When working with small agricultural machinery, having a clear understanding of its various components is essential for optimal operation and maintenance. This section aims to shed light on the intricate assembly of your machine, focusing on the essential elements that contribute to its functionality. By familiarizing yourself with these components, you can enhance your troubleshooting skills and ensure efficient performance.

Every machine consists of numerous interconnected parts, each serving a specific purpose. Recognizing these elements not only simplifies the repair process but also aids in the selection of appropriate replacements when necessary. Whether you are a seasoned operator or a newcomer, grasping the relationships between these components can significantly improve your confidence and proficiency in handling your equipment.

In this exploration, we will delve into the various sections of the machine, outlining their functions and importance. This knowledge will empower you to tackle maintenance tasks with greater ease and accuracy, ensuring your machinery remains in peak condition for years to come.

This section highlights the standout characteristics of a compact utility machine designed for versatility and efficiency. Its robust design and advanced functionality make it an ideal choice for various agricultural and landscaping tasks. Users can expect exceptional performance and reliability, regardless of the challenges faced in the field.

Performance and Capability

The model boasts a powerful engine that delivers impressive torque, ensuring effective operation under demanding conditions. Coupled with a reliable transmission system, it offers seamless shifting and enhances overall productivity. The thoughtful engineering behind this machine allows for efficient fuel consumption, making it a cost-effective option for users.

