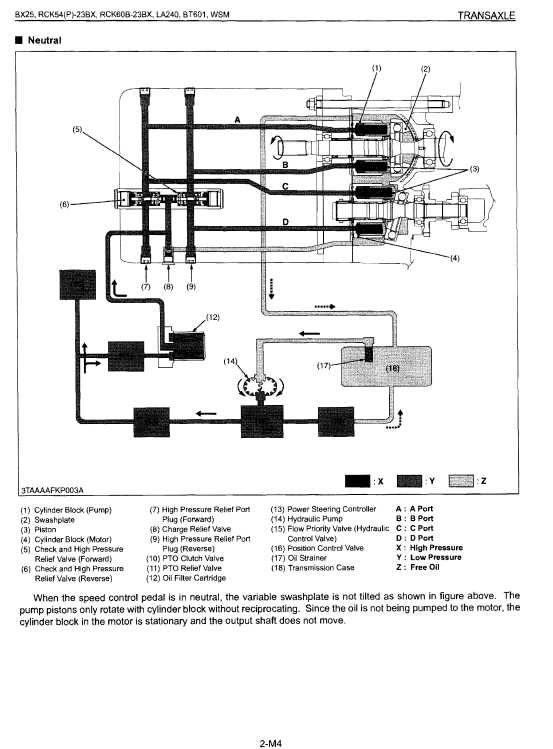

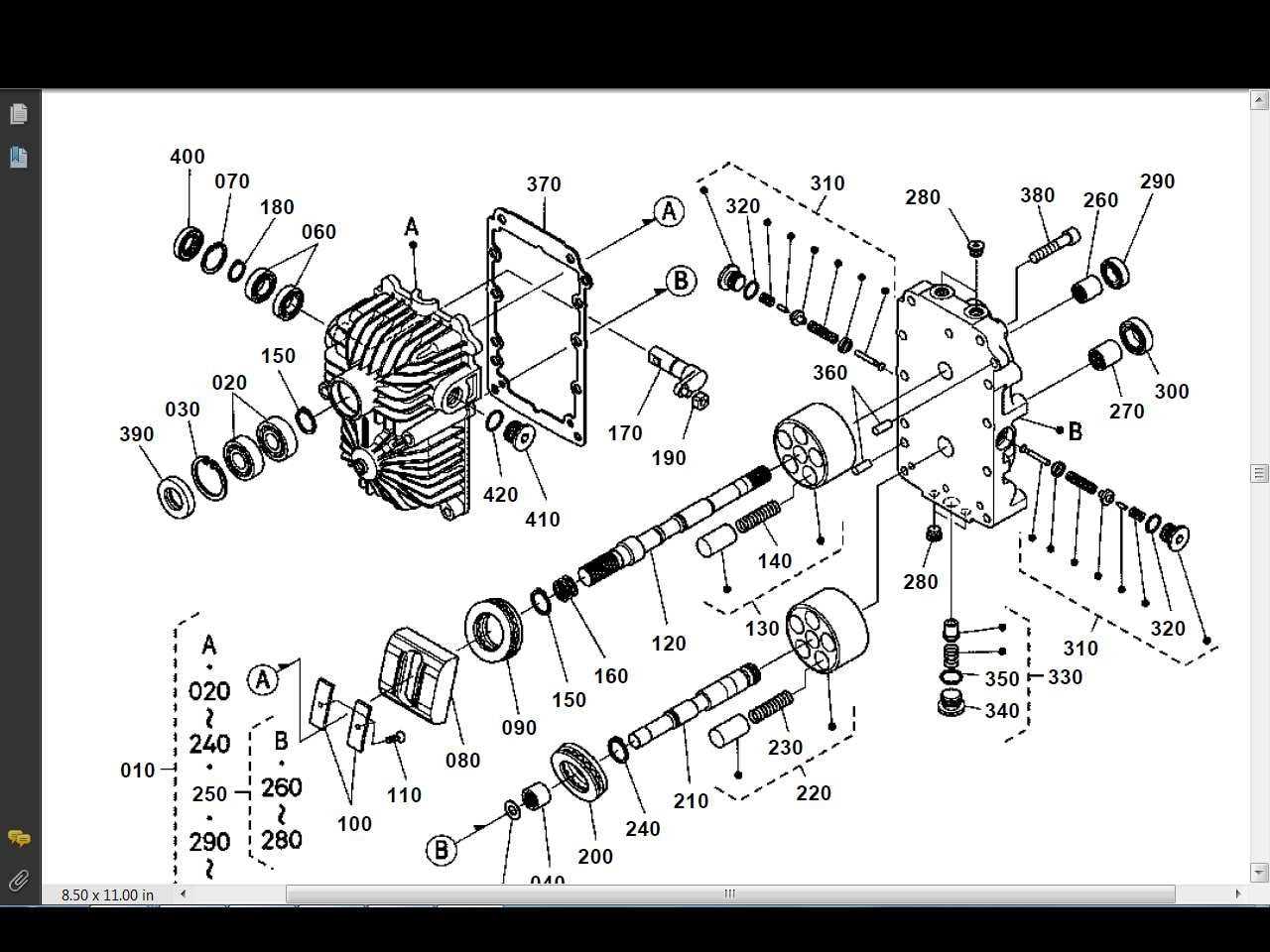

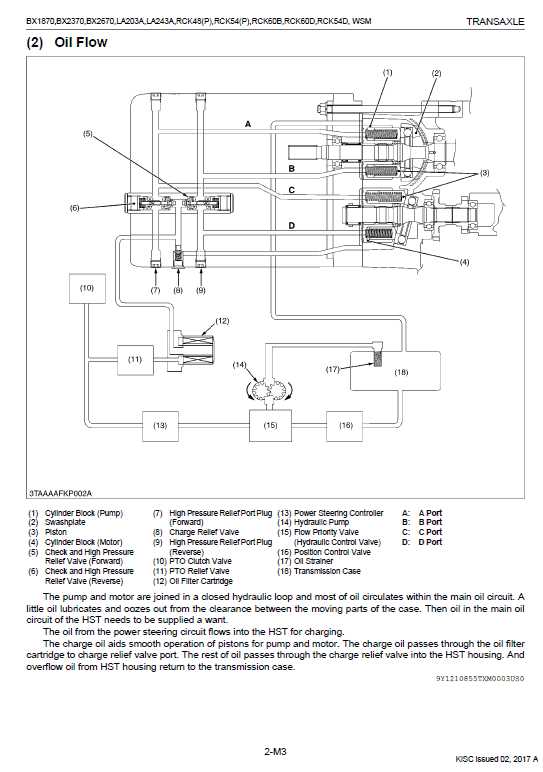

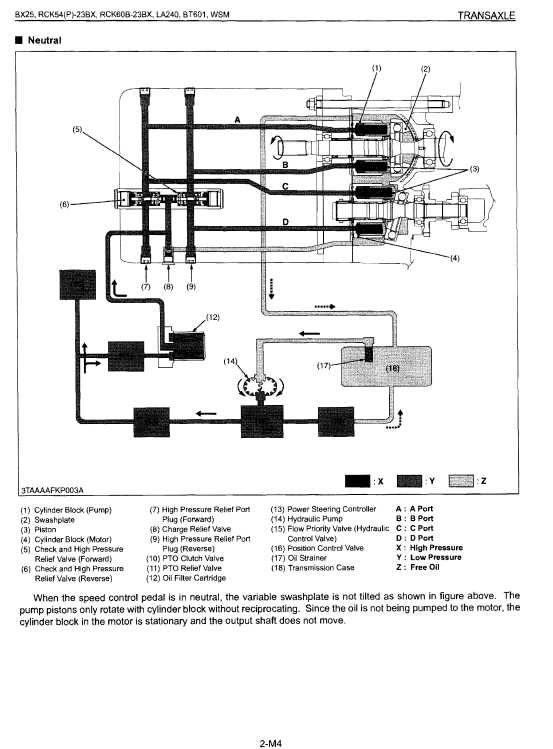

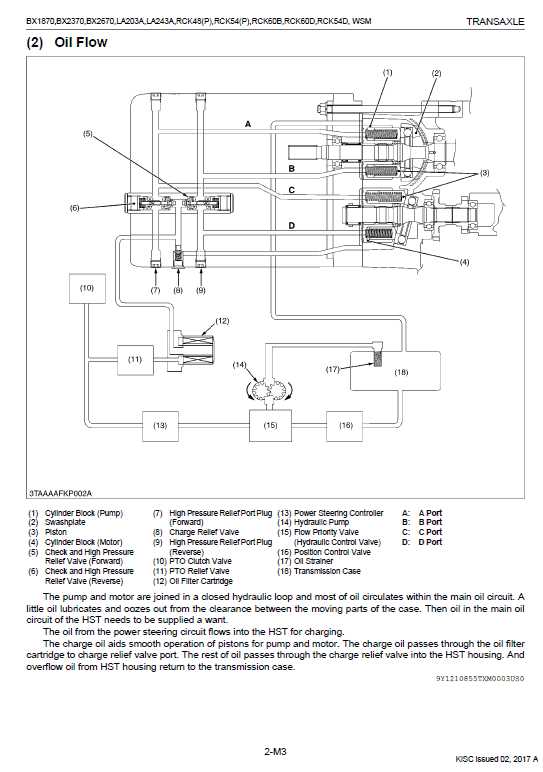

Hydraulic System Elements

The hydraulic system is a key component for operating machinery, enabling smooth movement and control through fluid dynamics. It powers essential functions that require precise force and pressure. The system’s effectiveness depends on its well-designed components, ensuring seamless performance in various tasks.

- Pumps: These devices create the flow of hydraulic fluid, driving the system’s power. Different types of pumps provide varying levels of pressure and efficiency.

- Valves: Valves regulate the flow and direction of hydraulic fluid, controlling the system’s movement and ensuring proper force distribution.

- Cylinders: Hydraulic cylinders convert fluid pressure into linear motion, enabling the machinery to lift, push, or pull with significant force.

