Understanding how different mechanical elements work together is essential for maintaining efficient operation. This section provides a detailed look at the essential components that ensure smooth functionality. By studying the arrangement and interaction of these elements, you can enhance your knowledge of how the entire system operates, making future adjustments and repairs more manageable.

Within this overview, we will focus on the core structural elements and their respective placements. Each part plays a specific role, contributing to overall performance. Knowing where these elements are located and how they function can significantly improve maintenance routines, preventing unnecessary breakdowns and prolonging the lifespan of the machine.

Additionally, we’ll explore the best practices for identifying and troubleshooting potential issues that might arise over time. By familiarizing yourself with this arrangement, you can ensure optimal operation and avoid common challenges related to wear and tear.

Toro Power Max 724 OE Overview

This section provides a comprehensive introduction to a reliable and efficient snow clearing machine designed to handle even the toughest winter conditions. Equipped with advanced features and built for durability, this device ensures smooth operation and long-lasting performance in various environments.

- Robust construction for enhanced durability in harsh weather.

- Engineered for efficiency in snow removal, allowing for quicker and easier work.

- Convenient controls for user-friendly operation in all conditions.

- Efficient chute design for precise snow discharge and control.

- Designed with ergonomics in mind, ensuring comfort during extended use.

Whether facing light snow or heavy snowfall, this machine is designed to meet diverse needs, offering both reliability and power for consistent performance.

Main Components of the Snowblower

A snow-clearing machine consists of several key elements that work together to efficiently remove snow from various surfaces. Understanding the primary features of this equipment is essential for its effective use and maintenance.

- Auger: The rotating blades located at the front of the machine, designed to gather and break up snow before moving it into the chute.

- Impeller: This component helps propel the collected snow through the chute and away from the cleared path.

- Chute: A directional outlet that allows you to control where the snow is

Exploring the Engine System

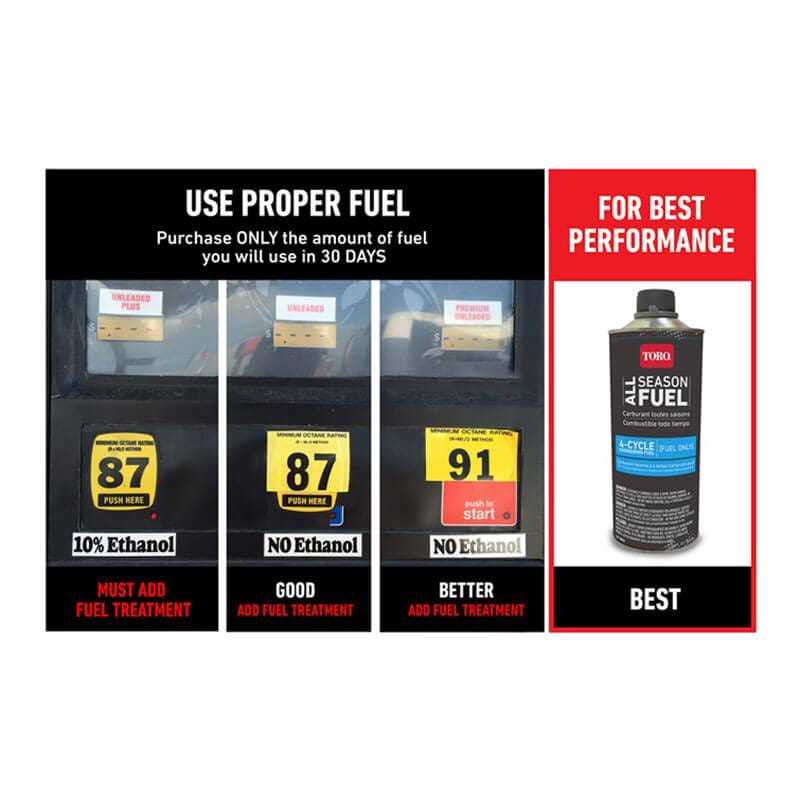

The engine system plays a critical role in ensuring the efficient operation of any snow-removal equipment. This section focuses on understanding how the internal components work together to provide the necessary power for optimal functionality. By examining the primary mechanisms, you will gain a clearer picture of the overall process, from fuel combustion to mechanical motion.