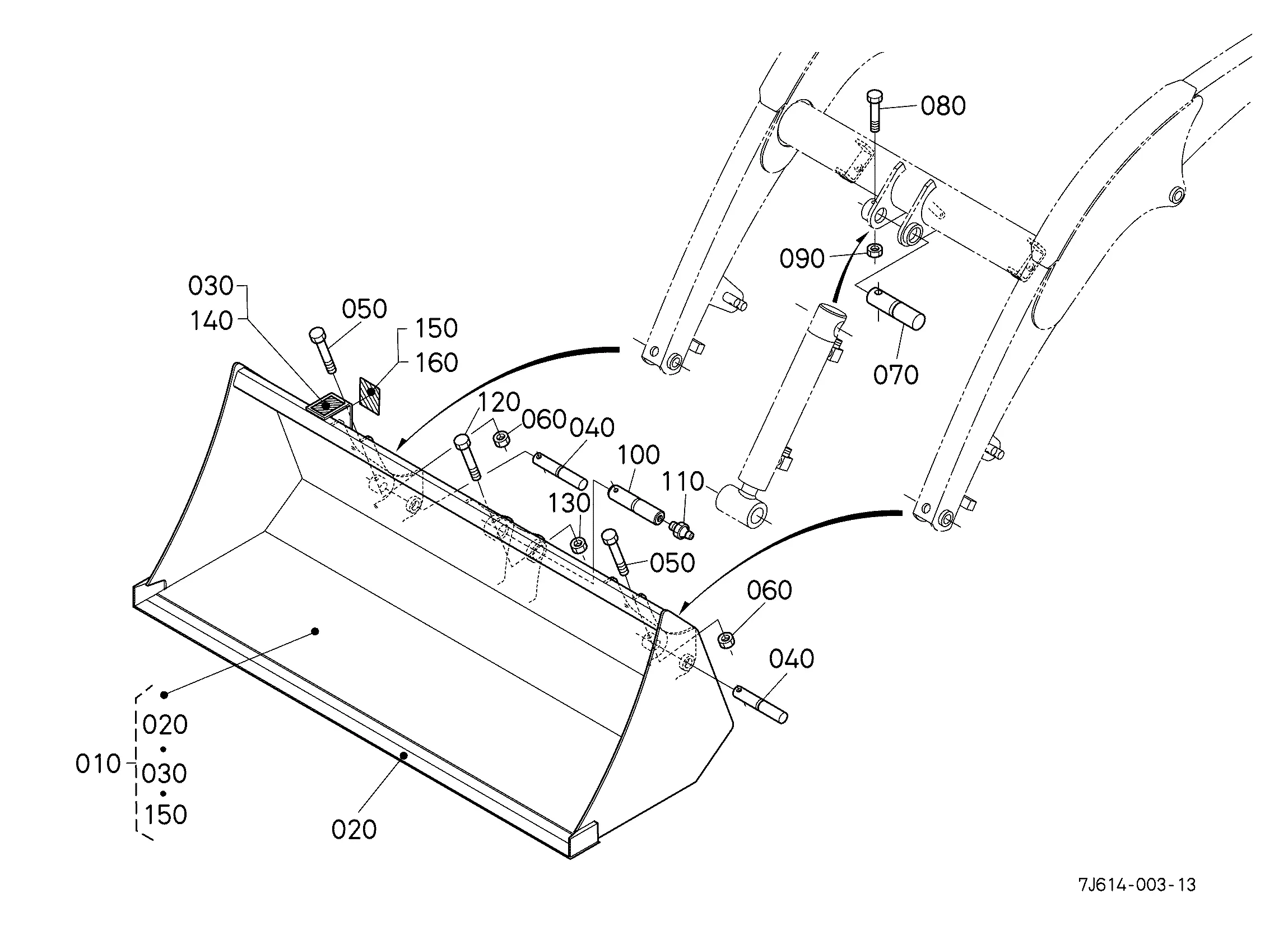

Versatile Attachments

Equipped with a range of compatible implements, this model can easily adapt to different tasks. From digging and lifting to hauling and grading, its flexibility is a significant advantage for users seeking to maximize productivity on their properties.

| Feature | Description |

|---|---|

| Engine Power | Strong engine that provides high torque and efficiency. |

| Transmission Type | Smooth shifting for optimal performance in various conditions. |

| Attachment Compatibility | Supports a variety of implements for different applications. |

| Fuel Efficiency | Designed to minimize fuel consumption without sacrificing power. |

Importance of Proper Maintenance

Regular upkeep of machinery is essential for ensuring optimal performance and longevity. Neglecting maintenance can lead to a range of issues, from minor inconveniences to major breakdowns. By prioritizing care, users can enhance the reliability and efficiency of their equipment.

Benefits of Routine Care

- Increased Efficiency: Well-maintained machines operate more smoothly, leading to better fuel economy and reduced operational costs.

- Extended Lifespan: Regular checks and servicing can significantly prolong the life of the equipment, saving money on replacements.

- Safety Assurance: Proper maintenance helps identify and rectify potential safety hazards, protecting users and operators from accidents.

Key Maintenance Practices

- Regular Inspections: Conduct thorough evaluations to identify wear and tear on various components.

- Fluid Checks: Ensure that all fluids are at appropriate levels and are changed according to the manufacturer’s recommendations.

- Cleaning: Keep machinery free from dirt and debris, which can interfere with functionality.

- Timely Repairs: Address any issues as soon as they arise to prevent further damage and maintain performance.

Identifying Essential Replacement Parts

When maintaining machinery, understanding the crucial components that may require substitution is vital for optimal performance. Recognizing these key elements ensures smooth operation and extends the lifespan of the equipment. This section aims to highlight essential elements that often need replacement and provide guidance on how to identify them effectively.

Common Components to Monitor

Several critical components play significant roles in the functionality of the equipment. Regularly inspecting these elements can help prevent unexpected breakdowns and costly repairs. Below are some common components that should be closely monitored:

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Hydraulic Filter | Reduced efficiency, discoloration | Replace regularly as per schedule |

| Belt | Cracks, fraying, noise during operation | Inspect frequently; replace if damaged |

| Battery | Slow starts, corrosion on terminals | Test regularly; replace if weak |

| Air Filter | Restricted airflow, dirt accumulation | Clean or replace as needed |

Identifying Replacement Needs

Recognizing when to replace components can be straightforward with proper observation. Keeping track of the equipment’s operational signs and scheduling regular maintenance checks can help identify when these essential elements need attention. By staying proactive, you can ensure the machinery remains in peak condition.

