When working on a high-performance off-road machine, understanding the arrangement of key components is essential for both maintenance and modification. This section provides a detailed overview of the main elements that make up the vehicle’s system, allowing for better insight into how each part contributes to its overall functionality.

Every motorcycle is made up of various interconnected elements, each designed to perform a specific role. From the engine block to the suspension system, each unit plays a pivotal part in ensuring optimal performance. Identifying these components and understanding their relationships is crucial for anyone looking to make adjustments or troubleshoot issues effectively.

Familiarity with this structure can save valuable time during repairs and upgrades, helping you quickly locate areas that may require attention. Whether you’re a seasoned mechanic or a novice enthusiast, grasping the layout of these key systems is fundamental to ensuring your machine runs smoothly on any terrain.

Through this exploration, we aim to provide clarity on the various components, offering insights that will support your journey in maintaining and enhancing your off-road vehicle. This understanding lays the groundwork for further in-depth analysis and guides the way toward efficient customization and repair practices.

Key Components of the DRZ 400

The key elements of a high-performance off-road machine are integral to its functionality and durability. Understanding these essential parts helps riders maintain peak performance and ensure longevity. These components work in unison, offering enhanced control, power delivery, and adaptability to various terrains.

Engine and Transmission: The heart of any off-road vehicle lies in its engine and transmission system. These parts are designed to provide substantial torque and efficiency under extreme conditions. The engine is tuned for both power and smooth delivery, while the transmission allows for seamless gear shifting to handle different riding demands.

Suspension System: Vital for absorbing impacts from rough terrain, the suspension system plays a crucial role in maintaining comfort and stability. The system ensures the rider remains in control even when navigating uneven or challenging surfaces.

Braking Mechanism: Effective stopping power is critical for safety. The braking system must be responsive, offering precise control when decelerating or coming to a complete stop on challenging terrain.

Chassis and Frame: The structure of the vehicle provides the foundation for all other components. A strong and lightweight frame supports the engine, suspension, and other key systems, ensuring maximum strength without compromising agility.

Fuel and Air Management: Efficient fuel delivery and air intake systems ensure optimal performance by providing the right mix of fuel and oxygen for combustion. These components help maintain smooth engine operation, even under load or in varying conditions.

