The efficient functioning of a machine depends heavily on the quality and arrangement of its mechanical elements. Understanding how different sections of the equipment interconnect ensures smooth operation and proper maintenance. This guide provides a detailed look into the various sections that work together to maintain the overall performance of the tool.

Each part plays a crucial role in ensuring durability and effectiveness. From the core mechanisms to the smallest details, every component has its own function and is essential for optimal performance. By familiarizing yourself with the internal structure, it becomes easier to diagnose issues and replace worn-out elements when necessary.

In the following sections, we will dive into the detailed structure, offering clear insights into the key elements that make up the heart of this tool, ensuring a longer lifespan

Stihl 024 Chainsaw Parts Overview

The mechanical system of this model is composed of several key components, each playing a crucial role in the operation and maintenance of the device. Understanding how these elements work together allows for better efficiency, durability, and ease of repair. Each piece, from the internal engine mechanisms to the external features, contributes to the overall performance and reliability.

Key elements of the machine include components responsible for cutting efficiency, power transfer, and protective features. Regular maintenance and correct installation of these parts ensure long-lasting functionality, making it essential to know the role and placement of each element within the system.

Main Components of the Stihl 024 Chainsaw

The core structure of this type of cutting tool consists of various essential elements that work together to ensure its functionality. These components are designed to maximize efficiency, safety, and durability during operation. Understanding the key parts and their roles can help in maintaining and troubleshooting the device.

Engine Assembly

The power unit is the heart of the tool, driving the entire mechanism. It converts fuel into the energy needed to rotate the cutting chain. A reliable motor ensures that the tool delivers consistent performance across different tasks. Regular maintenance of this section is crucial for longevity.

Cutting Mechanism

The sharp teeth on the cutting chain are responsible for slicing through wood with precision. Attached to the guide bar, the chain moves at high speeds,

Understanding the Engine Assembly

The engine assembly plays a crucial role in ensuring the functionality and efficiency of your power tool. Understanding the various components that come together in this assembly can help maintain optimal performance and prolong the life of the machine. This section provides a closer look at the structure and mechanics of the internal system that drives the tool.

Key Components: The engine consists of several integral parts that work in harmony. These include the cylinder, piston, and crankshaft, all of which are essential for generating the necessary power. Each part requires precise interaction with the others to ensure smooth operation.

Maintenance and Care: Regular inspection and cleaning of the engine assembly are critical for avoiding common issues like overheating and wear. Keeping the system free

Guide to the Fuel System

The fuel system plays a critical role in ensuring optimal performance, providing the engine with the necessary fuel mixture for efficient combustion. Understanding how this system works is essential for maintaining proper engine function and ensuring smooth operation over time.

Here’s a breakdown of the key components involved in the fuel delivery process:

- Fuel Tank: The container that stores the fuel mixture, which needs to be maintained and regularly checked for leaks or damage.

- Fuel Lines: These flexible tubes transport the fuel from the tank to the carburetor, and it’s important to ensure they remain free of cracks or blockages.

- Carburetor: This component mixes fuel with air in the proper ratio to create the combustible mixture that powers the engine. Regular cleaning and adjustments may be

Exploring the Stihl 024 Ignition System

The ignition system plays a critical role in the functionality of the equipment, ensuring smooth operation and efficient energy transfer. Understanding how this component works is essential for proper maintenance and troubleshooting. The system is designed to generate the necessary spark at the right moment, enabling the engine to run optimally.

Key Components of the ignition system include the coil, flywheel, and spark plug. Each of these elements works together to convert mechanical motion into electrical energy, which is then used to ignite the fuel mixture. Without proper synchronization, the equipment may experience issues such as misfiring or difficulty starting.

Maintenance of this system involves regular

Detailed View of the Carburetor

The carburetor plays a crucial role in the functioning of any small engine, ensuring a precise mixture of air and fuel for optimal performance. Understanding its components and operation can greatly enhance maintenance and troubleshooting efforts. This section provides an in-depth look at the various elements that constitute the carburetor, highlighting their functions and significance.

Key Components of the Carburetor

- Float Chamber: Maintains a steady level of fuel, allowing for consistent delivery to the mixing chamber.

- Jet Nozzle: Controls the flow of fuel into the airstream, essential for achieving the correct fuel-air mixture.

