In the realm of complex machinery, having a clear representation of the individual elements is crucial for effective assembly and maintenance. Such illustrations serve as essential guides, providing insight into the arrangement and functionality of various components within a system. By analyzing these visuals, users can enhance their understanding of how each piece interacts within the broader framework.

The exploration of these visuals not only aids technicians in troubleshooting and repairs but also assists in optimizing performance. A detailed breakdown of the assembly allows for quick identification of necessary adjustments or replacements, ensuring longevity and efficiency in operation. This knowledge is particularly valuable in industries where precision and reliability are paramount.

As we delve deeper into the intricacies of component arrangements, we will uncover the significance of each individual element and its role within the overall structure. This knowledge empowers users to make informed decisions, fostering a deeper appreciation for the technology they work with.

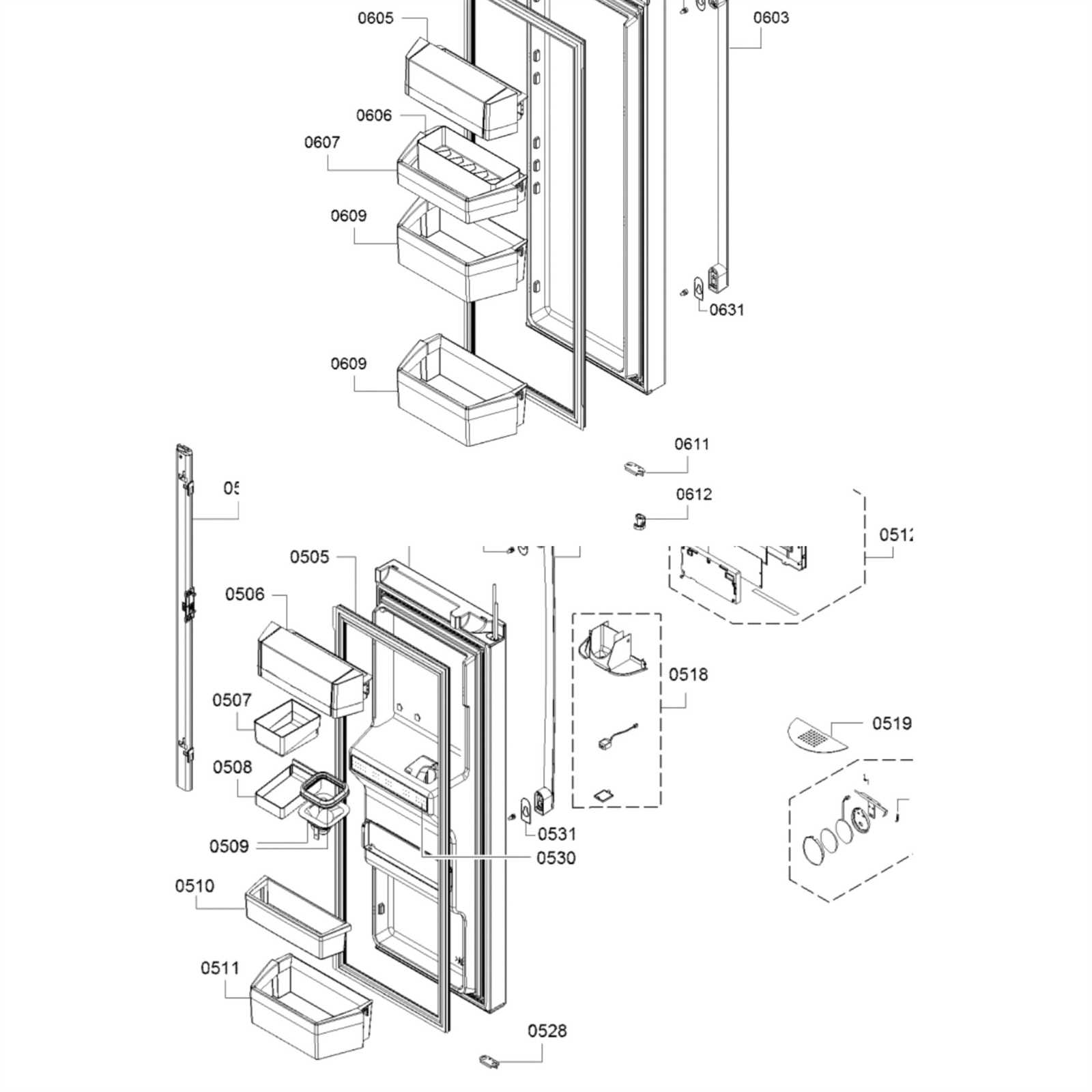

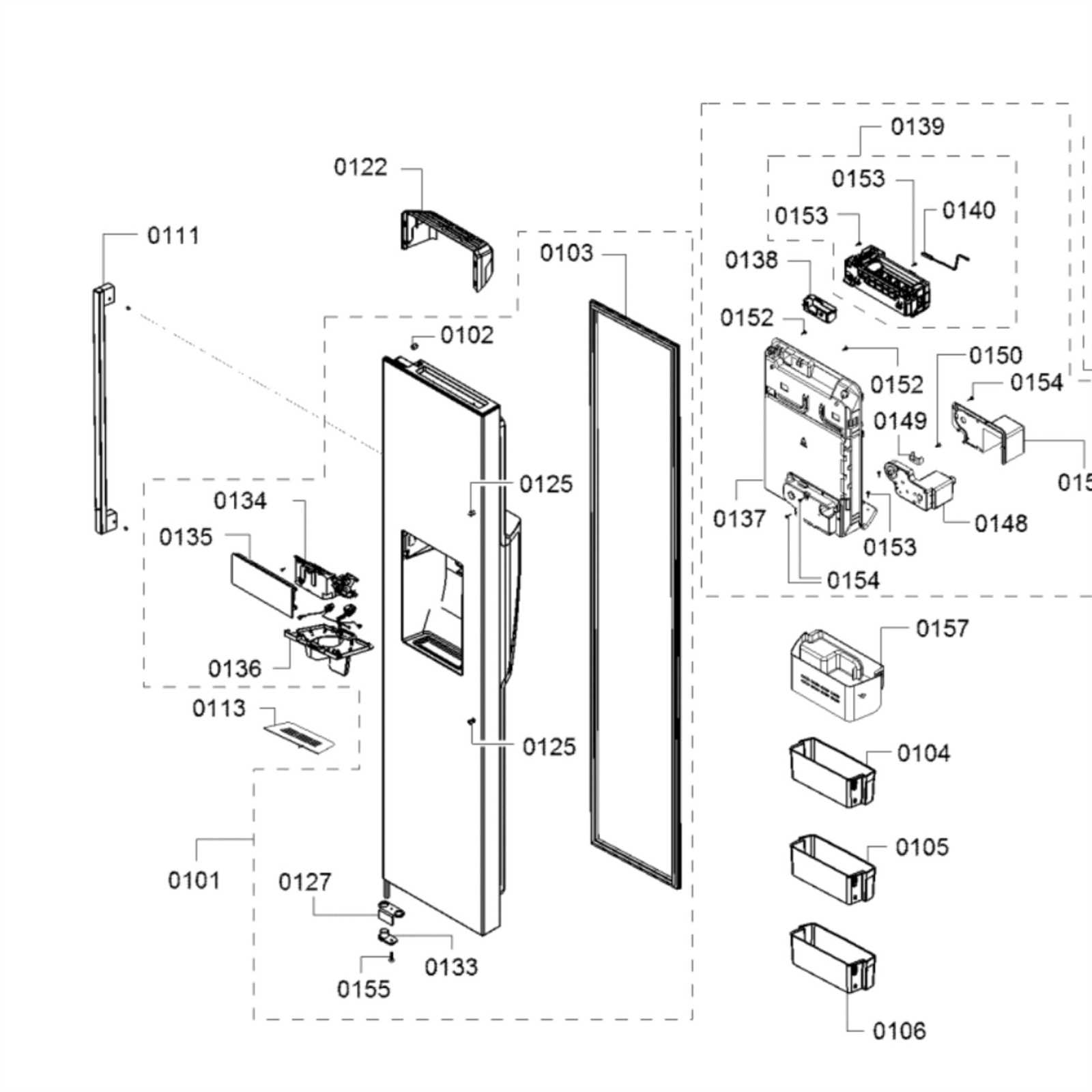

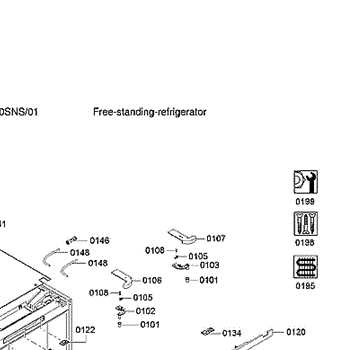

This section aims to provide a comprehensive overview of the arrangement and function of various components within a specific system. By examining the configuration and relationships of each element, one can gain valuable insights into the overall functionality and operational efficiency of the assembly. Understanding how these components interact is crucial for troubleshooting, maintenance, and optimizing performance.

Component Configuration

