When it comes to fluid dispensing systems, each element plays a crucial role in ensuring the smooth operation and quality of the final product. Every part is interconnected, forming a complex but efficient mechanism that delivers liquid to the consumer. Understanding these elements can help with both maintenance and optimization of the system’s performance.

In this section, we’ll explore the various components that make up the system, focusing on their specific functions and importance. Whether you’re dealing with home or commercial setups, knowing how each piece contributes to the overall flow can improve both reliability and user experience.

From valves that regulate flow to hoses that ensure proper delivery, each component is designed with precision. This section will highlight key features and explain how they interact to provide a seamless pouring experience.

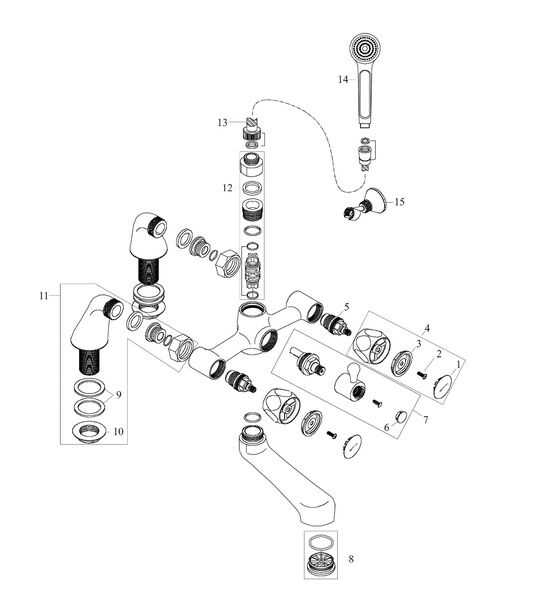

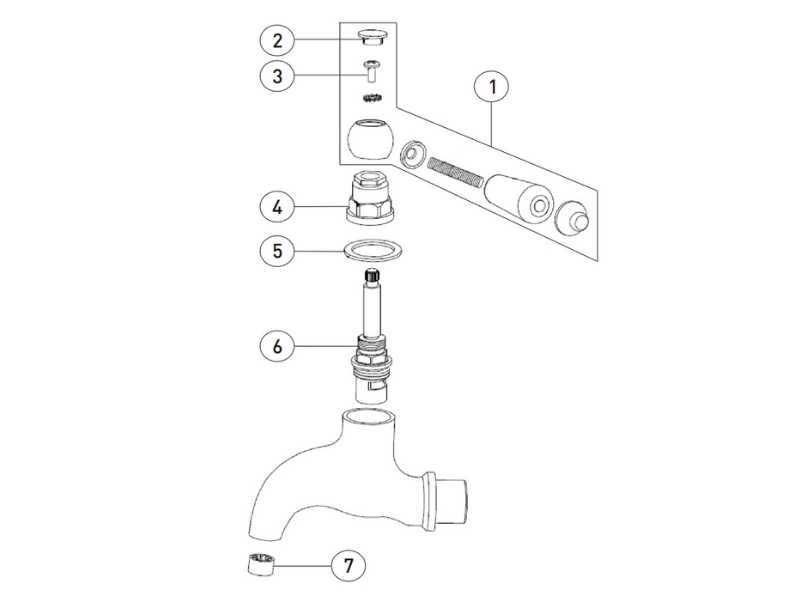

Beer Tap Parts Diagram Overview

This section presents a detailed examination of the components essential for dispensing beverages from kegs. The following content will outline how various elements work together to ensure a smooth and controlled flow, while maintaining the integrity of the liquid being served. The goal is to provide clarity on the structure and operation of the dispensing system.

Key Components

The mechanism for pouring drinks involves several critical elements. Each one plays a vital role in regulating flow, maintaining pressure, and ensuring quality. These components must be aligned properly to guarantee seamless operation and consistency in serving.

Operational Flow

The overall system relies on a harmonious interaction between various parts. Ensuring the correct installation and maintenance of these elements is crucial for optimal performance. Proper attention to detail will enhance both the functionality and durability of the system.

Essential Components of a Beer Tap

The operation of a draft system involves various key elements that work together to deliver a smooth and controlled pour. Understanding how these components function is essential for ensuring optimal performance and maintenance of the system.

Primary Mechanisms

- Faucet: The pouring mechanism, allowing liquid to flow out when activated by the user.

