When maintaining or repairing any machinery, having a clear visual representation of its components is essential. An effective layout can significantly simplify the process of identifying parts and understanding their functions within the overall system. This is particularly important for users who engage with complex equipment regularly, ensuring they can manage repairs and maintenance efficiently.

By delving into the intricate arrangement of essential components, operators can enhance their knowledge of how each part interacts and contributes to the machine’s performance. Visual aids serve as valuable tools for technicians and enthusiasts alike, facilitating a more comprehensive understanding of the machinery.

This section aims to provide an informative overview of the assembly structure associated with a specific model. Such insights will empower users to navigate the complexities of their equipment, ensuring effective troubleshooting and optimal functionality.

This model stands out due to its exceptional design and versatile functionality. Users can expect reliable performance and efficient operation, making it a favored choice among enthusiasts and professionals alike.

Performance and Efficiency

Engineered for robust power, this unit offers a remarkable balance of strength and fuel efficiency. The key performance attributes include:

- High torque output for demanding tasks

- Advanced cooling system to prevent overheating

- Efficient transmission for smooth gear shifts

User-Friendly Design

The thoughtful design enhances usability, ensuring that operators can navigate and control the machine with ease. Notable features include:

- Ergonomic seating for comfort during extended use

- Intuitive controls that simplify operation

- Compact dimensions for easy maneuverability in tight spaces

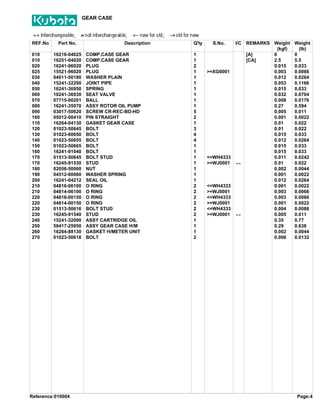

Commonly Replaced Parts and Accessories

In the realm of machinery maintenance, certain components frequently require replacement due to wear and tear from regular use. Understanding which elements are often substituted can enhance the longevity and efficiency of equipment, ensuring optimal performance in various tasks.

Essential Components

Among the vital elements that tend to wear out, filters and belts are paramount. Filters play a crucial role in maintaining fluid cleanliness, while belts are essential for transferring power between different parts of the machine. Regularly checking and replacing these items can prevent larger issues down the line.

Useful Accessories

Accessories such as blades and attachments can also greatly improve functionality. Investing in quality blades for mowing or cutting tasks enhances efficiency, while various attachments allow for versatility in operations. Keeping these tools in good condition is key to maintaining performance.

Understanding the Engine Assembly

The engine assembly is a complex and integral component of any machinery, serving as the heart that powers the entire system. Comprehending its structure and function is essential for effective maintenance and repair. This section delves into the key elements that constitute the engine assembly, highlighting their roles and interconnections.

Here are the primary components that form the engine assembly:

- Block: The main structure that houses various engine components and provides the necessary strength.

- Cylinder Head: Covers the top of the cylinders and contains passages for air and fuel, along with valves for exhaust and intake.

- Pistons: Move up and down within the cylinders, converting fuel energy into mechanical energy.

- Crankshaft: Transforms the linear motion of the pistons into rotational motion, driving the vehicle.

- Camshaft: Operates the intake and exhaust valves, ensuring the proper timing for air and fuel entry and exhaust exit.

- Oil Pump: Circulates oil throughout the engine, providing lubrication to reduce friction and wear.

Understanding these components is vital for anyone involved in the repair or maintenance of engines. Each part plays a critical role in ensuring optimal performance and longevity.

Transmission System Components Explained

The transmission system is a crucial aspect of any machinery, facilitating the transfer of power from the engine to the wheels or implements. Understanding the various elements that comprise this system helps in maintaining optimal performance and ensuring longevity. Each component plays a distinct role, contributing to the efficiency and reliability of the entire operation.

Key Elements of the Transmission Assembly

At the heart of the transmission assembly lies the gearbox, responsible for regulating the speed and torque delivered to the driving wheels. Coupled with the gearbox are the clutches, which engage and disengage power flow, allowing for smooth transitions between different gears. Additionally, the differential plays a vital role in managing the distribution of power between the wheels, enabling smooth cornering and enhanced stability.

Supporting Components and Their Functions

Alongside the primary elements, various auxiliary components support the transmission system’s operation. These include the shift linkage, which facilitates gear changes, and the hydraulic system, responsible for actuating the clutches and controlling the overall functionality of the transmission. Proper maintenance of these supporting elements is essential for ensuring seamless operation and preventing premature wear.