- Hoses and fittings: These components form the pathways for hydraulic fluid, securely connecting the system’s various parts to prevent leaks and ensure efficient operation.

- Filters: Filters are essential to keep the hydraulic fluid clean, protecting the system from contaminants that could impair performance or cause damage.

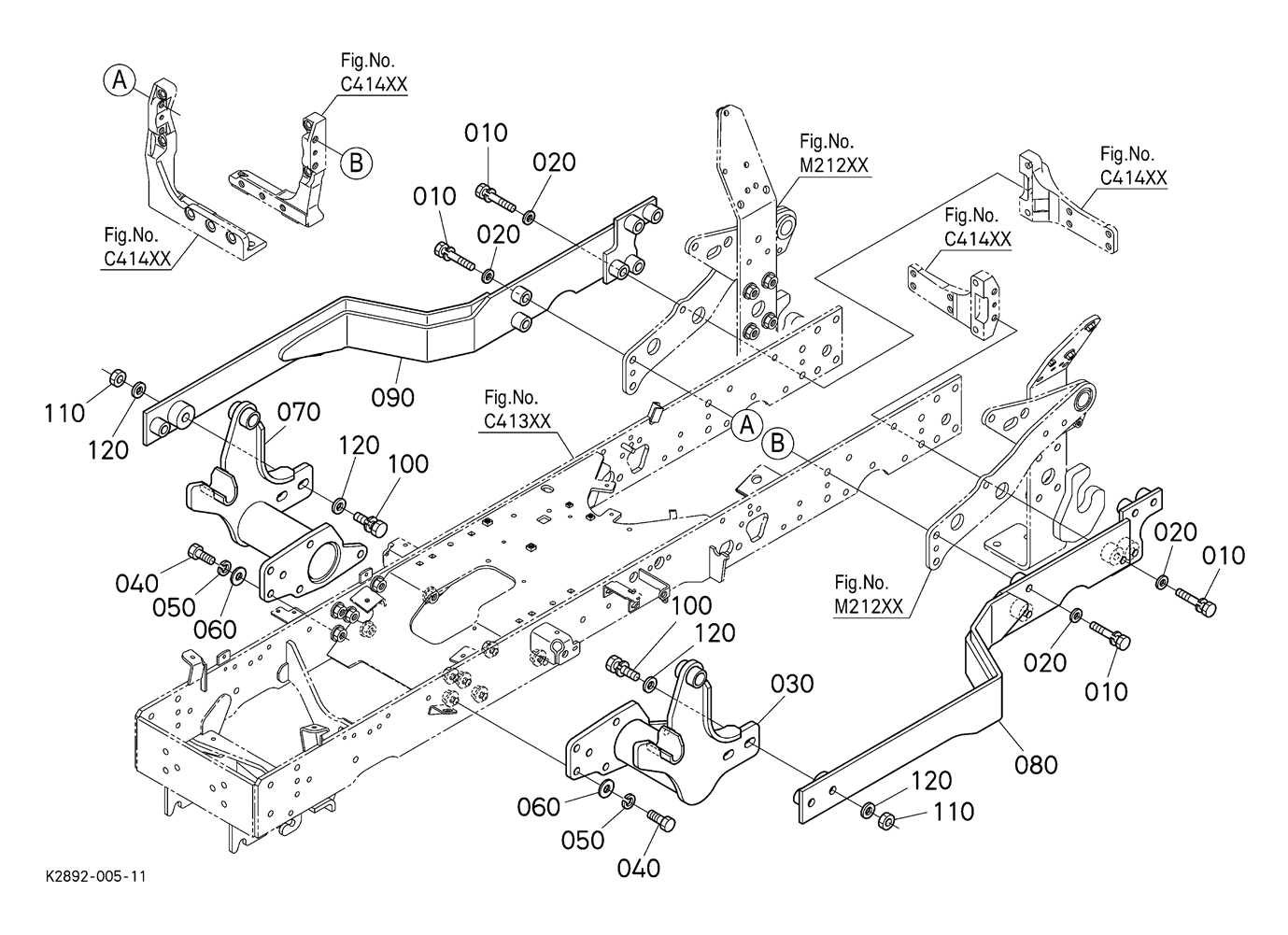

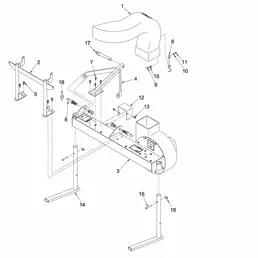

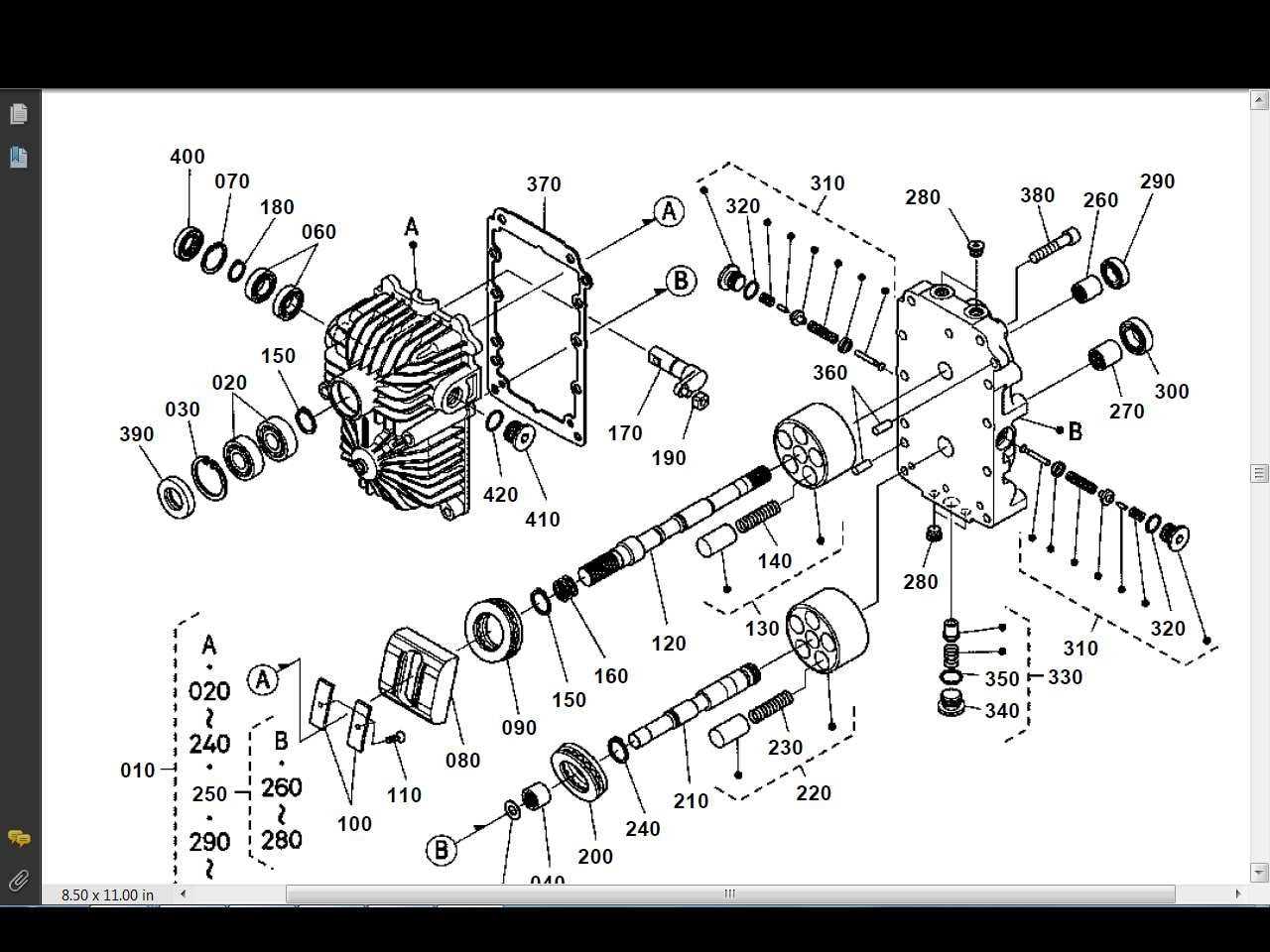

Transmission Parts Layout

The transmission system is an essential component that ensures smooth movement and efficient operation. It involves multiple interconnected elements, each playing a crucial role in transmitting power effectively.

Key Elements: The layout comprises various components such as gears, shafts, and connecting mechanisms that collaborate to manage speed and torque. These elements are designed to function harmoniously, providing stability and control during use.

Efficient design allows for easy maintenance and replacement, ensuring long-lasting performance. Understanding the layout of these elements can assist in keeping the system running at its optimal level.

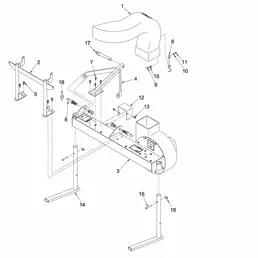

Steering Mechanism Diagram

The steering system is designed to ensure smooth and responsive control, allowing for precise direction changes. This mechanism involves multiple interconnected components, all working together to provide seamless steering performance, whether operating at low or high speeds.

