Maintaining a device that handles tough cleaning tasks often requires a good grasp of the inner mechanisms that make it work efficiently. Knowing how each element contributes to the whole setup ensures smooth operation and helps in identifying potential issues before they become major problems. This section aims to shed light on the various elements involved in such machines, providing insights into their roles and how they fit into the overall system.

Each component plays a unique role in ensuring that the cleaning process is both effective and reliable. From systems that manage water flow to those that control power distribution, understanding these elements can make a significant difference in maintaining and troubleshooting. This knowledge not only helps in regular upkeep but also in selecting suitable replacements or upgrades when needed.

By breaking down the setup into its core elements, we aim to simplify what might initially seem complex. Learning about the function of each part will empower you to perform minor fixes and make more

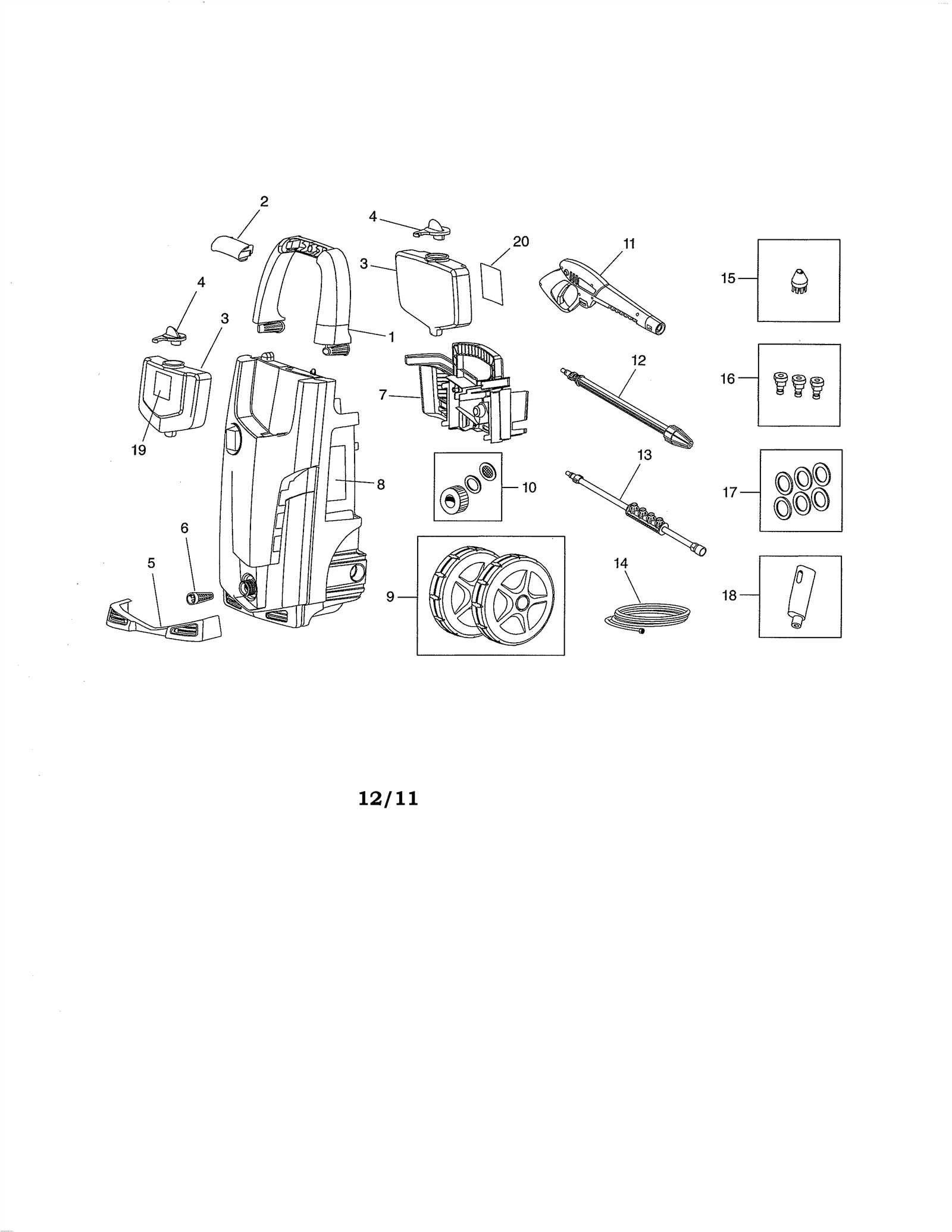

Overview of Pressure Washer Components

This section provides insight into the various elements that come together to make these cleaning machines highly effective. Each part has a specific role, contributing to the overall functionality and ensuring that the system operates smoothly and efficiently.