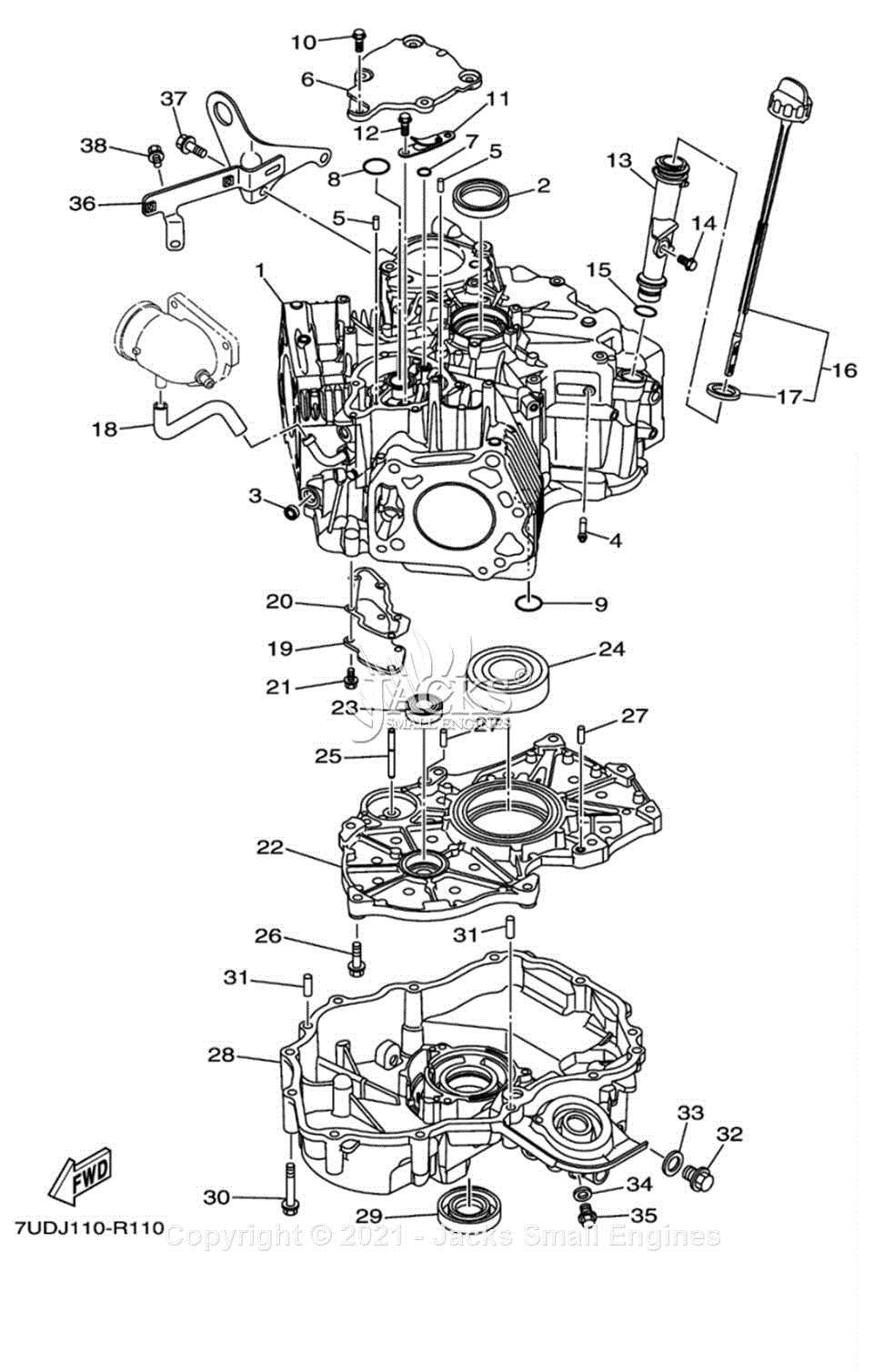

Engine Layout and Internal Parts

Understanding the layout of an engine and its internal components is essential for any mechanic or enthusiast. It reveals how each section of the engine contributes to the overall functioning, ensuring the optimal performance of the vehicle. The internal components work in unison to generate power and manage the complex processes of combustion, energy conversion, and mechanical movement.

Main Engine Components

- Cylinder Block: The main structure housing several internal components, providing a solid foundation for the engine.

- Pistons: Moving parts that travel up and down within the cylinders to convert energy into mechanical motion.

- Crankshaft: A key element that converts the up-and-down motion of the pistons into rotational force to drive the vehicle.

- Camshaft: Controls the timing of valve openings and closings, ensuring proper engine cycle management.

Supporting Internal Mechanisms

- Timing Chain/Belt: Ensures the synchronized movement of the crankshaft and camshaft, keeping engine timing accurate.

- Valves: Manage the intake of air and fuel and the expulsion of exhaust gases, contributing to efficient combustion.

- Connecting Rods: Transfer the force generated by the pistons to the crankshaft, linking the pistons to the engine’s power system.

Transmission System Overview

The transmission system plays a crucial role in transferring power from the engine to the wheels, ensuring smooth acceleration and deceleration. It is responsible for adapting the power output to the appropriate range for optimal performance under varying conditions.

This system consists of several key components that work together to manage the delivery of power. Each element has its own function, yet they are intricately connected to ensure efficiency and reliability. Understanding how these parts interact helps in maintaining and troubleshooting the system effectively.

- Gearbox: The gearbox controls the speed and torque sent to the wheels, offering different ratios for varied performance.

- Clutch: The clutch allows for smooth engagement and disengagement of the engine from the transmission system, enabling gear changes.

- Chain or Shaft Drive: This mechanism transmits power from the gearbox to the final drive, using either a chain or shaft system for efficiency and durability.

- Final Drive: This component adjusts the rotation of the drivetrain to the wheels, ensuring proper handling and stability.

By carefully monitoring these parts, users can enhance the longevity of the system while ensuring reliable performance in various riding conditions.

