Understanding how various mechanical assemblies work together is crucial for ensuring optimal performance and longevity of a machine. Each piece within the system serves a specific role, contributing to the overall functionality and reliability. Examining the structure and arrangement of these elements offers valuable insight into their interaction and effectiveness.

By breaking down these elements into individual sections, one can gain a deeper understanding of their unique roles within the broader system. This detailed exploration allows for more efficient troubleshooting and maintenance, ensuring that each section operates seamlessly with the others. Through this lens, the inner workings of the equipment become more transparent, revealing the intricate connections between the various elements.

In this guide, we will explore the key structural components, highlighting their positions and explaining how they contribute to the machine’s smooth operation. This detailed breakdown is designed to provide clarity and assist in identifying and addressing potential issues that may arise over time.

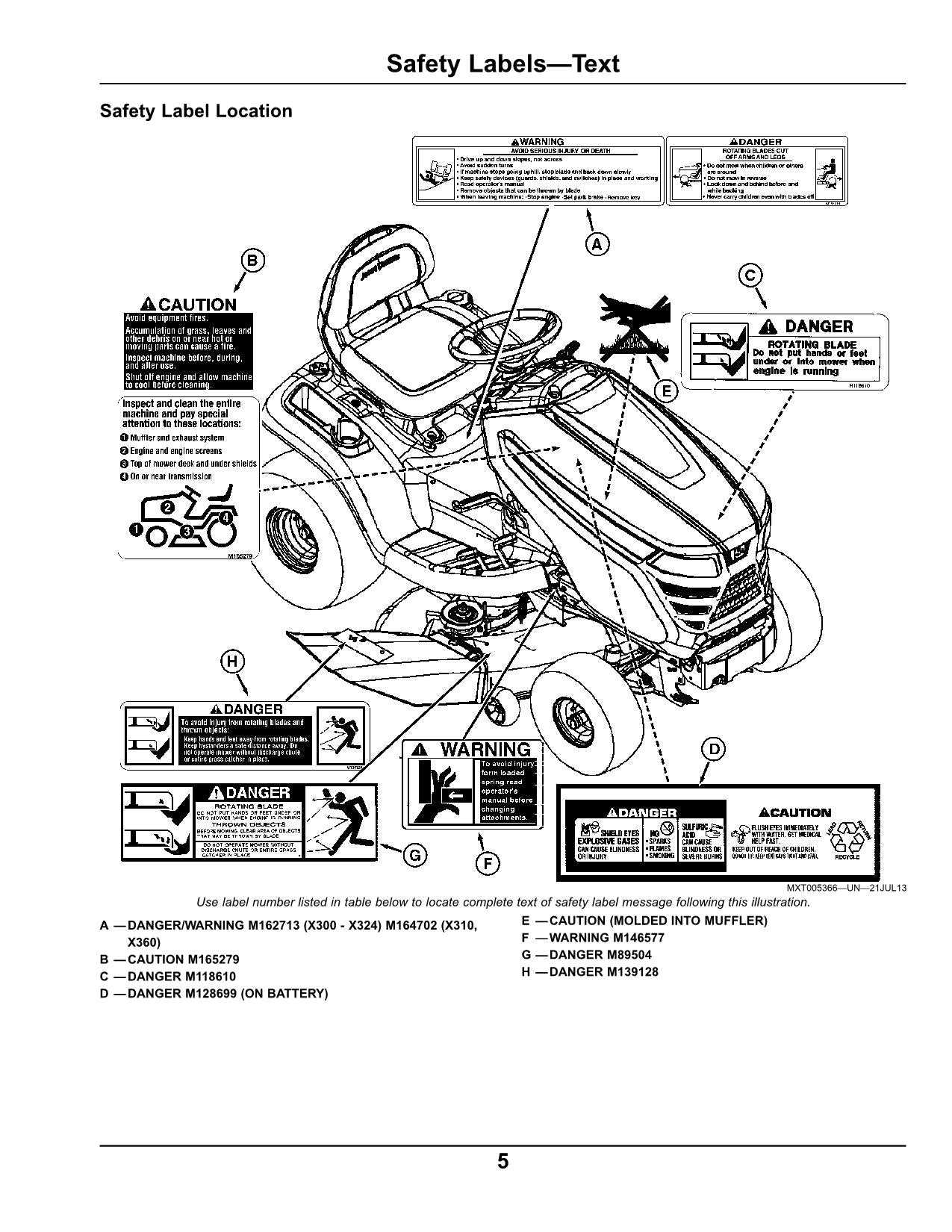

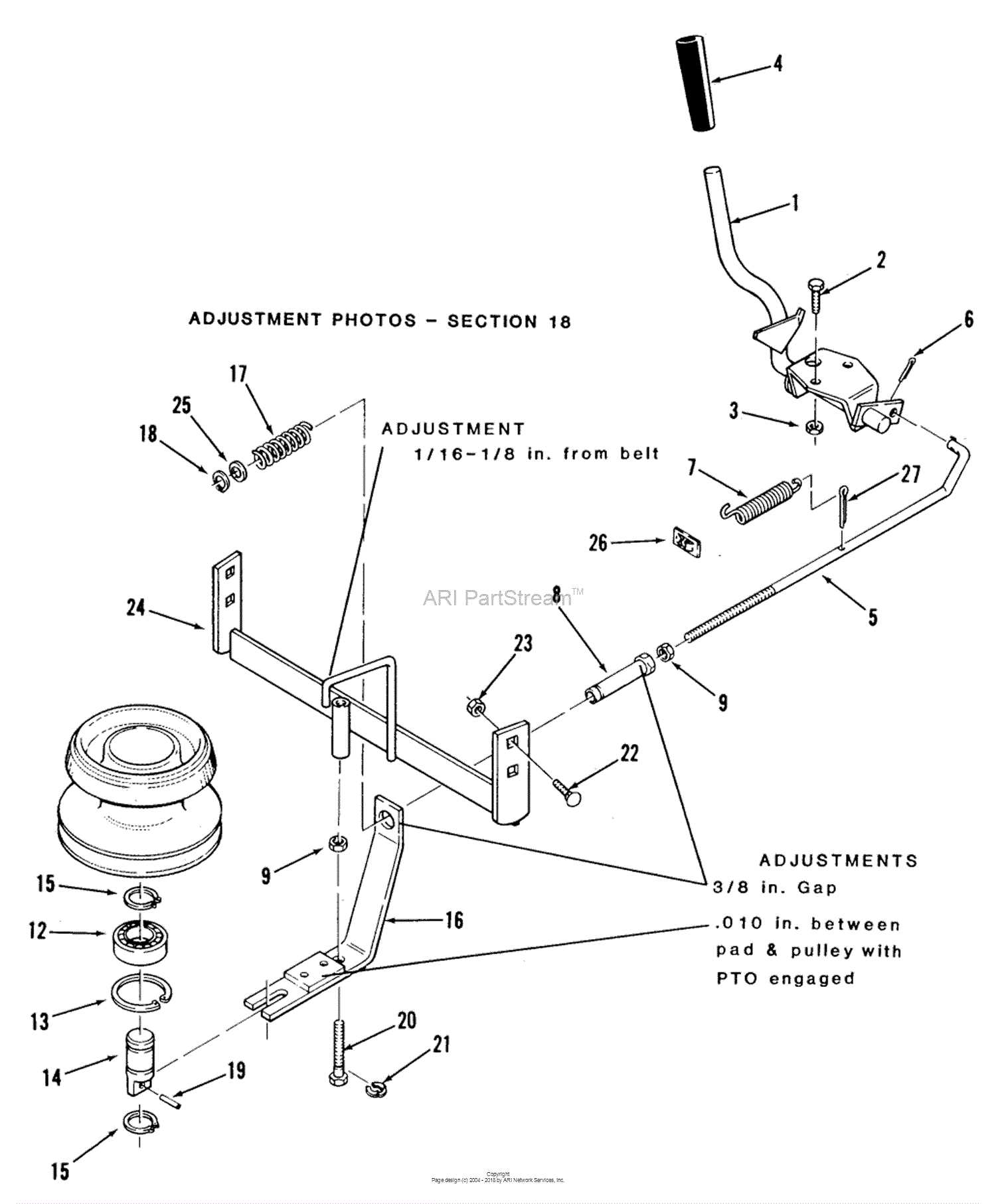

X300 Parts Diagram Overview

This section provides a comprehensive view of the layout, detailing the interconnected elements that form the structure of the device. Each component within the system is mapped out, highlighting their positions and roles within the assembly. The schematic representation offers insight into how different elements are arranged and how they contribute to the overall functionality.

The detailed illustration helps in understanding the individual components and their relationships, making it easier to trace connections and understand the operation. The layout simplifies the process of identifying key segments and how they interact within the system’s framework.

Key Components of X300 Machine

Understanding the essential elements that drive the functionality of this equipment is crucial for ensuring its optimal performance. These primary elements form a complex yet well-coordinated system, each playing a specific role in the overall operation.

Core Functional Units

The primary units are responsible for handling various operational tasks. These are critical for managing power, movement, and precision in the machinery’s workflow.

- Power Delivery System – This section ensures that energy is consistently supplied to all other modules, maintaining stability.

- Control Mechanism – This regulates the movement and functions of various elements, ensuring synchronization during operations.

- Support Structure – A robust framework that supports the machine’s overall design and integrity.

