In the realm of outdoor machinery, knowing the individual elements is essential for effective operation and maintenance. Each component plays a significant role in the overall functionality, and understanding their arrangement can enhance performance and longevity.

For those engaged in seasonal tasks, it is crucial to have a clear representation of how these elements interact. By familiarizing oneself with the configuration and roles of each section, users can better address issues, perform repairs, or carry out upgrades when necessary.

Visual aids can significantly simplify this process, providing a straightforward reference for users to identify and locate the various components. This knowledge not only facilitates maintenance but also empowers users to make informed decisions regarding repairs and replacements.

This section aims to provide a comprehensive overview of the various elements that make up a specific type of outdoor equipment used for managing winter weather conditions. By exploring the individual components and their functions, readers can gain valuable insights into how this machinery operates effectively. This knowledge is essential for maintenance, repair, and overall understanding of the device.

- Introduction to Winter Equipment

- Essential Components Overview

- Engine Functionality Explained

- Importance of the Auger Assembly

- Understanding the Chassis Structure

- Role of the Drive System

- Significance of the Control Panel

- Exploring the Fuel System

- Maintenance of Electrical Components

- Analyzing the Housing Design

- Safety Features and Their Importance

Each of these topics will delve into specific functionalities and maintenance tips, enabling users to enhance their knowledge and ensure optimal performance of their machinery throughout the winter months.

Essential Parts for Efficient Operation

To ensure optimal performance and longevity of your outdoor equipment, understanding the key components is crucial. Each element plays a significant role in the overall functionality, making it important to be familiar with their features and maintenance requirements.

Key Components to Consider

- Engine: Powers the entire mechanism and is vital for effective operation.

- Transmission: Facilitates the transfer of power from the engine to the working parts.

- Drive System: Ensures mobility and control during operation.

- Auger: Collects and propels materials away from the working area.

- Chassis: Provides structural integrity and support for all components.

Maintenance Tips

- Regularly check fluid levels to avoid overheating and ensure smooth operation.

- Inspect belts and cables for wear and replace them as needed.

- Clean components after each use to prevent buildup of debris.

- Lubricate moving parts to minimize friction and enhance performance.