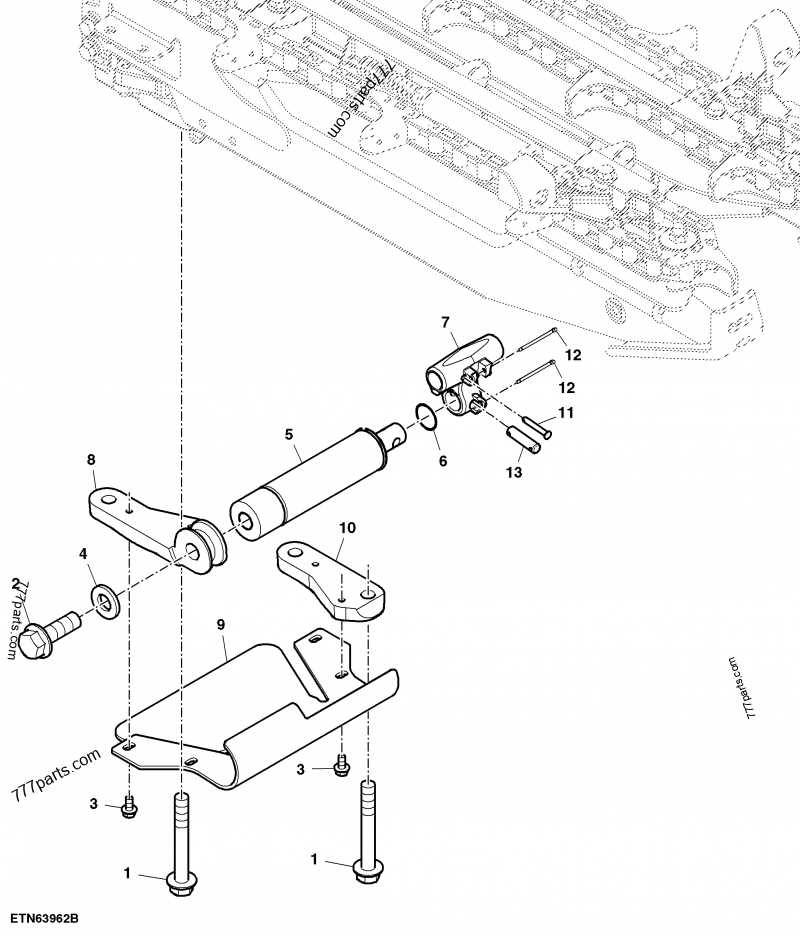

Exploring the Gearbox Structure

The gearbox plays a crucial role in the transmission system, offering a vital connection between the engine and the wheels. It is designed to adjust the power generated by the engine to ensure smooth and efficient movement. The structure of this component is essential for balancing torque, speed, and load, allowing the vehicle to perform optimally across different conditions.

A closer look at its internal configuration reveals a system of gears and shafts that work together to convert engine output into usable force. These gears come in various sizes and are precisely arranged to ensure proper synchronization during operation. The layout is engineered to minimize friction and wear while maximizing efficiency, ensuring the longevity of the entire system.

The materials used in constructing the gearbox are selected to withstand high pressures and temperatures, making durability a key factor. Every element, from the main casing to the smallest gear, is designed for resilience and precision. This careful design is essential to maintaining performance over time, particularly under heavy loads or extreme conditions.

Suspension System Breakdown

The suspension system plays a critical role in maintaining balance, stability, and comfort while riding. It consists of various components that work together to absorb shocks, distribute weight, and enhance the overall control of the vehicle. A well-functioning system ensures smooth handling, especially when navigating rough or uneven terrain.

| Component | Function |

|---|---|

| Shock Absorbers | Absorb impacts from bumps and rough surfaces, improving comfort and stability. |

| Forks | Support the front wheel and help dampen shocks during front-end impacts. |

| Swing Arm | Helps in rear suspension, providing stability and smooth motion over obstacles. |

| Springs | Store and release energy to handle different levels of load and terrain conditions. |

| Linkages | Transfer forces between various suspension components, contributing to optimal movement. |

Understanding Front and Rear Suspension

The suspension system plays a crucial role in the overall performance and comfort of a vehicle. It consists of several key components designed to absorb shocks, maintain stability, and ensure proper handling on various terrains. By understanding the relationship between the front and rear suspension, riders can optimize their experience and adjust the system to suit different riding conditions.