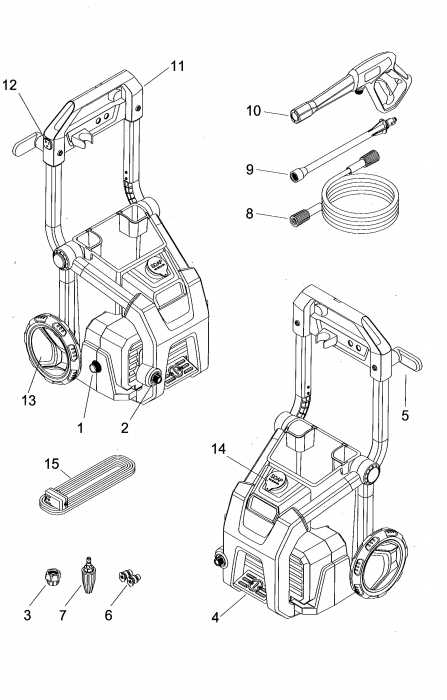

Main Structural Elements

The core structure includes a motor-driven unit that powers the mechanism, along with a sturdy framework designed to hold the entire assembly together. Coupled with these are the nozzles, which can be adjusted for different cleaning tasks, and hoses that connect to the water source, channeling liquid through the system.

Fluid Management and Control

Effective control over water flow is crucial for optimal performance. The setup typically includes a set of valves that regulate flow and pressure, ensuring that the right amount of force is delivered for various surfaces. An onboard control panel or trigger allows the user to fine-tune the output as needed.

