In the realm of agricultural machinery, comprehending the intricate arrangement of various components is essential for effective operation and maintenance. Such knowledge not only facilitates smoother functionality but also aids in troubleshooting issues that may arise during usage. Having a clear visual representation of these elements can significantly enhance the understanding of how different parts work together.

When examining the structural organization of machinery, one can appreciate the significance of each element in the overall system. By recognizing the role that every individual piece plays, operators can better anticipate potential malfunctions and ensure optimal performance. This insight is invaluable, particularly when seeking to streamline repairs and replacements.

Visual aids that illustrate the relationships between components serve as practical tools for both novice users and experienced professionals alike. They provide a comprehensive overview, making it easier to identify specific sections that require attention or improvement. Ultimately, mastering the layout of machinery components contributes to greater efficiency and longevity in agricultural operations.

Understanding the Hesston 1010 Design

The design of this agricultural machine emphasizes functionality and efficiency, ensuring optimal performance during operation. Its structure is engineered to withstand demanding tasks, combining innovative technology with practical elements that enhance usability. This overview delves into the various features that define its robust framework, providing insights into its construction and operational benefits.

Key Features of the Machine

This equipment is equipped with several distinctive characteristics that contribute to its effectiveness. These features not only improve productivity but also facilitate ease of maintenance and operation. Understanding these elements is crucial for anyone looking to utilize this model effectively.

| Feature | Description |

|---|---|

| Durability | Constructed from high-quality materials to endure harsh conditions. |

| Efficiency | Engineered for maximum output with minimal energy consumption. |

| Versatility | Designed to perform a variety of tasks in different agricultural settings. |

Operational Insights

Understanding how this machine operates can significantly impact its effectiveness in the field. Knowledge of its mechanics, coupled with familiarity with its features, empowers users to maximize its potential and troubleshoot any issues that may arise. Proper training and awareness can lead to enhanced productivity and longevity of the equipment.