Common Issues with BX24 Equipment

Operating machinery often leads to specific challenges that users may encounter over time. Understanding these common problems is crucial for effective maintenance and ensuring longevity. This section explores prevalent concerns associated with this particular model and offers insights into identifying and resolving them.

Hydraulic System Problems

One of the frequent issues reported involves the hydraulic system. Users may experience reduced performance or complete failure, often due to leaks or air trapped in the lines. Regular checks of fluid levels and inspecting for any visible leaks can help mitigate these problems.

Engine Performance Issues

Engine-related difficulties are another area where users may seek guidance. Symptoms like stalling, loss of power, or unusual noises can indicate underlying problems. Routine maintenance, including oil changes and air filter replacements, is essential for optimal operation.

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Hydraulic failure | Fluid leaks, air in lines | Inspect and repair leaks, bleed the system |

| Engine stalling | Clogged filters, low oil | Replace filters, check and refill oil |

| Noise from engine | Worn parts, improper lubrication | Inspect parts, ensure adequate lubrication |

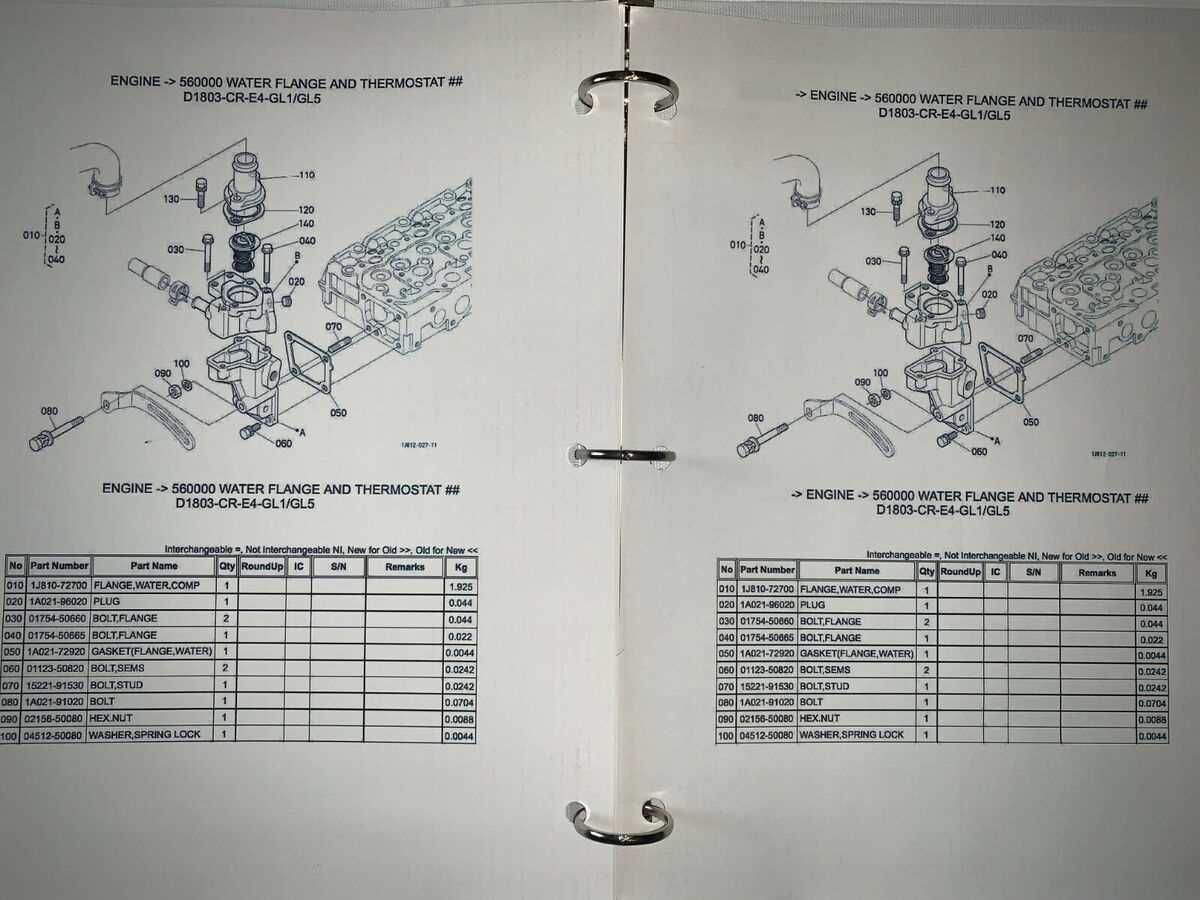

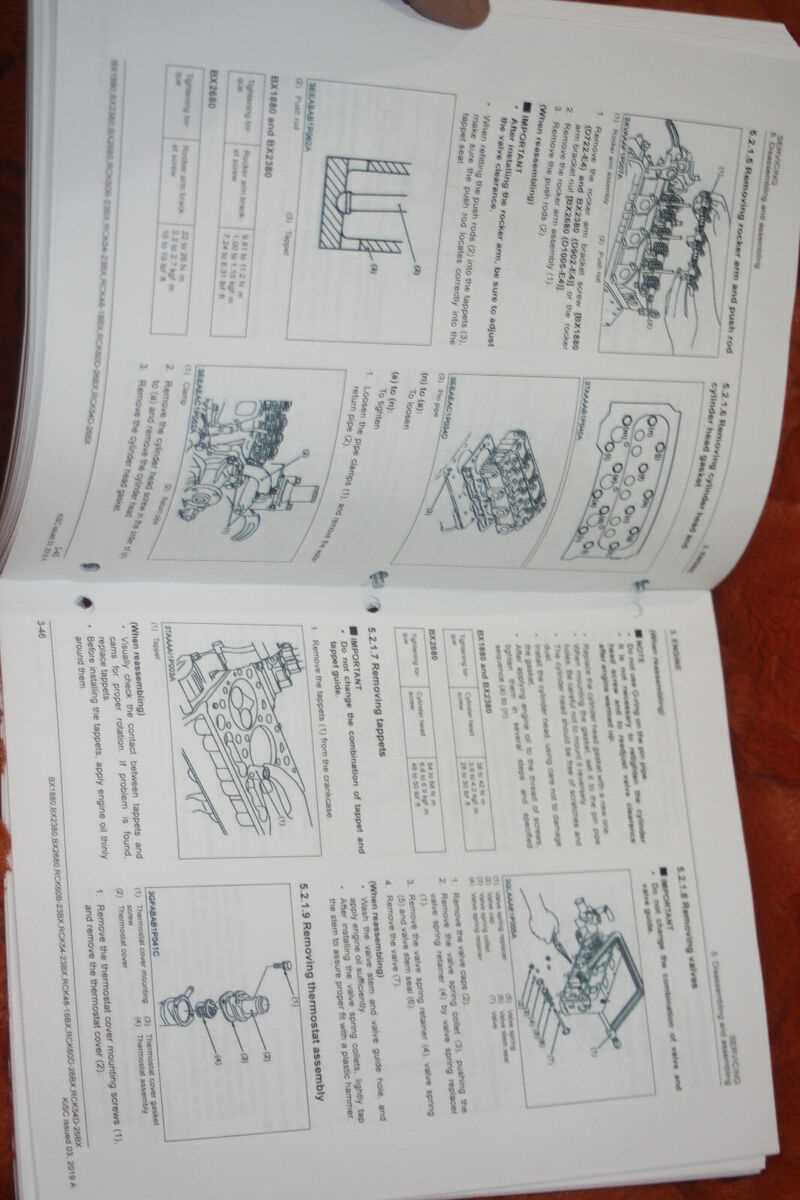

Exploring the Engine Assembly

The engine assembly serves as the heart of any machinery, driving its performance and efficiency. Understanding the components and their interactions is crucial for effective maintenance and repair. This section delves into the intricate structure of the engine, highlighting its essential parts and their functions.

