Maintaining a lush and vibrant garden requires the right tools, and understanding the components of your equipment is essential for optimal performance. Familiarity with each part allows for effective usage and ensures longevity, ultimately enhancing your gardening experience.

In this section, we will explore the intricate details of a popular device designed for efficient liquid application. By examining the various elements involved, you can identify potential issues and ensure your equipment operates at its best.

Detailed knowledge of these components not only aids in troubleshooting but also empowers you to undertake necessary repairs. Whether you are an experienced gardener or a novice, this guide will delve into the essential features that contribute to seamless operation.

Understanding Roundup Sprayer Components

Comprehending the various elements of a liquid application tool is essential for effective usage and maintenance. Each component plays a vital role in ensuring optimal performance and longevity, enabling users to achieve desired results with ease.

| Component | Function |

|---|---|

| Tank | Holds the solution for distribution. |

| Handle | Allows for maneuverability and control. |

| Nozzle | Regulates the flow and pattern of the liquid. |

| Pump | Creates pressure to propel the liquid. |

| Hose | Conveys the solution from the tank to the nozzle. |

Overview of the 2 Gallon Sprayer

This compact application tool is designed for efficient dispensing of liquids, making it an essential asset for various gardening and landscaping tasks. With its user-friendly design and portability, it facilitates the easy handling of herbicides, pesticides, and fertilizers, ensuring that users can effectively manage their outdoor spaces.

The unit features a sturdy construction, equipped with a comfortable handle and adjustable nozzle for precise targeting. Its lightweight nature allows for extended use without fatigue, making it ideal for both amateur and professional gardeners. Additionally, the reservoir capacity strikes a balance between convenience and functionality, allowing for multiple applications without frequent refills.

Maintenance is straightforward, with accessible components that simplify cleaning and repairs. Understanding the internal mechanisms can enhance the longevity of the device, ensuring it remains a reliable partner in maintaining healthy plants and gardens. This versatility makes it a valuable tool for anyone looking to achieve effective results in their outdoor endeavors.

Key Parts of the Sprayer

Understanding the essential components of a gardening tool can greatly enhance its effectiveness and longevity. Each section plays a vital role in ensuring optimal performance and user satisfaction.

- Tank: The main reservoir for holding the liquid solution.

- Pump: Responsible for creating the pressure needed to distribute the liquid.

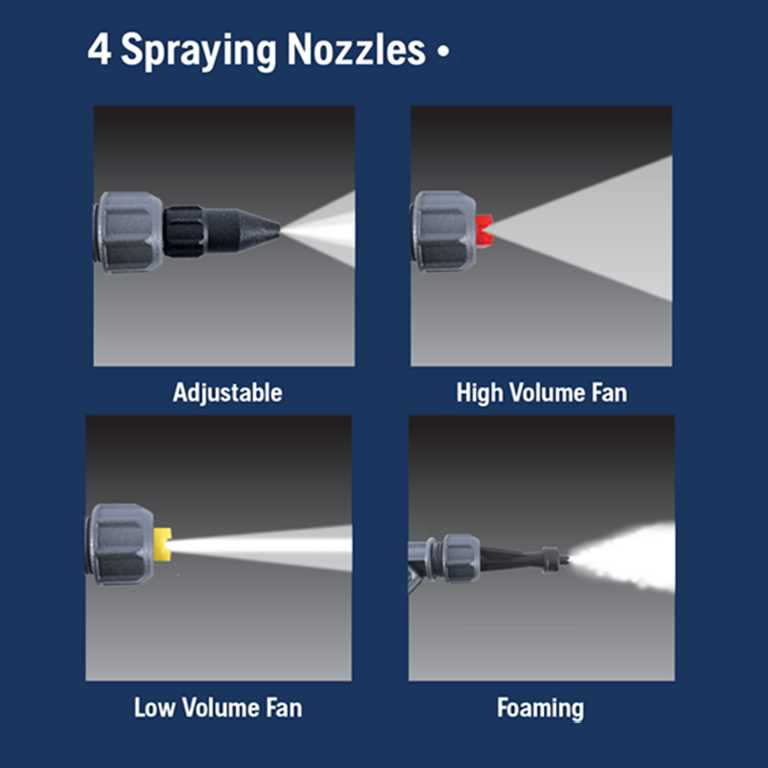

- Nozzle: The outlet that controls the flow and pattern of the spray.