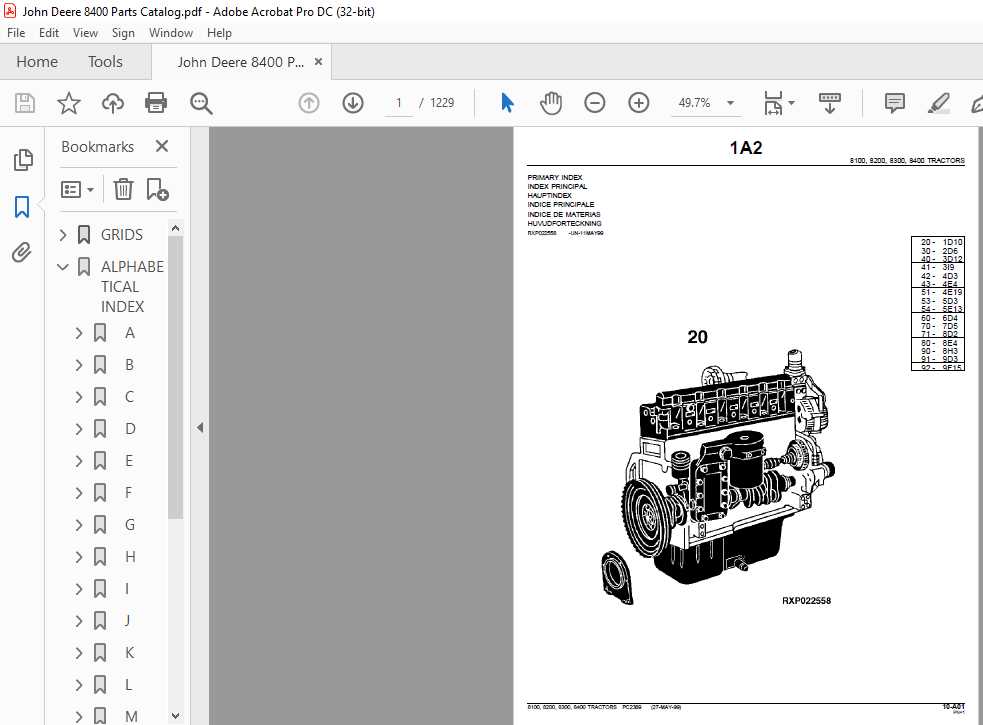

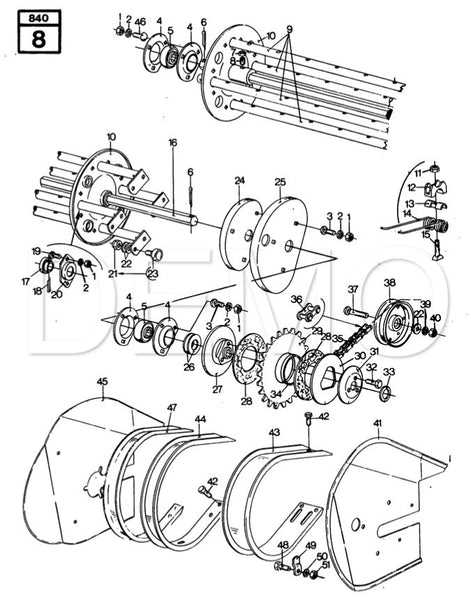

Overview of Hesston 1010 Components

This section provides a comprehensive examination of the various elements that comprise a specific agricultural machine. Understanding the individual components and their functions is essential for maintaining optimal performance and ensuring effective operation. By familiarizing oneself with these parts, users can make informed decisions regarding repairs, replacements, and upgrades.

Main Functional Elements

The core functionalities of the equipment rely on a harmonious interplay between multiple components. Each element plays a vital role in achieving the desired outcomes, and their proper maintenance can significantly impact efficiency and longevity.

Below is a summary of the key specifications for critical elements of the machine:

| Component Name | Description | Function |

|---|---|---|

| Drive System | Mechanism that transmits power from the engine. | Facilitates movement and operation of the equipment. |

| Cutting Mechanism | Assembly designed for harvesting. | Ensures precise cutting of crops. |

| Conveyor Belt | System for transporting harvested material. | Enhances the efficiency of material movement. |

| Control Panel | User interface for operating the machine. | Allows for adjustments and monitoring of functions. |

Importance of Accurate Parts Identification

Ensuring the correct identification of components is crucial for the efficient operation and maintenance of machinery. When every element is precisely recognized, it enhances the overall functionality and reduces the risk of malfunctions. This accuracy not only promotes seamless assembly but also minimizes the potential for costly repairs and downtime.

Enhanced Performance and Longevity

Recognizing the exact specifications of each element contributes to optimal performance and durability. When the right components are utilized, the system operates smoothly, leading to extended lifespan and reliability. This proactive approach ultimately saves time and resources, allowing for uninterrupted workflows.

Cost-Effectiveness and Resource Management

Proper identification of components also plays a vital role in managing budgets and resources. By ensuring that the correct elements are acquired and utilized, unnecessary expenses can be avoided. This efficiency translates into better financial planning and resource allocation, which is essential for any operation aiming for sustainability and growth.

Common Issues with Hesston 1010 Parts

When it comes to agricultural machinery, certain components can frequently present challenges that affect overall performance. Understanding these common issues can aid in efficient troubleshooting and maintenance, ultimately enhancing the longevity and functionality of the equipment.

Wear and Tear of Components

Over time, various elements within the machinery can experience significant wear and tear. This deterioration often leads to reduced efficiency and can necessitate replacements or repairs. Regular inspections are essential to identify these problems early, ensuring that the equipment operates smoothly.

Compatibility Problems

Another frequent issue involves compatibility between different elements. Using components that do not match or are not designed for the specific machinery can result in malfunctions. It is crucial to verify that all parts are appropriate for the specific model to prevent operational failures.