- Throttle Valve: Regulates the amount of air entering the engine, influencing speed and power output.

- Choke Mechanism: Aids in starting the engine by enriching the fuel mixture, facilitating easier ignition.

Functionality and Adjustment

Proper functionality of the carburetor is vital for engine efficiency. Regular adjustments may be necessary to maintain optimal performance. Here are some tips for effective tuning:

- Check the float height to ensure proper fuel level in the chamber.

- Inspect the jet nozzle for clogs or wear, replacing it if necessary.

- Adjust the throttle valve for the desired response during operation.

- Test the choke mechanism to ensure it operates smoothly for cold starts.

By familiarizing oneself with these components and their adjustments, users can significantly improve the reliability and longevity of their equipment.

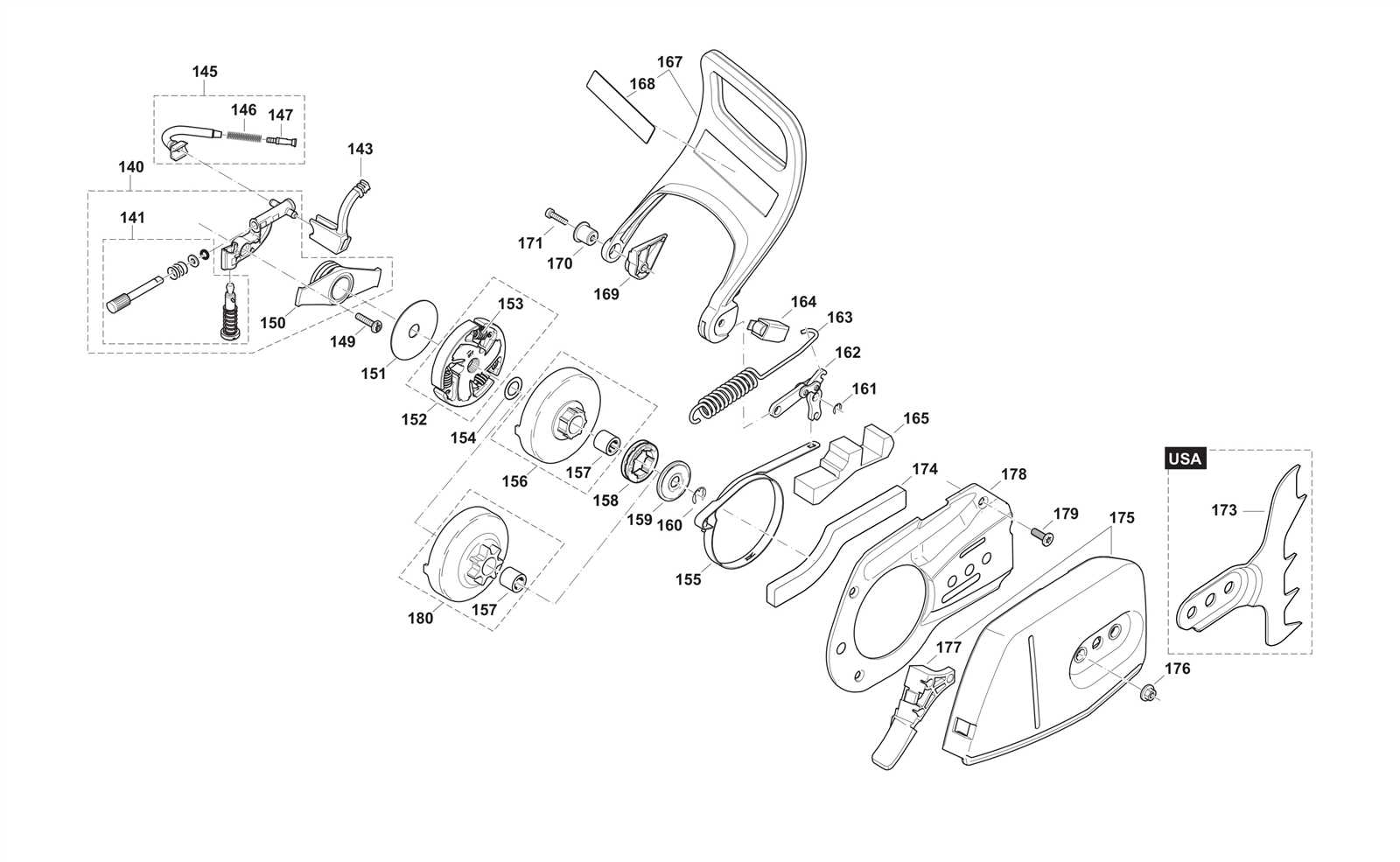

Chain and Bar Mechanism

The mechanism responsible for the movement of the cutting element plays a crucial role in the overall performance of a power tool designed for felling and trimming. Understanding this system is essential for efficient operation and maintenance, ensuring longevity and optimal functioning during various tasks.