Hydraulic Parts and Their Functions

Hydraulic systems play a crucial role in the functionality of various machinery, providing the necessary force to perform tasks efficiently. Understanding the components involved in these systems is essential for maintenance and troubleshooting. Each element contributes to the overall performance, ensuring smooth operation and effective power transmission.

| Component | Function |

|---|---|

| Hydraulic Pump | Generates flow and pressure in the system, converting mechanical energy into hydraulic energy. |

| Hydraulic Cylinder | Transforms hydraulic energy back into mechanical energy, enabling movement in various applications. |

| Control Valve | Regulates fluid flow and directs it to specific areas of the system, controlling the speed and direction of movement. |

| Hydraulic Reservoir | Stores hydraulic fluid, allowing for proper circulation and providing a buffer for the system. |

| Filter | Removes contaminants from the hydraulic fluid, protecting other components from damage and ensuring system efficiency. |

Electrical System Wiring Overview

The electrical system plays a vital role in ensuring the efficient operation of machinery, providing power to various components and facilitating communication between systems. Understanding the wiring layout and connections is essential for troubleshooting and maintenance.

Key Components of the Electrical System

- Battery: Supplies the necessary power for starting the engine and operating electrical devices.

- Alternator: Generates electricity while the engine is running, recharging the battery.

- Wiring Harness: A collection of wires that connects different electrical components, ensuring proper communication and power distribution.

- Fuses: Protect the electrical system from overloads by breaking the circuit in case of a fault.

- Switches: Control the flow of electricity to various systems, such as lights and ignition.

Wiring Connections and Maintenance

- Regularly inspect all wiring for signs of wear or damage.

- Ensure connections are secure and free from corrosion.

- Check the functionality of fuses and replace any that are blown.

- Test switches to confirm they operate correctly and make necessary repairs.

- Consult wiring schematics to understand the layout and identify potential issues.

Maintenance Tips for Longevity

To ensure the prolonged efficiency and performance of your machinery, regular upkeep is essential. By following specific practices, you can significantly extend the lifespan of your equipment and enhance its reliability.

Regular Inspections: Frequent checks of components are vital. Look for signs of wear or damage, and address issues promptly to prevent further complications.

Fluid Levels: Maintain optimal fluid levels, including engine oil, coolant, and hydraulic fluids. Regularly change these fluids as per the manufacturer’s recommendations to keep the engine running smoothly.

Cleanliness: Keep the exterior and interior of the machine clean. Remove debris and dirt from filters, vents, and other critical areas to avoid overheating and performance issues.

Proper Storage: Store equipment in a dry, sheltered environment to protect it from harsh weather conditions. Use covers to shield it from dust and moisture when not in use.

Scheduled Servicing: Adhere to a maintenance schedule recommended by professionals. Routine servicing helps identify potential problems before they escalate and ensures that all systems are functioning optimally.

Use Quality Parts: When replacements are necessary, opt for high-quality components that meet or exceed original specifications. This practice contributes to the durability and reliability of your machinery.

Where to Source Replacement Parts

Finding the right components for machinery maintenance can be a daunting task. It is essential to identify reliable sources that offer quality items tailored to specific models. Numerous options exist, each providing varying degrees of accessibility and assurance of quality.

Authorized dealers typically provide the most reliable option, ensuring that you receive genuine components that meet manufacturer standards. They often have knowledgeable staff who can assist with identifying the correct items and addressing any queries you may have.

Online marketplaces also offer a wide selection of alternatives. Websites specializing in agricultural equipment often feature detailed catalogs and customer reviews, enabling you to compare different options before making a purchase. Be sure to verify the credibility of the seller and the quality of their offerings.

Additionally, local repair shops can be a valuable resource. These establishments often have connections with suppliers and can either order the necessary components for you or suggest suitable substitutes. Their hands-on experience may also provide insights into the best choices for your machinery.

Consider checking classified ads or forums dedicated to equipment enthusiasts. These platforms often have listings for both new and used items, allowing you to find budget-friendly solutions. Engaging with a community of fellow owners can also lead to recommendations for trustworthy suppliers.