Main Components

| Component |

Function |

| Steering Wheel |

Controls the direction and transmits force to the rest of the system. |

| Steering Shaft |

Connects the wheel to the gear system, transferring movement efficiently. |

| Gear Assembly |

Converts the rotary motion of the wheel into linear motion for the wheels. |

| Linkages |

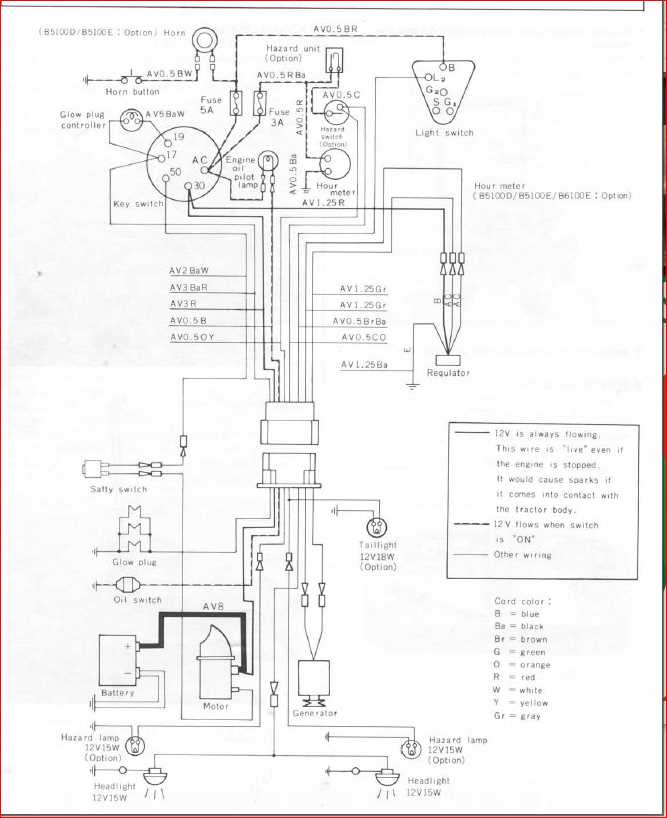

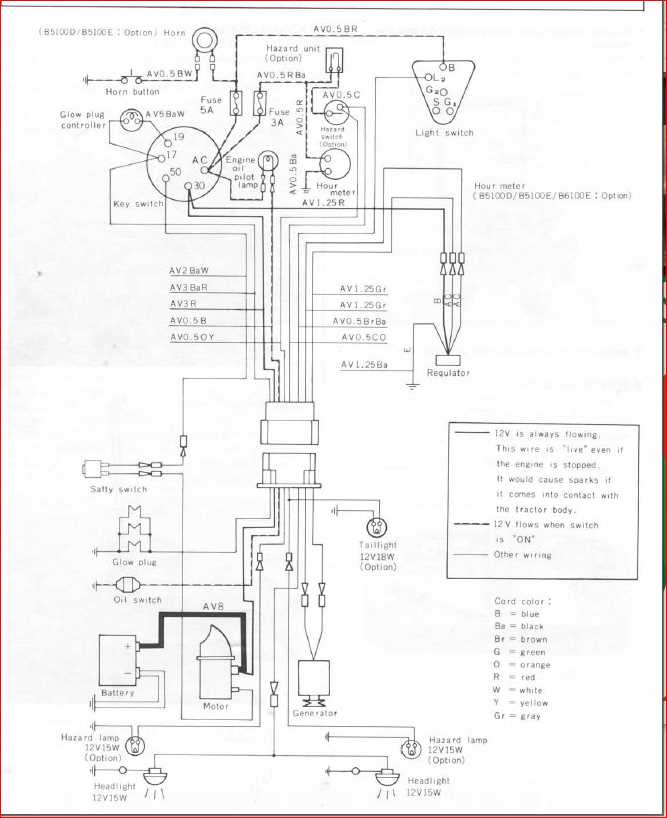

Electrical System Parts

The electrical system plays a vital role in ensuring the smooth operation and functionality of various components within the equipment. Proper maintenance and understanding of its structure can help prevent issues and ensure long-term efficiency. Various elements in this system are crucial for distributing power and managing electrical signals.

Main Components

- Alternator: Generates electricity to power the system and charge the battery.

- Battery: Stores energy for starting and running the electrical units.

- Wiring Harness: Connects all the electrical parts, ensuring proper power flow.

Additional Elements

- Switches and controls for managing the power distribution.

- Fuses and relays for protecting the system from overloads.

- Lights and indicators to provide visual feedback to the operator.

Cooling System Components

The cooling system is essential for maintaining optimal engine performance by regulating temperature during operation. This system consists of various interconnected elements that ensure heat is properly dissipated, preventing overheating and ensuring smooth functioning.

Main Elements

The key components involved include the coolant, which circulates through the system, and the radiator, where heat exchange takes place. The pump drives the coolant, while hoses connect all parts to enable continuous flow. Each of these plays a crucial role in keeping the engine at a stable temperature.

Additional Components

Other important elements include the thermostat, which controls the flow based on temperature, and fans that assist in cooling when needed. These elements work in harmony to avoid engine damage due to excessive heat.