Components of the System

This mechanism consists of several key elements that work together seamlessly. The guide component, which houses the cutting element, provides stability and directs the motion, while the looped cutting element is designed to tackle different types of wood with precision. Additionally, a drive system is incorporated to facilitate movement, enabling smooth operation.

Maintenance and Care

Regular inspection and maintenance of the chain and bar assembly are vital for sustained performance. Ensuring proper tension, lubrication, and alignment can prevent wear and tear, enhancing efficiency and safety during use. Always refer to the manufacturer’s guidelines for specific care instructions to maintain peak functionality.

Functionality of the Oil Pump in Stihl 024

The oil pump plays a crucial role in maintaining the optimal performance of a power tool. Its primary function is to ensure a consistent supply of lubrication to various moving parts, reducing friction and wear during operation. This mechanism is vital for enhancing efficiency and prolonging the lifespan of the equipment.

In addition to minimizing wear, the lubrication system aids in cooling the engine components, which is essential for preventing overheating. The oil pump is designed to deliver the right amount of lubricant, adapting to the tool’s operational demands. This responsiveness helps to maintain effective performance even under varying workloads.

Function Description Lubrication Reduces friction between moving parts, preventing premature wear. Cooling Helps maintain optimal temperatures by dissipating heat generated during use. Performance Maintenance Ensures smooth operation, enhancing the efficiency of the power tool. Adaptability Modifies oil flow according to varying workloads and operational demands. Recoil Starter Components Explained