At the front, the suspension typically involves a fork mechanism that controls the movement of the wheel in response to obstacles. In contrast, the rear suspension works in tandem with the frame to absorb impacts and prevent excessive motion, ensuring that the rear wheel remains in contact with the ground for better traction and control.

| Component | Function |

|---|---|

| Front Fork | Absorbs shocks from the front wheel, aiding in smooth handling and steering control. |

| Rear Shock | Handles impacts from the rear wheel, enhancing stability and comfort during rides over uneven surfaces. |

| Springs | Work with the shock absorbers to maintain the vehicle’s balance and control by adjusting to varying forces. |

| Linkage System | Transmits the force from the rear wheel to the shock, providing smooth motion and preventing bottoming out. |

Brake System Design

The braking mechanism is a crucial element of any vehicle, ensuring safety and control during operation. This system is engineered to effectively reduce speed and bring the vehicle to a halt when necessary. Understanding the components and their interactions can greatly enhance performance and reliability.

Key Components

At the heart of the braking mechanism lies several essential components. The calipers play a significant role in pressing the brake pads against the rotor, generating the friction needed to slow down the wheels. Additionally, the master cylinder is responsible for converting the force applied to the brake pedal into hydraulic pressure, which facilitates the movement of the calipers.

Design Considerations

When designing a braking system, various factors must be taken into account. Weight distribution, material selection, and heat dissipation are vital elements that influence the system’s efficiency and effectiveness. Optimizing these aspects not only enhances performance but also prolongs the lifespan of the braking components.

Components of the DRZ 400 Brakes

Braking systems play a crucial role in ensuring the safety and efficiency of any vehicle. The various elements of a braking assembly work together to provide optimal performance, control, and stability. In the case of this particular vehicle, understanding each part of the braking system helps maintain its functionality and longevity.

The key components involved in the braking system include:

- Brake Discs: These circular plates provide the surface on which the brake pads make contact to slow down or stop the vehicle.

- Brake Pads: These components are pressed against the brake discs to generate the necessary friction for deceleration.

- Calipers: These are the mechanisms that house the brake pads and apply the required pressure to them.

- Master Cylinder: This part contains the brake fluid and creates the hydraulic pressure needed to operate the braking system.

- Brake Lines: The pipes or hoses that carry brake fluid from the master cylinder to the brake calipers.

- Brake Fluid: A vital fluid that transfers pressure from the master cylinder to the brake calipers, enabling the braking action.

- Brake Levers: The control mechanism that activates the brake system, either by hydraulic or mechanical means.

Each of these elements is critical for the efficient operation of the braking system, ensuring safety, precision, and a responsive performance when needed most.

Fuel Delivery Components

The proper functioning of an engine relies on an efficient system to deliver the right amount of fuel at the correct time. Several key elements work together to ensure smooth fuel intake, from the moment fuel enters the system until it reaches the combustion chamber. These components must be precisely coordinated to ensure optimal performance and engine longevity.

| Component | Description |

|---|---|

| Fuel Tank | Stores the fuel before it is delivered to the engine system. |

| Fuel Pump | Transfers fuel from the tank to the engine system under the necessary pressure. |

| Fuel Filter | Removes impurities and debris from the fuel before it enters the engine. |

| Fuel Injector | Injects a fine mist of fuel into the combustion chamber at the correct moment. |

| Fuel Lines | Provide the pathway for fuel to travel from the tank to the engine components. |

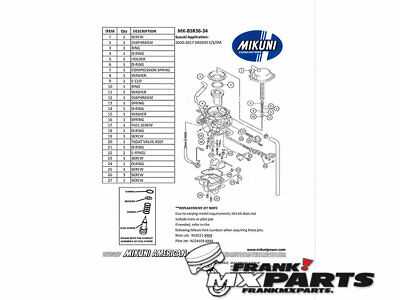

Fuel System and Carburetor Details

The fuel system plays a crucial role in ensuring optimal engine performance. It regulates the delivery of fuel to the engine, maintaining the correct air-fuel mixture for efficient combustion. One of the key components within this system is the carburetor, which is responsible for mixing the air and fuel in the right proportions before entering the engine. Understanding the specific details of this setup is essential for maintaining and tuning the engine for peak performance.