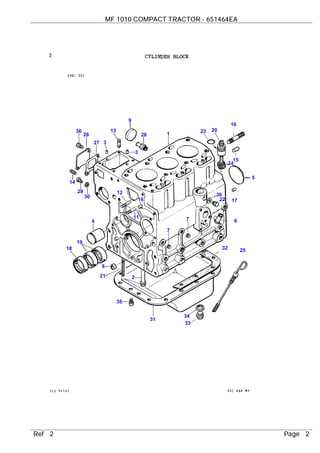

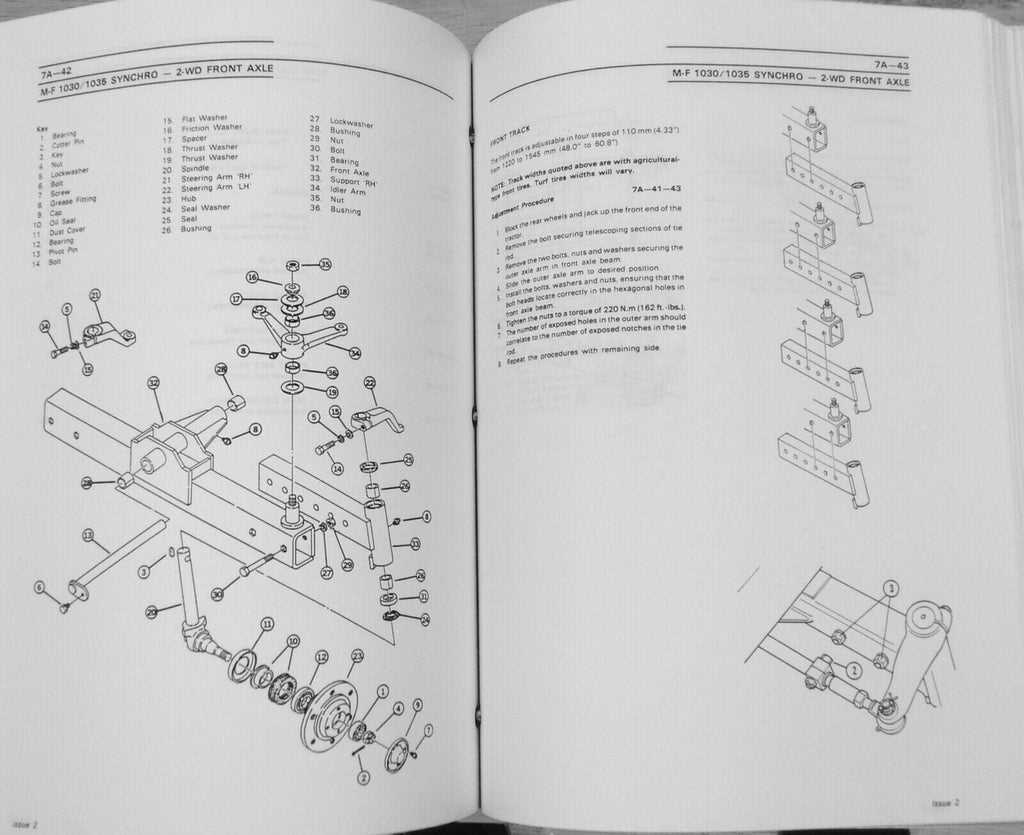

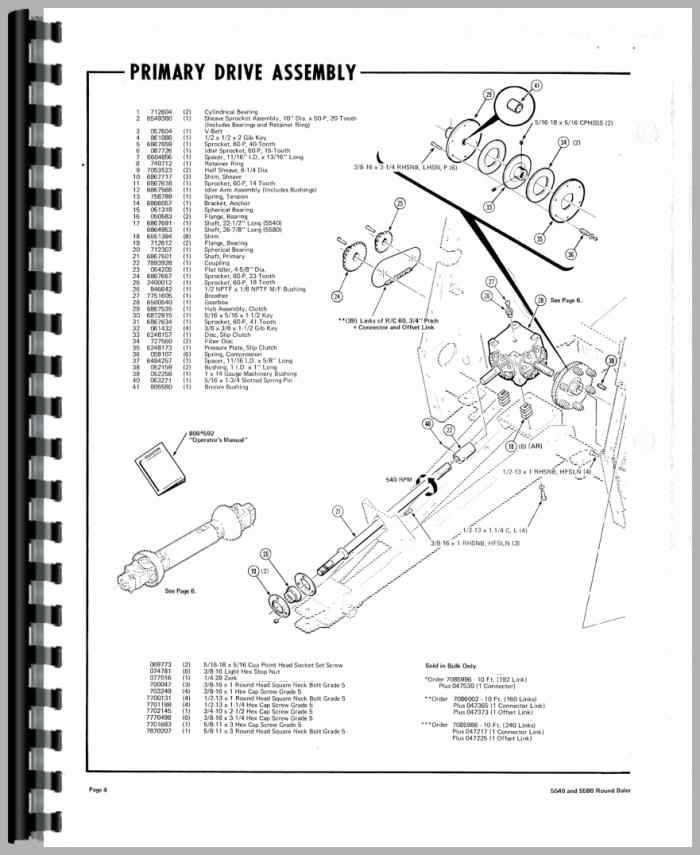

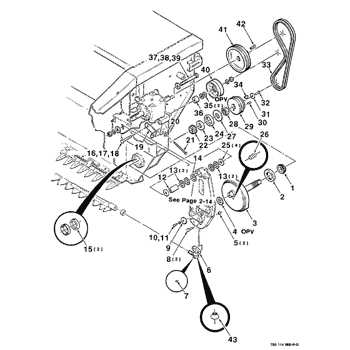

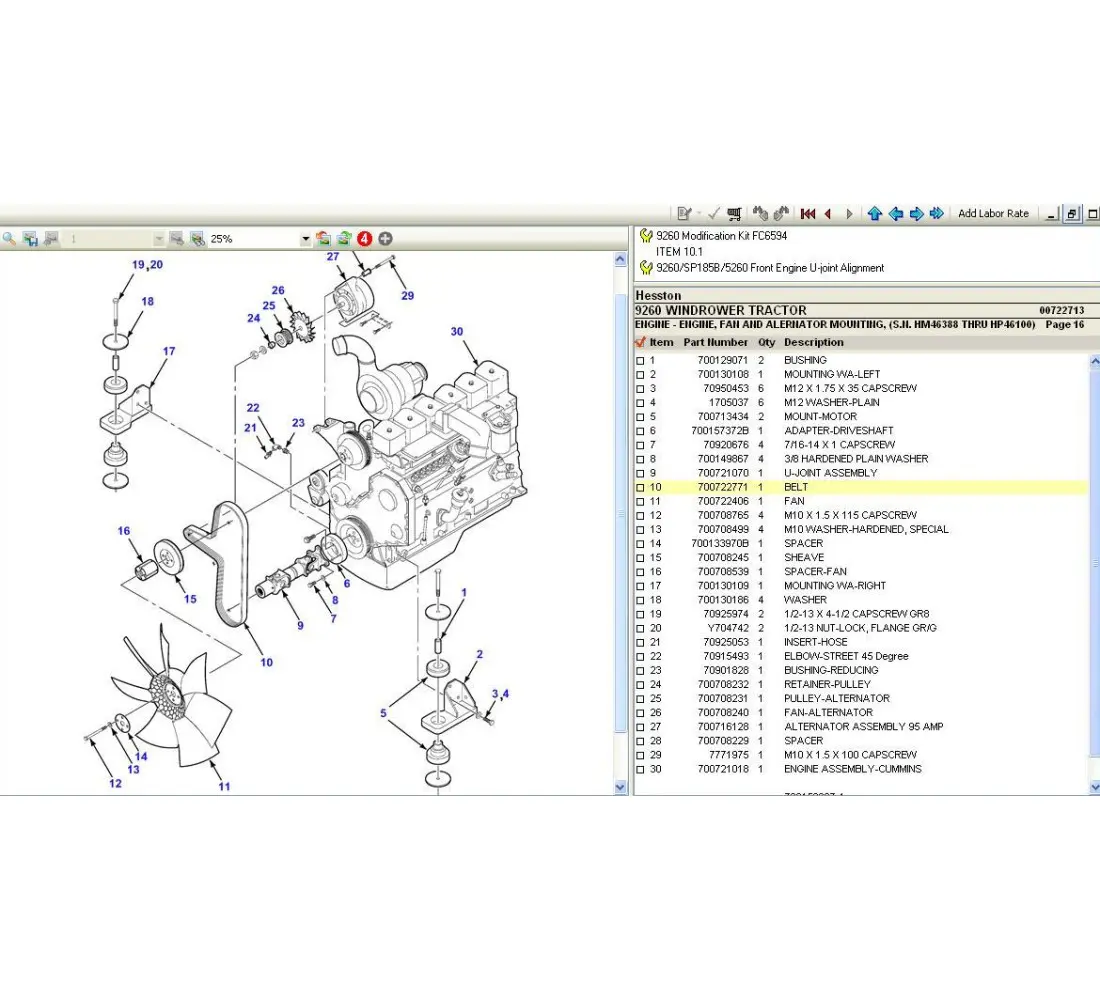

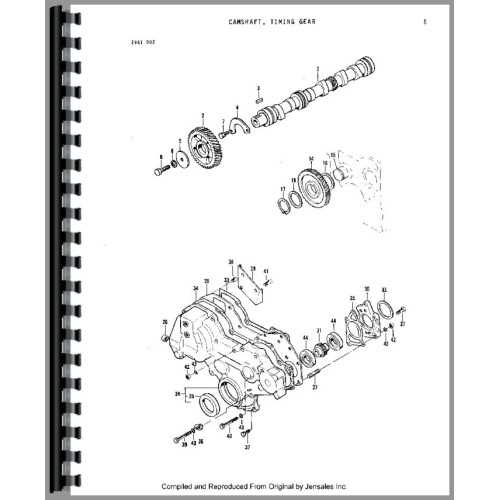

How to Read a Parts Diagram

Understanding an assembly illustration is essential for efficient maintenance and repair tasks. This visual representation simplifies complex systems, enabling users to identify individual components and their relationships within the overall structure. By mastering this skill, you can enhance your troubleshooting abilities and ensure that you have the right elements for repairs.

Initially, familiarize yourself with the layout. Most illustrations are organized in a way that mirrors the physical configuration of the machine, often displaying the components in a logical sequence. Numbers or labels associated with each part guide you to additional information, such as specifications and compatibility details. It’s important to correlate these identifiers with the accompanying documentation for precise understanding.