The organization of elements within the system plays a significant role in its performance. Each component has a designated place that contributes to the functionality of the entire setup. Below is a simplified representation of how different elements are arranged, along with their respective roles:

| Component Name | Description | Function |

|---|---|---|

| Element A | Main processing unit | Handles core functions |

| Element B | Power supply module | Provides necessary energy |

| Element C | Control interface | Facilitates user interaction |

Significance of Layout

The strategic positioning of these components not only enhances the efficiency of operations but also aids in minimizing potential issues. A well-organized configuration allows for easier access during maintenance and repairs, ensuring that the system remains reliable and effective over time. Understanding this layout is essential for anyone involved in the handling or operation of the equipment.

Importance of Accurate Diagrams

Clear and precise representations are essential in any technical field. They serve as vital references for understanding complex systems, facilitating communication among professionals, and ensuring efficient workflows. Accuracy in these illustrations can significantly impact the effectiveness of design, maintenance, and troubleshooting processes.

Enhancing Communication

Well-crafted representations play a crucial role in conveying information among team members. They help bridge gaps in understanding, particularly when dealing with intricate components. The following points highlight their significance:

- Facilitates collaboration by providing a common visual reference.

- Reduces the likelihood of misinterpretation and errors.

- Streamlines the onboarding process for new team members.

Supporting Maintenance and Repair

Accurate illustrations are indispensable during maintenance and repair tasks. They guide technicians in identifying and addressing issues effectively. Key advantages include:

- Enables quick location of components and their functions.

- Assists in diagnosing problems through clear visual cues.

- Increases overall efficiency, reducing downtime during repairs.

Common Applications for B36CT80SNS

This section explores various typical uses for a particular electronic component known for its versatility and reliability. Its unique characteristics enable it to function effectively in multiple environments, making it a popular choice among engineers and designers. The following applications demonstrate its significance across various industries.

1. Power Management Solutions

The component plays a crucial role in energy regulation systems, ensuring stable voltage supply and efficient power distribution. Its ability to handle high currents allows it to be integrated into various devices requiring robust energy management.

2. Industrial Automation

In manufacturing and production lines, this electronic element is instrumental in controlling motors and actuators. Its reliability ensures that machinery operates smoothly, enhancing overall productivity and safety within the work environment.

| Application Area | Key Benefits |

|---|---|

| Power Management | Stable voltage supply, energy efficiency |

| Industrial Automation | Reliable motor control, improved safety |

| Consumer Electronics | Compact design, high efficiency |

| Renewable Energy Systems | Enhanced performance, environmental sustainability |

Step-by-Step Assembly Instructions

Assembling a complex device requires careful attention to detail and a systematic approach. This section outlines the process to ensure each component is correctly positioned and securely connected, leading to optimal performance and reliability.