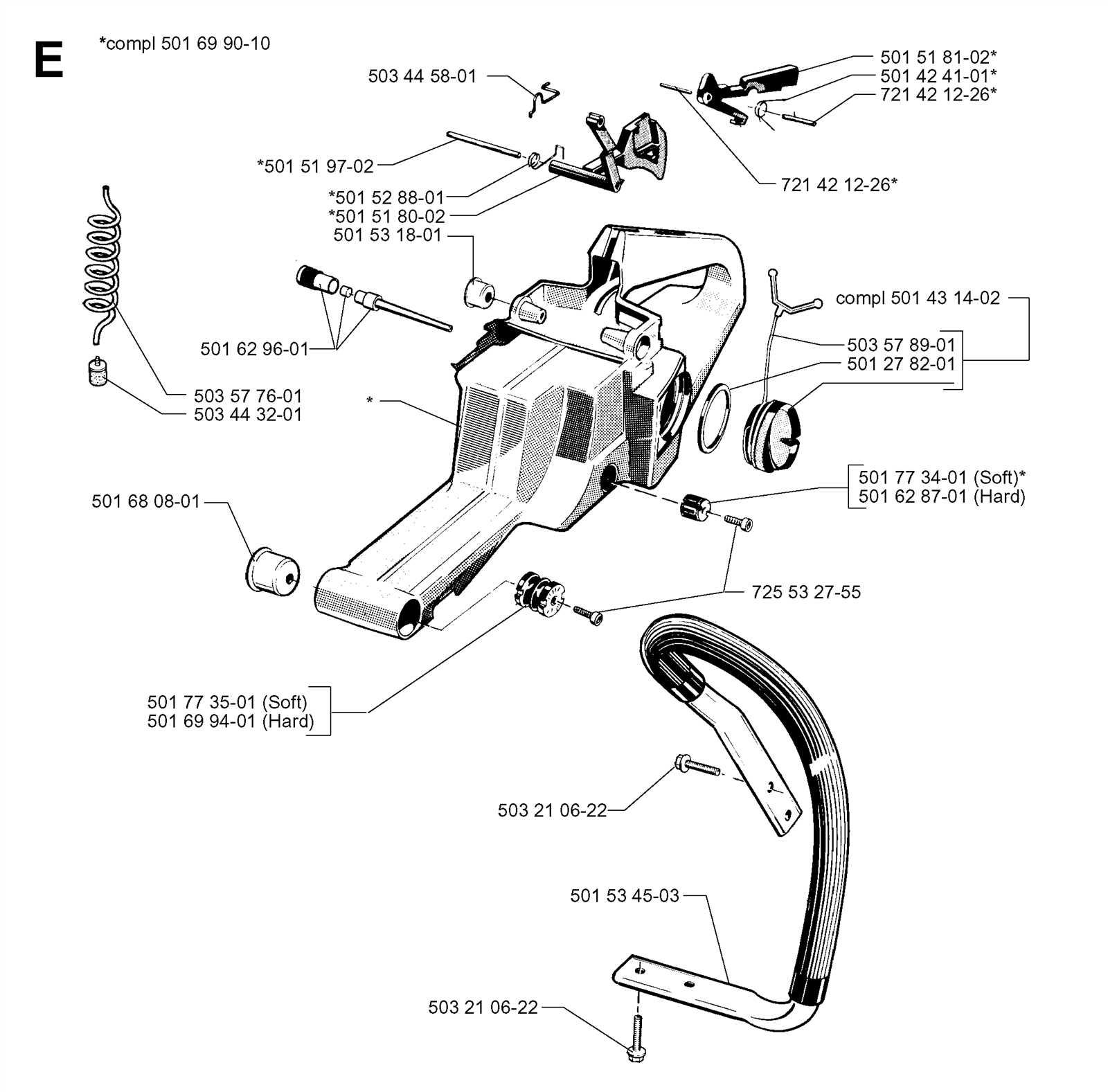

The recoil starter mechanism is a crucial element in the operation of many small engines, enabling the user to initiate the engine with a simple pull. Understanding the various components that make up this system can enhance the maintenance and troubleshooting processes, ensuring optimal performance and reliability.

Key Components

The recoil starter consists of several essential parts, each playing a vital role in the starting process. Below is an overview of the main components:

Component Description Starter Rope A durable cord that is pulled to engage the starting mechanism. Recoil Spring This spring provides the tension needed to retract the starter rope after pulling. Starter Housing The casing that houses the recoil mechanism, protecting it from debris and damage. Pulley The component that the starter rope wraps around, helping to transfer the pull force to the engine. Handle The grip that the user pulls to start the engine, designed for comfort and ease of use. Functionality Overview

When the handle is pulled, the rope unwinds from the pulley, engaging the recoil spring. This action rotates the engine’s flywheel, initiating the combustion process. Once released, the recoil spring retracts the rope, allowing the starter to reset for the next pull. Understanding this cycle is key to maintaining the starter system effectively.

Air Filter and Maintenance Tips

Maintaining the air filtration system is crucial for ensuring optimal performance and longevity of your equipment. A clean air filter allows for proper airflow, which is essential for efficient combustion and overall operation. Regular inspection and maintenance of the air filter can prevent engine issues and enhance reliability.

Regular Cleaning: It is advisable to check the air filter frequently and clean it as needed. This can typically be done by gently tapping it to remove loose debris or using compressed air to blow out dirt. Avoid using water or solvents, as these can damage the filter material.

Replacement Frequency: Depending on usage conditions, replacing the air filter is often necessary. If the equipment is frequently used in dusty or dirty environments, consider replacing the filter more often. Always refer to the manufacturer’s guidelines for specific recommendations regarding replacement intervals.

Visual Inspection: During maintenance checks, visually inspect the air filter for signs of damage or excessive wear. If the filter is torn, clogged, or severely discolored, it should be replaced promptly to maintain optimal performance.

Proper Installation: When reinstalling the air filter, ensure it is seated correctly in its housing. A proper seal prevents unfiltered air from entering the engine, safeguarding it from contaminants and potential damage.

By following these maintenance tips, you can enhance the efficiency and lifespan of your equipment, ensuring it operates at its best.