Key Components of the Engine

At the core of the engine lies the cylinder block, where fuel combustion occurs, generating the power necessary for operation. Attached to the block are various critical elements, including pistons, which convert the energy from combustion into mechanical motion, and crankshafts, which translate this motion into rotational force. Other vital components such as valves, camshafts, and timing belts work harmoniously to regulate airflow and fuel intake, ensuring optimal performance.

Maintenance Considerations

Regular inspection and maintenance of the engine assembly are imperative to ensure longevity and reliability. Key areas to focus on include checking oil levels, monitoring for leaks, and ensuring that all components are securely fastened. Understanding the function of each part allows for more informed decisions during servicing, helping to prevent potential issues before they arise.

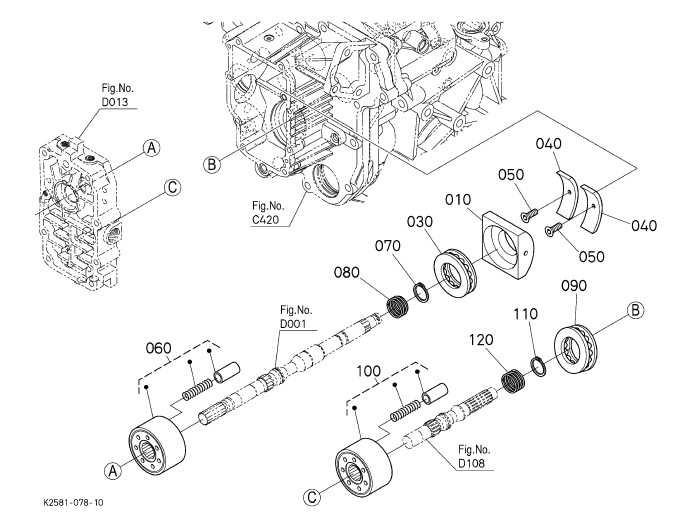

Transmission and Drive System Overview

The efficiency of any machinery heavily relies on its transmission and drive systems, which play a critical role in converting engine power into usable motion. Understanding the components and functions of these systems is essential for optimal performance and maintenance.

Key Components

- Transmission: This component is responsible for adjusting the engine’s power output to the wheels, allowing for varying speeds and torque.

- Drive Shaft: The drive shaft transfers power from the transmission to the wheels, ensuring smooth and effective movement.

- Differential: This mechanism allows for differences in wheel speed between the left and right wheels, improving traction and handling during turns.

Functionality and Importance

The drive system must effectively manage the engine’s output to maintain performance and efficiency. Properly functioning components enhance mobility and control, while any discrepancies can lead to reduced effectiveness and potential mechanical issues. Regular inspection and maintenance of these systems are vital for long-lasting operation and reliability.

Understanding these elements enables operators to diagnose issues promptly and ensures that the machinery performs at its best, making the drive system a crucial aspect of overall functionality.

Hydraulic System Functions Explained

The hydraulic system in machinery serves a critical role in facilitating various operational tasks. This system utilizes fluid pressure to perform work efficiently, making it essential for effective performance. Understanding its functions can significantly enhance the utilization and maintenance of the equipment.

At the core of hydraulic operation is the ability to transmit force through incompressible fluid. This allows for the smooth movement of components, enabling actions such as lifting, tilting, and steering. Each part of the hydraulic assembly contributes to the overall functionality, working in unison to achieve desired outcomes.

| Component | Function |

|---|---|

| Hydraulic Pump | Generates fluid flow and pressure to power the system. |

| Hydraulic Cylinder | Converts hydraulic energy into mechanical motion. |

| Control Valves | Regulate fluid flow and direct it to specific components. |

| Reservoir | Stores hydraulic fluid and ensures a steady supply to the system. |

| Filters | Remove contaminants from the fluid to protect the system. |

In summary, the hydraulic system is a fundamental aspect of equipment operation, enabling various functionalities through well-coordinated components. Knowledge of each part’s role can lead to improved performance and longevity of the machinery.