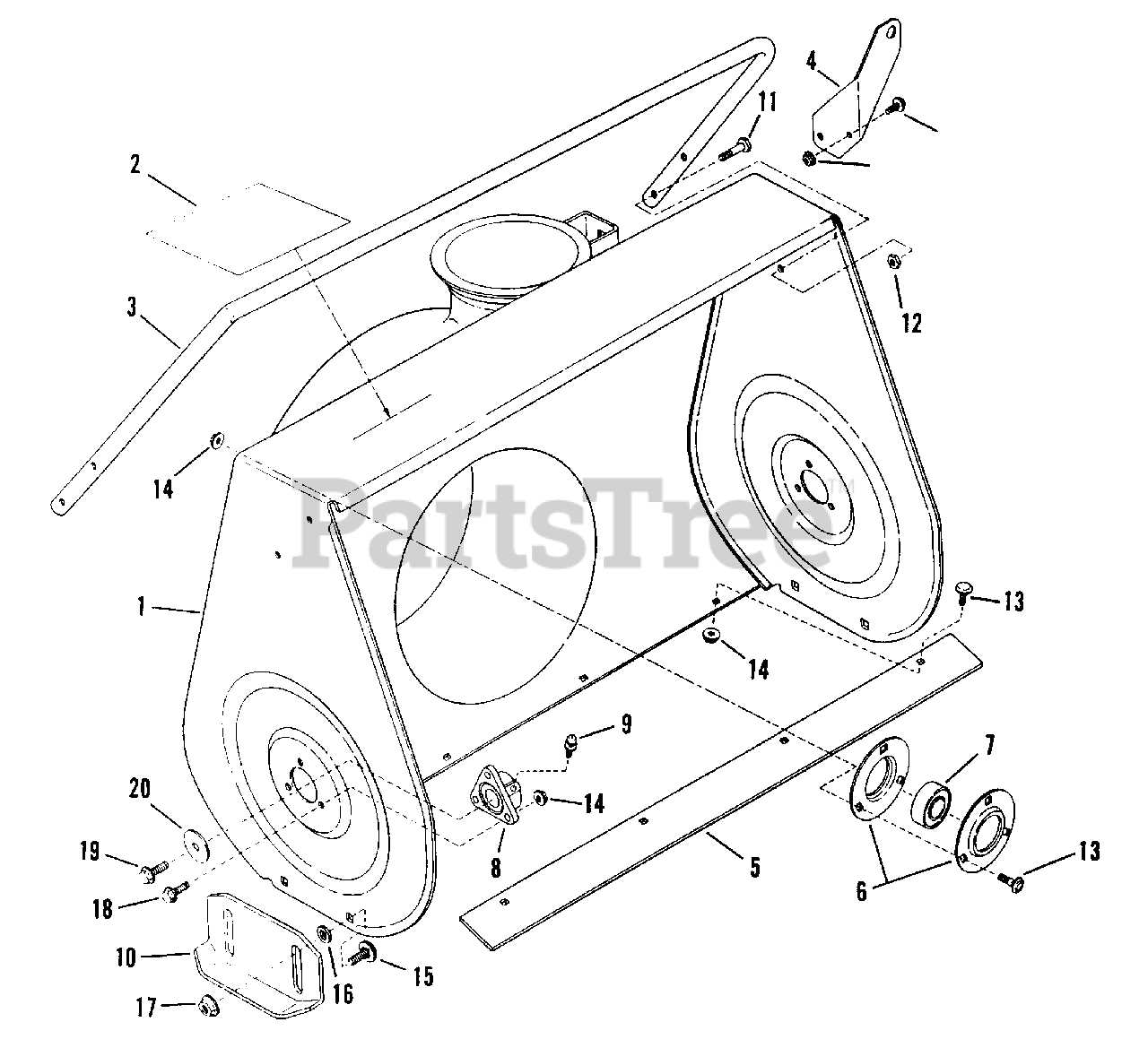

Identifying the Drive Mechanism

Understanding the driving system of a mechanical apparatus is crucial for effective maintenance and operation. The drive mechanism is responsible for translating power into movement, enabling the device to function efficiently. Recognizing the various components involved in this process can assist in troubleshooting issues and performing necessary repairs.

Typically, this system consists of several key elements, including belts, gears, and pulleys, which work together to transmit motion from the engine to the wheels or augers. Identifying these components and their arrangement can help users comprehend how power is delivered, and what may be causing any malfunctions.

Moreover, regular inspection of the drive mechanism can prevent potential breakdowns and prolong the lifespan of the machine. Familiarity with the layout and condition of the components allows for timely replacements and adjustments, ensuring optimal performance throughout its use.

Snow Blower Blade Functionality Explained

The essential component of any clearing device is its cutting mechanism, designed to efficiently handle various conditions. Understanding how this mechanism operates helps users maximize its performance and effectiveness. The design and structure of this element significantly influence its ability to handle different types of accumulated materials, ensuring smooth and efficient operation.

Cutting Edge Design

The cutting edge plays a pivotal role in determining the efficiency of the device. Typically crafted from durable materials, it is shaped to slice through accumulated debris effectively. A well-designed edge enhances the overall performance, allowing for swift and precise clearing, regardless of the terrain.

Mechanism of Action

The operation of this cutting mechanism involves a combination of rotation and force, enabling it to lift and expel the materials effectively. As the mechanism rotates, it generates momentum, which propels the cleared debris away from the area. This action not only ensures thorough cleaning but also prevents clogging, making the process more efficient and less labor-intensive.

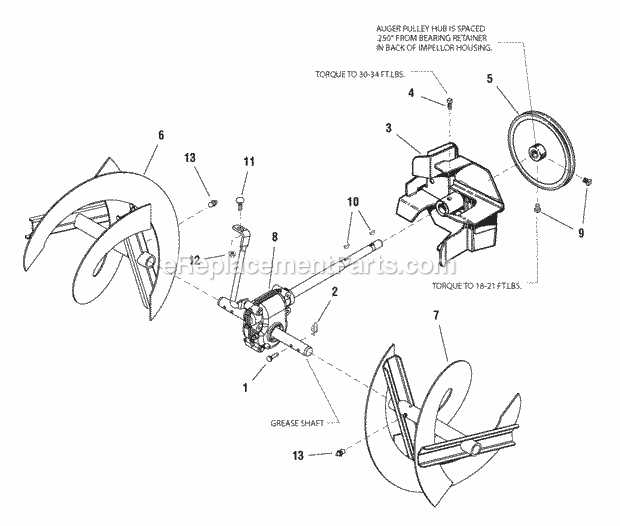

Importance of the Auger Assembly

The auger assembly plays a crucial role in the functionality of winter machinery designed for clearing pathways. This component is responsible for efficiently gathering and directing snow, ensuring that the machine performs optimally in various conditions. A well-functioning auger allows for quick and effective removal, making operations smoother and more efficient.

When this assembly is in good condition, it enhances the overall performance of the equipment. It facilitates better handling of accumulated snow, contributing to faster clearing times and reduced physical strain on the operator. Regular maintenance and timely replacement of worn components within the auger assembly are vital for preserving the machine’s efficiency and extending its lifespan.

Role of the Chassis in Performance

The structural framework of a machine plays a critical role in its overall efficiency and capability. It serves as the foundation that supports various components, ensuring stability and durability during operation. A well-designed framework not only contributes to enhanced functionality but also influences maneuverability and handling in diverse environments.