- Hose: Connects the tank to the nozzle, allowing fluid movement.

- Handle: Provides control and ease of use during application.

Each component contributes significantly to the overall functionality and effectiveness of the equipment.

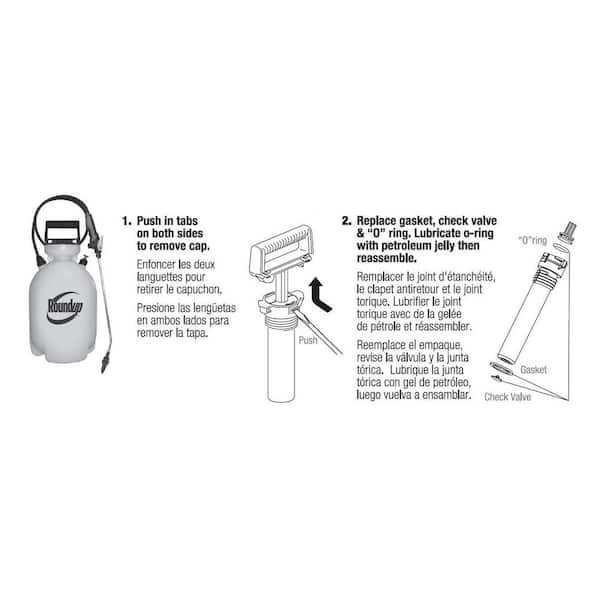

How to Read the Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. It allows users to identify each section and comprehend how various elements interact within the entire system.

Identifying Key Elements

- Look for labels that indicate specific components.

- Pay attention to numbers or codes that correspond to a list.

- Note any arrows or lines that illustrate connections or flow.

Using the Legend

- Find the legend or key that explains symbols used.

- Cross-reference with the labeled items for clarity.

- Ensure understanding of each symbol’s meaning to avoid confusion.

Common Issues with Roundup Sprayers

Users often encounter a range of problems when operating these devices, which can hinder their effectiveness and efficiency. Understanding these common challenges can help in troubleshooting and ensuring optimal performance. Regular maintenance and awareness of potential issues can significantly improve the user experience.

Clogs and Blockages

One of the most frequent complications is clogging in the delivery system. Residue buildup in nozzles or hoses can prevent the fluid from flowing properly. To mitigate this issue, it’s crucial to regularly clean all components and use the appropriate filters to catch debris before it enters the system.

Pressure Problems

Another common issue involves inconsistent pressure, which can lead to uneven application. This might be caused by a faulty pump or leaks in the system. Checking seals and connections is essential to maintain the desired pressure levels. Additionally, ensuring that the device is filled to the recommended level can help prevent fluctuations during use.

Essential Maintenance Tips for Longevity

To ensure the extended lifespan and optimal performance of your equipment, consistent care and attention are paramount. Regular maintenance not only prevents potential issues but also enhances efficiency and reliability over time.

First, always clean the device after each use to remove any residual substances that could lead to corrosion or clogging. Pay special attention to all components, ensuring no debris remains. Second, inspect hoses and fittings periodically for wear and tear, replacing any damaged parts promptly to avoid leaks and malfunctions.

Additionally, lubricate moving parts regularly to minimize friction and wear. Following the manufacturer’s guidelines for fluid changes and seasonal check-ups can also make a significant difference in performance. Lastly, store your equipment in a dry, sheltered location to protect it from environmental factors that may accelerate deterioration.

Identifying Replacement Parts Easily

When it comes to maintaining your equipment, knowing how to recognize and source the necessary components is crucial for seamless operation. Having a clear understanding of each element allows for timely replacements, ensuring that your tools function optimally. This guide will assist you in navigating the various sections and components effectively.

Utilizing Reference Guides

One of the most efficient ways to identify specific elements is by consulting reference manuals or guides. These resources often include comprehensive lists and images, allowing you to match your equipment’s needs with the correct items. By familiarizing yourself with the terminology and layout, you can quickly pinpoint what you require.

Online Resources and Communities

The internet provides a wealth of information, including forums and websites dedicated to equipment maintenance. Engaging with online communities can yield valuable insights, as experienced users often share their knowledge about compatible components and troubleshooting techniques. Leveraging these platforms can save you time and enhance your understanding of what to look for.