In this section, we will examine the important elements of the fuel delivery system, focusing on the functionality of the carburetor and its components. Proper maintenance and adjustments to these parts can significantly improve engine responsiveness and fuel efficiency.

| Component | Description | Function |

|---|---|---|

| Carburetor | A device that mixes air and fuel in proper ratios. | Ensures optimal air-fuel mixture for combustion. |

| Fuel Bowl | A reservoir that holds the fuel before it is mixed with air. | Maintains consistent fuel levels for stable operation. |

| Needle Valve | Controls fuel flow from the fuel bowl to the carburetor. | Regulates the amount of fuel entering the carburetor. |

| Jets | Small orifices that control the flow of fuel into the carburetor. | Fine-tune the fuel-air mixture depending on engine demand. |

| Throttle Valve | A component that controls airflow into the carburetor. | Adjusts the engine’s power output by controlling air intake. |

Electrical System Overview

The electrical system plays a critical role in the overall performance and reliability of a motorcycle. It is responsible for powering essential components such as lighting, ignition, and communication systems. Understanding the key elements of this network ensures efficient operation and maintenance, allowing the rider to avoid issues related to energy distribution and system failures.

Key Components

The heart of the system includes the battery, which stores energy for ignition and auxiliary functions. This energy is distributed through the wiring harness, connecting various components like the starter motor, voltage regulator, and ignition coils. Each element is designed to work in harmony, ensuring proper voltage levels are maintained across the vehicle’s electrical infrastructure.

Power Distribution

Power distribution is essential for managing the electrical load efficiently. The system uses fuses to protect critical components from overcurrent. Regulators help maintain a stable voltage, while alternators recharge the battery during operation. This interconnected setup allows the machine to function reliably, even under varying conditions and load demands.

Key Wiring and Electrical Parts

Understanding the core components of the electrical system is essential for maintaining optimal performance. The wiring layout and the various electrical elements serve as the foundation for the proper functioning of the vehicle. These elements ensure the transfer of energy to critical systems such as the ignition, lighting, and sensors, which are crucial for overall operation.

Among the key components are the battery connections, grounding wires, and voltage regulators, which maintain consistent power flow. The ignition system, with its coils and spark plugs, plays a pivotal role in ensuring the engine fires up correctly. Additionally, connectors and relays are integral for controlling electrical signals, ensuring that each component operates at the right time and in harmony with the rest of the system.

Careful inspection and maintenance of these components help prevent issues such as electrical failures, overheating, or loss of power, which could disrupt the performance and safety of the entire system. Proper knowledge of the wiring structure aids in troubleshooting and ensures longevity for the vehicle’s electrical infrastructure.

Exhaust and Cooling Mechanism

Efficient heat management and exhaust systems are critical for maintaining optimal engine performance. These components work together to regulate temperatures, enhance airflow, and minimize the buildup of harmful gases. The cooling system ensures that the engine operates within safe thermal limits, while the exhaust system efficiently expels byproducts of combustion. Proper integration of these systems is essential for long-term durability and efficient power delivery.

Cooling System Components

The cooling system is designed to maintain an engine’s temperature by dissipating excess heat. It involves several key components:

- Radiator: This part helps transfer heat from the engine to the surrounding air.

- Thermostat: Regulates coolant temperature to ensure optimal engine operation.

- Coolant Pump: Circulates the coolant throughout the engine to absorb heat and prevent overheating.

- Cooling Fins: These external parts help dissipate heat more efficiently from the engine block.

Exhaust System Features

The exhaust system removes waste gases produced during combustion. Key components include:

- Exhaust Pipe: Carries exhaust gases from the engine to the rear of the vehicle.

- Muffler: Reduces noise produced by the engine during operation.

- Catalytic Converter: Converts harmful gases into less harmful substances, reducing environmental impact.

- Exhaust Manifold: Collects exhaust gases from the engine’s cylinders and directs them into the exhaust system.