- Shank: Connects the dispensing system to the external supply, creating a pathway for the liquid.

- Coupler: The link between the container and the system, responsible for securing and regulating the flow.

Supporting Elements

- Hose: Carries liquid from the source to the faucet, ensuring consistent pressure throughout.

- Regulator: Manages the pressure from the gas supply, ensuring a steady, controlled flow.

- Handle:

Understanding the Function of the Faucet

The faucet plays a pivotal role in ensuring smooth and controlled dispensing of liquids. Its primary purpose is to manage the flow, allowing users to efficiently control the output while preventing spillage and waste. By operating the faucet, one can regulate the exact amount and pressure, ensuring a seamless experience with minimal effort.

Flow Regulation Mechanism

The internal components of the faucet are designed to provide precision. With a simple handle movement, the mechanism adjusts the flow, offering control over the speed and pressure of the liquid. This design ensures that the output is neither too rapid nor too slow, delivering a balanced and steady stream.

Maintaining Consistent Output

Another essential function is ensuring that the output remains consistent throughout its use. The faucet must maintain a steady flow regardless of external conditions, providing a reliable and predictable experience. This consistency is achieved through a combination of well-engineered internal valves and seals that work together to prevent fluctuations.

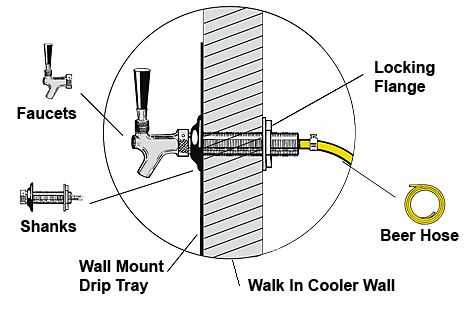

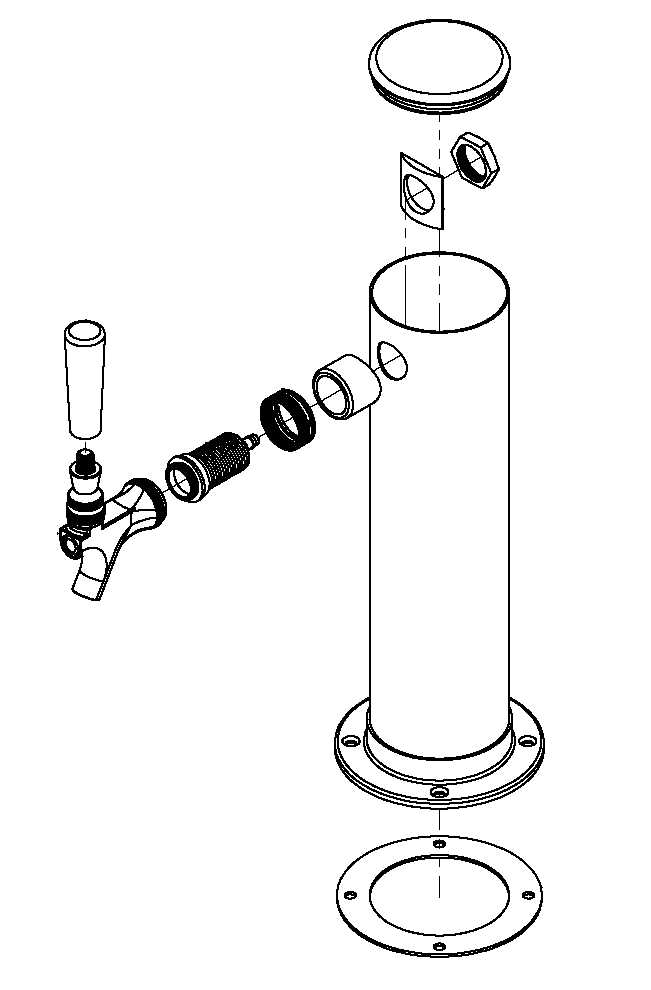

Role of the Shank in Beer Dispensing

The shank plays a critical role in fluid delivery systems, acting as a conduit between the liquid source and the dispensing mechanism. It ensures smooth flow, maintaining the right pressure while preventing leakage or disruptions. Without this essential component, maintaining a consistent stream would be difficult, leading to potential operational issues.