Key Components and Their Functions

The engine consists of several interconnected parts that each perform a specific function. These include the combustion chamber, where fuel mixes with air and ignites, and the piston, which transfers energy from the explosion to the drivetrain. Each component works in harmony to ensure that the machine runs smoothly under various conditions.

Maintenance and Efficiency

Regular maintenance of the engine system ensures long-lasting performance and reliability. Proper care includes checking the oil level, inspecting air filters, and ensuring the fuel system is clean. A well-maintained engine will operate more efficiently, reducing the

Details of the Auger Assembly

The auger assembly plays a crucial role in the efficient operation of snow-clearing equipment. It is designed to break through heavy snow and ice, channeling them towards the discharge chute for smooth removal. Understanding its individual components can help with maintenance and repairs, ensuring optimal performance during winter conditions.

Main Components

- Auger Blades: These rotating blades cut through snow and ice, making them one of the most vital parts of the system.

- Shaft: The central rod that holds the blades in place, ensuring they rotate smoothly as the machine operates.

- Bearings: These are essential for minimizing friction and enabling smooth movement of the auger shaft during use.

- Retaining Bolts: Secures the assembly together, allowing it to handle tough con

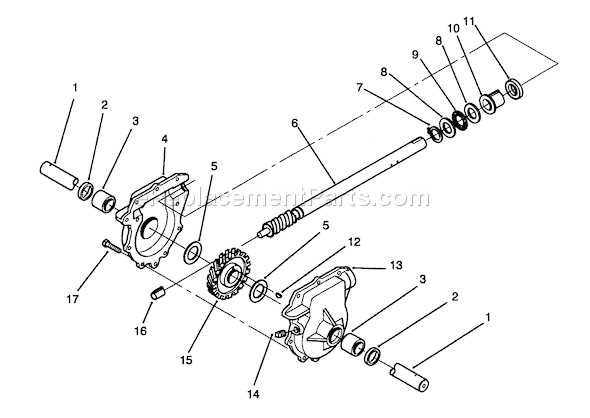

Understanding the Drive Mechanism

The drive mechanism is an essential component that ensures smooth movement and optimal performance. It is responsible for converting the power from the engine into forward and reverse motion, allowing for efficient control and maneuverability during operation. Understanding how the various elements of the system work together can help improve performance and ensure proper maintenance.

Main Components of the Drive System

The drive system is comprised of several key parts that work in tandem to ensure smooth operation. These include gears, belts, pulleys, and friction discs. Each of these components plays a crucial role in transmitting force and maintaining stability during use. Regular inspection of these elements is important for preventing wear and tear and ensuring long-lasting functionality.

Identifying Key Safety Features

Ensuring optimal safety during operation is crucial when utilizing outdoor machinery. Recognizing essential protective elements can significantly reduce the risk of accidents and enhance user confidence. These features are designed to safeguard both the operator and the equipment while facilitating efficient performance.

One fundamental aspect to consider is the presence of safety switches, which prevent the equipment from starting under unsafe conditions. Additionally, robust guards and shields are often integrated into the design to protect users from moving parts and debris. Understanding these components is vital for safe handling and maintenance.

Another key feature includes ergonomic handles that provide better control and stability during use. These are often designed to reduce strain on the user, allowing for more comfortable operation over extended periods. Safety labels and instructions are also critical, serving as reminders of best practices and potential hazards.

Finally, reliable braking systems contribute significantly to overall safety. These systems allow for immediate cessation of operation when needed, ensuring that users can react swiftly in emergencies. Familiarizing oneself with these safety mechanisms is essential for maximizing both protection and efficiency in any outdoor task.