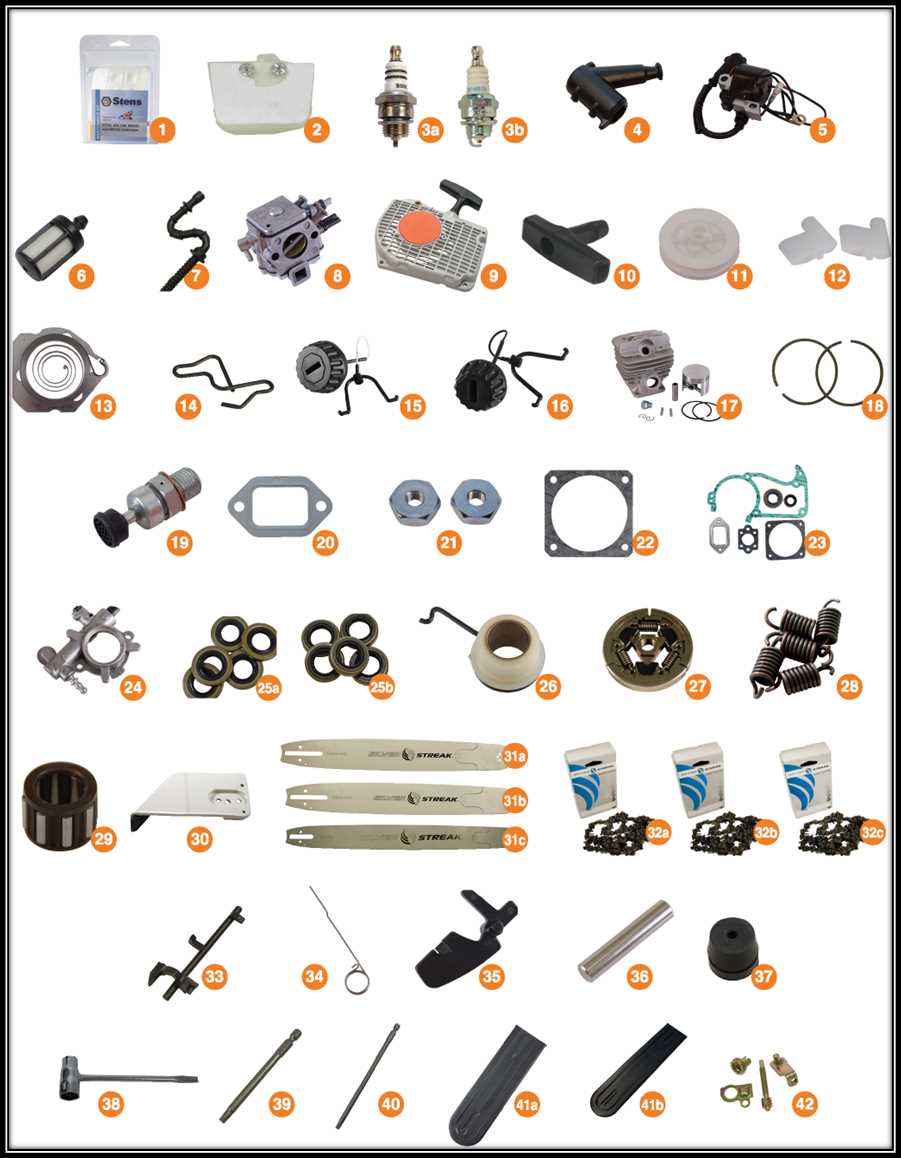

Replacing Worn Parts of the Stihl 024

Maintaining the efficiency of your cutting tool is essential for optimal performance. Regularly assessing and replacing any components that show signs of wear can significantly enhance the longevity and effectiveness of your equipment. Understanding which elements are prone to deterioration and how to replace them is crucial for maintaining a reliable tool.

When it comes to replacing components, identifying the specific elements that require attention is the first step. Commonly worn items include the guide bar, chain, and spark plug. Below is a brief overview of these components and their significance in maintaining cutting efficiency:

Component Signs of Wear Replacement Tips Guide Bar Visible grooves, bending, or cracking Ensure proper alignment and use the correct length when replacing. Chain Loose links, dull edges, or missing teeth Regularly check tension and sharpen as needed before replacement. Spark Plug Difficulty starting or inconsistent performance Use the recommended type for your model and ensure proper gap settings. By focusing on these key components and replacing them as needed, you can ensure that your cutting tool remains in peak condition. Regular maintenance not only extends the lifespan of your equipment but also enhances your overall cutting experience.