Additionally, pay attention to groupings and connections between items. Components often share common features or functions, which can help in recognizing their roles in the assembly. Take note of any annotations or notes provided, as they may highlight crucial installation tips or specific requirements for certain elements.

Finally, practice is key. The more you engage with these visuals, the more intuitive they will become. Over time, you’ll develop an eye for quickly locating and understanding the necessary components, making your maintenance tasks more efficient and effective.

Essential Tools for Maintenance

Proper upkeep of machinery requires a set of fundamental instruments that ensure efficiency and longevity. These tools facilitate routine inspections, repairs, and adjustments, ultimately enhancing the performance of equipment. By having the right resources at hand, operators can address issues promptly, thereby minimizing downtime and extending the life of their machinery.

Key Instruments

Several essential tools are indispensable for maintaining machinery effectively. Below is a summary of these critical resources and their functions:

| Tool | Function |

|---|---|

| Wrenches | Used for tightening or loosening nuts and bolts. |

| Screwdrivers | Essential for securing and removing screws. |

| Socket Set | Facilitates the loosening or tightening of fasteners in tight spaces. |

| Pliers | Useful for gripping, bending, and cutting materials. |

| Multimeter | Measures electrical properties such as voltage and current. |

Maintenance Essentials

In addition to the basic tools, certain items are crucial for maintaining optimal functionality. These may include lubricants, cleaning agents, and diagnostic equipment. Regular use of these resources not only aids in the performance of the machinery but also prevents potential failures. Investing in high-quality tools can yield significant benefits in the long run, ensuring that the machinery operates smoothly.

