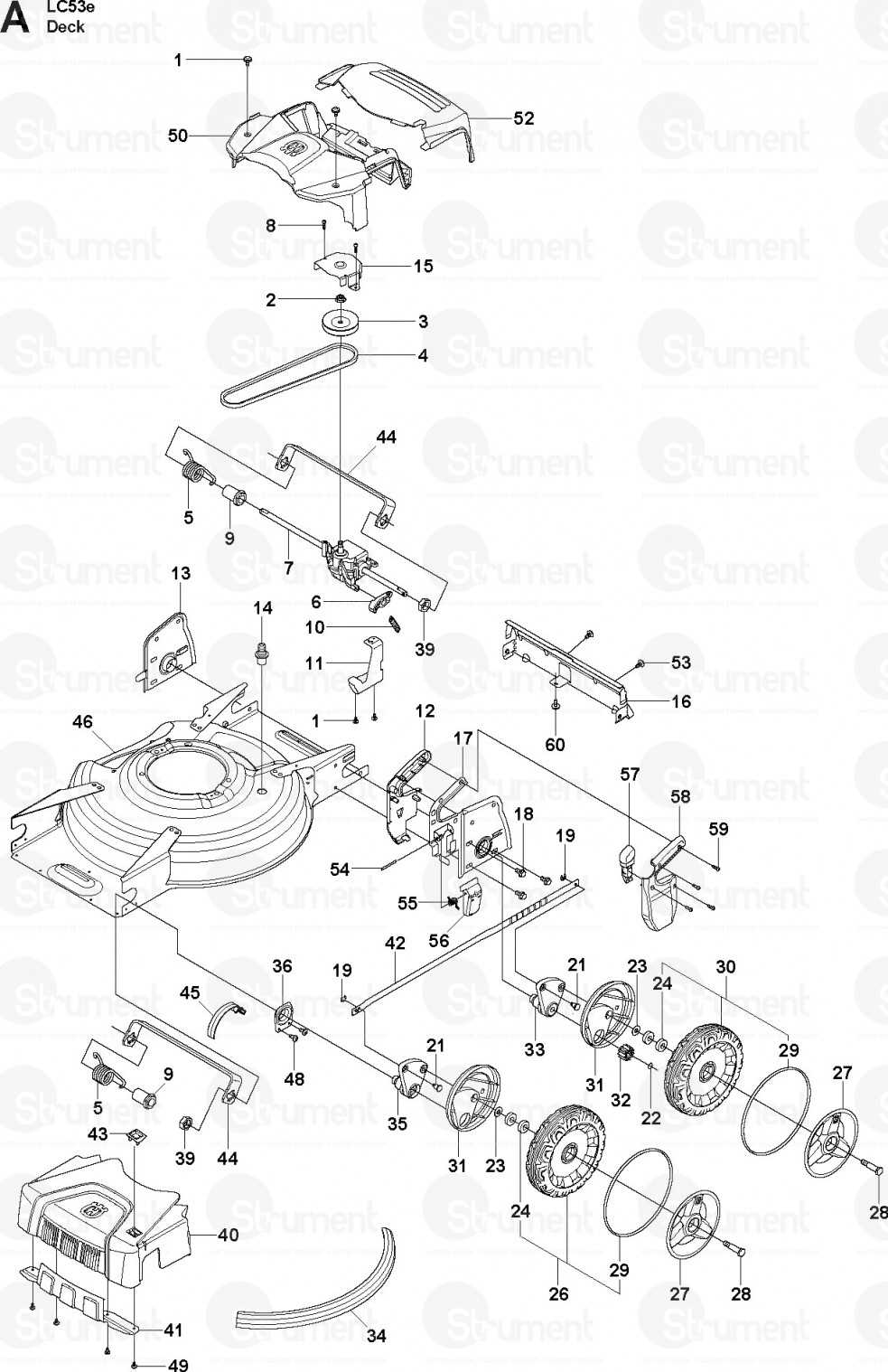

When it comes to maintaining outdoor equipment, having a clear understanding of the various elements and their placement can significantly simplify the process. Knowing the layout of individual components helps in identifying potential issues and ensures smoother repairs or replacements. This section aims to offer a comprehensive overview of essential mechanical elements and their arrangement.