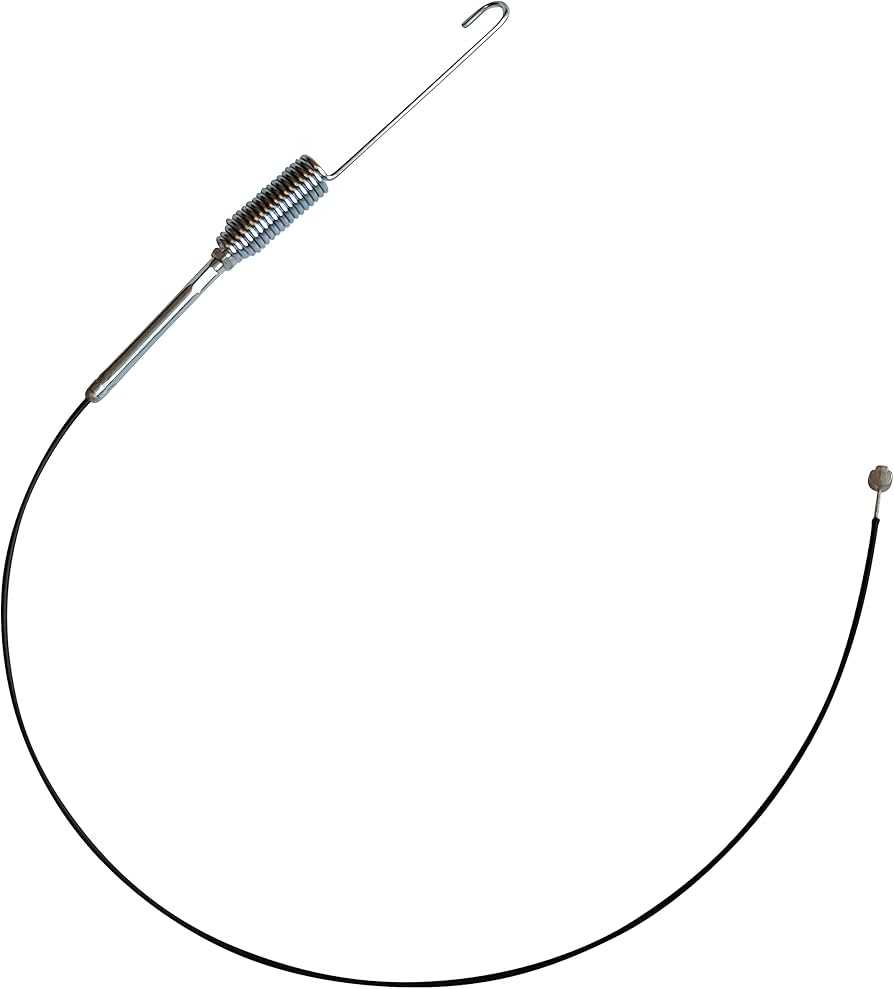

Belt and Pulley Layout

The arrangement of belts and pulleys plays a crucial role in the functionality of machinery. This system is responsible for transferring power efficiently from the engine to various components, ensuring smooth operation. Understanding the configuration of these elements is essential for maintenance and troubleshooting, as it directly impacts performance and reliability.

Configuration Overview

The belt and pulley system typically consists of multiple components working in harmony. The primary function of the belts is to connect different pulleys, allowing for the transmission of rotational force. The design of this system can vary, influencing the overall efficiency and effectiveness of the equipment. Regular inspections can help identify wear and tear, ensuring that the system operates optimally.

Component Specifications

Component Description Function Belt Flexible loop of material Transfers power between pulleys Pulley Circular wheel with a groove Guides and supports the belt Tensioner Device that maintains belt tension Ensures proper contact and prevents slippage Control Panel and Handlebar Setup

The control interface and steering assembly are crucial components that enhance the overall functionality and user experience of your equipment. Proper configuration and understanding of these elements ensure optimal operation and comfort during use.

Control Interface

The control panel typically features various switches and levers that allow the operator to manage different settings effectively. Familiarize yourself with each control to maximize efficiency and ensure safety during operation. Always verify that all controls are in their correct positions before starting the machine.

Steering Assembly

The handlebar setup is designed to provide stability and maneuverability. Ensure that the handlebars are securely attached and positioned at a comfortable height for the operator. Adjusting the handlebar angle may also be necessary to suit individual preferences, promoting ease of use during extended periods of operation.

Final Checks

Before initiating any tasks, double-check that all components are functioning correctly and are free of obstructions. A well-set control interface and handlebar not only enhance performance but also contribute to a safer working environment.

Shear Pins and Fasteners

In various machinery, shear pins and fasteners play a critical role in ensuring operational efficiency and safety. These components are designed to protect more substantial parts from damage during unforeseen circumstances, such as overloads or blockages. By strategically breaking under excessive stress, they prevent more severe consequences, preserving the integrity of the equipment.