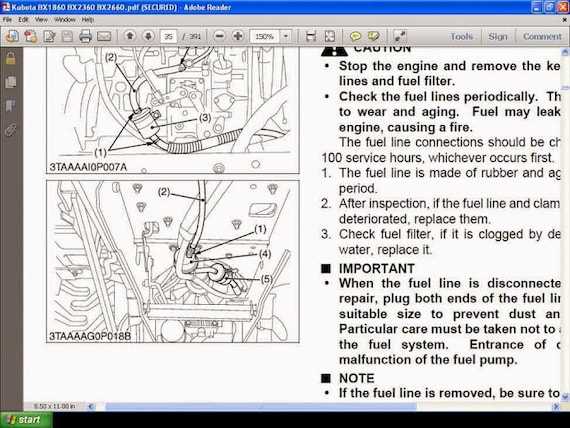

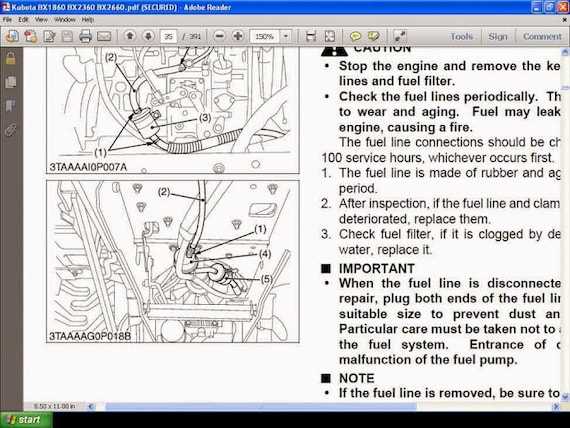

Fuel System Assembly

The fuel system assembly is a critical component responsible for delivering the necessary amount of fuel to the engine. It ensures efficient combustion, providing the power required for smooth operation. This system consists of various interconnected elements that work together to maintain optimal fuel flow and pressure, ensuring reliable performance in different conditions.

Main Components

The assembly is made up of several key components that function together seamlessly. These include the tank, which stores the fuel, the lines that transport it, and the filters that ensure it remains clean. Each part has a specific role, contributing to the overall efficiency of the machine.

Common Issues

Over time, certain elements may require maintenance or replacement. Typical problems include clogged filters, leaks in the fuel lines, or wear and tear on connectors. Regular inspection of the assembly can prevent more significant issues and ensure longevity.

| Component |

Function |

Maintenance Tip |

Exhaust System Structure

The exhaust system plays a vital role in managing engine emissions and enhancing overall performance. Its design is essential for directing exhaust gases away from the engine, ensuring efficient operation and maintaining a clean environment. Understanding its components and layout can help users appreciate how it contributes to the functionality of the machine.

Key Components: The primary elements of the exhaust assembly include the manifold, pipes, and muffler. Each part works together to facilitate the safe exit of combustion gases while minimizing noise levels. The manifold collects exhaust from the cylinders and channels it into the subsequent piping, which guides the gases towards the muffler.

Muffler Functionality: The muffler serves a critical function by reducing noise produced during engine operation. It employs various internal structures to dampen sound waves and promote smoother gas flow. Proper maintenance of this component is crucial to ensure optimal performance and compliance with environmental standards.

In summary, the exhaust system’s structure is integral to the engine’s performance, focusing on efficient gas management and noise reduction. Regular inspection and maintenance of these components are necessary to ensure long-lasting functionality.

Brake System Layout

The brake mechanism is a crucial component in ensuring safe operation and control of the vehicle. Understanding its configuration is essential for effective maintenance and troubleshooting. This section provides a comprehensive overview of how the braking components are arranged and their interconnections.

Key Components

The primary elements of the braking system include the brake pedal, hydraulic lines, calipers, and brake discs. Each part plays a vital role in the overall function, contributing to the system’s efficiency and reliability. Proper alignment and connection among these components are necessary for optimal performance.

System Operation

The operation of the brake assembly relies on the transfer of force from the pedal to the brake pads. When the pedal is pressed, hydraulic pressure is generated, engaging the calipers to clamp onto the discs. This action slows down or halts the movement of the vehicle, ensuring safety during operation.