1. Gather Necessary Components: Before starting, ensure all necessary elements are on hand. Check for any specific tools required for assembly to avoid interruptions during the process.

2. Prepare the Workspace: Set up a clean, organized workspace to facilitate an efficient assembly process. Ensure good lighting and easy access to all components.

3. Follow the Sequence: Begin by assembling the base structure. Ensure all connections are firm and precise. Next, move on to integrating additional elements, following the logical sequence outlined in the accompanying instructions.

4. Verify Connections: After each step, double-check that all connections are secure. This will help prevent issues during operation and ensure the integrity of the assembly.

5. Final Review: Once all components are in place, conduct a thorough inspection. Ensure everything aligns correctly and is securely fastened before proceeding to the next phase of operation.

Troubleshooting Common Issues

When working with complex mechanical systems, encountering problems is inevitable. Understanding common challenges and their solutions can significantly enhance performance and prolong the lifespan of the equipment. This section focuses on identifying frequent issues and provides practical steps for effective resolution.

Identifying Typical Challenges

- Inconsistent operation or performance fluctuations.

- Unusual noises or vibrations during functioning.

- Difficulty in starting or responding to commands.

- Frequent overheating or improper temperature regulation.

Steps to Resolve Issues

- Conduct a Visual Inspection: Examine the entire assembly for visible signs of wear, damage, or loose connections.

- Check Electrical Connections: Ensure all wires and terminals are secure and free from corrosion.

- Monitor Operating Conditions: Verify that the environment meets the specified operational standards.

- Test Component Functionality: Utilize appropriate diagnostic tools to assess the performance of individual elements.

- Consult Documentation: Refer to manuals or service guides for detailed troubleshooting steps and specifications.

Replacement Parts Availability

Ensuring the functionality of your appliance often relies on the accessibility of essential components. In today’s market, various options are available for sourcing these vital elements, allowing users to maintain and enhance their devices effectively. Understanding the channels through which these items can be acquired is crucial for optimal performance and longevity.

Sources for Components

Replacement elements can typically be obtained through authorized retailers, specialized online platforms, and manufacturer websites. These sources offer a range of options, ensuring that users can find the right solutions to meet their specific needs. Additionally, local hardware stores may stock generic versions that can serve as viable alternatives, providing flexibility in sourcing.

Considerations for Purchase

When seeking out necessary components, it’s important to consider factors such as compatibility, quality, and warranty options. Investing in high-quality replacements can prevent future issues and ensure that the device operates at its best. Furthermore, checking for customer reviews and ratings can offer valuable insights into the reliability of the components being considered.

Best Practices for Maintenance

Regular upkeep is essential for ensuring optimal performance and longevity of any mechanical or electronic system. Implementing effective strategies can help prevent unexpected failures and enhance overall efficiency. Adopting a proactive approach to maintenance can save both time and resources in the long run.

Routine Inspections: Conducting frequent examinations is crucial for identifying potential issues before they escalate. Establish a schedule for checking components and connections to ensure everything is functioning correctly. Pay close attention to signs of wear or damage that may require immediate attention.

Cleanliness and Organization: Maintaining a clean and organized workspace can significantly impact the efficiency of maintenance tasks. Remove dust and debris from components regularly to prevent overheating and ensure proper airflow. Keeping tools and equipment organized will facilitate quicker repairs and adjustments.

Documentation: Keeping detailed records of maintenance activities is vital for tracking performance and identifying trends. Document any repairs, replacements, or adjustments made, along with dates and observations. This information can be invaluable for future reference and troubleshooting.