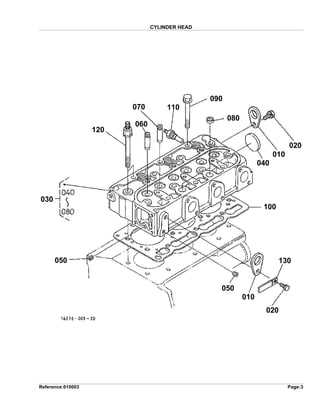

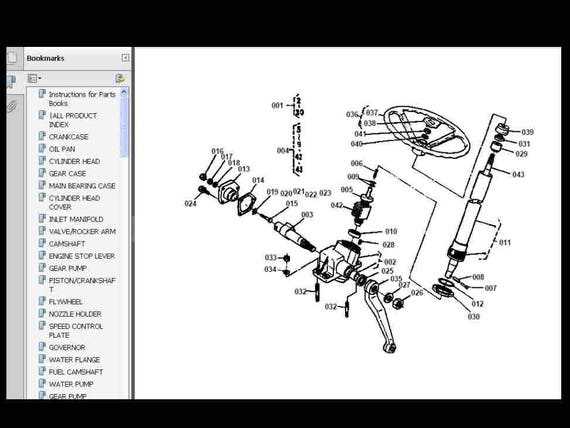

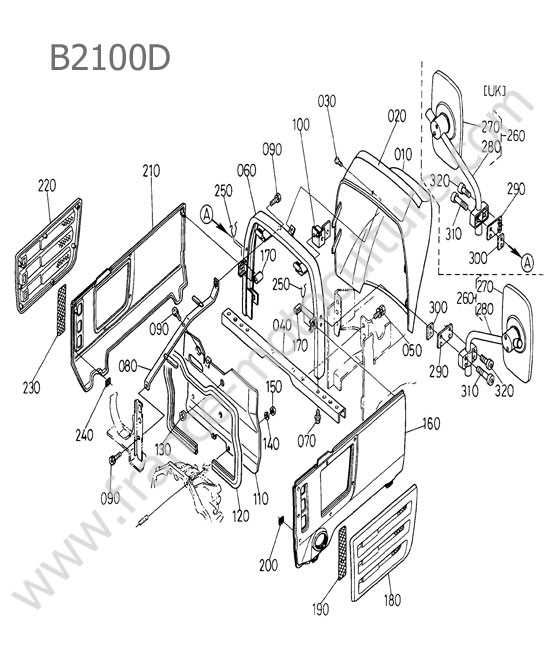

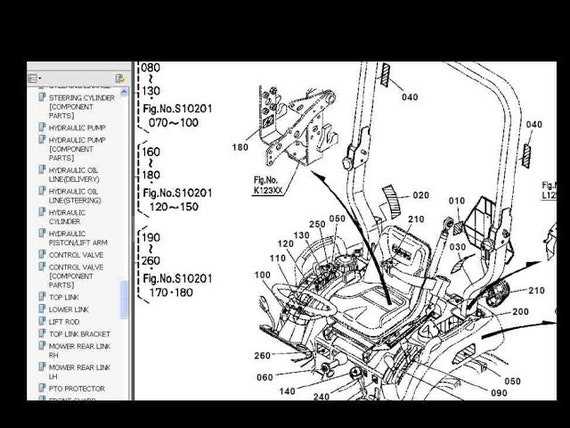

Visual Guide to Component Locations

This section provides a comprehensive overview of where essential elements are situated within the machine. Understanding the arrangement of various components is crucial for efficient maintenance and repair tasks. By familiarizing yourself with these locations, you can enhance your operational efficiency and streamline troubleshooting processes.

Key Element Overview

Recognizing the primary components and their respective placements allows operators to access vital areas quickly. This knowledge is especially beneficial during routine checks, enabling timely identification of any wear or damage that may occur over time.

Detailed Component Layout

The arrangement of specific parts is strategically designed to optimize functionality and accessibility. Familiarity with this layout not only aids in maintenance efforts but also contributes to the overall performance and longevity of the equipment. Regular reviews of these locations ensure that operators remain aware of the critical areas needing attention.

Frequently Asked Questions about B2100

This section addresses common inquiries related to the specific model, providing clarity and guidance for users and enthusiasts. Understanding key aspects can enhance the ownership experience and ensure optimal performance.

What are the essential maintenance practices for this machine?

Regular upkeep is vital for ensuring longevity and efficiency. Routine checks on fluid levels, filter replacements, and general inspections are recommended to keep everything running smoothly.

Where can I find replacement components?

Replacement components can typically be sourced from authorized dealers, local retailers, or online platforms specializing in agricultural machinery supplies. It’s advisable to verify compatibility with the intended model.

How often should oil changes be performed?

Oil changes should generally be conducted every 50 to 100 hours of operation, depending on usage intensity. Always consult the owner’s manual for specific intervals tailored to your needs.

What safety precautions should be taken while operating this equipment?

Safety measures include wearing appropriate protective gear, ensuring the area is clear of obstacles, and adhering to the manufacturer’s operational guidelines. Regular training sessions are also beneficial.

Can I upgrade features on this model?

Yes, various upgrades are available, including enhanced implements and performance modifications. It’s important to assess compatibility and consult with experts before making significant changes.