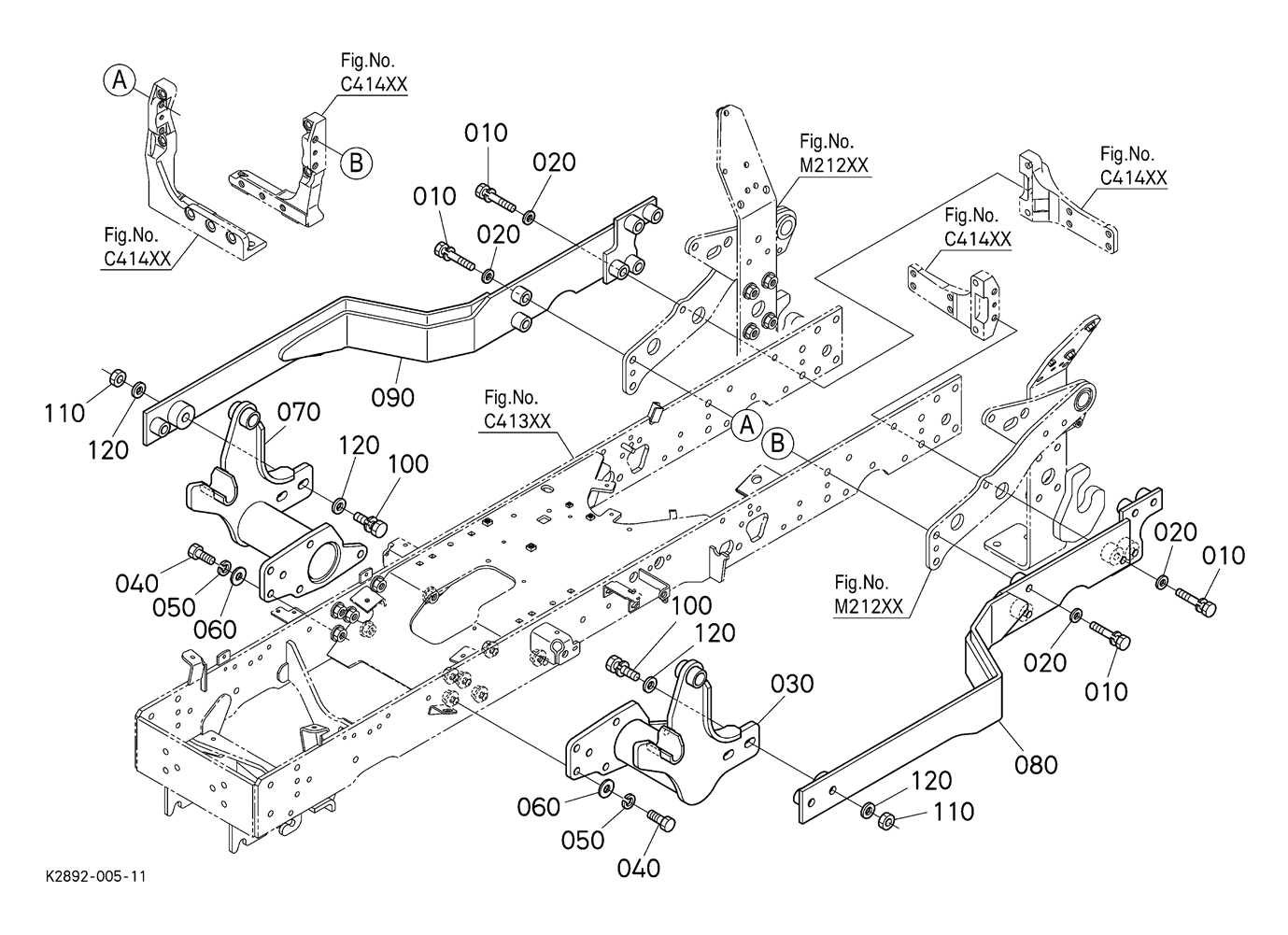

Front Axle Parts

The front axle assembly plays a crucial role in the overall performance and stability of the machinery. Understanding its components is essential for maintenance and efficient operation. This section outlines the various elements associated with the front axle system, providing insights into their functions and importance.

- Axle Housing: The main structure that houses the internal components and provides support.

- Spindles: These components connect the wheel hubs to the axle, allowing for steering and movement.

- Bearings: Essential for reducing friction between moving parts, ensuring smooth operation.

- Brackets: Used to secure various elements of the axle assembly, providing stability and alignment.

- Steering Linkages: Connect the steering mechanism to the axle, facilitating directional control.

Regular inspection and maintenance of these components are vital for ensuring optimal performance and longevity of the machinery. Understanding how each element interacts can significantly enhance operational efficiency.

Rear Axle Components

The rear axle assembly plays a vital role in the overall functionality and performance of the vehicle. It is responsible for transferring power from the engine to the wheels, ensuring smooth operation and stability during various tasks.

Key Elements of the Rear Axle

- Axle Housing: The main structure that encases the internal components.

- Wheel Hubs: These connect the wheels to the axle, allowing for rotation.

- Differential: A crucial element that enables the wheels to rotate at different speeds, especially during turns.

- Drive Shaft: Transmits power from the engine to the rear axle.

- Bearings: Support the axle and reduce friction for smooth movement.

Maintenance Considerations

- Regular inspection of all components for wear and tear.

- Ensuring proper lubrication to minimize friction and heat.

- Checking alignment to prevent uneven tire wear.

- Monitoring for unusual noises that may indicate underlying issues.

Understanding these components is essential for effective maintenance and optimal performance of the vehicle.