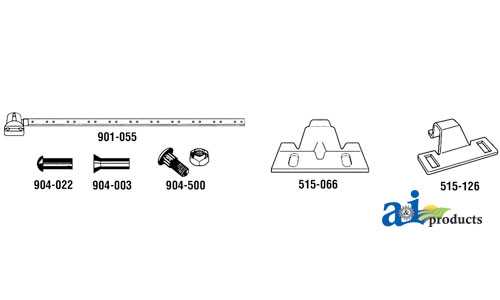

Replacement Parts: Where to Find Them

Finding suitable components for machinery can be a challenging task, but knowing where to look can simplify the process significantly. Whether you need to replace a worn-out item or upgrade a specific feature, there are various resources available to help you locate the necessary components efficiently.

Authorized Dealers and Distributors

One of the most reliable ways to acquire components is through authorized dealers and distributors. These businesses specialize in offering genuine replacements and can provide expert advice on compatibility and installation. It’s essential to ensure that you are dealing with reputable sources to avoid counterfeit items.

Online Marketplaces and Auction Sites

The internet provides a wealth of options for sourcing components. Various online marketplaces and auction sites host listings for new and used items, often at competitive prices. Always check the seller’s ratings and reviews to ensure a positive purchasing experience.

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers offering genuine components and expert guidance. |

| Online Marketplaces | Websites featuring a wide range of items from various sellers, including used options. |

| Local Repair Shops | Businesses specializing in machinery repairs often have access to components. |

| Manufacturer’s Website | The official website may offer direct sales or links to authorized dealers. |

Hesston 1010 Repair Techniques

Effective maintenance and restoration of agricultural machinery are crucial for ensuring optimal performance and longevity. Understanding various methods and practices can significantly enhance the efficiency of equipment repairs. This section explores essential techniques that can be employed during the troubleshooting and fixing processes.

Routine Maintenance is fundamental to keeping machinery in peak condition. Regular inspections allow operators to identify wear and tear before it escalates into more significant issues. Simple tasks such as lubricating moving parts, checking fluid levels, and tightening bolts can prevent breakdowns and prolong the lifespan of the equipment.

Component Replacement is often necessary when parts become damaged or worn out. Familiarity with disassembly and reassembly procedures is vital. Utilizing manufacturer guidelines can assist in accurately replacing components without causing additional harm to the system. Always ensure that replacements are compatible and of high quality to maintain performance standards.

Diagnostic Techniques play a significant role in identifying the root causes of malfunctions. Utilizing tools such as multimeters, pressure gauges, and diagnostic software can provide insights into the health of various systems. Systematic troubleshooting helps pinpoint issues effectively, allowing for targeted repairs rather than guesswork.

Upgrades and Modifications can enhance functionality and efficiency. Evaluating the current capabilities and considering improvements can lead to better performance. When making upgrades, it’s essential to consult with experts or refer to technical resources to ensure compatibility and avoid complications.

Safety Practices should always be prioritized during repair activities. Ensuring that the equipment is powered down and properly secured can prevent accidents. Using personal protective equipment (PPE) and following safety protocols is essential to protect operators from potential hazards associated with machinery repairs.

By implementing these techniques, operators can effectively manage the upkeep and repair of their agricultural equipment, leading to enhanced productivity and reduced downtime.

Preventative Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of any machinery. By implementing a proactive maintenance routine, operators can significantly extend the lifespan of their equipment, minimize unexpected breakdowns, and enhance overall performance. This section outlines key strategies for maintaining equipment to achieve optimal functionality and longevity.

Routine Inspections

Conducting frequent evaluations is crucial for identifying potential issues before they escalate. Operators should check for wear and tear, loose components, and any signs of leakage. Establishing a checklist can streamline this process, ensuring that all critical areas are examined consistently. By addressing minor concerns promptly, larger, more costly repairs can be avoided.

Lubrication and Cleaning

Proper lubrication is vital for reducing friction and preventing premature wear on moving parts. Regularly apply the appropriate lubricants to all necessary components as specified in the manufacturer’s guidelines. Additionally, keeping machinery clean from dirt and debris helps maintain its efficiency. A clean environment reduces the risk of contamination, which can negatively impact performance.