Training and Knowledge: Ensure that all personnel involved in maintenance are adequately trained and informed about the systems they work with. Ongoing education about new technologies and best practices can enhance the team’s effectiveness and responsiveness to issues.

Use of Quality Components: When replacing or upgrading any elements, prioritize high-quality components that meet or exceed the original specifications. Investing in reliable parts can lead to improved performance and reduce the likelihood of future problems.

By following these guidelines, you can enhance the reliability and functionality of your systems, ultimately leading to increased productivity and reduced downtime.

Safety Guidelines When Handling

When working with complex equipment, ensuring safety is paramount. Proper precautions can prevent accidents and ensure a smooth operational process. Familiarizing yourself with safety protocols can mitigate risks associated with handling various components and tools.

Understanding Potential Hazards

Awareness of potential dangers is the first step toward safe handling. This includes recognizing risks such as electrical shocks, sharp edges, and heavy lifting. Always approach tasks with caution and maintain focus on the surrounding environment to minimize the likelihood of mishaps.

Proper Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is essential for safeguarding yourself. This may include gloves, safety goggles, and sturdy footwear. Ensure that all protective gear is in good condition and suitable for the specific tasks at hand to provide the best possible protection.

Comparison with Similar Models

This section explores the similarities and differences among various models that serve comparable functions. By analyzing their specifications, features, and performance, users can gain insights into which unit best fits their needs. Understanding these aspects is crucial for making informed purchasing decisions, especially when considering alternatives in a crowded market.

Key Features Analysis

When comparing similar units, it is essential to evaluate the key features that define their performance. Factors such as energy efficiency, capacity, and ease of use can significantly influence a consumer’s choice. For instance, while some models may offer advanced technological integrations, others might prioritize user-friendly interfaces. Assessing these features allows potential buyers to align their preferences with the available options.

Performance and Reliability

The performance and reliability of comparable devices can vary widely. Users often look for durability and consistent operation in any unit. Researching user reviews and expert opinions on the performance of similar devices provides valuable insights. By weighing these considerations, one can identify which model excels in real-world applications and meets long-term expectations.

Customer Reviews and Feedback

This section highlights the experiences and insights shared by users regarding their encounters with the product. Feedback from customers can offer valuable perspectives, revealing both strengths and areas for improvement, ultimately aiding potential buyers in making informed decisions.

Overall Satisfaction: Many users express high levels of satisfaction, often noting the reliability and efficiency of the item in various applications. Positive reviews frequently highlight its functionality, praising the ease of use and integration into existing systems.

Areas for Improvement: While the feedback is largely favorable, some users have pointed out aspects that could be enhanced. Suggestions include improved documentation and more comprehensive support options to assist new users in navigating their purchases.

Real-World Applications: Customers share diverse experiences, illustrating how the product has met their needs in practical scenarios. These testimonials often provide insight into the versatility and adaptability of the item, making it easier for prospective buyers to envision its use in their own projects.

Final Thoughts: User reviews serve as a testament to the product’s performance and reliability. The collective feedback paints a picture of a well-received solution that, despite minor critiques, generally fulfills its intended purpose effectively.

Resources for Further Learning

Exploring additional materials and resources can greatly enhance your understanding of complex systems and components. Whether you are a beginner or looking to deepen your knowledge, various platforms offer valuable insights and information. This section highlights several avenues for gaining further expertise in the subject matter.

Online Courses and Tutorials

- Platforms such as Coursera and Udemy offer specialized courses focusing on electronic systems and their components.

- Many universities provide free online lectures covering fundamental principles relevant to your studies.

- YouTube hosts a range of tutorials, allowing you to visualize concepts through practical demonstrations.

Books and Publications

- Textbooks that cover electrical engineering basics can provide a solid foundation for understanding system functionalities.

- Industry journals and magazines often publish articles detailing the latest advancements and innovations.

- Reference guides can serve as handy resources for quick information and clarifications on specific topics.