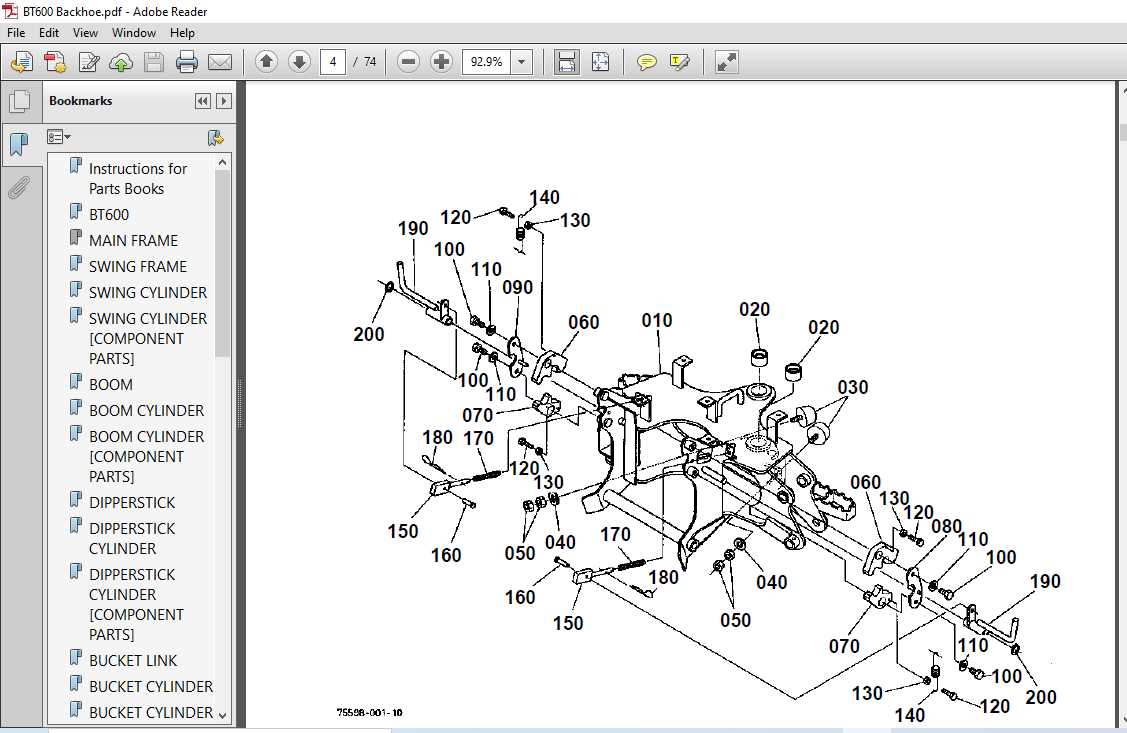

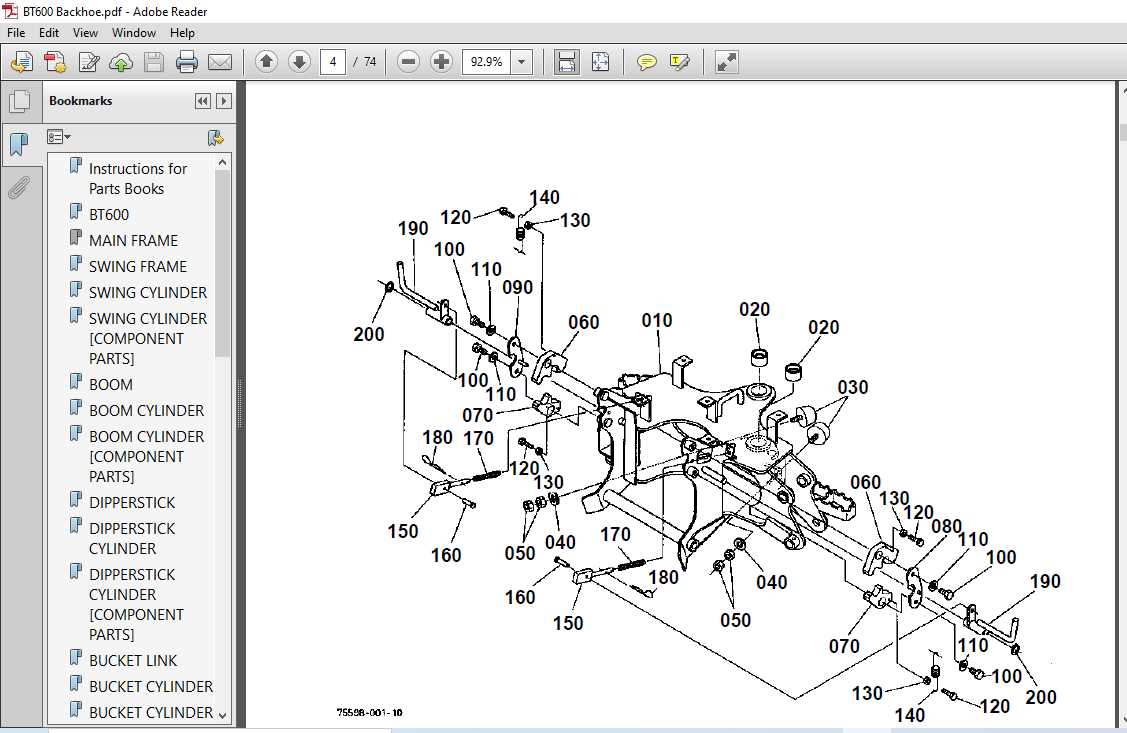

Attachments and Implements Overview

This section provides insights into the various tools and accessories that enhance the functionality of compact tractors. Understanding these attachments can significantly improve efficiency and versatility in numerous tasks.

Common Types of Attachments

Several categories of accessories are available, each designed to assist in specific activities. For example, loaders are essential for lifting and moving materials, while tillers prepare soil for planting. Other tools may include mowers for grass cutting and snow blowers for winter conditions.

Benefits of Using Implements

Utilizing the right accessories can lead to increased productivity and better outcomes for agricultural and landscaping projects. With the proper attachments, operators can tackle various tasks more effectively, making the equipment a valuable asset in various environments.