Electrical System Breakdown

This section delves into the intricacies of the electrical framework within compact machinery, highlighting the essential components that ensure optimal functionality. Understanding this network is crucial for effective maintenance and troubleshooting, as it encompasses various elements working in harmony to power the equipment efficiently.

Key Components

The electrical setup consists of several vital parts, each playing a specific role in the overall performance of the machinery. From power sources to control units, each component contributes to seamless operation.

| Component | Function |

|---|---|

| Battery | Stores energy for starting the engine and powering electrical systems. |

| Alternator | Generates electricity to recharge the battery and power electrical components while the engine runs. |

| Starter Motor | Engages the engine to initiate the combustion process. |

| Wiring Harness | Connects various electrical parts and facilitates the flow of electricity. |

Troubleshooting Tips

Proper diagnostics can prevent electrical failures and ensure longevity. Regular inspections of connections and components, along with prompt replacements, are key practices for maintaining the integrity of the electrical system.

Accessories to Enhance Performance

Enhancing the capabilities of your compact utility vehicle involves incorporating various accessories designed to optimize functionality and efficiency. These additions can significantly improve productivity, making tasks easier and more effective, whether for landscaping, agricultural, or construction applications.

Essential Accessories

Several key accessories can boost the performance of your vehicle. From attachments that extend operational versatility to enhancements that improve comfort and control, these tools are invaluable for any operator looking to maximize their machine’s potential.

| Accessory | Description | Benefits |

|---|---|---|

| Front Loader | An attachment that allows for lifting and moving materials with ease. | Increases loading capacity and efficiency in material handling. |

| Backhoe Attachment | Enables digging and excavation tasks. | Improves versatility for construction and landscaping projects. |

| Grapple Bucket | Designed for grasping and lifting bulky items. | Enhances capability for moving logs, rocks, and debris. |

| Turf Tires | Specialized tires that minimize ground disturbance. | Maintains lawn integrity while providing traction and stability. |

Performance Improvements

Investing in the right accessories not only enhances the efficiency of your machine but also improves the overall user experience. These enhancements ensure that operators can handle a wider variety of tasks with ease and precision, leading to better outcomes and higher satisfaction in performance.

Tips for Efficient Repair Processes

Ensuring a smooth and effective repair workflow requires careful planning and organization. By following certain strategies, individuals can minimize downtime, enhance productivity, and achieve successful outcomes in maintenance tasks. Here are several recommendations to facilitate a more streamlined approach to repairs.

Organize Tools and Materials

Prioritizing the arrangement of tools and materials is essential for quick access during repairs. Categorizing items based on their function and frequently used tools can save valuable time. Having a dedicated workspace with clearly labeled storage solutions helps prevent frustration and increases efficiency in executing repair tasks.

Utilize Reference Resources

Having access to comprehensive reference materials, such as manuals or guides, is invaluable for troubleshooting and understanding repair procedures. These resources provide essential insights, allowing individuals to approach issues with confidence and clarity. Regularly consulting these documents during repairs can lead to a deeper understanding of the machinery and improve the overall repair process.

Finding Quality Parts Suppliers

When it comes to maintaining and enhancing your machinery, sourcing reliable suppliers for components is crucial. Quality and dependability play a significant role in ensuring that your equipment operates efficiently. Understanding where to find trustworthy vendors can make a substantial difference in the longevity and performance of your machinery.

Research and Recommendations

Start by conducting thorough research to identify potential vendors. Online reviews and testimonials can provide valuable insights into the experiences of other customers. Additionally, seeking recommendations from industry peers can lead you to reputable suppliers who offer high-quality components. Networking within your community or industry can also uncover hidden gems that might not be widely advertised.

Evaluating Supplier Credentials

Once you’ve compiled a list of potential suppliers, it’s essential to evaluate their credentials. Look for vendors with a solid track record of providing authentic components and excellent customer service. Certifications, warranties, and return policies are good indicators of a supplier’s commitment to quality. Engaging directly with suppliers can also help gauge their expertise and willingness to assist with your specific needs.