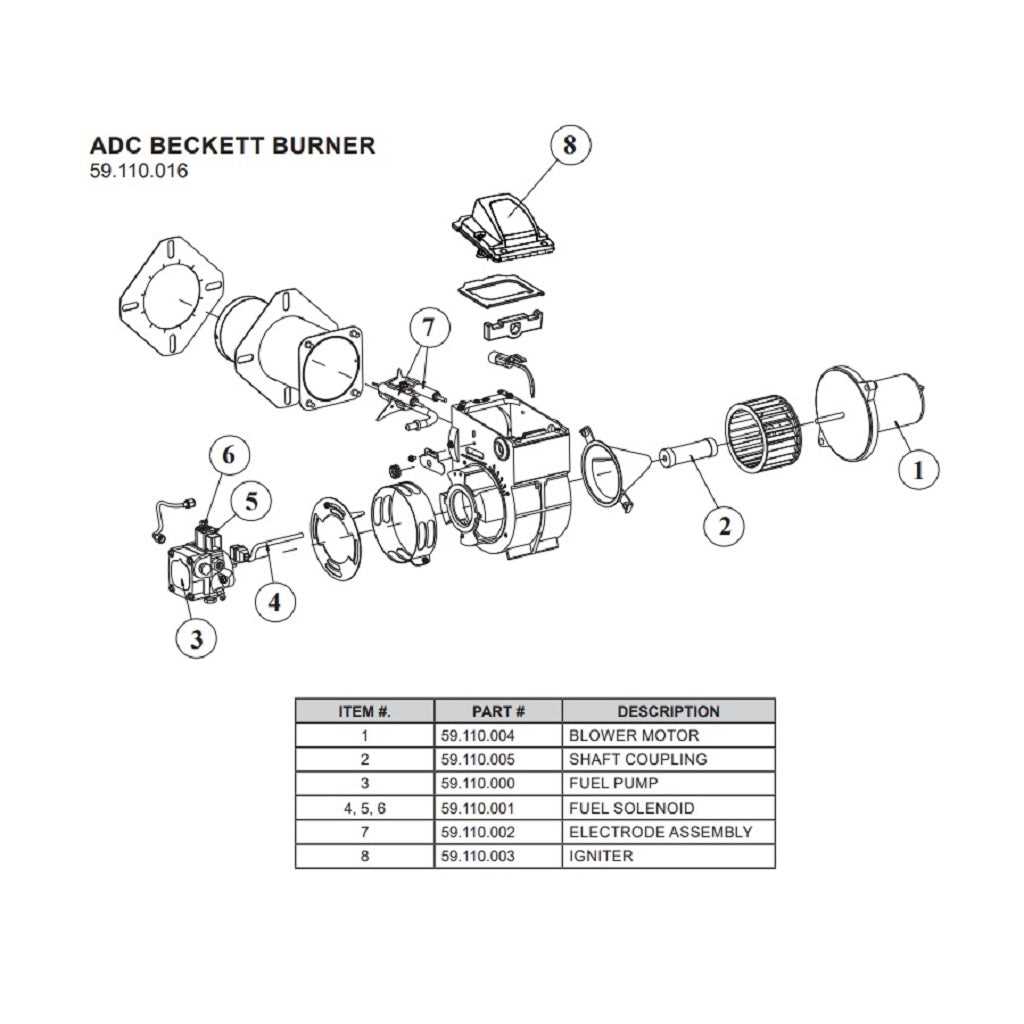

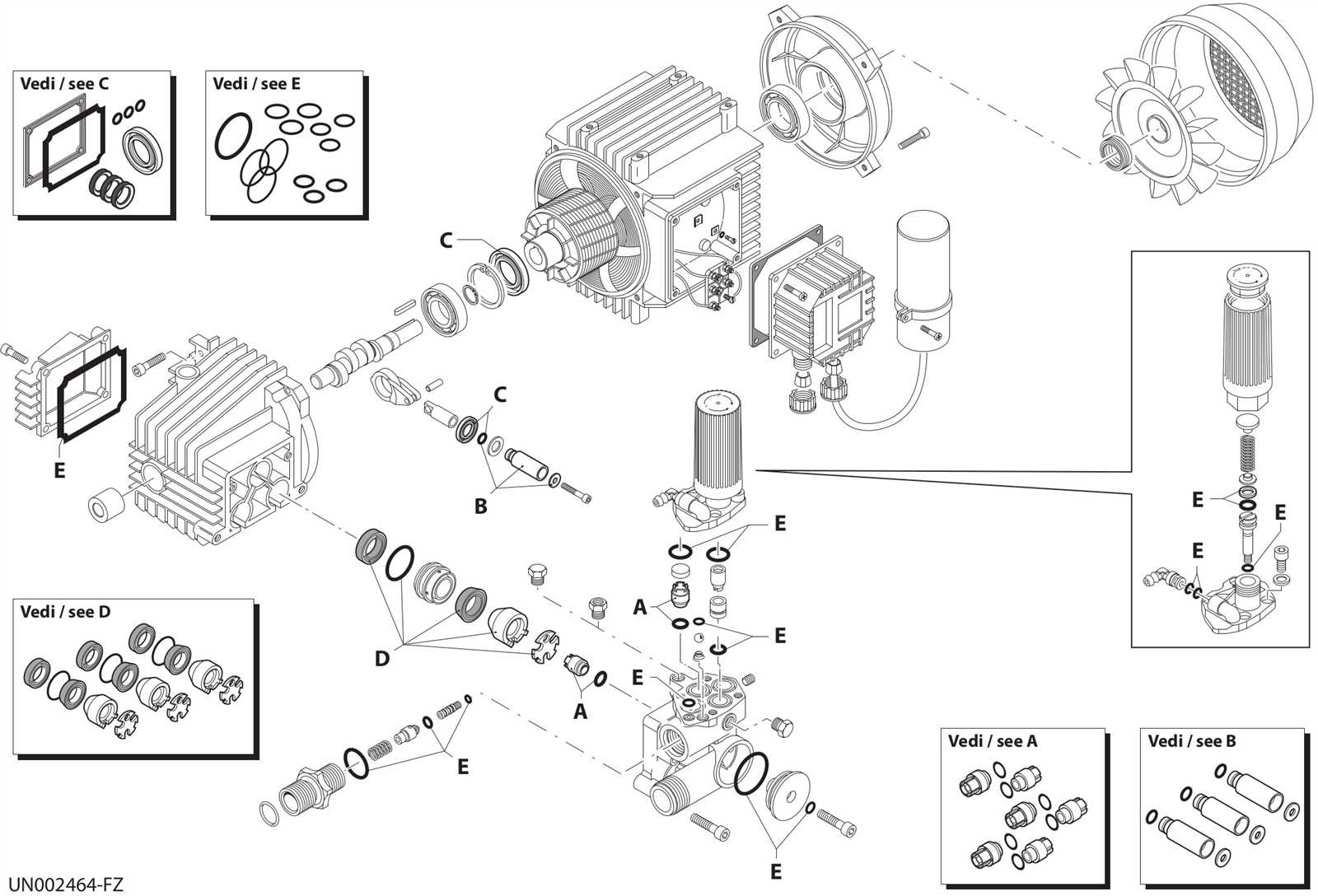

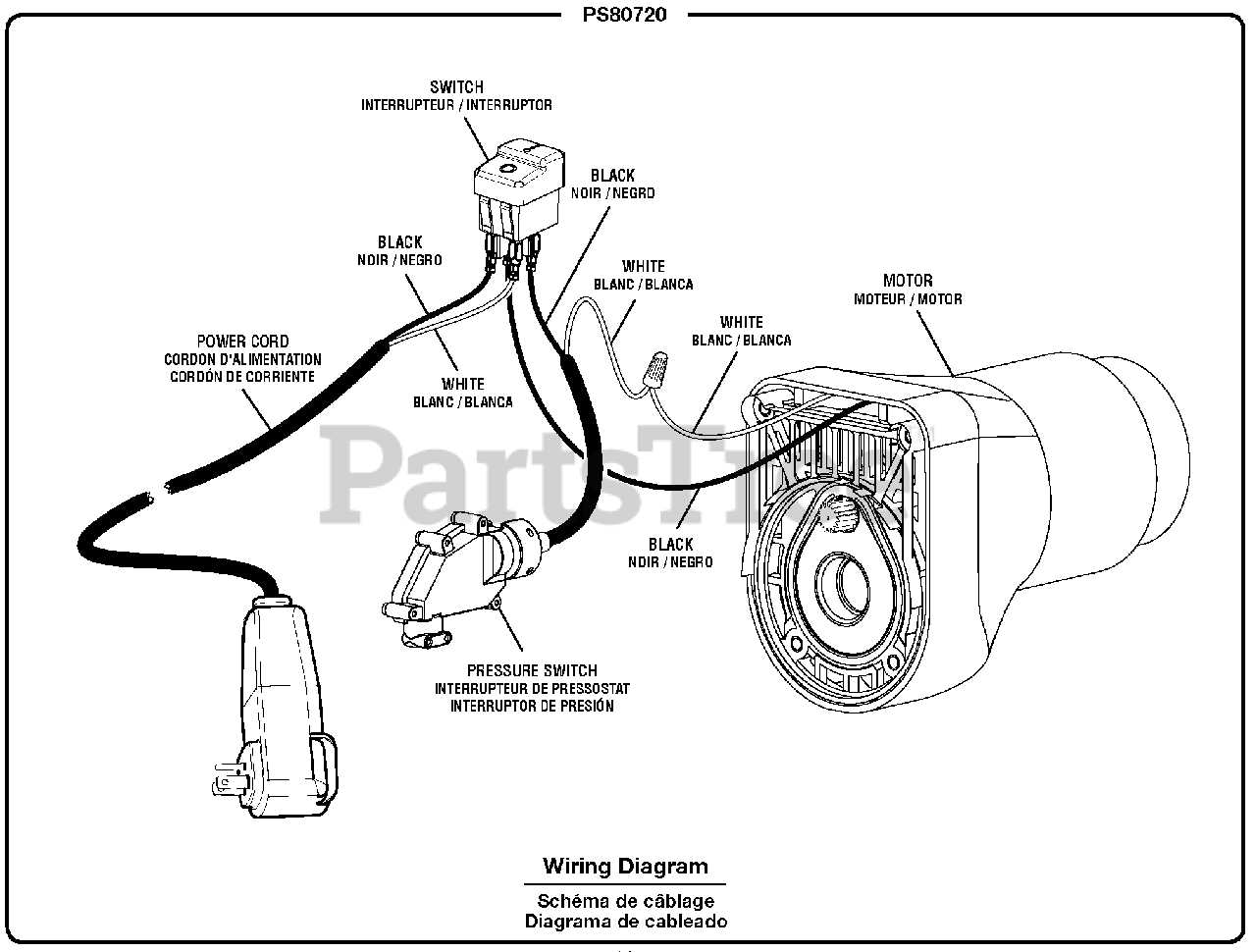

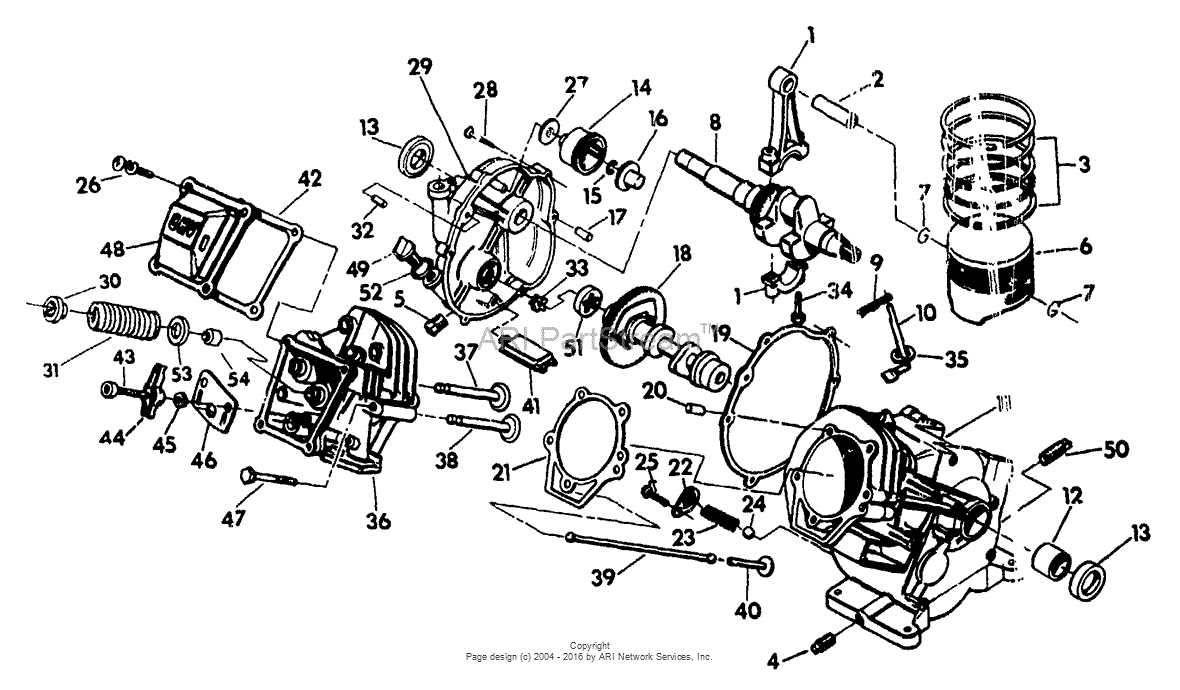

Understanding the Motor Mechanism

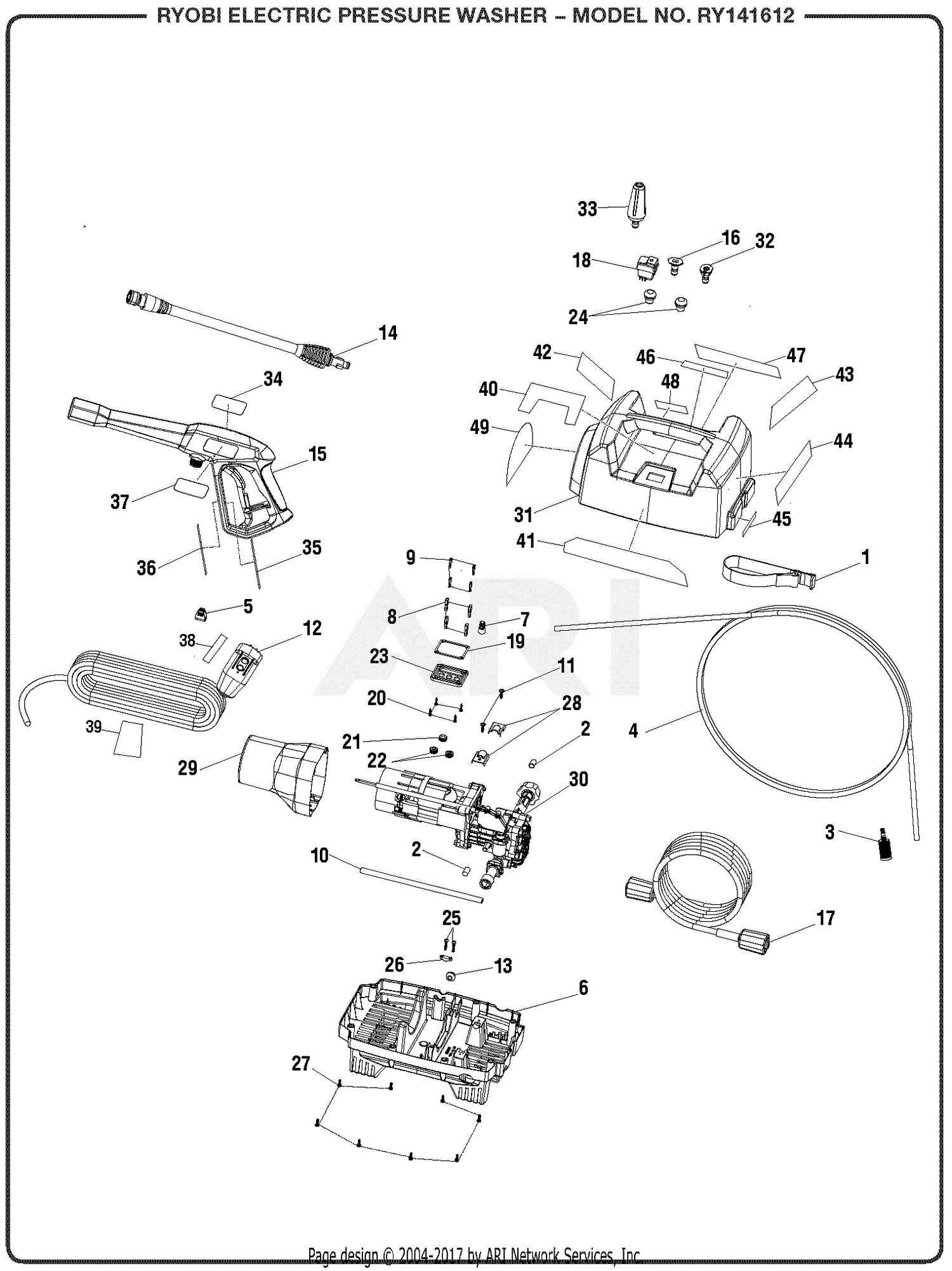

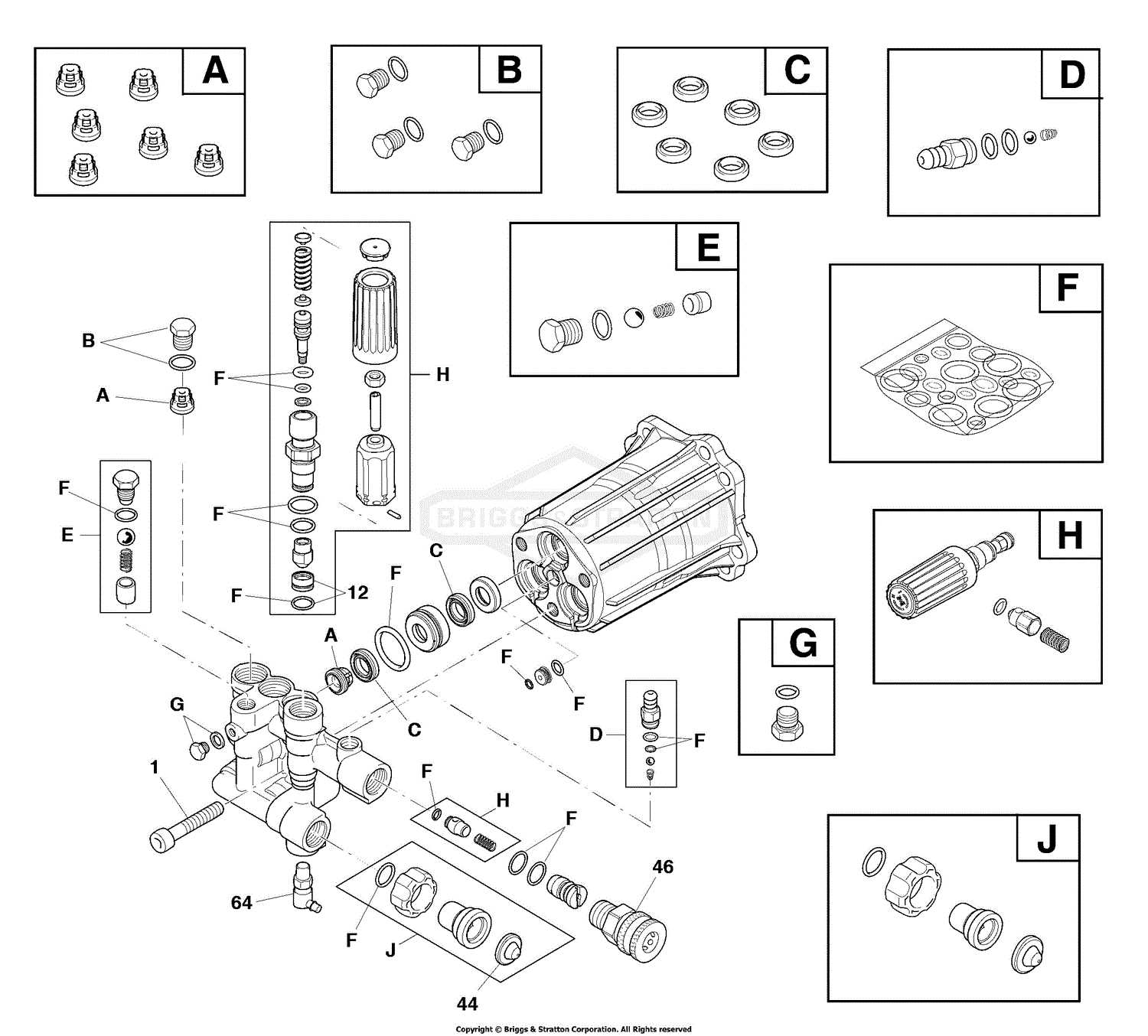

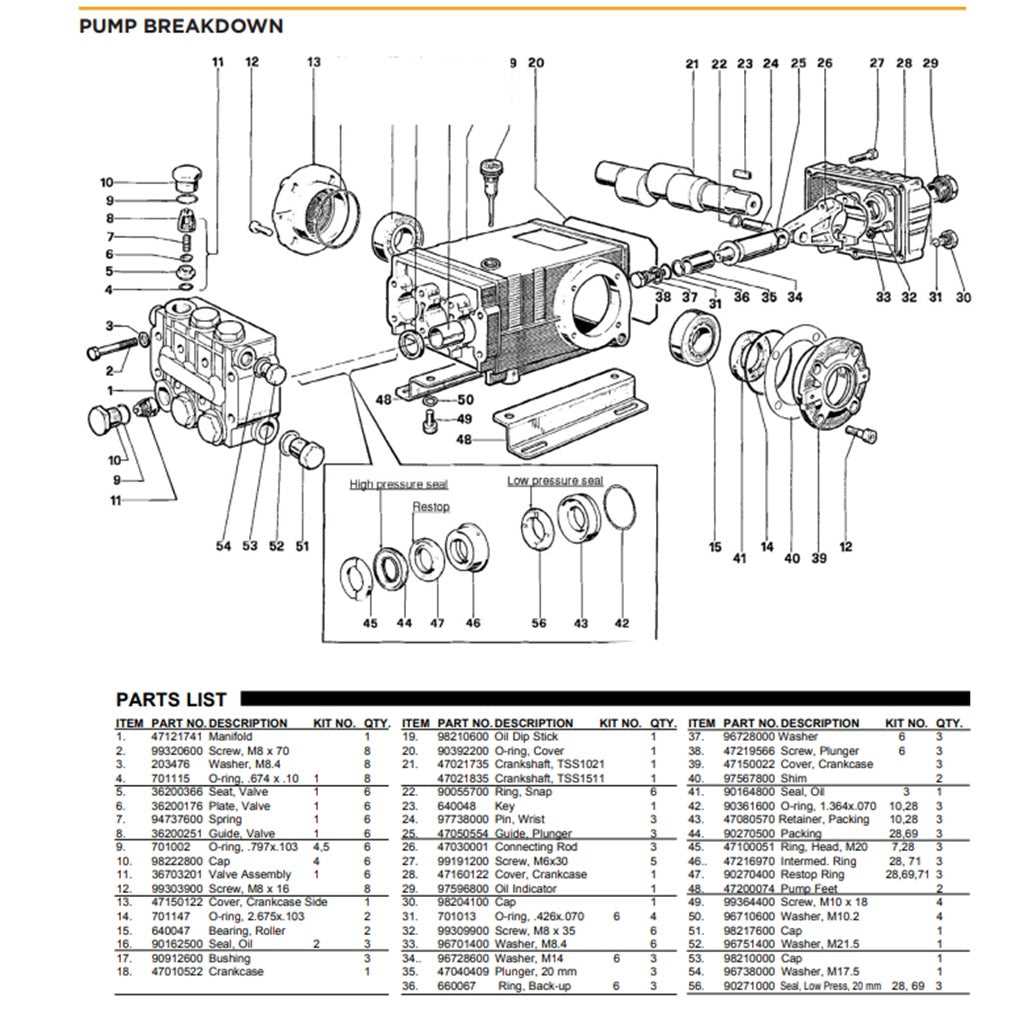

The core of this cleaning device lies in its dynamic drive system. This component is responsible for converting energy into rotational force, enabling the unit to generate sufficient output for various cleaning applications. The design ensures a smooth transition between power sources and the rotating elements, allowing the system to maintain consistent efficiency during operation. Key