Upgrading Components for Improved Performance

Enhancing machinery often involves the strategic replacement of certain elements to boost efficiency and effectiveness. By selecting high-quality alternatives and incorporating advanced technologies, users can significantly increase overall functionality. This section explores various enhancements that can be made to optimize performance, reduce downtime, and extend the lifespan of the equipment.

Evaluating Current Components

Before initiating upgrades, it’s crucial to assess the existing components thoroughly. Identify parts that may be underperforming or outdated. This evaluation will help prioritize which elements need replacement and which can be retained. Focus on aspects such as wear and tear, compatibility with new technologies, and the potential for improved efficiency through modernization.

Choosing Upgraded Alternatives

When selecting replacements, consider options that provide enhanced durability and performance. For instance, opting for stronger materials or advanced designs can lead to better reliability under various operating conditions. Additionally, integrating smart technology can offer real-time monitoring, allowing for proactive maintenance and improved operational insights. Always ensure that the new components are compatible with the existing system to prevent unnecessary complications.

Safety Precautions During Repairs

When conducting maintenance or repairs on machinery, adhering to safety measures is crucial to ensure the well-being of all individuals involved. Understanding the inherent risks associated with mechanical work helps mitigate potential accidents. Proper precautions foster a safer environment and enhance the effectiveness of the repair process.

General Guidelines

Before starting any repair work, it is vital to follow established protocols. This includes wearing appropriate personal protective equipment (PPE) such as gloves, goggles, and hard hats. Additionally, ensure the work area is organized and free of clutter to minimize hazards. Always be aware of your surroundings and avoid distractions while operating tools or machinery.

Equipment Safety

Regularly inspecting tools and equipment is essential for safe operation. Ensure that all devices are in good condition and functioning properly. Always disconnect power sources before performing any maintenance tasks. When lifting heavy components, use proper techniques or mechanical aids to prevent injury.

| Safety Measure | Description |

|---|---|

| Personal Protective Equipment | Use gloves, goggles, and hard hats to protect against injury. |

| Workspace Organization | Keep the area tidy to prevent accidents and promote efficiency. |

| Tool Inspection | Regularly check tools for damage or wear to ensure safe usage. |

| Power Disconnection | Always disconnect machines from power sources before repairs. |

| Proper Lifting Techniques | Utilize safe lifting methods or equipment for heavy components. |

Frequently Asked Questions about Parts

This section addresses common inquiries regarding components and their maintenance for various agricultural machinery. Understanding these elements is essential for effective operation and longevity, ensuring optimal performance and minimal downtime.

What should I consider when purchasing components?

When acquiring components, it’s vital to verify compatibility with your specific equipment model. Additionally, evaluate the quality and durability of the items to ensure they meet operational standards and provide long-lasting service.

How can I identify the right components for my equipment?

Identifying suitable components involves referencing the equipment manual, which typically includes specifications and recommendations. Alternatively, consulting with a knowledgeable dealer or technician can provide valuable insights into suitable options tailored to your machinery’s needs.

Resources for Hesston 1010 Owners

For individuals seeking to maintain and enhance their agricultural machinery, a wealth of information is available to facilitate ownership experience. This encompasses a range of manuals, online communities, and instructional videos designed to assist users in understanding their equipment better. Access to reliable resources can significantly simplify maintenance tasks and troubleshooting processes, ensuring optimal functionality.

Various online platforms host forums where enthusiasts and owners can share insights, experiences, and solutions to common challenges. Engaging with these communities allows users to gain practical advice and learn from the experiences of others who have encountered similar situations. Additionally, many manufacturers provide downloadable manuals that contain essential information about the machinery’s specifications and maintenance requirements.

Video tutorials on platforms like YouTube offer visual guidance for repairs and maintenance procedures, making complex tasks more accessible. These resources can enhance the owner’s confidence in performing their own upkeep and modifications. Furthermore, local dealers and specialized shops often carry a selection of accessories and replacement components, catering to the needs of equipment owners.

By leveraging these diverse resources, users can ensure their agricultural machinery remains in top condition, ultimately enhancing productivity and performance in their operations.