Efficient maintenance often relies on recognizing how different elements are interconnected. Properly understanding the structure can make troubleshooting more intuitive and enable quicker identification of necessary replacements. With an organized layout, pinpointing specific areas for repair becomes less challenging.

Recognizing each mechanical element in relation to others not only aids in troubleshooting but also helps in preventative care. Ensuring that all components function together harmoniously extends the life of the equipment and reduces downtime.

Main Features of the HU800AWD

This section outlines the key characteristics that make this lawn maintenance tool a practical choice for users seeking efficiency and convenience. The machine is designed to handle various terrains and offer ease of use while performing its primary tasks. Below, we explore the main elements that contribute to its functionality and overall performance.

Engine Power and Efficiency

Equipped with a robust motor, this equipment provides ample force for tackling different grass lengths and thicknesses. The engine’s design ensures consistent performance, making it suitable for extended use. Additionally, its fuel consumption is optimized, helping users minimize refueling frequency during operation.

Adjustability and Comfort

The device features multiple settings that allow users to customize its operation to suit specific lawn conditions. The handle height can be adjusted, ensuring ergonomic use for individuals of different statures. The cutting height is also flexible, enabling smooth adaptation to various lawn preferences.

| Feature | Description | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Motor Strength | Ensures powerful and consistent performance. | |||||||||