Features of the Drive System The drive unit typically includes a combination of internal rotors and a casing that houses various gears and bearings. The design of these elements ensures minimal friction and heat generation, thus extending the lifespan of the system. Additionally, many modern systems include thermal safeguards, which automatically adjust to prevent overheating, ensuring stable performance even under continuous use. Maintenance Considerations Regular inspection and lubrication of the drive unit are essential to prevent wear and tear. By keeping the internal components clean and well-lub Exploring the Pump AssemblyThe central mechanism plays a crucial role in converting flow into a more intense stream. It is designed to handle the entire process of taking in water, adjusting its force, and releasing it through the system. This component is essential for ensuring the correct distribution of liquid, providing stability and efficiency during operation. The assembly typically consists of several interconnected parts, including valves, seals, and a motorized unit that drives the flow. These elements work together seamlessly to regulate the movement, ensuring consistent output. The smooth function of this system depends heavily on the condition and alignment of its internal pieces. Maintaining this core part is key to ensuring a longer lifespan and optimal function. Regular inspection and replacement of worn elements, such as seals and valves, can prevent leaks and maintain steady performance. Understanding the internal workings of this assembly aids in troubleshooting issues and maximizing the effectiveness of the entire setup. High-Pressure Hose Functionality

The flexible tubing serves as a crucial component in delivering water to the targeted areas, ensuring efficient flow and optimal cleaning results. Its design is tailored to handle significant force, enabling the swift transfer of liquids without any compromise in performance. Key Features of the TubingThe hose is built with durability in mind, using materials that can withstand high levels of force and abrasion. It often includes a reinforced layer, which provides additional strength to prevent ruptures or leaks during intense use. This construction allows it to maintain a consistent flow rate, contributing to the overall effectiveness of the system. Comparison of Various Types

Common Issues with Parts and FixesUnderstanding the typical challenges that can arise with various components of cleaning equipment is essential for effective maintenance. Many users encounter similar problems, often resulting from wear and tear or improper handling. Addressing these issues promptly can enhance the longevity and efficiency of the machinery. Leaks and DripsLeaks are among the most frequent complaints associated with cleaning devices. These can occur due to worn seals, damaged hoses, or loose connections. Regular inspections are vital to detect any signs of moisture accumulation. To rectify this, ensure all fittings are tightened and replace any faulty gaskets. For hose leaks, consider using high-quality repair tape or replacing the hose entirely. Motor Malfunctions

Another common dilemma involves motor performance issues, such as stalling or failure to start. This can stem from electrical faults or overheating. Always check the power supply and ensure the device is not overloaded. For persistent issues, it may be necessary to consult the user manual for troubleshooting steps or seek professional repair services to diagnose underlying electrical problems. |

|---|