Key Functions of the Shank

Primarily, the shank serves as the connection point for tubes that transport liquids from the storage container. Its sturdy design helps withstand the pressure of the flow, ensuring durability and efficiency. Additionally, it provides structural support, ensuring that all elements remain securely in place during the dispensing process.

Shank Variations and Installation

Shanks come in different lengths and materials, tailored for specific dispensing setups. The correct selection depends on the type of liquid and the overall configuration of the system. Proper installation is essential to ensure a leak-free and efficient operation.

Shank Material Durability Common Use Stainless Steel High Frequent Use in High-Pressure Systems Brass Moderate How the Tap Handle Operates

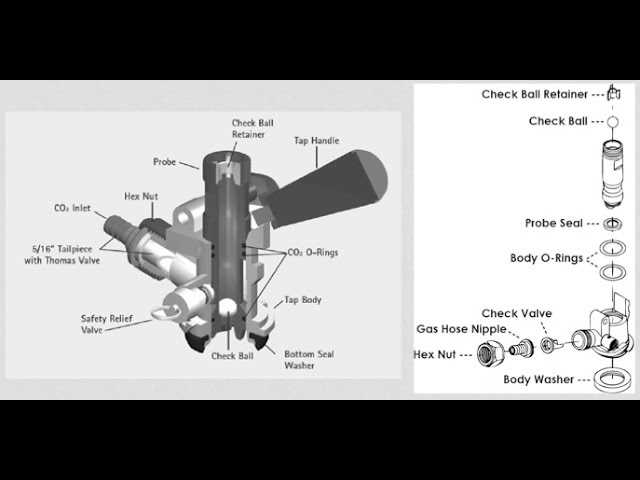

The handle mechanism plays a crucial role in controlling the flow of liquid from a dispenser. By moving the lever, the user regulates how much liquid is released, ensuring a smooth and efficient pouring process. The design of the handle allows for easy operation, making it a key component in ensuring precision and consistency.

Lever Mechanism

The lever itself is designed to be ergonomically friendly, allowing for comfortable use. When pulled, the internal valve opens, allowing liquid to pass through. Releasing the lever closes the valve, stopping the flow immediately. This simple yet effective design ensures minimal waste and optimal control over the pour.

Impact on Flow Control

The operation of the handle directly affects the speed and volume of liquid dispensed. By applying pressure to the handle, the user can either increase or decrease the flow. This provides full control over the amount of liquid released, making it an essential feature for accurate dispensing.

The Importance of the Keg Coupler

The coupler plays a crucial role in the dispensing process of various beverages, serving as the vital connection between the storage container and the serving system. It facilitates the flow of liquid while maintaining pressure and preventing contamination, ensuring a consistent and high-quality pour.

Functionality and Efficiency

This component is essential for enabling smooth operation. It allows for quick engagement and disengagement from the keg, which enhances the efficiency of service in busy environments. Proper functioning of the coupler minimizes waste and maximizes the yield of the beverage, which is critical for both consumer satisfaction and economic considerations.

Types and Compatibility

Different types of couplers are designed for specific container configurations, making compatibility a key factor. Understanding the distinctions among various coupler models ensures that operators can select the right one for their setup, ultimately leading to optimal performance and user experience. Investing in the correct coupler type is paramount for effective beverage management.