Supporting Components

Beyond the core

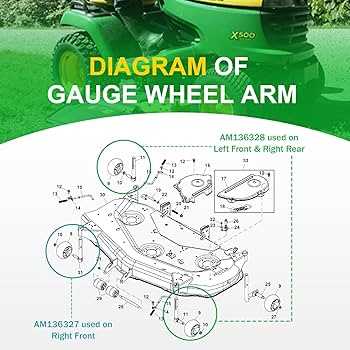

Visual Guide to X300 Structure

This section provides a comprehensive overview of the layout and composition of the device’s internal framework. By breaking down each element, we aim to give a clearer understanding of how the individual components are arranged to work together efficiently. The visual breakdown will help to clarify the organization of these interconnected elements.

In this guide, we will highlight the key structural features, focusing on their positioning and role within the overall design. This will allow for a deeper appreciation of how the assembly contributes to the functionality and reliability of the unit.

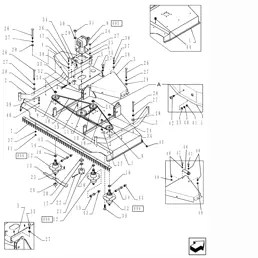

Understanding X300 Assembly Layout

To fully comprehend the configuration of this complex system, it is essential to explore how its various components interact and fit together. The arrangement of individual elements plays a crucial role in the functionality and performance of the overall structure.

Main Structural Elements

- Primary housing structure, which serves as the foundation for all internal mechanisms

- Fastening elements that secure the internal modules in place

- Sub-modules, responsible for various operational tasks within the system

Critical Connections

The layout is designed with precision, ensuring that each link between sections allows for smooth operation. Critical junctions between elements must be clearly understood to maintain proper function and avoid potential issues.

- Interlocking mechanisms for enhanced stability

- Pathways for power and data transmission

- Detailed Breakdown of X300 Elements

The intricate structure of this device relies on the precise arrangement of its components. Understanding how each section functions is crucial for maintaining and optimizing performance. By breaking down the individual elements, we can gain a better appreciation of the overall mechanism and ensure that each part operates in harmony with the others.

Component Function Element A Responsible for managing the input signals and directing them accordingly. Element B Ensures the regulation of power distribution throughout the system. Element C Acts as a stabilizer, maintaining consistent performance under varying conditions. Element D X300 Mechanical Sections Explained

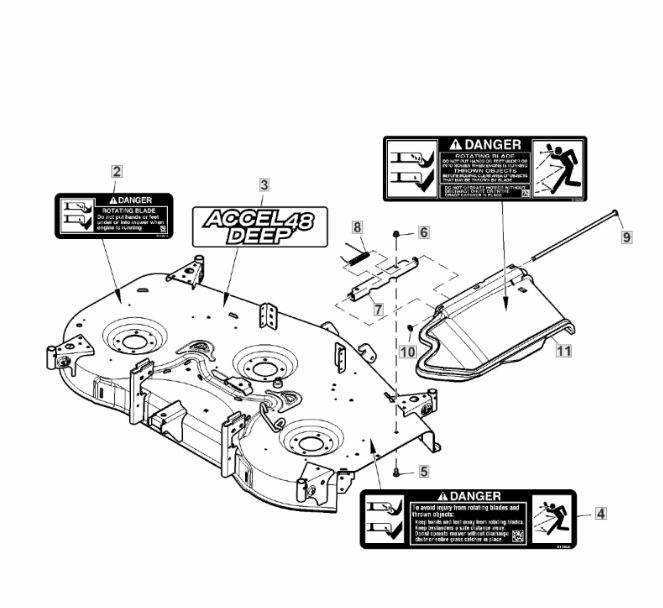

The intricate design of a sophisticated machine comprises various interconnected components, each serving a specific function. Understanding the layout and interaction of these elements is essential for effective operation and maintenance. This section aims to illuminate the mechanical sections, detailing their roles and significance in the overall system.

Key Components Overview

Every machine features distinct mechanical sections that contribute to its functionality. Here are some critical components:

- Framework: The structural backbone providing stability and support.

- Drive System: The mechanism responsible for motion, often powered by an engine or motor.

- Transmission: This section transfers energy from the drive system to other parts, enabling movement.

- Control Elements: Components that regulate the operation, allowing for user inputs and automated functions.

Understanding Interconnections

The relationship between these mechanical sections is vital for the machine’s performance. Each part must work in harmony to ensure efficiency. Here are some interdependencies:

- The framework must accommodate the drive system’s size and mounting requirements.

- The transmission must align with the drive system to facilitate smooth energy transfer.

- Control elements should integrate seamlessly with the drive system to provide responsive operation.

Comprehending these mechanical sections and their interactions is crucial for troubleshooting and optimizing performance, making maintenance and repairs more effective.