Tools Needed for Sprayer Repairs

Repairing your equipment requires specific instruments to ensure efficiency and precision. Having the right tools at hand can make the repair process smoother and more effective, ultimately prolonging the life of your device.

Essential Tools

- Wrenches and Socket Sets

- Screwdrivers (Flathead and Phillips)

- Pliers (Needle Nose and Regular)

- Replacement Seals and Gaskets

- Cleaning Brushes

Additional Equipment

- Safety Goggles

- Gloves

- Workbench or Sturdy Surface

- Measuring Tools

Step-by-Step Repair Instructions

This section provides a comprehensive guide to effectively address common issues with your equipment. By following these detailed steps, you can ensure that your device operates smoothly and efficiently.

Preparation

- Gather necessary tools: screwdriver, wrench, replacement parts.

- Ensure safety by wearing gloves and protective eyewear.

- Work in a well-ventilated area to avoid inhaling fumes.

Repair Process

- Disconnect the device from any power source to ensure safety.

- Identify the specific area that requires attention.

- Carefully disassemble the components, keeping track of screws and small parts.

- Replace damaged components with new ones, ensuring a snug fit.

- Reassemble the device in the reverse order of disassembly.

- Test the functionality to confirm the repair was successful.

Upgrading Your Sprayer Experience

Enhancing your application tool can significantly improve efficiency and results in your gardening or landscaping projects. By integrating advanced features and reliable components, you can achieve a more seamless and effective operation. This guide will explore various enhancements that elevate the overall experience, ensuring that your tasks are completed with ease and precision.

Consider investing in ergonomic handles and adjustable nozzles, which offer comfort and flexibility during use. Upgraded tanks designed for optimal pressure retention can also enhance performance, allowing for a consistent flow of liquid without interruptions. Additionally, look into reinforced hoses that resist wear and tear, ensuring longevity and reliability over time.

Utilizing high-quality filters will prevent clogs and maintain the integrity of your mixtures, while innovative application techniques can help you save time and reduce waste. By adopting these improvements, you will ultimately transform the way you manage your outdoor projects, leading to better results and greater satisfaction.

Safety Precautions During Use

Ensuring safety while operating equipment is crucial for preventing accidents and ensuring effective use. Adhering to proper guidelines not only protects the user but also safeguards the environment and nearby individuals.

Before beginning any task, familiarize yourself with the operational manual and adhere to the recommended practices. Use protective gear to minimize exposure to chemicals and potential hazards. Proper maintenance of the equipment also plays a vital role in preventing malfunctions.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Wear gloves, goggles, and masks to protect against harmful substances. |

| Area Preparation | Clear the work area of obstacles and ensure proper ventilation. |

| Check Equipment | Inspect the device for leaks or damage before use. |

| Proper Handling | Follow the instructions for operation to avoid spills and mishaps. |

| Emergency Procedures | Know the steps to take in case of an accidental exposure or spillage. |

By following these safety measures, users can greatly reduce risks associated with equipment operation and ensure a safer working environment for everyone involved.

Benefits of Regular Maintenance

- Improved Efficiency: Regular checks can identify issues early, keeping your tools operating at peak performance.

- Increased Lifespan: Consistent maintenance reduces wear and tear, extending the life of your equipment.

- Cost Savings: Preventive care can minimize costly repairs or replacements down the road.

- Enhanced Safety: Regular inspections help detect potential hazards, ensuring safe operation.

- Better Performance: Well-maintained tools deliver superior results, enhancing your overall productivity.

Where to Find Parts Online

Finding the right components for your equipment can be a straightforward process with the right resources. Numerous online platforms specialize in providing these essential items, ensuring that you can quickly restore functionality to your tools.

- Manufacturer Websites: Visit the official site of the manufacturer for a comprehensive selection of genuine items.

- Specialty Retailers: Many online stores focus on gardening and maintenance supplies, offering a wide variety of options.

- E-commerce Platforms: Websites like Amazon and eBay feature a range of listings, including both new and used components.

- Local Hardware Stores: Some stores provide online shopping with options for local pickup, allowing for immediate access to necessary items.

- Forums and Community Groups: Engaging with online communities can lead to recommendations for reliable suppliers and hard-to-find components.

Utilizing these resources can streamline your search and help you acquire the necessary tools efficiently.