In evaluating the importance of the framework, several factors come into play that directly impact performance:

| Factor | Impact on Performance |

|---|---|

| Stability | Provides a balanced structure, reducing vibrations and improving control. |

| Weight Distribution | Ensures optimal balance, enhancing traction and reducing fatigue on components. |

| Material Quality | Affects durability and resistance to wear, influencing the lifespan of the machinery. |

| Design Precision | Ensures proper alignment of components, reducing maintenance needs and improving efficiency. |

Ultimately, the framework is essential in optimizing performance, making it a vital consideration for effective machine design and operation.

Features of the Control Panel

The control panel is a vital component that enhances the user experience by providing essential functionalities and intuitive operation. It integrates various controls that allow users to efficiently manage the equipment, ensuring optimal performance and convenience during use.

This panel typically includes a range of features that cater to different operational needs. Below is a table summarizing some common attributes:

| Feature | Description |

|---|---|

| Power Switch | Enables quick and easy activation or deactivation of the system. |

| Speed Control | Allows adjustment of the operating speed to suit various conditions. |

| Indicator Lights | Provides visual feedback on the status of the machine, ensuring users are informed. |

| Throttle Lever | Facilitates precise control over the engine power output. |

| Safety Features | Includes emergency shut-off mechanisms to prevent accidents. |

These features work together to provide a seamless experience, allowing users to focus on their tasks with confidence in the equipment’s reliability.

Maintenance Tips for Key Parts

Proper care of essential components can significantly enhance the longevity and performance of your equipment. Regular inspection and maintenance are crucial to ensure everything operates smoothly, reducing the risk of unexpected failures during use. Here are some effective practices to keep in mind.

Regular Inspections

Conduct frequent evaluations of the main elements to identify any signs of wear or damage. Look for cracks, rust, or loose connections that could affect functionality. Early detection of issues can save time and expenses in the long run.

Cleaning and Lubrication

Ensure that all moving parts are kept clean and adequately lubricated. Cleaning helps prevent the buildup of debris that can hinder performance, while lubrication reduces friction and wear, contributing to the efficiency of operation.

Common Issues with Snow Blower Parts

Understanding the typical challenges that can arise with outdoor equipment is essential for maintaining its efficiency. Various components may encounter issues that hinder performance and effectiveness. Recognizing these problems early can save time and resources.

Wear and Tear: Over time, many components experience natural degradation due to regular use. This can lead to decreased efficiency and may necessitate timely replacements.

Clogs and Blockages: Accumulation of debris can obstruct pathways and mechanisms, leading to malfunctions. Regular cleaning and maintenance can help mitigate this issue.

Fluid Leaks: Leakage of fluids can occur due to damaged seals or connections, which can impair functionality and performance. It’s crucial to check for any signs of leaks regularly.

Starting Difficulties: Many users report challenges in initiating operation, often linked to fuel quality or battery health. Ensuring proper fuel and battery maintenance is vital for reliable starts.

Where to Find Replacement Components

Locating suitable spare components for your equipment is essential for maintaining optimal performance. Various resources are available to help you find the necessary items quickly and effectively. From authorized dealers to online retailers, understanding where to look can save both time and effort.

One of the most reliable options is to visit local authorized dealers, where you can find original components specifically designed for your model. Additionally, many manufacturers provide official websites featuring an extensive catalog of available replacements. Online marketplaces are another valuable resource, often offering a wide range of options at competitive prices.

| Source Type | Description | Benefits |

|---|---|---|

| Authorized Dealers | Local retailers with official affiliations. | Genuine components and expert advice. |

| Manufacturer Websites | Official sites providing product catalogs. | Access to original components and specifications. |

| Online Marketplaces | Platforms like eBay or Amazon. | Variety and competitive pricing. |

| Specialty Parts Stores | Shops focusing on specific equipment needs. | Expert guidance and unique components. |

By exploring these avenues, you can efficiently source the replacements needed to ensure your machinery continues to function smoothly.