| Fuel Efficiency | Designed to reduce fuel consumption. | |||||||||

| Adjustable Handle |

| Component | Function |

|---|---|

| Handle Grip | Provides a secure hold for maneuverability. |

| Control Buttons | Enable various operational modes and settings. |

| Trigger Mechanism | Activates primary functions of the device. |

| Adjustment Knob | Allows fine-tuning of performance parameters. |

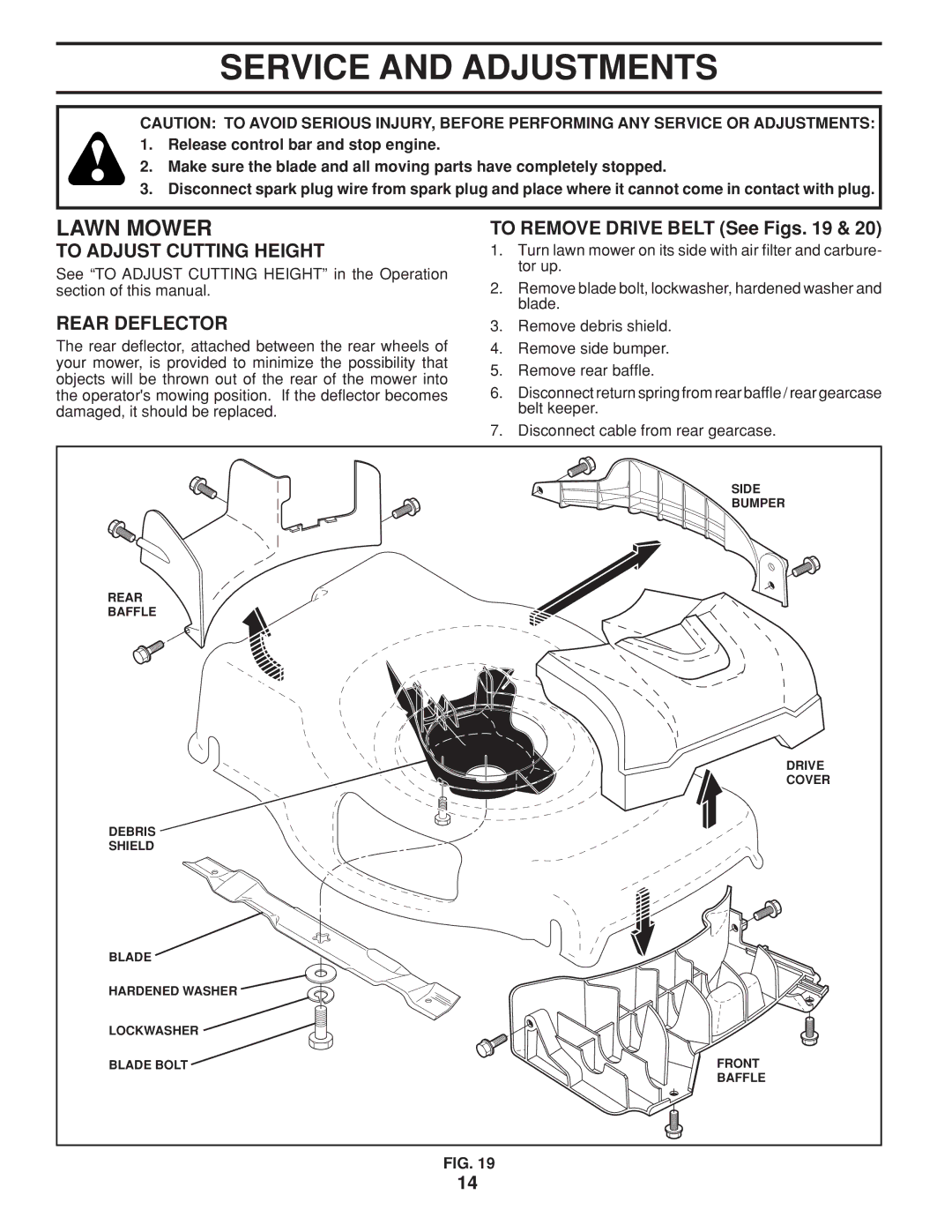

Installation Guidelines

To achieve a reliable setup, follow these installation guidelines: ensure the handle is securely attached, check that all controls are easily reachable, and confirm that the components function smoothly together. Regular maintenance and adjustments may be required to uphold performance standards.

Maintenance Tips for Key Parts

Ensuring the longevity and optimal performance of essential components in your equipment requires regular care and attention. By adhering to proper maintenance practices, you can enhance functionality and prevent unnecessary breakdowns. This section provides practical advice for maintaining critical elements to ensure reliable operation.

Regularly inspect the main units for signs of wear or damage. Keeping an eye on potential issues early can save you from costly repairs later. Always follow the manufacturer’s recommendations for maintenance schedules to guarantee that each part functions at its best.

Utilize appropriate cleaning techniques tailored to specific materials and designs. Accumulation of dirt and debris can hinder performance, so gentle cleaning should be part of your routine. For moving parts, lubricating as per guidelines helps minimize friction and ensures smooth operation.

Lastly, replace any worn or damaged components promptly. Ignoring these issues can lead to more severe problems down the line. Staying proactive about replacements can significantly extend the lifespan of your equipment and improve overall efficiency.

Troubleshooting Common Part Issues

Identifying and resolving issues related to components can significantly enhance the performance of your device. Many users encounter common problems that can often be addressed with a systematic approach. Below are typical concerns and their potential solutions.

- Component Not Functioning:

- Ensure that the device is properly powered on.

- Check for loose connections that may disrupt functionality.

- Inspect the component for visible signs of damage.

- Unusual Noises:

- Examine the installation of the part to confirm it is secure.

- Look for any foreign objects that might be obstructing movement.

- Lubricate moving parts if necessary to reduce friction.

- Decreased Performance:

- Regularly clean the component to remove debris and dust buildup.

- Check for worn-out pieces that may require replacement.

- Ensure that all connections are tight and secure to maintain optimal function.

- Inconsistent Operation:

- Test the part in different conditions to identify patterns in its behavior.

- Consult the manual for troubleshooting guidance specific to the component.

- Consider seeking professional assistance if the problem persists.

By systematically addressing these issues, users can often restore functionality and extend the lifespan of their equipment.