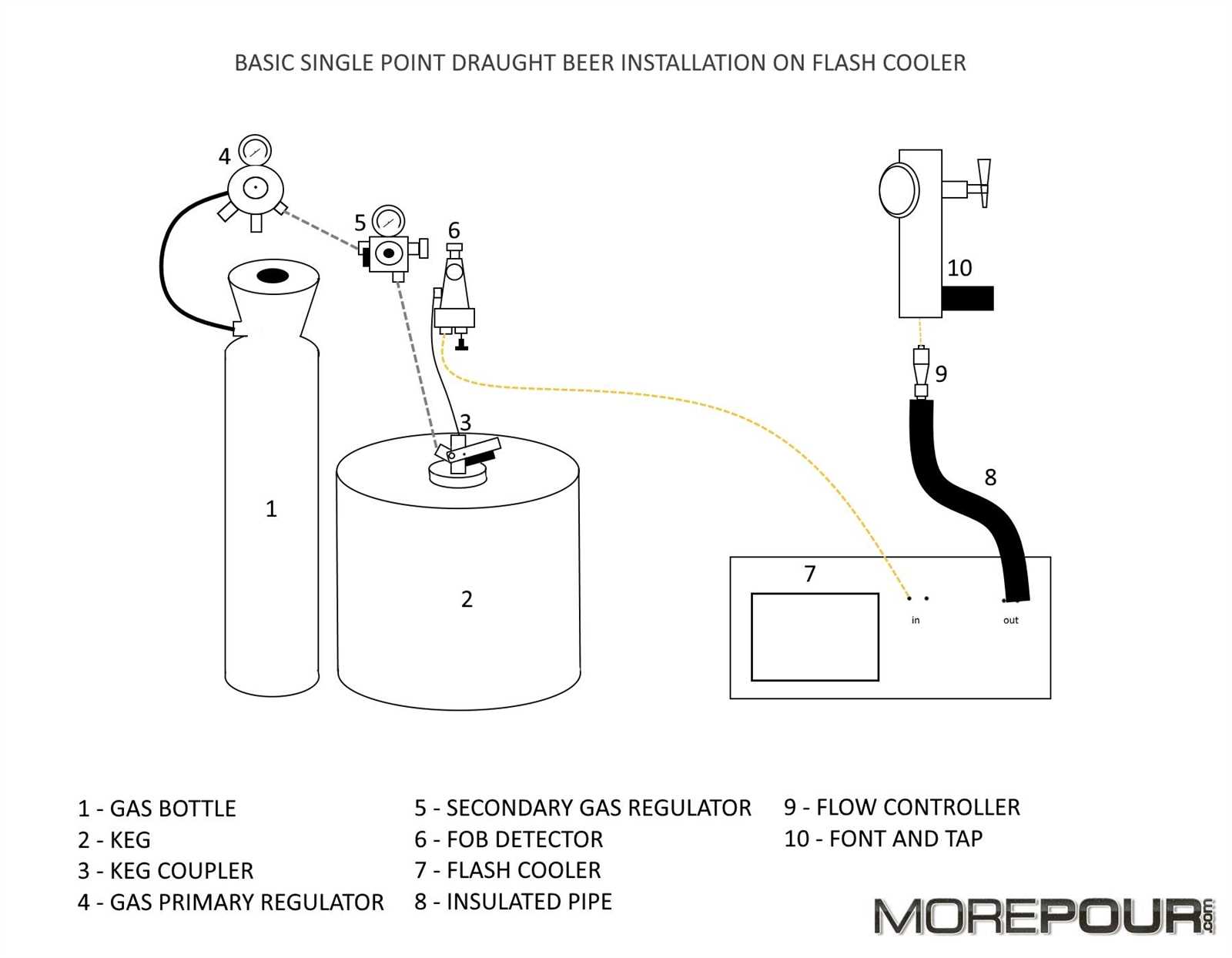

Working Mechanism of the Beer Line

The operation of the fluid delivery system relies on a carefully orchestrated process that ensures the efficient flow of liquid from a storage container to the serving outlet. Understanding this mechanism is crucial for maintaining optimal performance and quality.

Key components involved in this system include:

- Storage Reservoir: The initial point where the beverage is kept under pressure, ensuring freshness and carbonation.

- Connecting Tubing: A series of flexible or rigid conduits that transport the liquid to the dispensing mechanism.

- Pressure Regulator: A device that maintains a consistent pressure level within the system to facilitate smooth flow.

- Faucet Mechanism: The interface through which the beverage is dispensed, allowing for controlled pouring.

The process begins with the pressurization of the storage reservoir, which propels the liquid through the connecting tubing. As the user engages the dispensing mechanism, the pressure is released, allowing the beverage to flow out in a controlled manner. This entire cycle ensures that the liquid maintains its desired characteristics, providing an enjoyable experience.

Regular maintenance of these components is essential for optimal operation. Issues such as leaks, blockages, or pressure inconsistencies can adversely affect the performance of the entire system. Thus, routine inspections and timely repairs are necessary to ensure continued efficiency.

Significance of the CO2 Regulator

The CO2 regulator plays a vital role in maintaining the quality and consistency of carbonated beverages. By controlling the pressure of the gas, it ensures optimal dispensing and prevents excessive foaming or flatness, which can adversely affect the drinking experience.

Proper regulation of carbon dioxide is crucial for the preservation of flavors and aromas. An effective regulator allows for precise adjustments, catering to various types of beverages and their unique requirements. This adaptability enhances the overall enjoyment and satisfaction of the consumer.