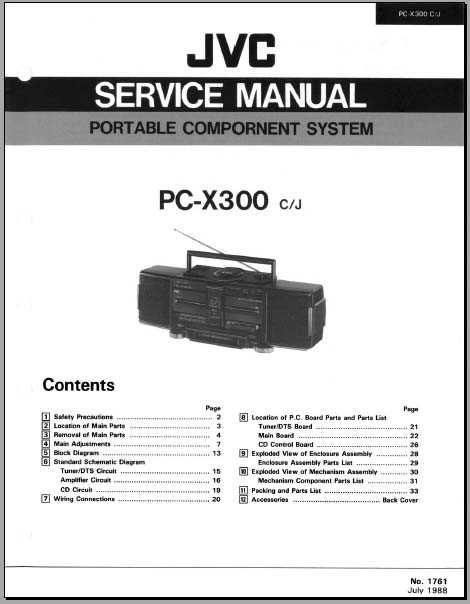

Overview of X300 Internal Systems

The internal mechanisms of this advanced model showcase a sophisticated interplay of components designed for optimal functionality. Each element works cohesively to enhance performance, reliability, and user experience. Understanding the arrangement and purpose of these systems is crucial for anyone looking to comprehend the overall efficiency and capabilities of the unit.

Core Functionalities

At the heart of the design lies a robust architecture that facilitates various operations. The system integrates multiple features, including power management, data processing, and communication interfaces. These core functionalities are essential for ensuring smooth operation, allowing for seamless interaction with external devices and networks.

System Integration

The harmonious integration of all internal components results in a streamlined operation. This collaboration between various systems ensures that resources are utilized efficiently, maximizing performance while minimizing potential conflicts. Understanding this integration provides valuable insights into the operational excellence of the unit.

X300 Hardware Configuration Overview

This section provides a comprehensive overview of the hardware setup utilized in the specified model. Understanding the arrangement and functionality of various components is essential for effective troubleshooting and system enhancement. This overview outlines the primary elements, their roles, and the interconnections that facilitate optimal performance.

Component Layout and Interaction

The configuration consists of several critical components that interact seamlessly. Each part has a designated function, contributing to the overall efficiency of the system. The table below illustrates the key elements along with their descriptions and interrelationships.

Component Description Function Processor The main processing unit responsible for executing instructions. Handles computations and control tasks. Memory Module Temporary storage for data and instructions. Enables quick access to active data. Power Supply Component that provides electrical energy. Ensures stable operation of all parts. Cooling System Maintains optimal operating temperatures. Prevents overheating of critical components. I/O Ports Interfaces for external connections. Facilitates communication with peripherals. Performance Considerations

A well-configured hardware setup significantly influences the performance and reliability of the system. Proper installation and arrangement of components can enhance functionality, leading to a smoother user experience. Regular maintenance and upgrades are recommended to ensure that all elements operate at their best.

Exploring X300 Functional Units

Understanding the various functional components of a system is essential for optimizing its performance and reliability. Each segment plays a critical role, contributing to the overall functionality and efficiency. This exploration delves into the intricacies of these units, highlighting their unique contributions and interconnections.

Key Functional Elements

Among the critical segments, we find units responsible for processing, communication, and power management. These segments work in harmony, ensuring seamless operation and interaction within the system. The processing unit, for instance, executes instructions and manages data flow, while the communication components facilitate the exchange of information between different modules.

Integration and Collaboration

The collaboration among these units is vital for achieving optimal performance. For example, the interaction between the processing and communication units enhances data handling capabilities, leading to improved efficiency. Moreover, power management elements ensure that each unit operates within its optimal energy range, preventing overload and extending the system’s lifespan.

Mapping Out X300 Component Connections

Understanding the intricate layout of a device’s components is essential for effective troubleshooting and enhancement. This section delves into the various connections and interrelations among different elements within the system. By comprehending how each component interacts, one can better optimize functionality and address potential issues.

Exploring the Interconnections

The connections between various elements form a complex network that enables the device to operate seamlessly. Each link plays a crucial role, allowing signals and power to flow efficiently throughout the system. Recognizing these pathways can lead to improved performance and reliability.

Identifying Key Components

Among the numerous components, certain parts hold significant importance due to their roles in facilitating operations. Understanding the function of these key elements helps in diagnosing faults and making informed upgrades. A clear overview of their connections provides a roadmap for effective maintenance and modifications.

X300 Parts Layout and Function

The arrangement of components in a mechanical system plays a crucial role in its overall performance and functionality. Understanding how these elements interact and contribute to the system’s operation is essential for effective troubleshooting and maintenance. Each component has a specific role, influencing the efficiency and effectiveness of the entire mechanism.

In this section, we will explore the layout and operational characteristics of key elements within the assembly. The following table highlights various components, their respective locations, and functions.

Component Name Location Function Element A Top Section Controls the primary operations Element B Middle Section Facilitates energy transfer Element C Bottom Section Provides structural support Element D Side Section Enhances overall stability