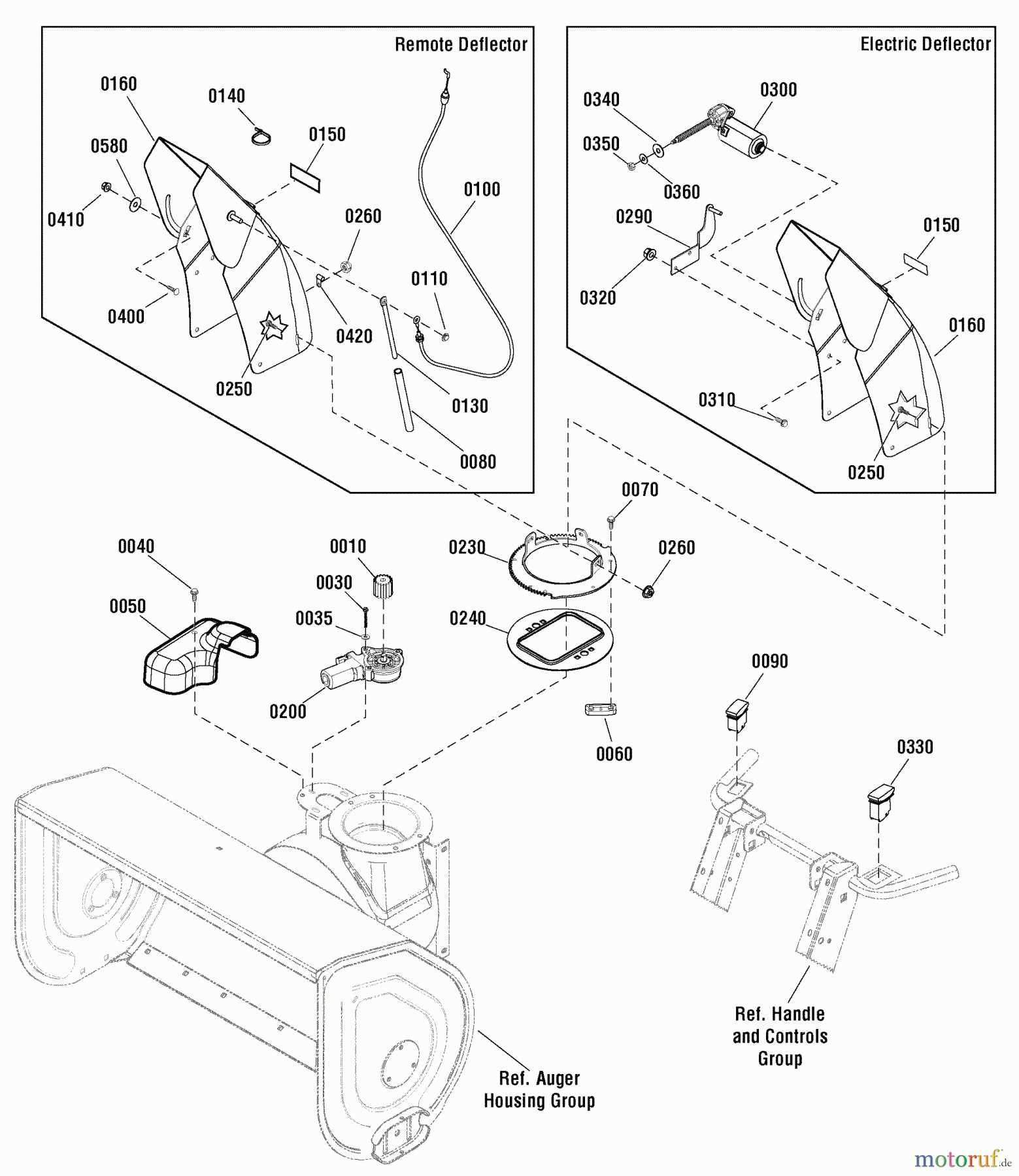

Understanding the Parts Diagram

The illustration of components serves as a crucial resource for users aiming to comprehend the various elements of their equipment. This visual representation simplifies the identification and organization of each segment, ensuring that users can easily grasp how everything fits together. By familiarizing oneself with this layout, individuals can enhance their knowledge of maintenance and repairs.

Each labeled section provides clarity on the functionality of different pieces, making it easier to understand how they interact within the entire mechanism. Recognizing each component’s role allows for more effective troubleshooting and ensures that the device operates at optimal efficiency. Additionally, it can assist in determining the right replacements when necessary, contributing to a more informed approach to upkeep.

Utilizing such illustrations can ultimately empower users to manage their equipment more confidently. With a clear understanding of the layout, individuals can engage in repairs or adjustments with greater assurance, knowing they have the knowledge to handle their machinery effectively.

How to Assemble Your Snow Blower

Assembling your winter machinery can seem challenging, but with the right approach, you can ensure that it operates efficiently. Following a systematic method allows you to combine various components effectively, ensuring optimal performance during the colder months.

Gather Necessary Tools

Before you begin the assembly process, make sure you have all the required tools on hand. Here’s a list of items you may need:

- Wrenches

- Screwdrivers

- Pliers

- Safety glasses

- Owner’s manual

Step-by-Step Assembly Process

Follow these steps to piece together your equipment:

- Start by placing the main frame on a flat surface.

- Attach the wheels securely to the base.

- Connect the engine unit to the designated area.

- Affix the control handle at the appropriate height.

- Ensure all bolts and screws are tightened properly to prevent any loose parts.

- Finish by checking that all connections are secure and functional.