Shear pins are typically constructed from durable materials that provide adequate strength while being designed to fail at a predetermined load. This characteristic makes them essential in a variety of applications. Here are some key points about shear pins:

- Functionality: They serve as sacrificial components that absorb excessive force.

- Replacement: Regular inspection and timely replacement are vital to maintain the machine’s efficiency.

- Compatibility: Selecting the right shear pin for specific equipment is crucial for optimal performance.

Fasteners also play a significant role in the assembly and maintenance of machinery. They secure various components together, ensuring structural stability and operational reliability. Important considerations for fasteners include:

- Material Quality: The choice of material affects the fasteners’ strength and corrosion resistance.

- Size and Type: Using the correct size and type of fastener is essential for effective assembly.

- Regular Checks: Periodic inspections can prevent failures and ensure the longevity of the machinery.

Understanding the significance of shear pins and fasteners in machinery operation aids in the maintenance and troubleshooting processes, ultimately contributing to the longevity and reliability of the equipment.

Chassis and Frame Construction

The chassis and frame are critical components of any machine, serving as the backbone that supports various functionalities and ensures stability during operation. Their design and construction influence the overall performance, durability, and ease of maintenance of the equipment. A well-engineered frame not only provides structural integrity but also enhances maneuverability, making it essential for optimal performance.

Typically constructed from robust materials such as steel or aluminum, the frame is designed to withstand significant stress and impact while maintaining a lightweight profile. The integration of cross members and reinforcements is common, offering additional strength and rigidity. This construction method is crucial for ensuring that the machine can endure harsh conditions and heavy usage without compromising its structural integrity.

Moreover, the chassis layout often includes designated mounting points for various components, facilitating organized assembly and ease of access for maintenance. This thoughtful arrangement can significantly reduce the time and effort required for servicing, contributing to prolonged operational life and enhanced user satisfaction.

In summary, the chassis and frame construction play a vital role in the functionality and longevity of machinery. Attention to detail in the design and materials used can lead to improvements in both performance and reliability, making it a key focus area for manufacturers and users alike.

Wheels and Skid Shoe Assembly

The wheels and skid shoe assembly plays a crucial role in the overall functionality of outdoor equipment. This component ensures smooth movement and stability while operating on various terrains. Proper maintenance and understanding of this assembly can significantly enhance performance and prolong the lifespan of the machinery.

Wheels are vital for mobility, allowing the equipment to traverse different surfaces effectively. Their construction typically includes durable materials designed to withstand wear and tear. Regular inspection is essential to ensure that the wheels are free of debris and functioning optimally. Signs of damage or excessive wear should be addressed promptly to maintain efficient operation.

Skid shoes serve as protective elements, guiding the equipment and preventing it from damaging the surface beneath. They help maintain the correct height during operation, ensuring that the equipment performs its tasks without causing unnecessary harm to the ground. Over time, skid shoes can wear down and may require replacement to maintain effective operation.

To ensure optimal performance, it is important to follow manufacturer guidelines for installation and maintenance. Regularly checking the alignment and securing all fasteners can prevent premature wear and enhance the assembly’s overall effectiveness. Understanding the relationship between the wheels and skid shoes will lead to better performance and a more efficient operation.

Maintenance Parts and Tools

Regular upkeep of equipment is essential to ensure optimal performance and longevity. Having the right components and tools at hand is crucial for effective maintenance, allowing users to address issues promptly and efficiently. This section outlines the necessary supplies and instruments to facilitate routine care and repairs.

Essential Components

- Belts: Ensure smooth operation and prevent slippage.

- Filters: Keep the engine and other systems clean by trapping dirt and debris.

- Blades: Sharp and well-maintained cutting edges are vital for efficiency.

- Spark plugs: Ensure proper ignition for optimal engine performance.

- Fuel lines: Check for leaks and maintain fuel flow.

Required Tools

- Wrenches: For loosening and tightening various fasteners.

- Screwdrivers: Essential for assembling and disassembling components.

- Socket set: Provides versatility in working with different sized bolts.

- Torque wrench: Ensures fasteners are tightened to the correct specifications.

- Safety gear: Always prioritize protection with gloves and goggles.