Function Description Pressure Control Maintains consistent gas pressure for optimal dispensing. Flavor Preservation Ensures that carbonation levels enhance the beverage’s taste. Foam Management Prevents excessive foaming during serving. Versatility Accommodates different beverage types and serving conditions. Pressure Control in Beer Systems

Effective regulation of pressure is essential for maintaining optimal performance in beverage dispensing systems. Proper management ensures that the flow remains consistent and prevents undesirable characteristics in the served product.

Understanding the role of pressure: The pressure applied to the liquid influences its delivery speed and overall quality. Inadequate pressure can lead to foaming issues, while excessive pressure may cause rapid dispensing and negatively affect the flavor profile.

Key components of pressure management: Regulators, gauges, and relief valves are critical elements in controlling the system’s pressure. These devices work together to maintain a stable environment, allowing for precise adjustments based on the specific requirements of different beverages.

Implementing a reliable pressure control strategy enhances the overall experience for consumers, ensuring that each pour meets quality standards. Regular maintenance and monitoring of pressure levels are vital for achieving consistent results in beverage service.

Explaining the Purpose of the Drip Tray

The drip tray serves a vital function in managing spills and ensuring a clean environment around beverage dispensing units. It captures any excess liquid that may escape during pouring, helping to maintain hygiene and prevent unsightly messes. This component not only enhances user experience but also contributes to the longevity of surrounding equipment by reducing the risk of corrosion and damage.

Maintaining Cleanliness

One of the primary roles of the drip tray is to collect drips and spills, keeping the area tidy. Without this essential accessory, liquids could accumulate on surfaces, creating a breeding ground for bacteria and attracting pests. By containing these fluids, the tray promotes a safer and more pleasant atmosphere for both staff and patrons.

Protecting Equipment

In addition to cleanliness, the drip tray helps protect the infrastructure of beverage dispensing systems. Liquids that are left unchecked can cause significant wear and tear over time, leading to costly repairs or replacements. The drip tray acts as a barrier, catching any stray liquids before they can harm the underlying mechanisms.

Maintenance Tips for Beer Tap Parts

Proper upkeep of dispensing mechanisms is essential to ensure optimal performance and longevity. Regular attention can prevent issues that affect efficiency and the quality of service. Below are some practical suggestions for maintaining these components.

Regular Cleaning: Establish a routine for cleaning all surfaces that come into contact with beverages. This helps eliminate residue and prevents build-up that could alter taste and functionality.

Inspect Seals and Connections: Periodically check the integrity of seals and connections. Any wear or damage can lead to leaks and inefficiencies. Replace any compromised components immediately to maintain a tight system.

Lubrication: Apply appropriate lubricants to moving elements to ensure smooth operation. Avoid over-lubrication, as excess can attract dirt and cause malfunction.

Temperature Control: Monitor the temperature settings of your storage units. Keeping beverages at optimal temperatures prevents spoilage and enhances user experience.

Professional Servicing: Schedule regular professional inspections to address any potential issues that may not be visible during routine checks. Trained technicians can provide insights and preventative measures that can save time and costs in the long run.

Choosing the Right Beer Dispensing Equipment

Selecting the appropriate apparatus for serving beverages is crucial for ensuring quality and efficiency. The right setup not only enhances the experience for consumers but also streamlines the pouring process, maintaining the desired temperature and flavor profile of the drink. Understanding the different options available can greatly influence the overall success of your establishment.

When evaluating dispensing equipment, consider the following factors:

- Type of Beverage: Determine if you will serve various styles or stick to one particular kind, as this affects the equipment needed.

- Volume Requirements: Assess the expected demand to select machinery that can handle peak times without compromising quality.

- Space Considerations: Ensure that the selected setup fits well within your available area, allowing for both functionality and accessibility.

- Temperature Control: Look for systems that maintain optimal serving conditions to preserve the integrity of the drink.

Additionally, investing in quality components will lead to better performance and longevity of the equipment:

- Research reputable manufacturers known for durability and reliability.

- Consider the ease of maintenance and availability of replacement parts.

- Evaluate features that enhance user experience, such as adjustable pressure and quick-connect fittings.

Ultimately, a well-thought-out choice in dispensing apparatus will enhance customer satisfaction and contribute to the overall success of your beverage-serving operation.